Low temperature large wall thickness x80hd large deformation pipeline steel and its production method

A production method and pipeline steel technology, which is applied in the production of low-temperature large-wall thickness X80HD large-deformation pipeline steel and the production of pipeline steel plate and longitudinal welded pipe, which can solve the problems of no design specification and different performance requirements of steel pipes, etc. , to achieve uniform deformation, high uniform elongation, and economical production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

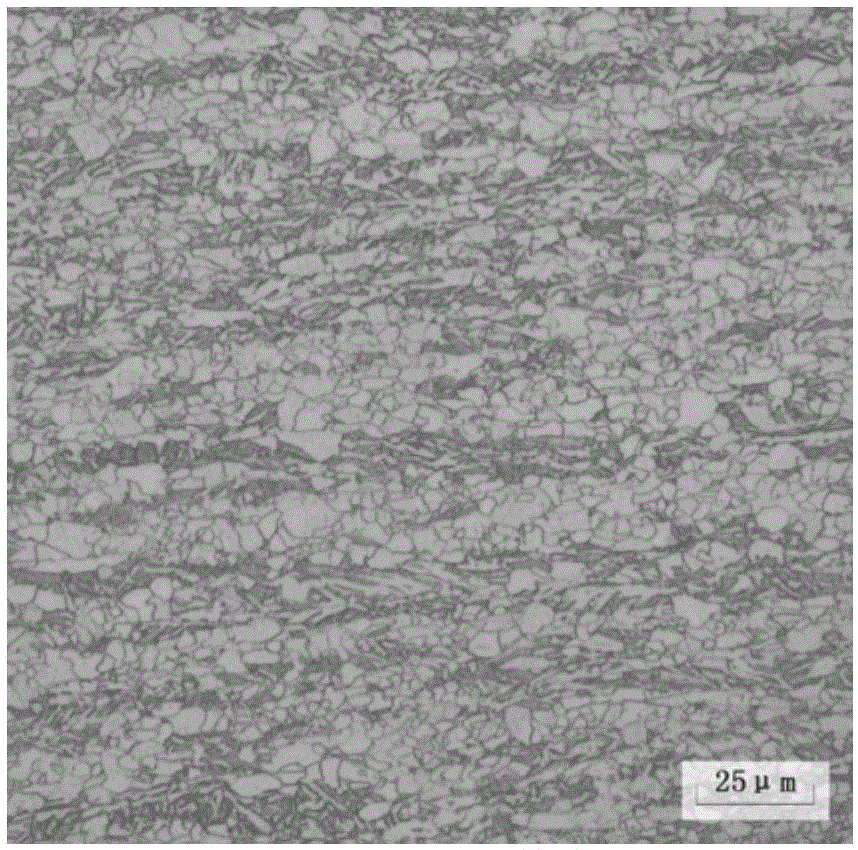

Embodiment 1

[0037] The thickness of the steel plate is 26.4mm, the width of the steel plate is 3740, the corresponding steel pipe specification is Φ1219*26.4mm, the thickness of the continuous casting billet is 400mm, and the casting speed is 0.80m / min. , and its chemical composition is shown in Table 1. The heating temperature of the slab is 1160°C, and the heating time is 390min; the starting temperature of the rough rolling stage is 1035°C, and the final rolling temperature is 990°C; The secondary reduction rate is 18%-22%; the starting rolling temperature in the finish rolling stage is 835°C, the final rolling temperature is 786°C, and the total reduction rate of the steel plate at this stage is 73.2%; Slowly cool from 786°C to 711°C at a rate of 2°C / s, wait for 66 seconds, and then quickly cool to 360°C at a cooling rate of 21.2°C / s. The transverse properties of the steel plates are shown in Table 2, and the longitudinal properties of the steel plates are shown in Table 3.

[0038]...

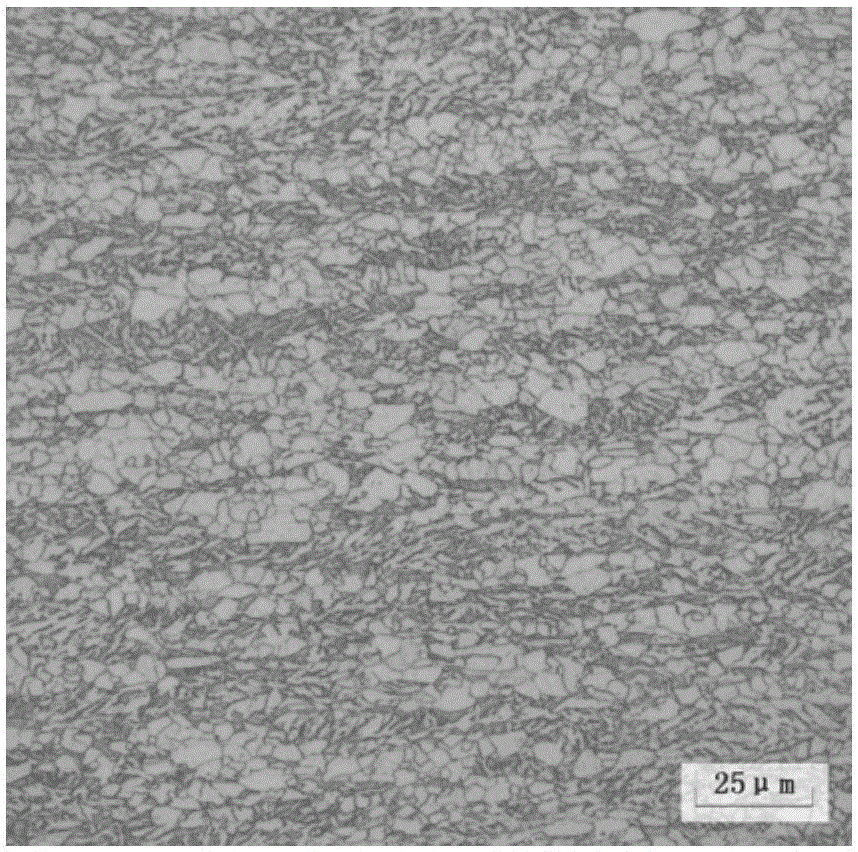

Embodiment 2

[0040] The thickness of the steel plate is 27.5mm, the width of the steel plate is 3740, the corresponding steel pipe specification is Φ1219*27.5mm, the thickness of the continuous casting billet is 400mm, and the casting speed is 0.80m / min. , and its chemical composition is shown in Table 1. The heating temperature of the slab is 1150°C, and the heating time is 430min; the starting temperature of the rough rolling stage is 1020°C, the final rolling temperature is 1000°C, and the total reduction rate of the longitudinal rolling after the rough rolling is 61.4%. The secondary reduction rate is 18%-22%; the starting rolling temperature in the finish rolling stage is 830°C, the final rolling temperature is 798°C, and the total reduction rate of the steel plate at this stage is 67%; Slowly cool from 798°C to 720°C at a speed of 2°C / s, wait for 72s, then rapidly cool to 340°C at a cooling rate of 19.8°C / s. The transverse properties of the steel plates are shown in Table 2, and the...

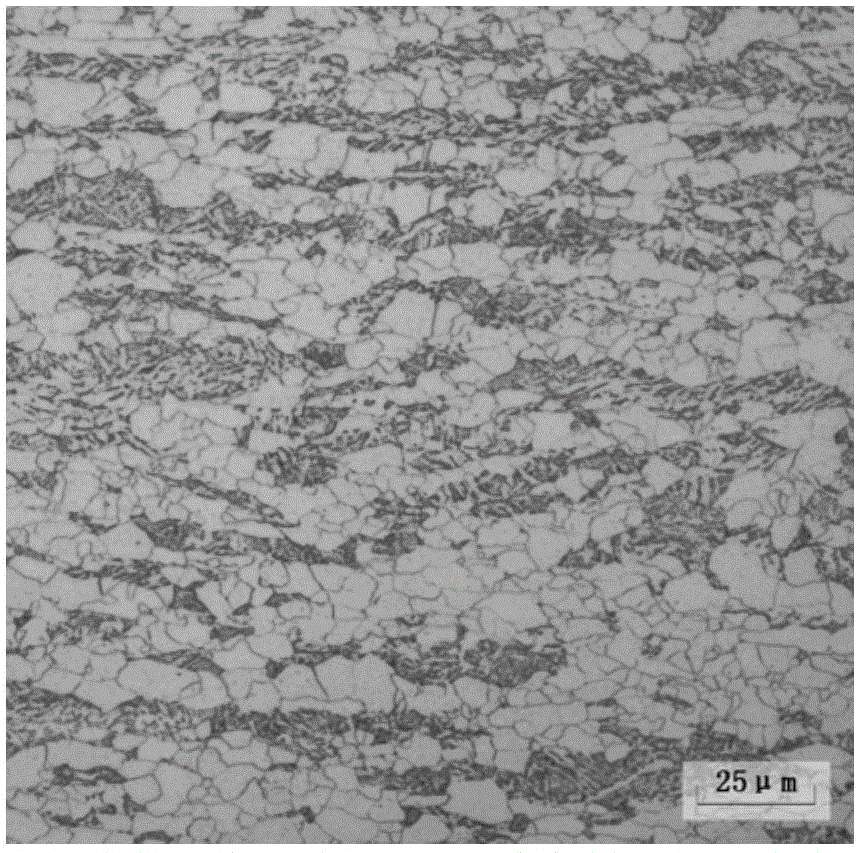

Embodiment 3

[0043] The thickness of the steel plate is 23.7mm, the width of the steel plate is 3745, the corresponding steel pipe specification is Φ1219*23.7mm, the thickness of the continuous casting slab is 350mm, and the casting speed is 0.85m / min. , and its chemical composition is shown in Table 1. The heating temperature of the slab is 1170°C, and the heating time is 340min; the starting temperature of the rough rolling stage is 1030°C, and the final rolling temperature is 1017°C; The secondary reduction rate is 18%-24%; the starting rolling temperature in the finish rolling stage is 840°C, the final rolling temperature is 803°C, and the total reduction rate of the steel plate at this stage is 70%; Slowly cool from 803°C to 733°C at a rate of 2°C / s, wait for 39s, and then quickly cool to 320°C at a cooling rate of 23.7°C / s. The transverse properties of the steel plates are shown in Table 2, and the longitudinal properties of the steel plates are shown in Table 3.

[0044] When the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com