High altitude placing steel pole inner concrete operating platform frame

An operating platform and concrete technology, which is applied in construction, building structure, scaffolding supported by house structure, etc., can solve the problems of increasing labor intensity and danger of personnel, low safety factor of hanging baskets, and increasing the number of hoisting and transportation. Increase the convenience of operation, simple force transmission, and reduce the effect of using time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

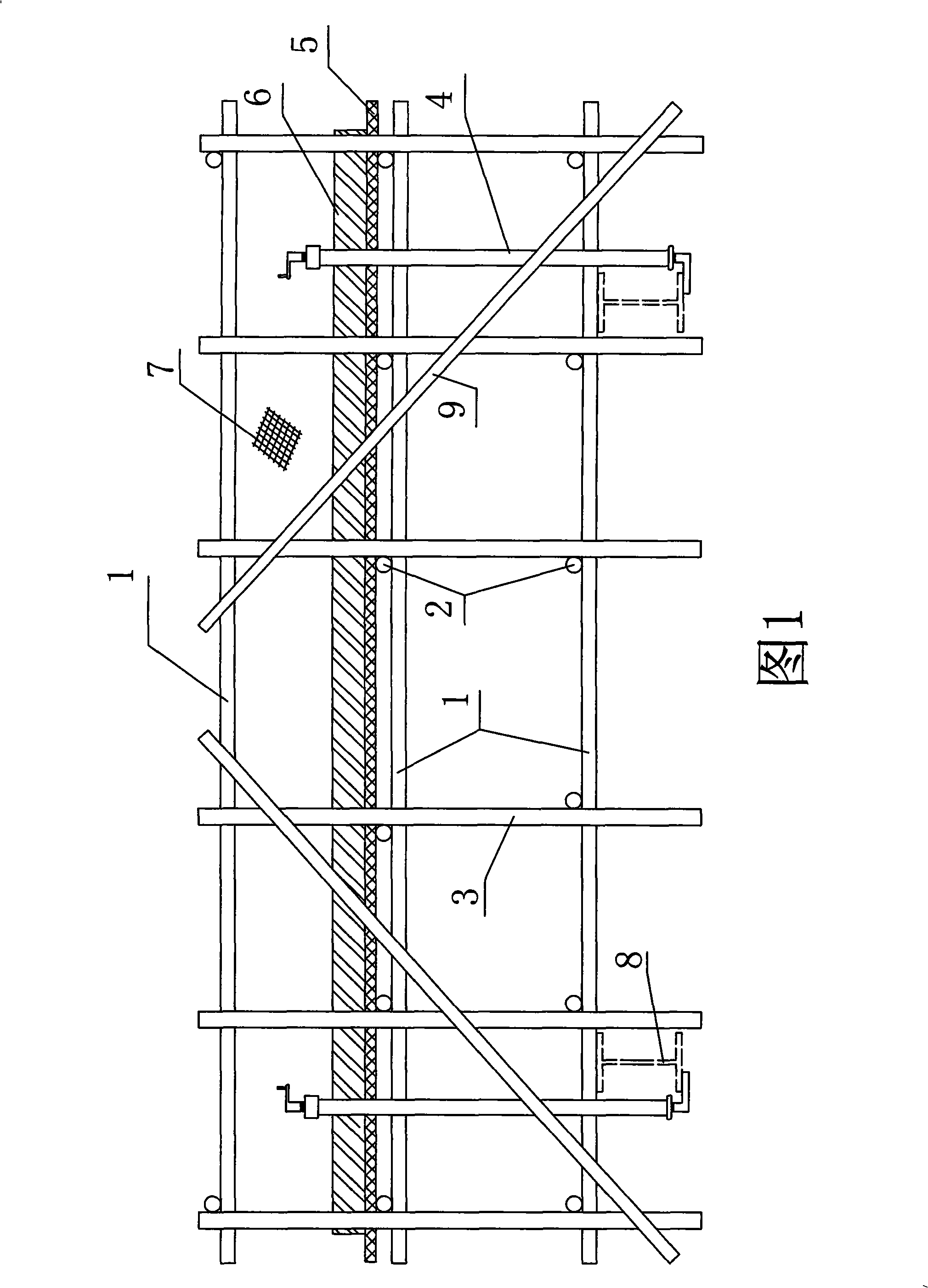

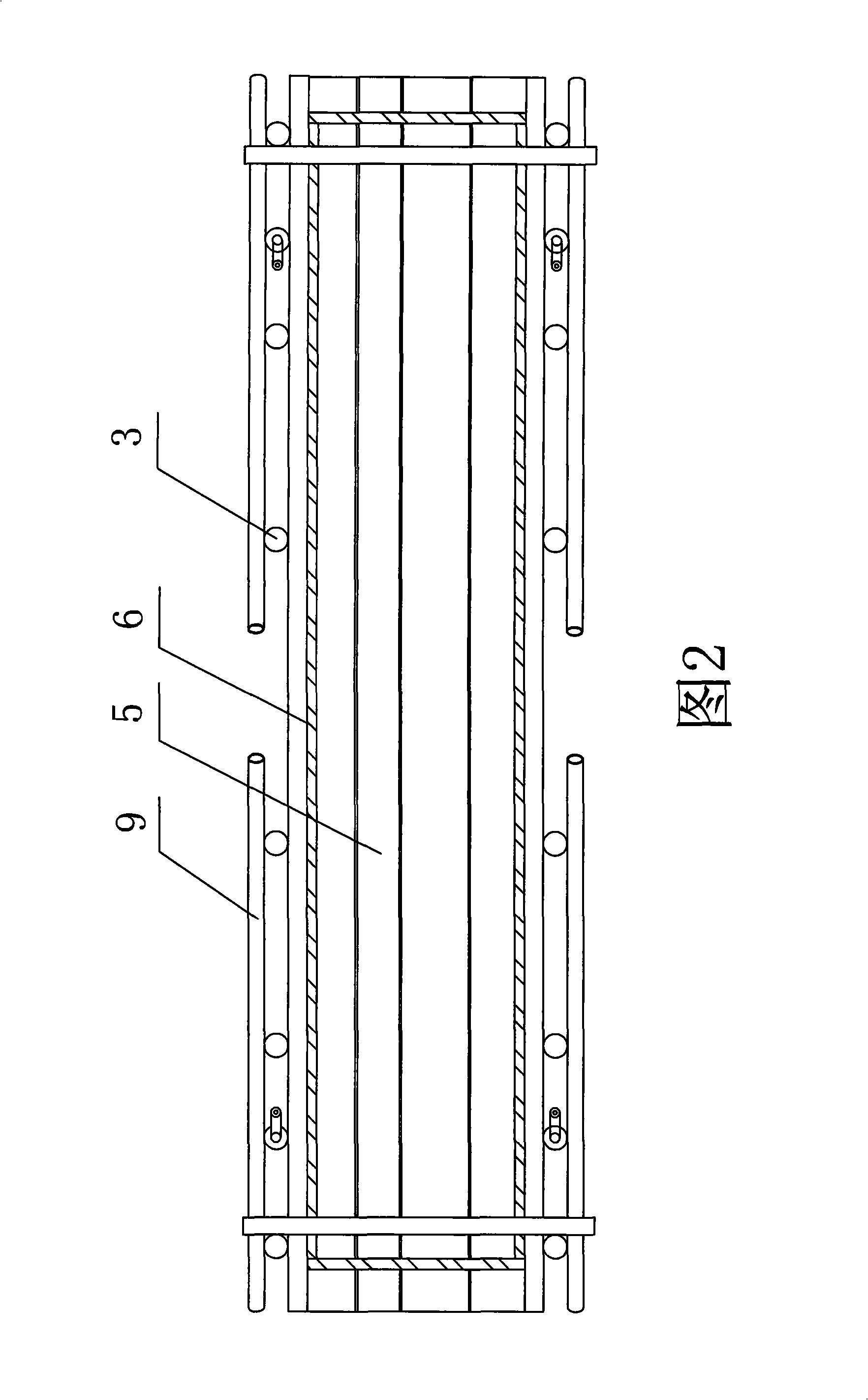

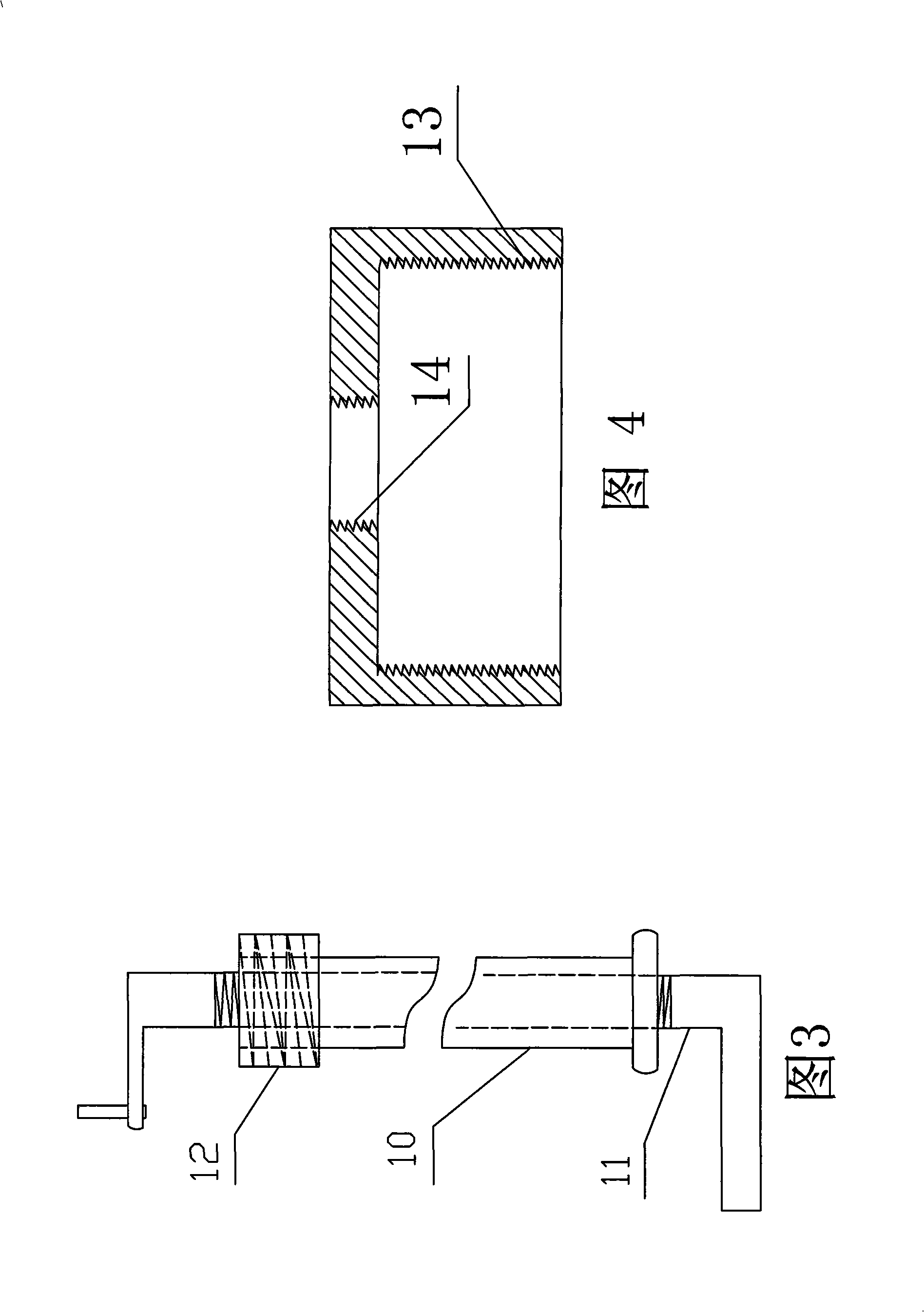

[0018] Build the tool-type scaffolding platform frame with horizontal longitudinal bar 1, horizontal small horizontal bar 2, vertical bar 3, scissors brace 9 and fasteners. Horizontal longitudinal bar 1, horizontal small horizontal bar 2, vertical bar 3, scissor support 9 or more 48 steel pipe as the base material. The tool-type scaffolding platform frame is placed on the steel beam 8 (the installed steel beams of two adjacent steel structure frames) that is convenient for pouring concrete in at least two steel columns, and the tool-type scaffolding platform frame and the steel beam are used Fastening bolt 4 is fixedly connected. The operating platform frame has a group of vertical poles 3, and the positions of four vertical poles are on the inner side of the beam near the corresponding shelving steel beam 8. Set the first group of horizontal longitudinal rods 1 at the appropriate position of the vertical rods. When the operating platform frame is in use, this group of hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com