Glass reinforced plastic pipe concrete member

A technology of glass concrete and steel pipes, which is applied in the field of composite pipes and can solve problems such as cracking of concrete and obstacles to the application of waste glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

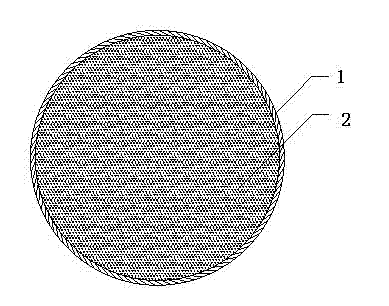

[0014] figure 1 The reference numbers in the drawings are: steel pipe 1; glass concrete 2.

[0015] Such as figure 1 As shown, a steel pipe glass concrete member includes a steel pipe 1 filled with glass concrete 2 .

[0016] Such as figure 1 As shown, the glass concrete 2 includes the first waste glass with a particle size of 0.15-2.36 mm and the second waste glass with a particle size of 5-25 mm.

[0017] Such as figure 1 As shown, the first waste glass and the second waste glass are mixed at a mass ratio of 1:2.

[0018] Such as figure 1 As shown, both ends of the steel pipe 1 are closed.

[0019] The steel pipe glass concrete component provided by the present invention has a wide range of applications, mainly used as compression components, such as power transmission and transformation components, single-layer or multi-layer industri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com