Bridge-cut-off concrete composite partition wall and manufacturing method thereof

A composite partition wall and concrete technology, applied in the direction of walls, building components, climate change adaptation, etc., can solve the problems of non-compliance with the modern requirements of energy-saving green buildings, poor heat insulation effect, low fire protection level, etc., to overcome the wall hollow shell. and cracking defects, easy installation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

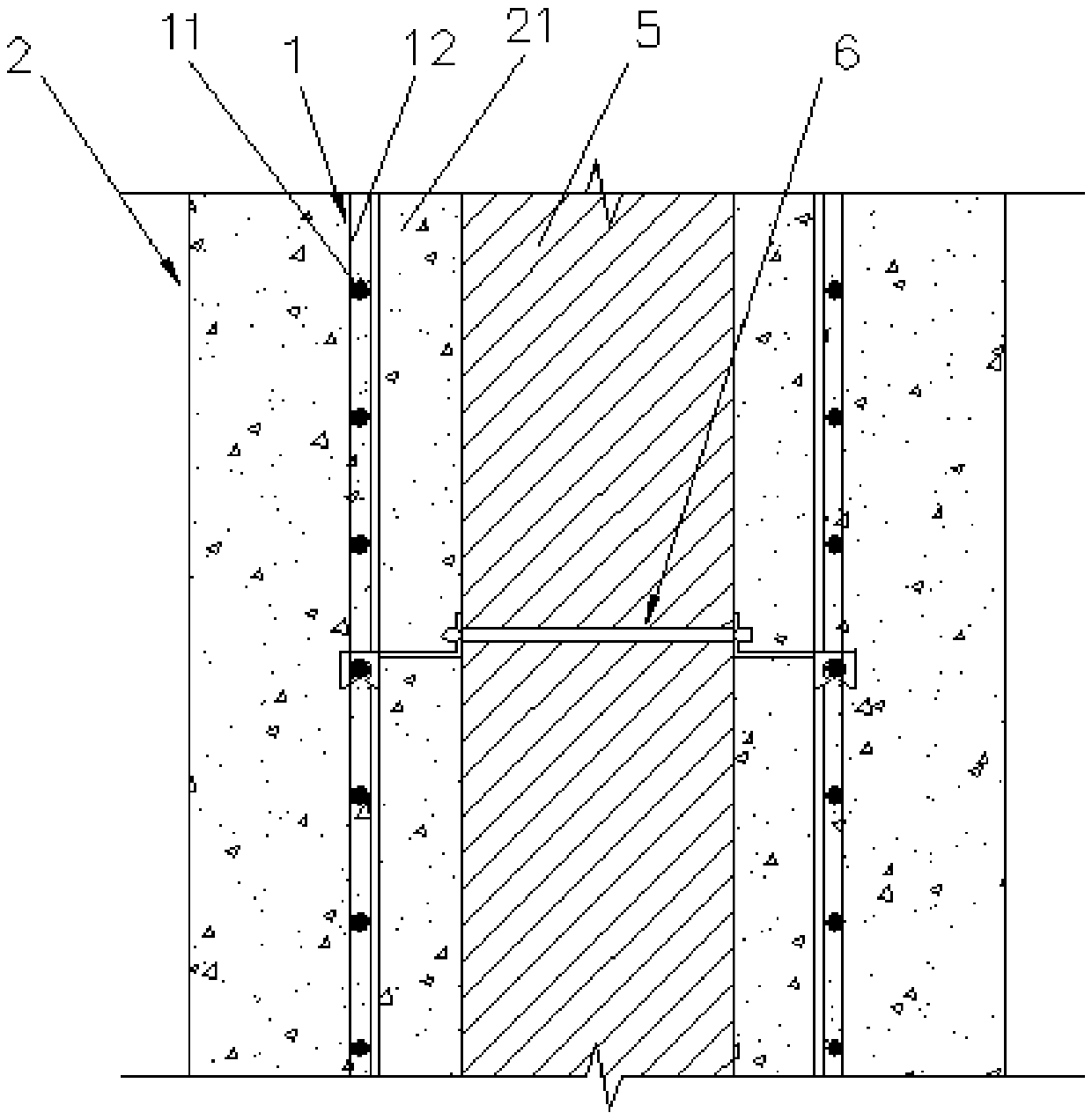

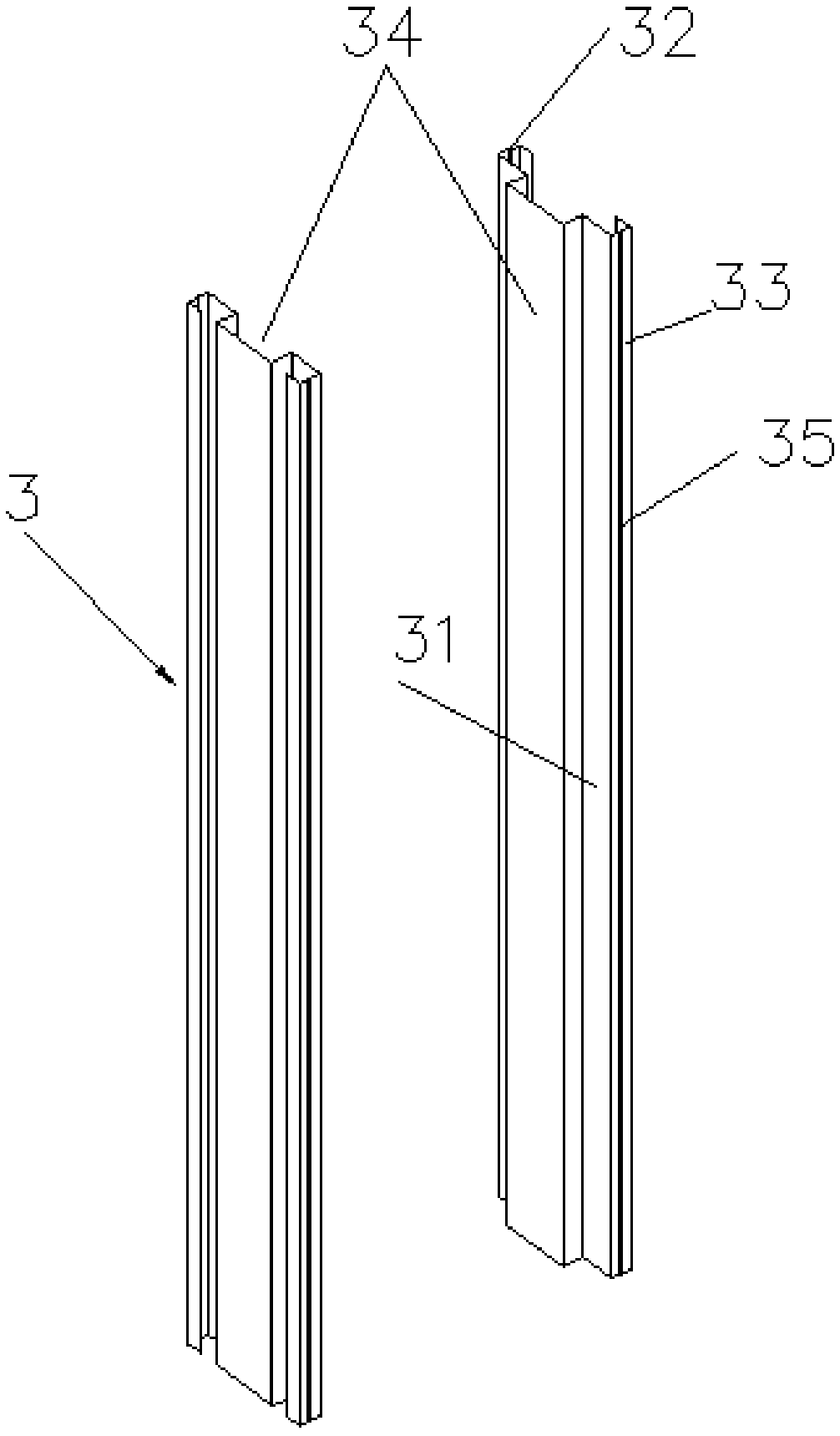

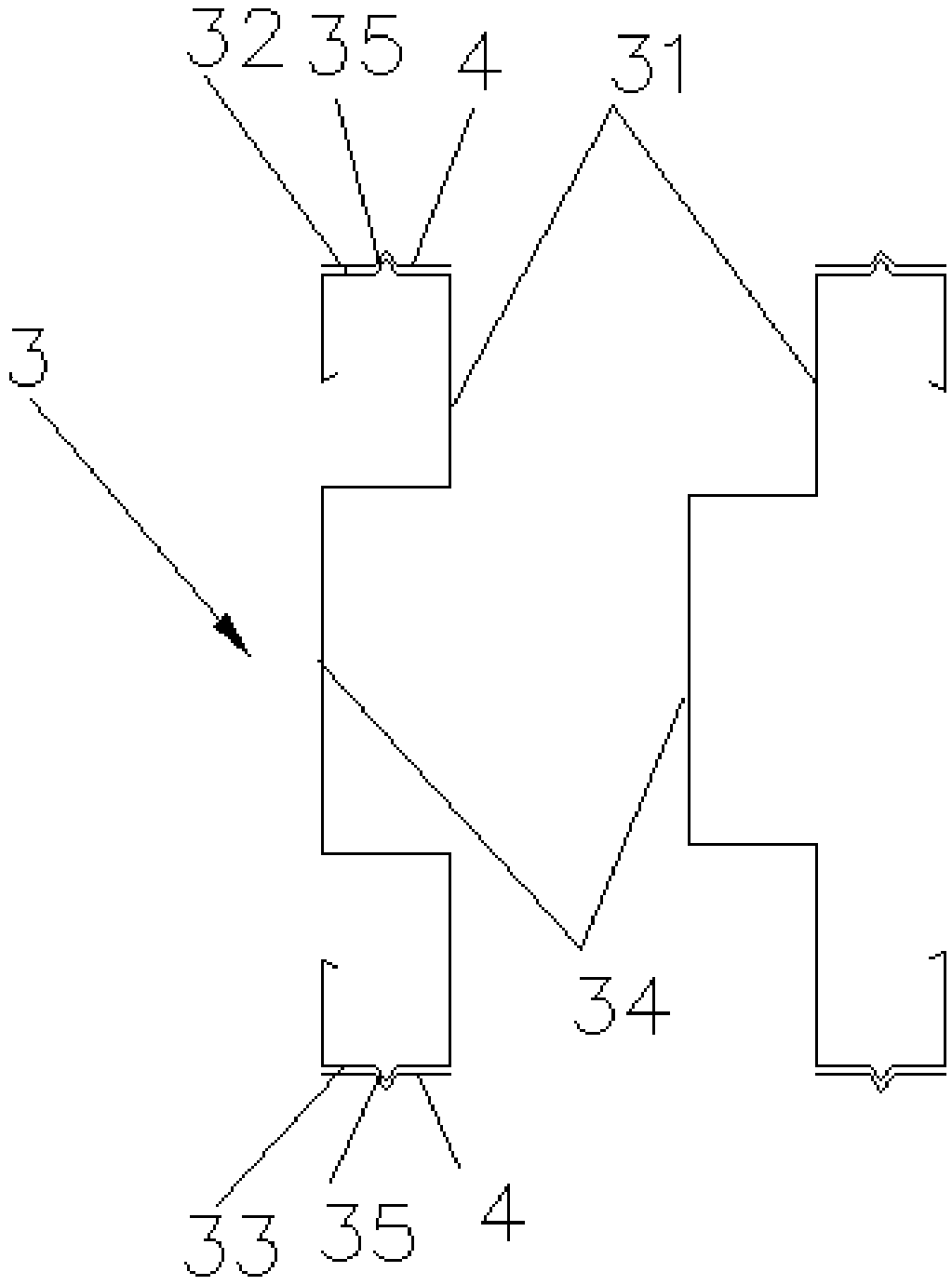

[0025] Such as Figure 1 to Figure 4 As shown, a broken bridge concrete composite partition wall includes a metal frame, a steel mesh 1 and a wall surface layer 2. The four frame bars of the metal frame are keels 3 with concave-convex joints 34, and the concave-convex joints 34 are on the keel 3. Extending in the length direction of the outer surface 31, the outer surface 31 of the keel 3 is bent on the left and right sides in the width direction to form left and right sides 32, 33 perpendicular to the outer surface 31. The right sides 32, 33 are provided with protruding ribs 35, and the ribs 35 extend along the length direction of the keel 3, and the ribs 35 are welded with the steel mesh 1 covering the left and right sides of the metal frame, so that The outer surfaces of the left and right sides 32, 33 of the keel 3 are covered with a heat-insulating paint layer 4, which blocks the heat of the wall surface layer 2 from passing through the left and right sides 32, 33 of the ...

Embodiment 2

[0030] The structure of each component of the broken bridge concrete composite partition wall in this embodiment, and the mutual relationship between each component, is basically the same as that of embodiment 1, and the difference is as follows Figure 5 As shown, the connecting tail 612 of the card joint 61 is a straight rod, one end of the straight rod is connected to the card 611, and the other end is connected to the connecting rod 62 through the plastic connecting head 614. The connecting tail 612, the plastic connecting head 614 are connected to the The rod 62 is coaxial, and the two ends of the plastic connector 614 are provided with connecting holes for interference fit with the connecting tail 612 and the connecting rod 62 . The flame-retardant lightweight filling board 5 in the present embodiment is a grade A fireproof material, such as inorganic materials such as rock wool or perlite, and the thickness of the lightweight concrete 21 positioned at the outside of the ...

Embodiment 3

[0032] The structure of each component of the broken bridge concrete composite partition wall in this embodiment, and the mutual relationship between each component, is basically the same as that of embodiment 1, and the difference is as follows Figure 6 As shown, it also includes an interior wall interior decoration surface layer 7 and an exterior wall exterior decoration surface layer 8, the interior wall interior decoration surface layer 7 and the exterior wall exterior decoration surface layer 8 are attached to the outer surface of the wall surface In fact, this can improve the assembly level of the building, reduce the on-site workload of the building, and improve the fire prevention, heat preservation, sound insulation, heat insulation effect and overall strength of the wall panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com