Building Structure

a technology for building structures and concrete, applied in the direction of building components, building parts, building shape, etc., can solve the problems of high labor intensity, potential danger to workers, inherent dimensional and structural irregularities of natural products,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

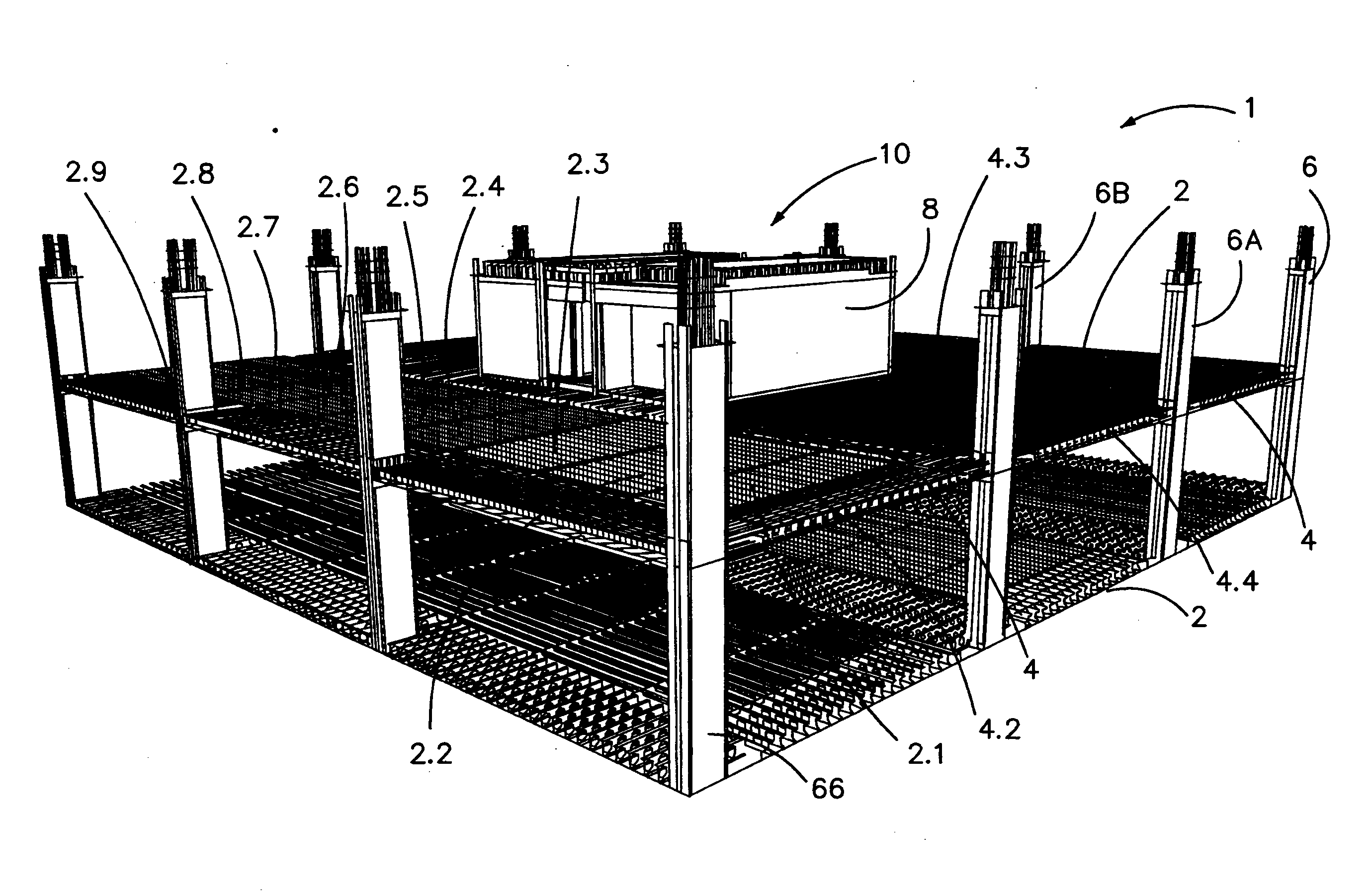

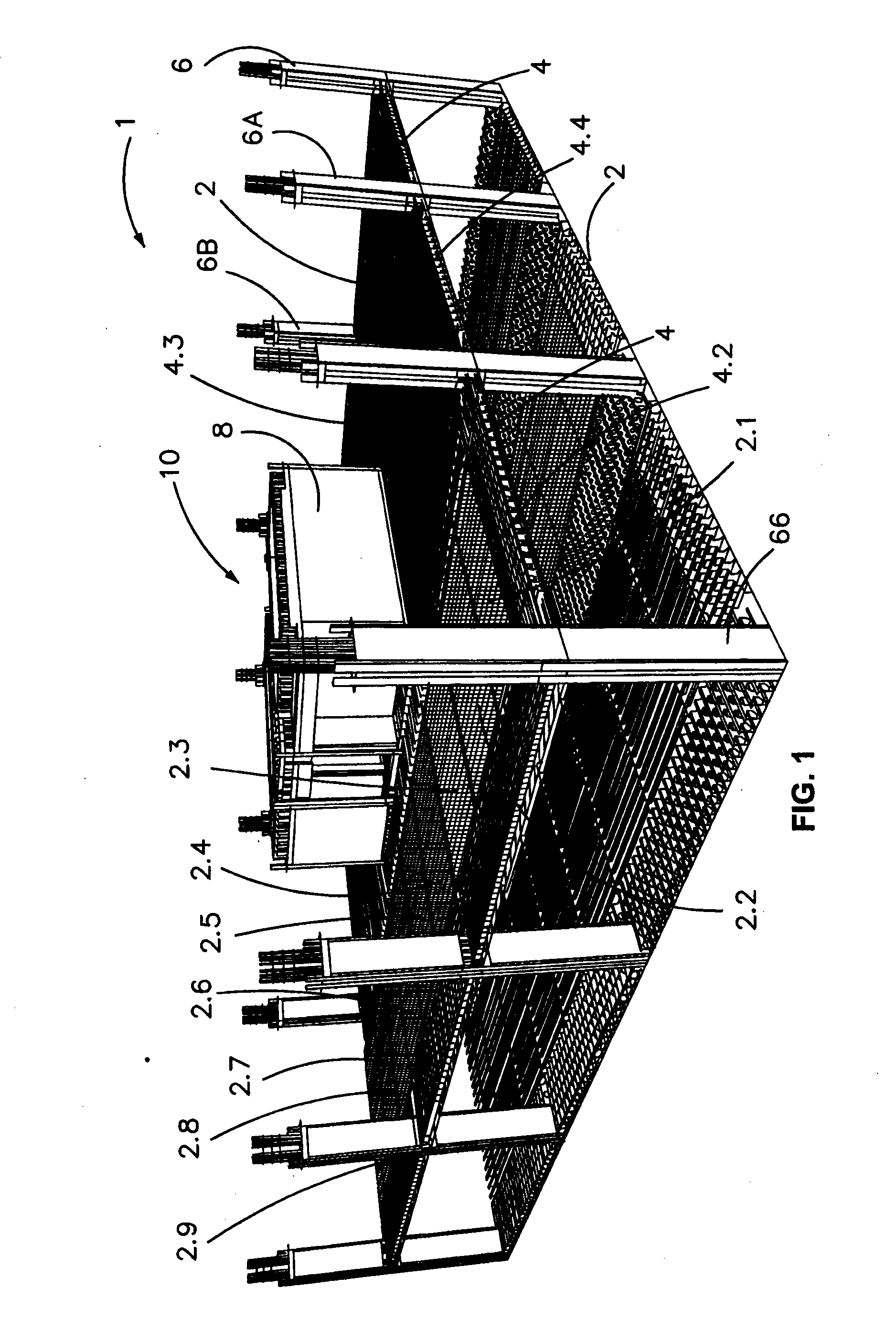

[0117]FIG. 1 shows a partially constructed building 1. The building will ultimately include several storeys, but in FIG. 1 only two are shown. In FIG. 1 the structure of the partial building 1 consists of a plurality of pre-fabricated modules assembled to define an external formwork structure carrying concrete reinforcing bars to strengthen the concrete once it is poured. In FIG. 1 the concrete is not shown. The structure of the building illustrated in FIG. 1 is assembled on site, on suitable foundations (that may be constructed using a similar methodology to the upper storeys illustrated or conventionally) from a plurality of pre-fabricated formwork modules as described below.

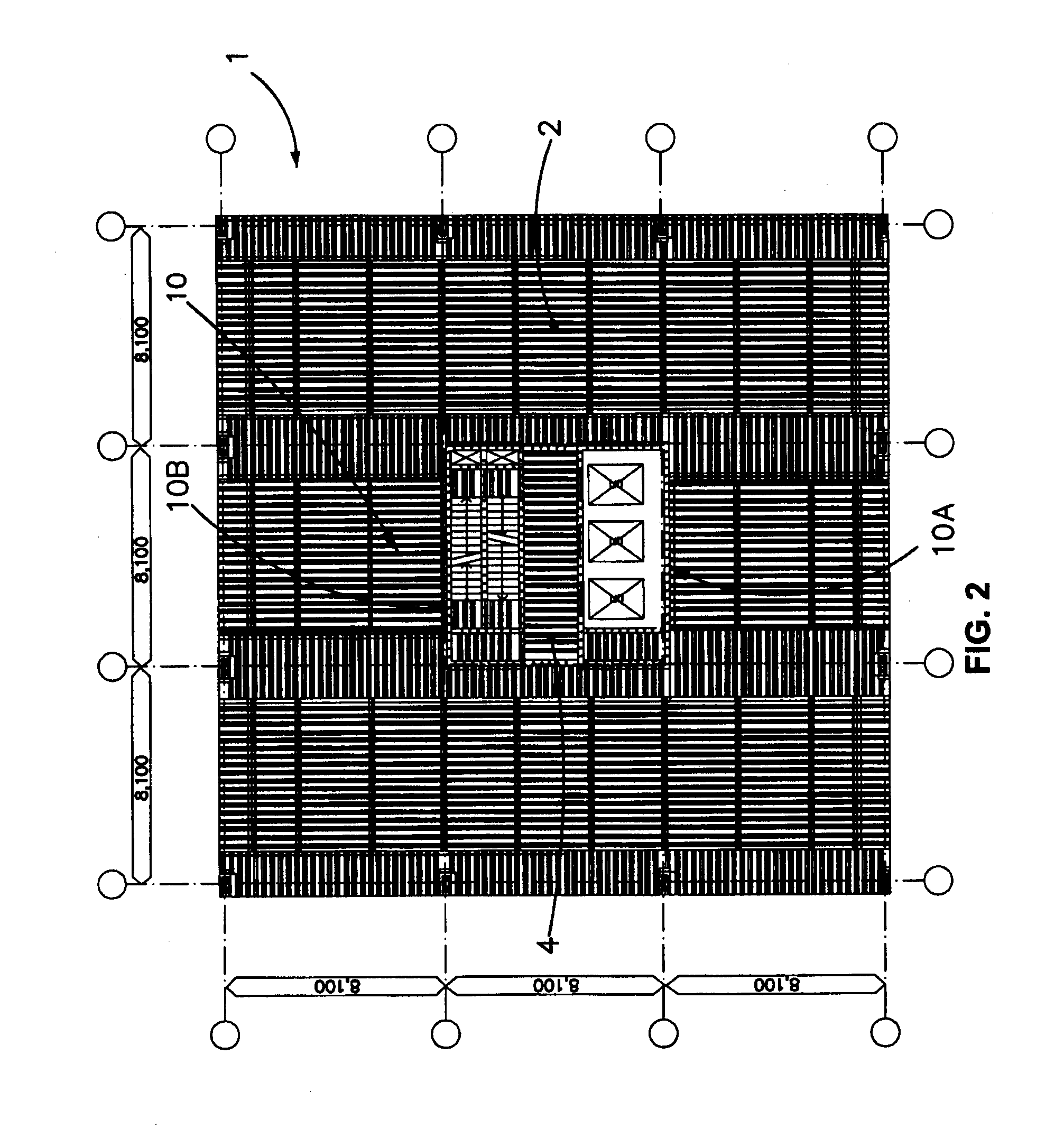

[0118]The building 1 includes various building portions including floors 2, beams 4, columns 6, walls 8 and a central core 10. As shown in FIG. 2 the core 10 is made up of two core portions 10A and 10B.

[0119]As will be described, the floor portions 2 and beam portions 4 have a similar construction. As best ill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com