Decorative moulding assembly and construction method thereof

A technology of decorative lines and construction methods, which is applied in the fields of architecture, building structure, and building materials, and can solve problems such as difficulty in completing construction at one time, affecting appearance and life, and low installation accuracy, so as to eliminate low installation accuracy , Improve construction efficiency and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

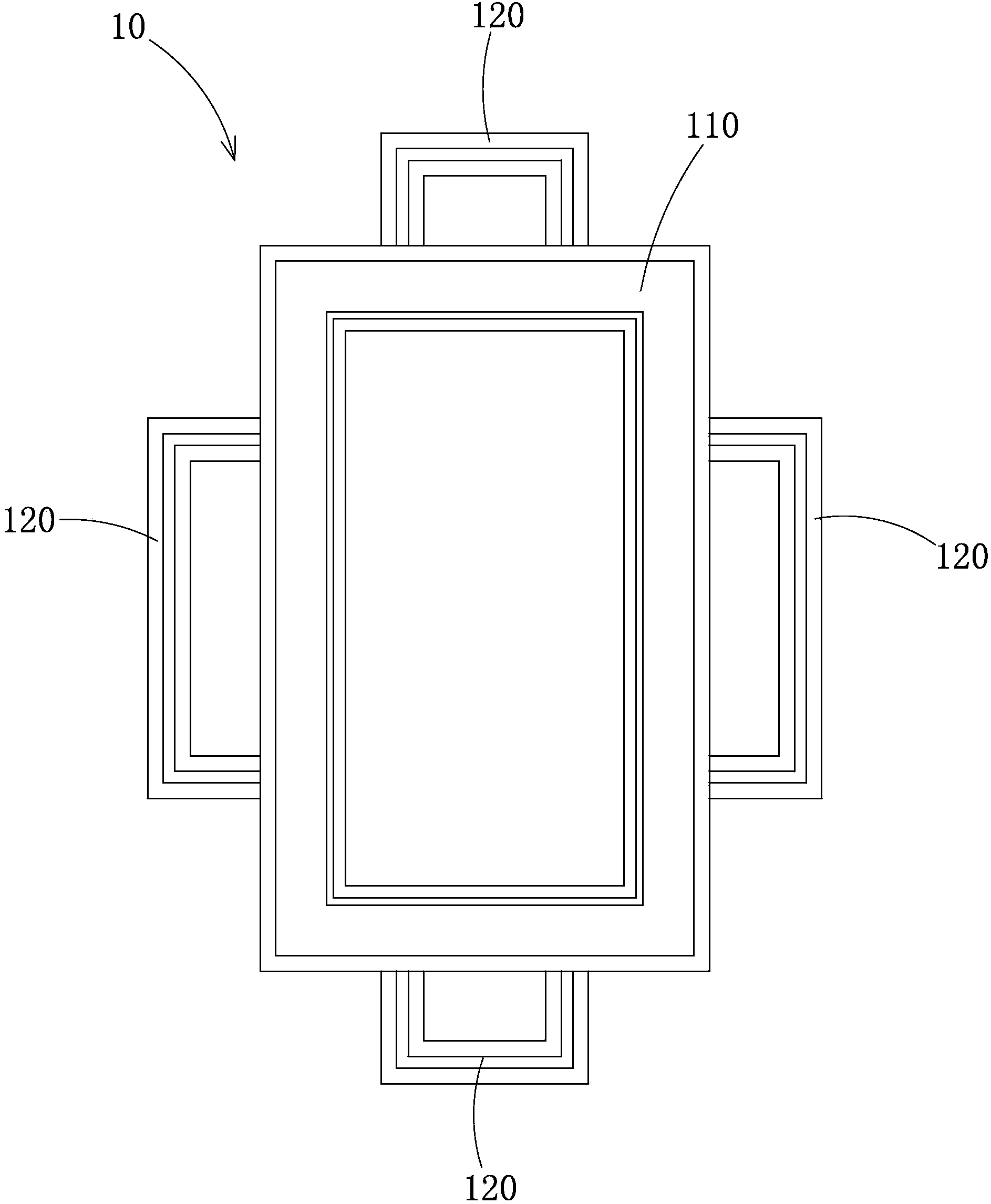

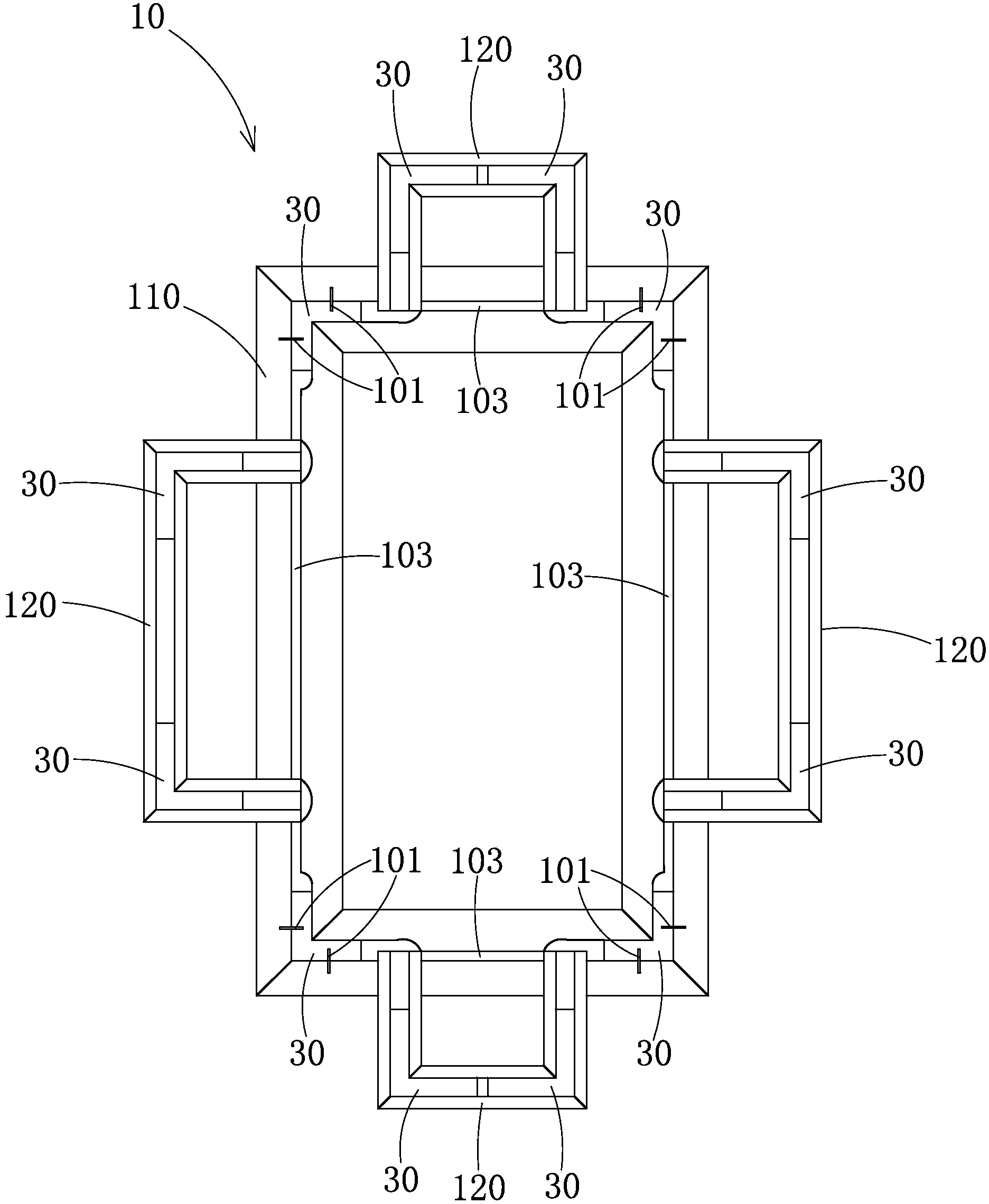

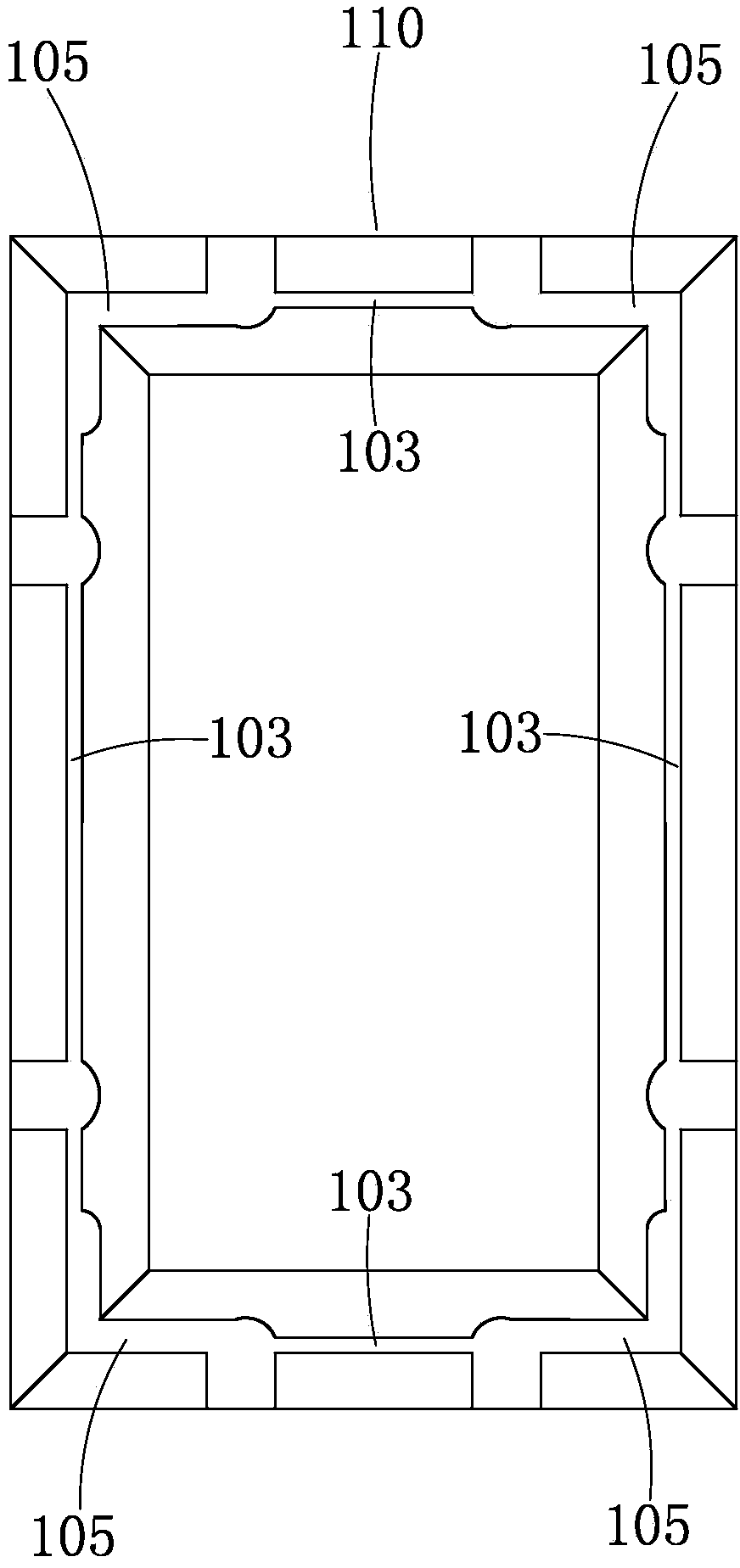

[0035] The decorative line assembly of the present invention includes a decorative line 10 , a template 50 and a fixture 40 that can be fixed to the wall. As an example, the front view and rear view of the molding 10 are as follows figure 1 and figure 2 As shown, it is composed of a decorative line body 110 and a small line 120 , the small line 120 is U-shaped and its end is connected to the edge of the decorative line body 110 . Both the main body of the decorative line and the small lines are assembled by multiple line units. The decorative line in the figure is roughly assembled into a rectangle, and it can also be designed and assembled into other shapes according to the decoration needs.

[0036] Since the decorative line main body and the small lines are assembled by a plurality of line units, there are seams at the corners of the decorative line main body 110 and the small lines 120, and the front side of the decorative line 10 is coated with a Seamed decorative surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com