Double-stand rolling method for rolling super-thick steel plate by giving consideration to both plate shape and flaw detection performance

A technology of extra-thick steel plates and double stands, applied in metal rolling, rolling force/roll gap control, roll speed control, etc., can solve the problem of plate shape, the flaw detection performance of finished steel plates and the uniformity of performance in the thickness direction. Guarantee, head and tail drift, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、160

[0014] Embodiment 1, 160mm Q345B

[0015] Billet size: 400*2000*2800mm

[0016] Steel plate size: 160*2000*6800mm

[0017] Rough rolling and direct longitudinal rolling, the maximum reduction in a single pass is 38mm, the maximum reduction rate is 15.5%, and the rolling speed is 2m / s;

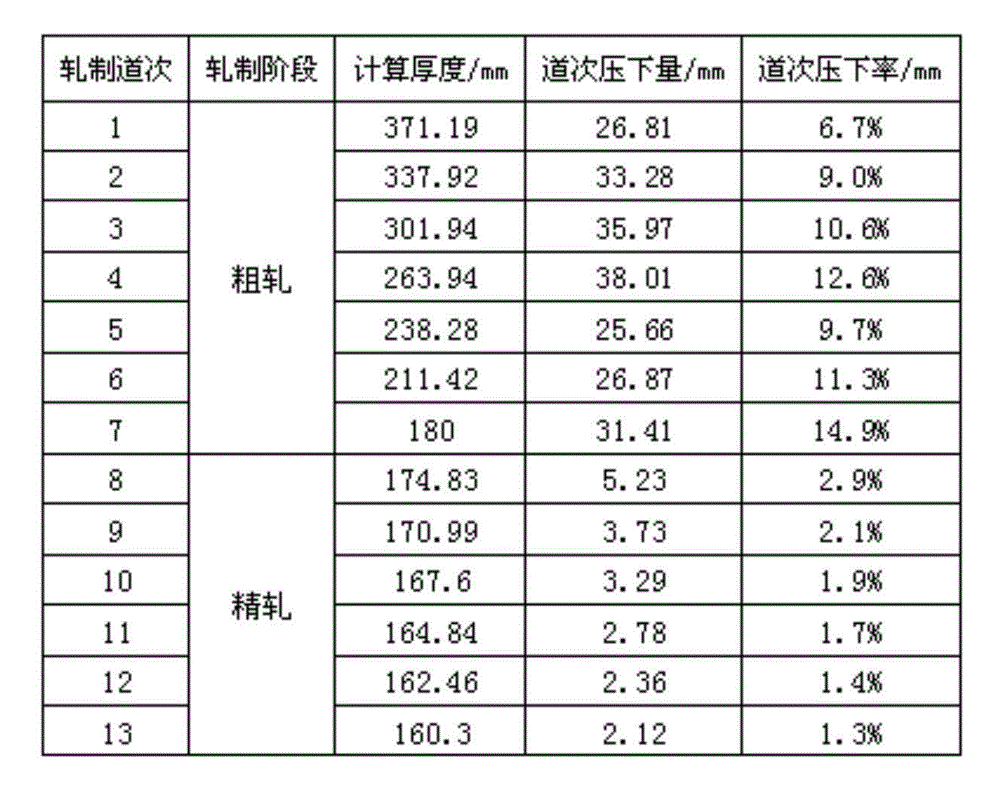

[0018] The temperature control thickness is 180mm, the finish rolling is 6 passes, the final pass reduction is 2.1mm, and the rolling speed is 4m / s. The detailed rolling procedure is shown in Table 1:

[0019] Table 1: 160mmQ345B rolling schedule

[0020]

Embodiment 2、170

[0021] Embodiment 2, 170mm Q345B

[0022] Billet size: 400*1800*3700mm

[0023] Steel plate size: 170*2000*4700-12000mm

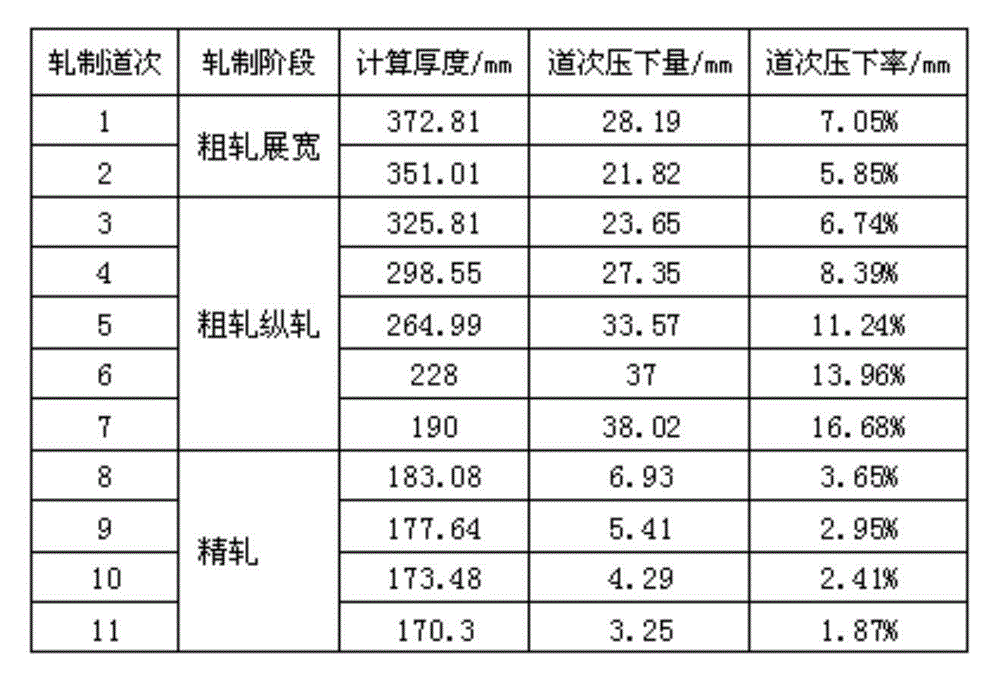

[0024] Rough rolling is first carried out with two passes of widening rolling, followed by longitudinal rolling. The maximum reduction in a single pass is 38mm, the maximum reduction rate is 16.7%, and the rolling speed is 1.5m / s;

[0025] Temperature control thickness 190mm, rolling 4 passes, final pass reduction 3.8mm, rolling speed 3.5m / s. The detailed rolling procedure is shown in Table 2:

[0026] Table 2: 170mmQ345B rolling schedule

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com