A forward drawing-backward bulging composite superplastic forming device and method thereof under the action of sheet material inflated back pressure

A technology for superplastic forming and sheet metal, which is applied in the field of superplastic forming devices and can solve the problems of unformable parts and broken parts walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

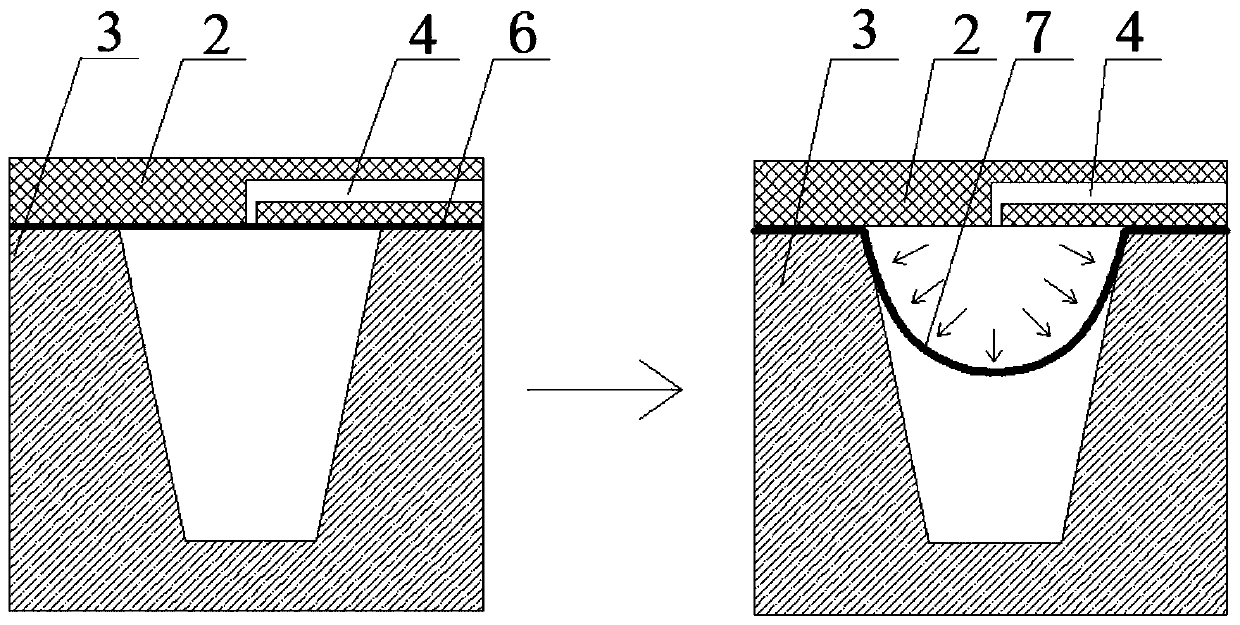

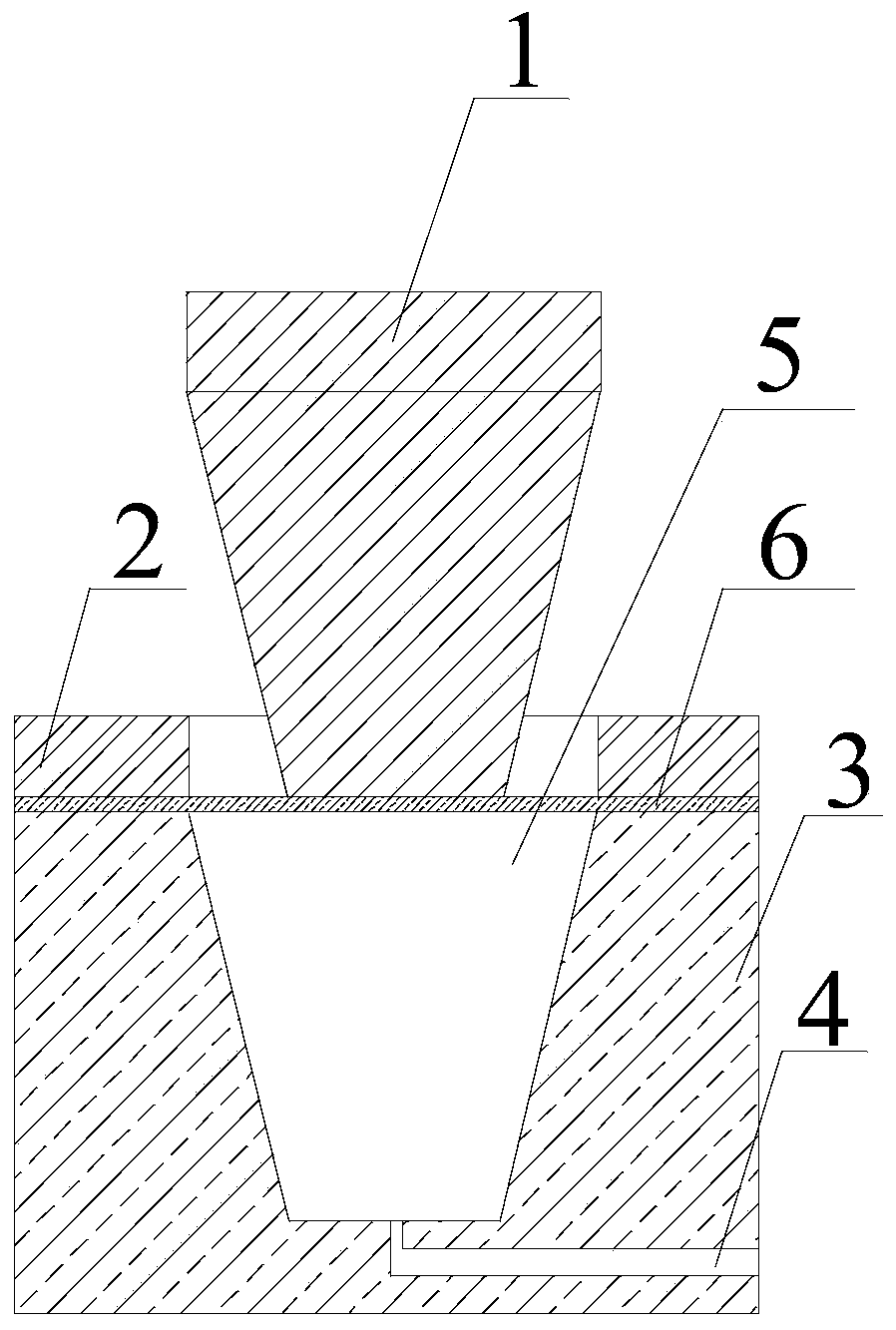

[0049] Specific implementation mode one: combine figure 1 Describe this embodiment. This embodiment is a forward drawing-backward bulging composite superplastic forming device under the action of sheet material inflation back pressure, including a punch 1, a pressure ring 2, a die 3 and an air hole 4;

[0050] The inside of the die 3 is provided with a die cavity 5 and an inflation hole 4, and the bottom of the die cavity 5 communicates with the inflation hole 4;

[0051] The top of the die 3 is provided with a punch 1 and a pressure ring 2; the punch 1 is placed inside the pressure ring 2, the central axis of the punch 1 and the die 3 coincides, and the punch 1 can be connected to the die cavity 5 Clamping;

[0052] The inner diameter of the pressure ring 2 is equal to the diameter of the inner wall cross-section at the top of the die cavity 5;

[0053] The plate to be formed is placed in the gap formed by the punch 1 , the pressure ring 2 and the die 3 .

specific Embodiment approach 2

[0054] Specific embodiment 2: In this embodiment, a forward drawing-backward bulging composite superplastic forming method under the action of sheet inflated back pressure is to use a forward drawing-backward bulging under the action of sheet inflated back pressure Shaped composite superplastic forming device is completed, specifically according to the following steps:

[0055] 1. Mold assembly: connect the punch 1 to the inner slider of the double-action press through the pressure plate, so that the punch 1 can move up and down; connect the pressure ring 2 to the outer slider of the double-action press through the pressure plate, so that The pressure ring 2 can move up and down; then the die 3 is fixed on the lower platform of the double-action press through the pressure plate;

[0056] 2. Heating: place the plate to be formed on the die 3, move the punch 1 and the pressure ring 2, so that the punch 1 and the pressure ring 2 are in contact with the plate to be formed; The te...

specific Embodiment approach 3

[0066] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the plate to be formed in Step 2 is titanium alloy, aluminum alloy, magnesium alloy, superalloy or stainless steel. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com