Superplastic discontinuous reinforced titanium-based composite material and superplastic forming method thereof

A titanium-based composite material and superplastic technology, which is applied in heat treatment equipment, manufacturing tools, heat treatment process control, etc., can solve the problems of poor plastic forming ability of titanium-based composite materials, limited superplastic deformation ability, and increased superplastic forming cost. , to achieve the effect of reducing processing cost, reducing energy consumption, and saving thermal processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

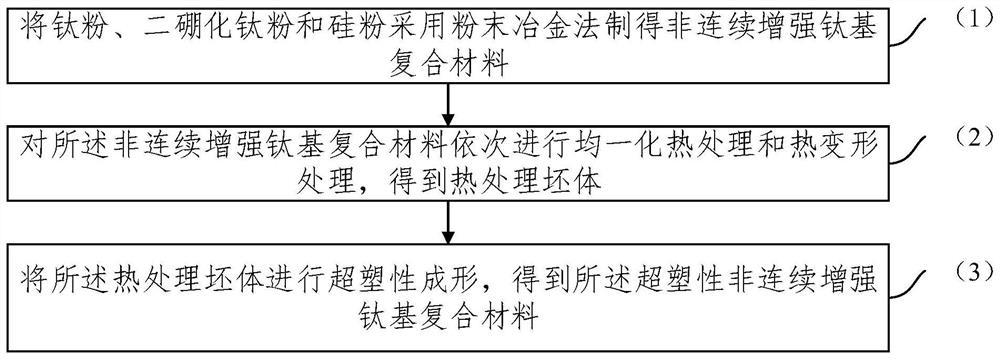

[0090] (1) Preparation of TA15(Si) titanium-based composite material containing 3.5vol.% TiBw reinforcement:

[0091] TA15 powder, titanium diboride powder and silicon powder (the mass ratio of the three is 98:2:0.3) are prepared by powder metallurgy to obtain discontinuously reinforced titanium matrix composites;

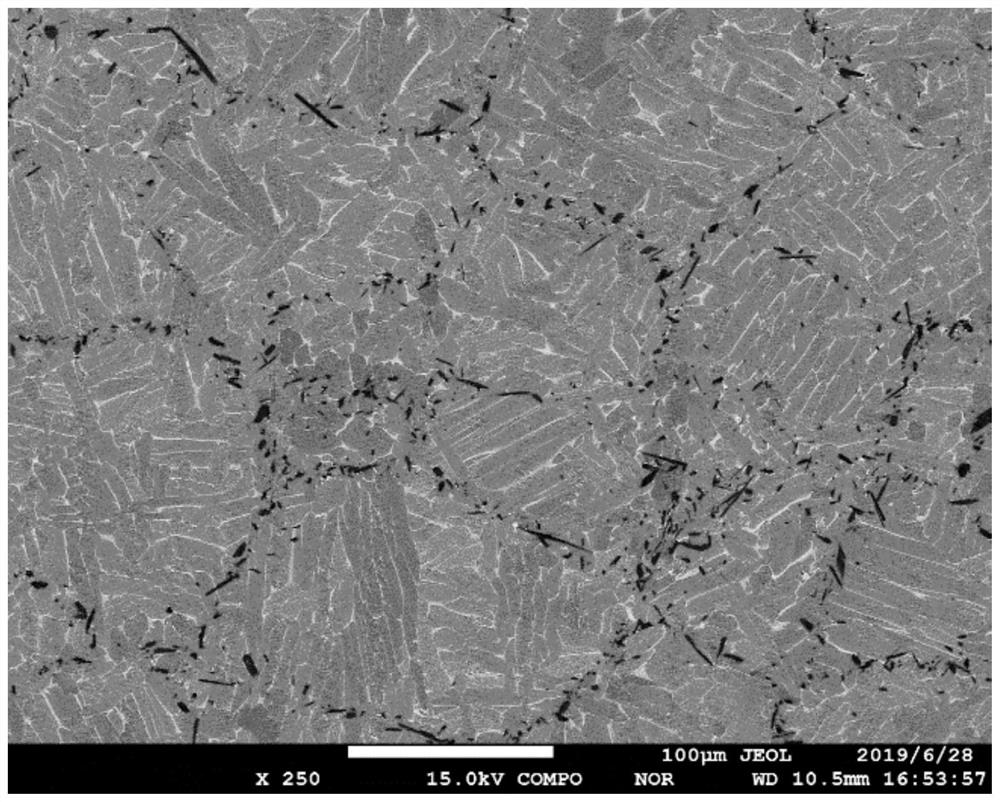

[0092] (2) Place the discontinuously reinforced titanium-based composite material obtained in step (1) at 1050°C and keep it warm for 30 minutes, and then air-cool it to room temperature (25°C) at a rate of 10°C / s to obtain a material with a uniform structure;

[0093] Then place the homogeneous texture material at 910°C for unidirectional forging with a deformation of 75%, and then cool it to room temperature (25°C) with the furnace at a rate of 7°C / min to obtain a heat-treated green body;

[0094] (3) The heat-treated green body obtained in step (2) is sample-prepared, and each sample prepared is respectively placed under the deformation temperature and deformati...

Embodiment 2

[0096] (1) Preparation of TA15(Si) titanium-based composite material containing 3.5vol.% TiBw reinforcement:

[0097] TA15 powder, titanium diboride powder and silicon powder (the mass ratio of the three is 98:2:0.3) are prepared by powder metallurgy to obtain discontinuously reinforced titanium matrix composites;

[0098] (2) Place the discontinuously reinforced titanium-based composite material obtained in step (1) at 1050°C and keep it warm for 30 minutes, and then air-cool it to room temperature (25°C) at a rate of 10°C / s to obtain a material with a uniform structure;

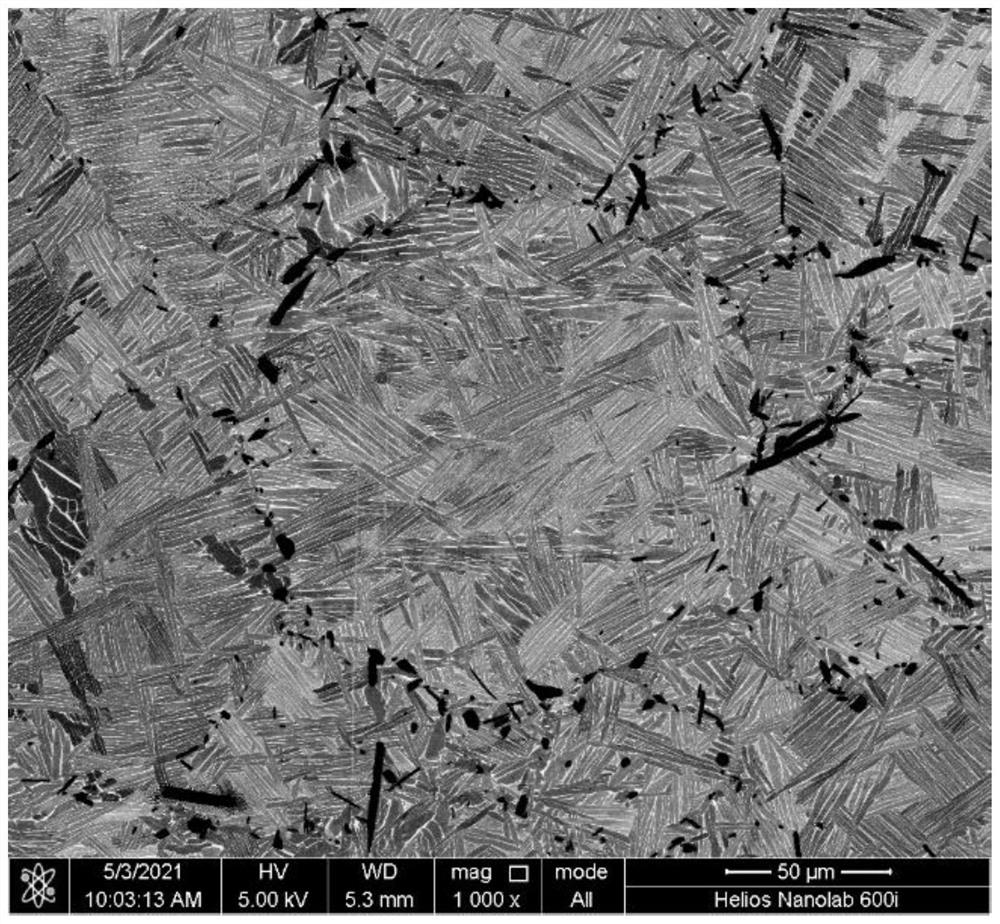

[0099] Then place the material with uniform structure at 910°C for unidirectional forging with a deformation of 75%, and then cool it to room temperature (25°C) with the furnace at a rate of 7°C / min to obtain a typical structure after heat treatment;

[0100] Then place the heat-treated typical structure at 980°C and keep it warm for 0.5h, and then air-cool to room temperature (25°C) at a rate of 7°C / s to o...

Embodiment 3

[0103] (1) Preparation of TA15(Si) titanium-based composite material containing 2vol.% TiBw reinforcement:

[0104] TA15 powder, titanium diboride powder and silicon powder (the mass ratio of the three is 98.8:1.2:0.5) are prepared by powder metallurgy to obtain discontinuously reinforced titanium-based composite materials;

[0105] (2) Place the discontinuously reinforced titanium-based composite material obtained in step (1) at 1060°C and keep it warm for 30 minutes, and then air-cool it to room temperature (25°C) at a rate of 10°C / s to obtain a material with a uniform structure;

[0106] Then place the material with uniform structure at 930°C for unidirectional forging with a deformation of 75%, and then cool it to room temperature (25°C) with the furnace at a rate of 7°C / min to obtain a typical structure after heat treatment;

[0107] Then place the heat-treated typical structure at 1010°C and keep it warm for 0.5h, and then air-cool it to room temperature (25°C) at a rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com