Tungsten (molybdenum) alloy with double-size grains, preparation method of tungsten (molybdenum) alloy and stirring tool for friction stir welding

A dual-size, grain-based technology, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of difficult boron nitride processing, large grain size, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

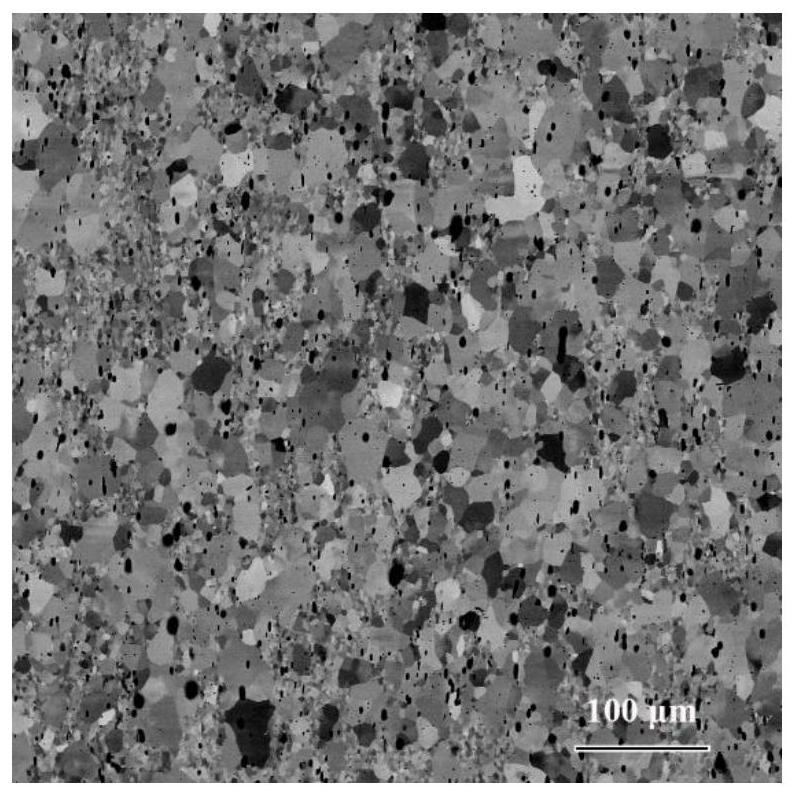

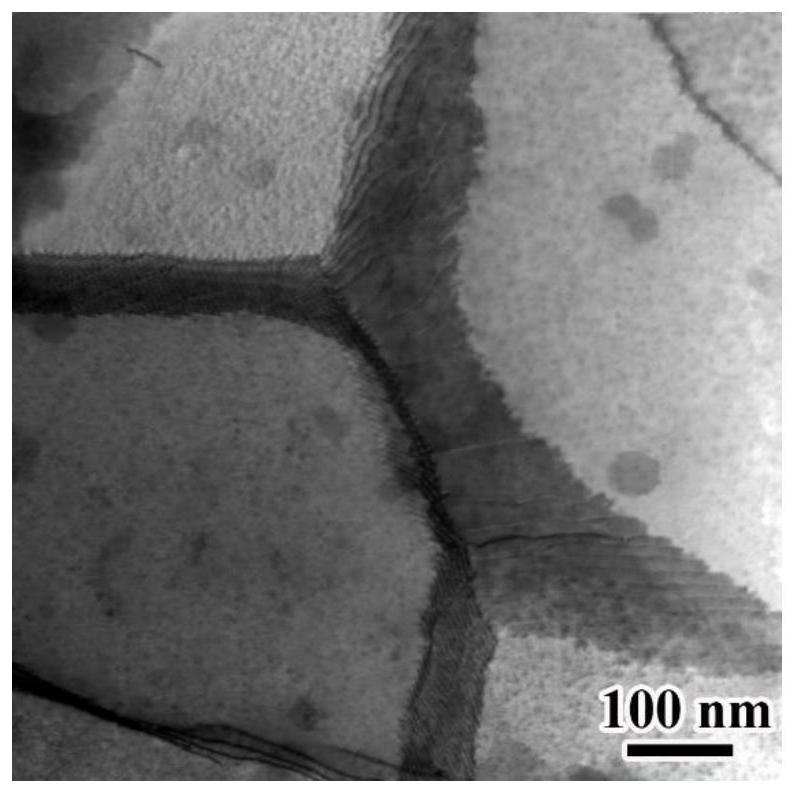

[0042]An embodiment of the present invention provides a tungsten (molybdenum) alloy with double-sized grains. The tungsten (molybdenum) alloy with double-sized grains is a solid solution prepared by tungsten (molybdenum) rhenium alloy powder, titanium powder and carbon powder. Alloys prepared. And specifically, the preparation method for preparing the tungsten (molybdenum) alloy with double-sized grains includes: performing high-energy ball milling on a mixture of tungsten (molybdenum) rhenium alloy powder, titanium powder and carbon powder to obtain solid solution powder; The molten powder is sequentially subjected to cold isostatic pressing, hot isostatic pressing sintering, forging and annealing to obtain a tungsten (molybdenum) alloy with double-sized grains.

[0043] In detail, from the point of view of material design, the raw materials for the preparation of the double-sized grain tungsten (molybdenum) alloy are tungsten (molybdenum) rhenium alloy powder, titanium powde...

Embodiment 1

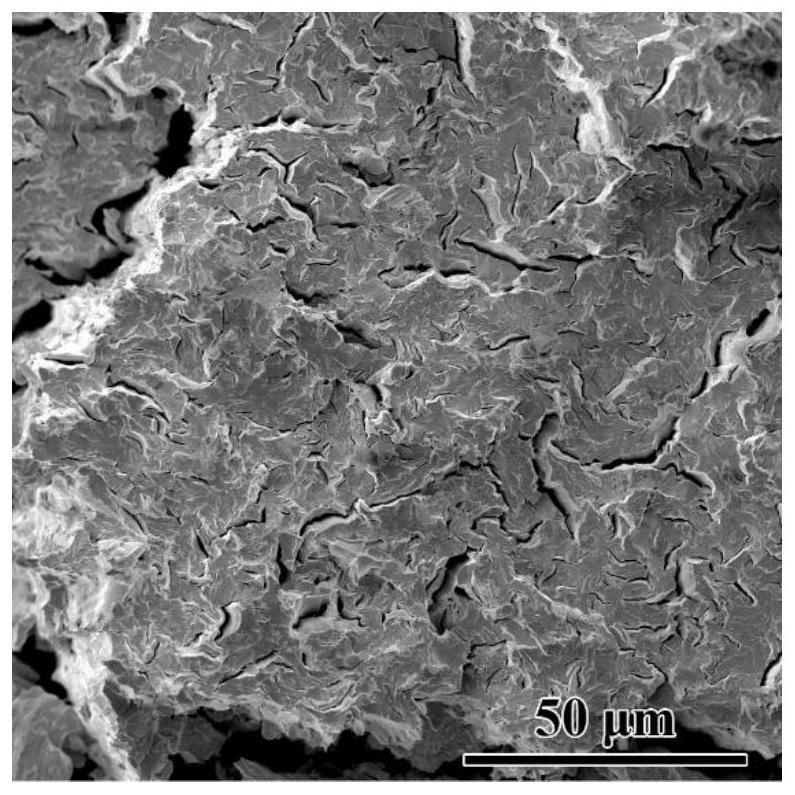

[0058] This embodiment provides a stirring tool for friction stir welding, which is prepared by a tungsten alloy with double-sized grains, and the tungsten alloy with double-sized grains is prepared by the following method:

[0059] S1: Under the protection of high-purity argon, the mixture of tungsten-rhenium alloy powder, titanium powder and carbon powder is subjected to high-energy ball milling to obtain solid solution powder. The time is 5h; wherein, the particle size of the tungsten-rhenium alloy powder is 3μm; the titanium powder is nano-titanium powder, the average grain size is 40μm, and the particle size is 50nm, and the amount of titanium powder is 0.3% of the total mass of solid solution powder. %; the amount of carbon powder is 0.005% of the total mass of the solid solution powder; and in the tungsten-rhenium alloy powder, the tungsten element accounts for 80%, and the rhenium element accounts for 20%;

[0060] S2: Carry out cold isostatic pressing operation, where...

Embodiment 2

[0065] This embodiment provides a stirring tool for friction stir welding, which is prepared by a molybdenum alloy with double-sized grains, and the molybdenum alloy with double-sized grains is prepared by the following method:

[0066] S1: Under the protection of high-purity argon, the mixture of molybdenum-rhenium alloy powder, titanium powder and carbon powder is subjected to high-energy ball milling to obtain solid solution powder. The time is 10h; among them, the particle size of the molybdenum-rhenium alloy powder is 10μm; the titanium powder is TiH 2 Powder, the average grain size is 40-60μm, the particle size is 30-45μm, the amount of titanium powder is 1% of the total mass of the solid solution powder; the carbon powder is nano-carbon powder, the particle size is 50nm, the carbon powder The dosage is 0.1% of the total mass of the solid solution powder; in the molybdenum-rhenium alloy, the molybdenum element accounts for 90%, and the rhenium element accounts for 10%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com