Light alloy magnetic ultrasonic casting and rolling integrated device and method

A light alloy and ultrasonic technology, applied in the direction of metal rolling, etc., can solve the problems of high metal loss, difficult plastic processing of slabs, high cost, etc., to improve deformation rate and yield, improve internal quality and plastic deformation ability, crystallization fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

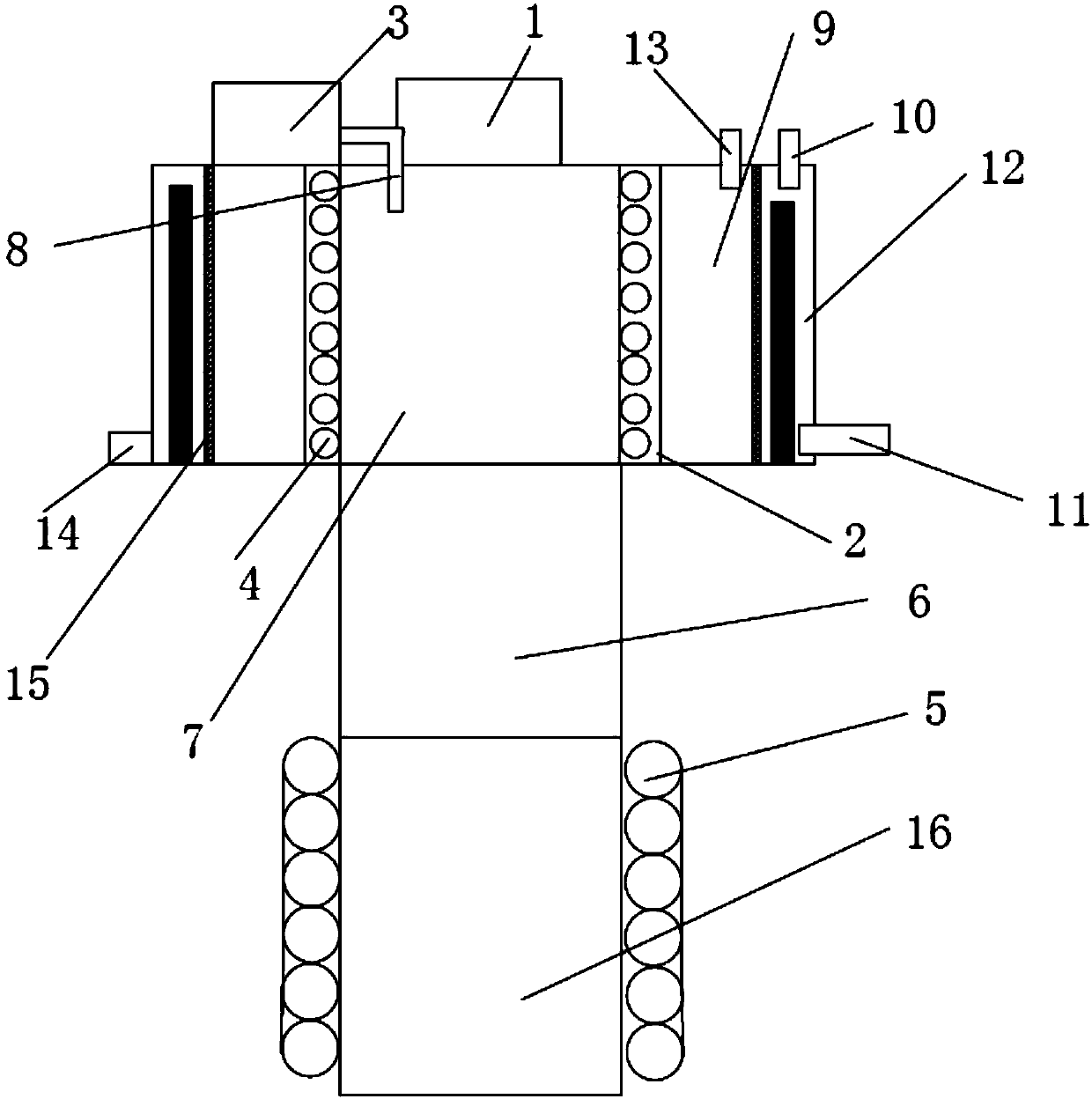

[0023] Such as figure 1 As shown, a light alloy magneto-ultrasonic casting and rolling integrated device provided in this embodiment includes a flow channel 1 and a crystallizer 2, and the flow channel 1 is above the crystallizer 2, and the molten metal after smelting passes through the flow channel 1 Inject into the inner groove 7 in the crystallizer 2; Also comprise supersonic generator 3, induction coil 4, roll 5 and hinge straight road 6, described supersonic generator 3 is as for crystallizer 2 side, and the generation of supersonic generator 3 The device 8 extends into the crystallizer 2, the induction coil 4 is arranged on the outer wall of the inner groove 7 of the crystallizer 2 and covers the inner groove 7 of the crystallizer 2, and the outer side of the induction coil 4 is provided with inner, The outer two-layer cooling chamber, the outer cooling chamber 12 is a water-cooling structure with double-layer channels, and the upper end of the outer cooling chamber 12 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com