A maintenance-free slip ring with high current and high power

A high-power, maintenance-free technology, applied in the direction of circuits, current collectors, electrical components, etc., can solve the problems of high cost of use and poor reliability, and achieve the effect of reducing raw material costs, cost reduction, and good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

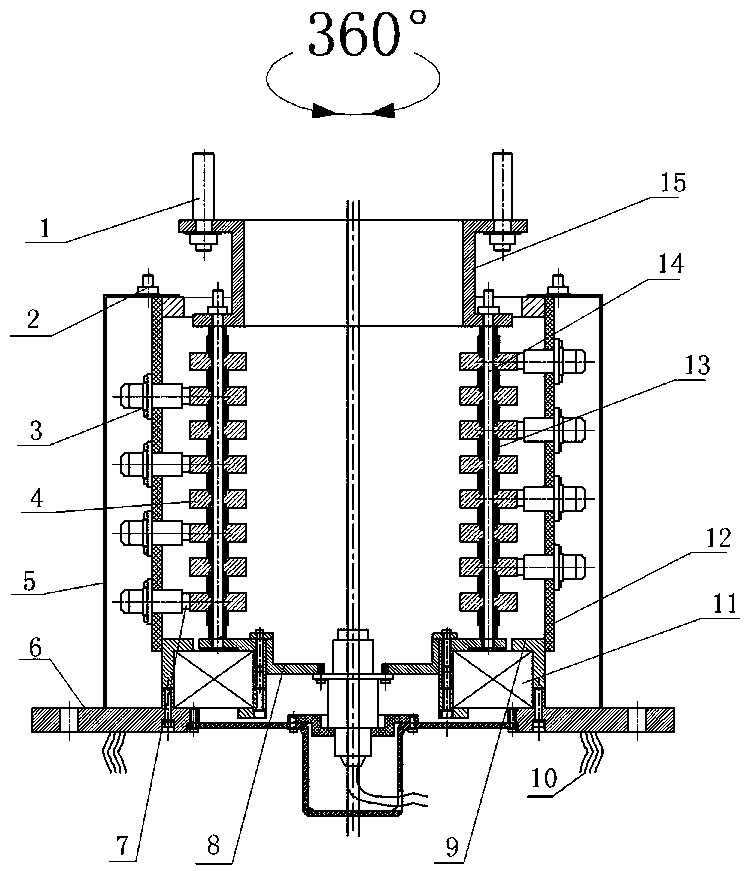

[0019] according to figure 1 , the present invention includes a mounting plate 6; the top surface of the mounting plate 6 is fixedly provided with a bearing seat 11;

[0020] The inner ring of the bearing seat 11 is tightly connected with the slip ring 8, and the top surface of the slip ring 8 is fixed with a column 14; the column The top of 14 is tightly connected with the rotating ring 15; the top of the rotating ring 15 is provided with a shift fork 1; the column 14 is evenly provided with a number of conductive rings 4 fixedly connected to each other through the bracket 13;

[0021] The outer ring and column of the bearing housing 11 12 fixed connections; the uprights The top of 12 is fixedly connected with protective cover 5 by fastening bolt 2; 12 is evenly provided with a number of brushes 3, and the inner end of the brush 3 is movably plugged with a conductive column 7; the conductive column 7 is elastically connected to the brush 3 through a spring; the con...

Embodiment 2

[0025] The conductive ring described in embodiment 1 is prepared according to the following process:

[0026] First put copper into a vacuum induction melting furnace, heat it to 300°C, then add aluminum, zirconium, nickel, manganese, vanadium, titanium, yttrium and cerium for melting, the melting temperature is 1220°C, the melting time is 20min, and then argon Protective injection molding, the argon protection pressure is 0.9MPa, the nozzle diameter is 3mm, the oblique angle is 37°, the eccentricity is 30mm, and the melt mass flow rate is 10kg / min; the injection-molded alloy material is put into the hot extrusion Hot extrusion in a press, extrusion temperature 300°C, pressure 300MP, heat preservation and pressing for 4 hours; cool down to room temperature, then perform cold pressing at a pressure of 70MP for 2 times, each pressing for 2 hours; finally use a lathe for surface treatment to obtain the product. The mass ratio of copper, aluminum, zirconium, nickel, manganese, van...

Embodiment 3

[0028] A conductive ring, which is prepared according to the following process:

[0029] First put copper into a vacuum induction melting furnace and heat it to 300°C, then add aluminum, zirconium, nickel, manganese, vanadium, titanium, yttrium and cerium for melting, the melting temperature is 1230°C, the melting time is 20min, and then argon Protective injection molding, the argon protection pressure is 0.9MPa, the nozzle diameter is 3mm, the oblique angle is 37°, the eccentricity is 30mm, and the melt mass flow rate is 10kg / min; the injection-molded alloy material is put into the hot extrusion Hot extrusion in a press, extrusion temperature 300°C, pressure 300MP, heat preservation and pressing for 4h; cool down to room temperature, then perform cold pressing at a pressure of 70MP twice, each pressing for 2h; finally use a lathe for surface treatment to obtain the product. The mass ratio of copper, aluminum, zirconium, nickel, manganese, vanadium, titanium, yttrium and ceriu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com