Moisture-resistant sound-insulation gypsum-based self-leveling mortar

A self-leveling mortar and gypsum-based technology, applied in ceramic products, sustainable waste treatment, solid waste management, etc., can solve the problems of poor foot comfort, unfavorable construction, moisture resistance, etc., to achieve poor foot comfort and facilitate construction , Improve the effect of moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

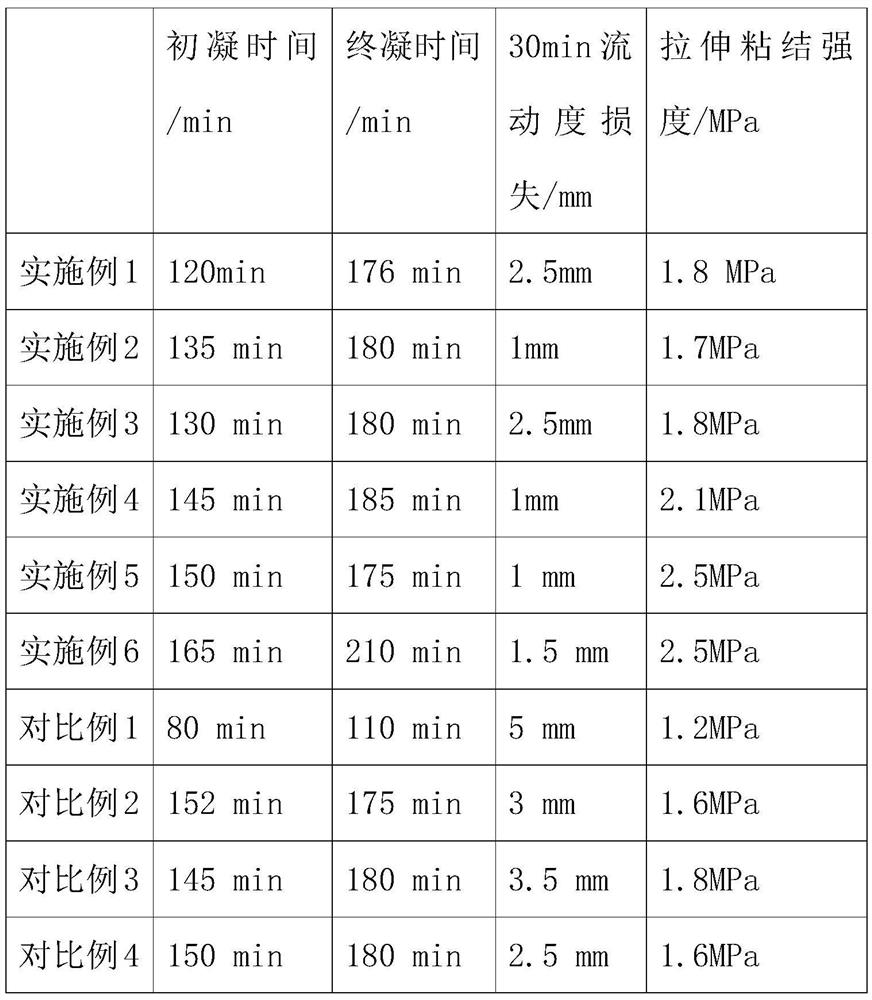

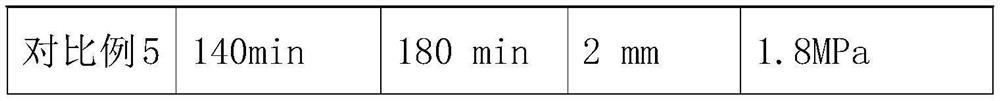

Examples

Embodiment 1

[0036] A moisture-resistant soundproof gypsum-based self-leveling mortar, comprising 900 parts of gypsum, 30 parts of cement, 1 part of water reducing agent, 5 parts of coagulant retaining agent, 10 parts of latex powder, 1 part of P8823 defoamer, 1 part of gypsum reinforcing agent, 3 parts of hydroxyethyl cellulose ether, 3 parts of silicone water repellent, 36 parts of auxiliary material resin.

[0037] Wherein, the auxiliary material resin is mainly polyolefin elastomer ethylene / α-olefin random copolymer (POE).

Embodiment 2

[0039] A moisture-resistant and soundproof gypsum-based self-leveling mortar, including 950 parts of gypsum, 100 parts of cement, 5 parts of P823 water reducer, 5 parts of coagulant calcium formate, 12 parts of latex powder, 2 parts of 1691 defoamer, and 1 part of gypsum reinforcing agent 2 parts, 2 parts of methyl hydroxyethyl cellulose ether, 3 parts of silicone water repellent, 55 parts of auxiliary material resin.

[0040] Wherein, the auxiliary material resin is mainly polyolefin elastomer ethylene / α-olefin random copolymer (POE).

Embodiment 3

[0042] A moisture-resistant and sound-insulating gypsum-based self-leveling mortar, comprising 920 parts of gypsum, 100 parts of cement, 3 parts of P823 water reducer, 3 parts of coagulant retaining agent, 5 parts of latex powder, 2 parts of defoamer, 2 parts of gypsum reinforcing agent, 1 part of hydroxypropyl cellulose ether, 5 parts of hydrophobic agent hydrogenated silicone oil, 50 parts of auxiliary material resin.

[0043] Wherein, the auxiliary material resin is mainly polyolefin elastomer binary ethylene-propylene rubber (EPM).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com