Ultrasonic-assisted lye tomato peeling method and product

An ultrasonic-assisted tomato technology is applied in the field of ultrasonic-assisted lye tomato peeling methods and products, which can solve the problems of skin cracking and being unsuitable for large-scale production, and achieve the effects of reducing dosage, shortening processing time, and increasing brittleness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of peeled tomato by ultrasonic-assisted lye tomato peeling method

[0026] (1) Soak tomatoes in a sodium hydroxide solution with a temperature of 95° C. and a concentration of 40 g / L for 30 seconds at a mass-volume ratio of 1:9 to obtain alkali-treated tomatoes; the mass-volume ratio unit is kg:L;

[0027] (2) ultrasonically treating the tomato treated in step (1) for 50 s at 70° C. and an ultrasonic power of 2100 W to obtain ultrasonically treated tomato;

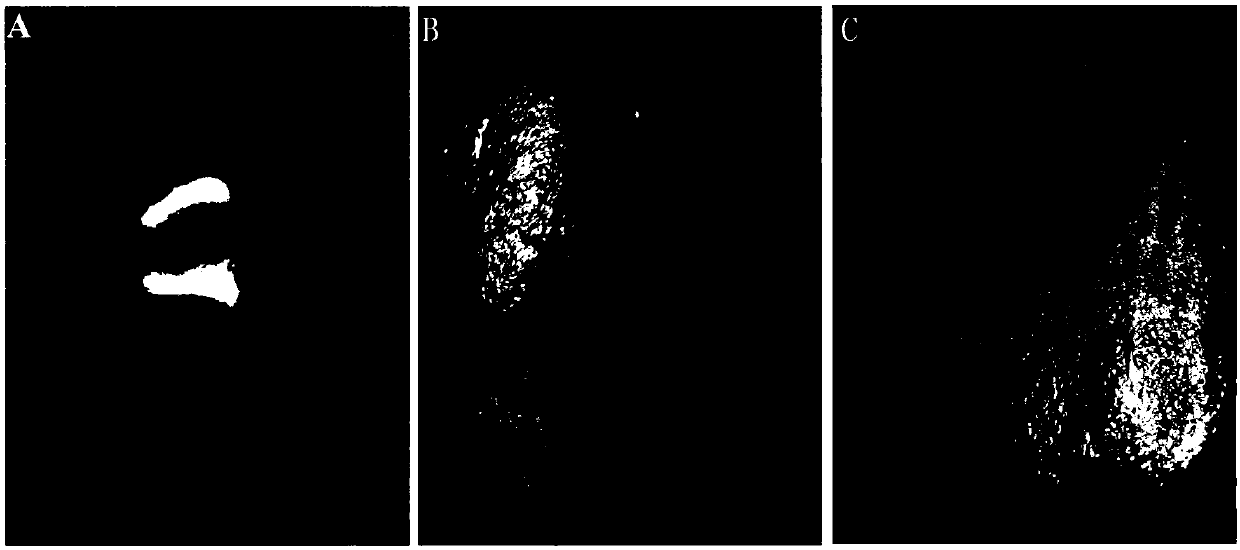

[0028] (3) Spray cold water on the tomatoes treated in step (2) and rotate each tomato slightly at the same time, so that friction occurs between each tomato, and a peeled tomato is obtained. The appearance of the peeled tomato is as follows: figure 1 shown in B, by figure 1 From middle B, it can be seen that the peeled tomato retains most of the red layer of the tomato.

Embodiment 2

[0030] Preparation of peeled tomato by ultrasonic-assisted lye tomato peeling method

[0031] (1) According to the mass-volume ratio of 0.5:10, the tomato is added into a calcium hydroxide solution with a temperature of 70° C. and a concentration of 20 g / L and soaked for 40 seconds to obtain an alkali-treated tomato; the mass-volume ratio unit is kg:L;

[0032] (2) ultrasonically treating the tomato treated in step (1) for 30 seconds at 50° C. and an ultrasonic power of 2500 W to obtain ultrasonically treated tomato;

[0033] (3) Spray cold water on the tomatoes treated in step (2) and rotate each tomato slightly at the same time to cause friction among the tomatoes to obtain peeled tomatoes.

Embodiment 3

[0035] Preparation of peeled tomato by ultrasonic-assisted lye tomato peeling method

[0036] (1) Soak tomatoes in a sodium hydroxide solution with a temperature of 100° C. and a concentration of 60 g / L for 50 seconds according to a mass-volume ratio of 5:5 to obtain alkali-treated tomatoes; the mass-volume ratio unit is kg:L;

[0037] (2) ultrasonically treating the tomato treated in step (1) for 50 s at 80° C. and an ultrasonic power of 3000 W to obtain ultrasonically treated tomato;

[0038] (3) Spray cold water on the tomatoes treated in step (2) and rotate each tomato slightly at the same time to cause friction among the tomatoes to obtain peeled tomatoes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com