Optical fibre-LED coaxial connector

A coaxial connector, LED base technology, applied in the direction of semiconductor devices, instruments, optics, etc. of light-emitting elements, can solve the problems of inconvenient assembly and disassembly, waste of light, not reflecting the huge advantages of coupling between LEDs and optical fibers, etc. size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

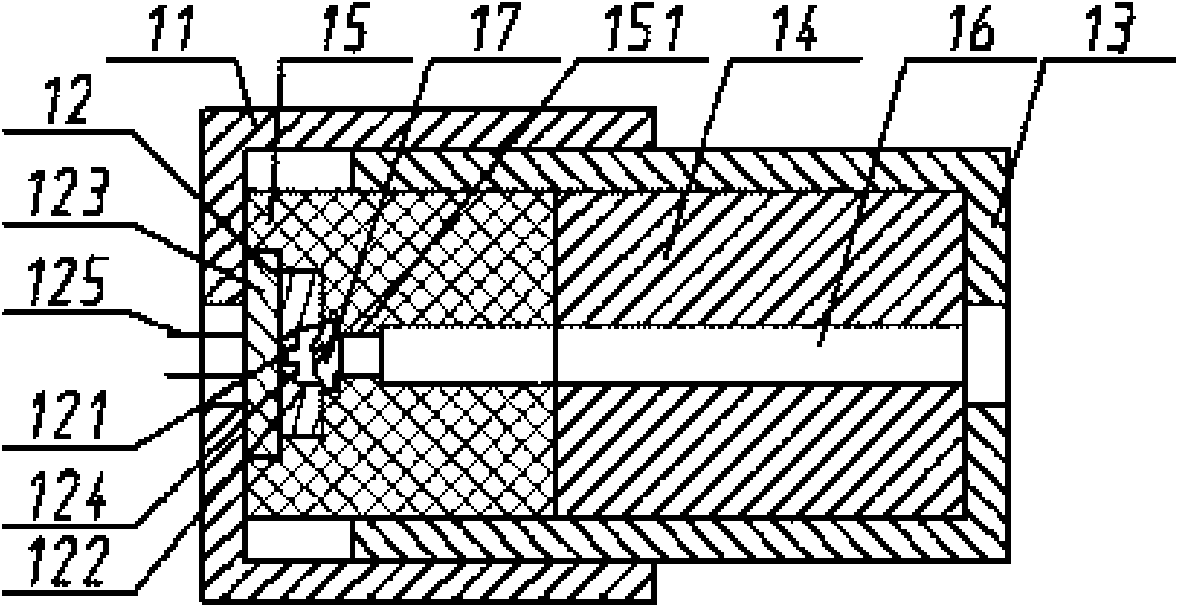

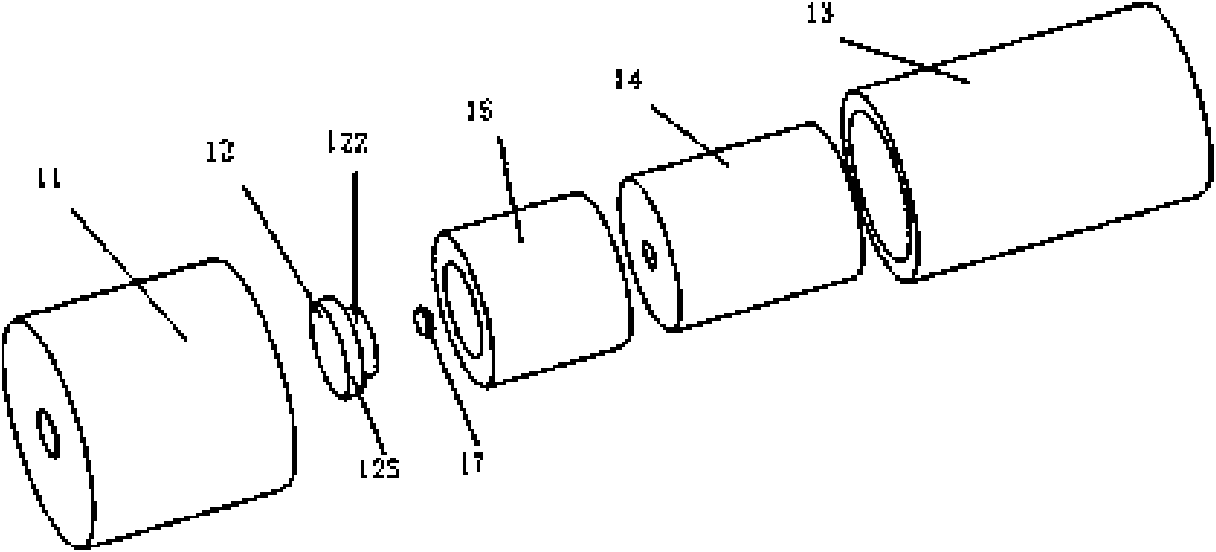

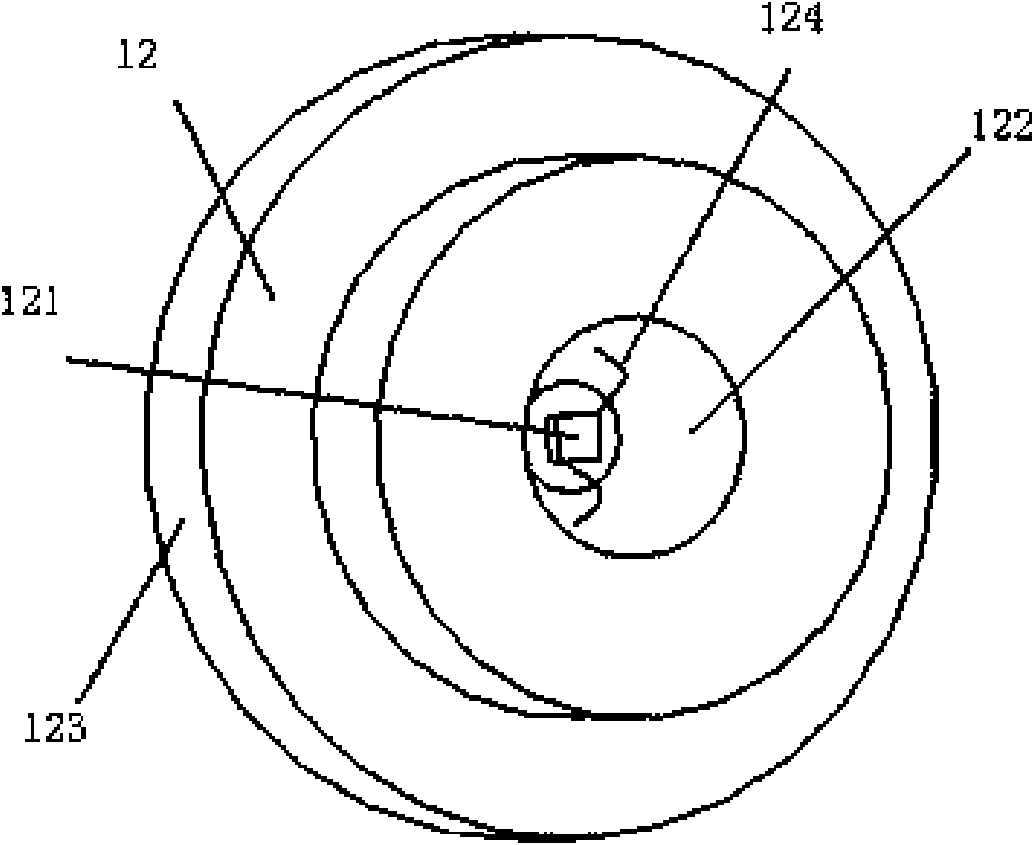

[0039] Such as figure 1 , 2 As shown, the present invention proposes a self-aligning optical fiber-LED coaxial connector, including a front outer sleeve 11 and a rear outer sleeve 13, and an LED base 12 placed in the front outer sleeve 11 and placed The fiber holder and the condenser lens 17 in the outer sleeve 13 at the rear end. The fiber holder consists of a centering ring 15 and a clamping ring 14 . The front end outer sleeve 11 and the rear end outer sleeve 13 are connected by threads.

[0040] The assembly of the present invention adopts an in-line structure, such as figure 2 and refer to image 3 As shown, the assembly can be subdivided into four steps. In the first step, you only need to insert the optical fiber into the rear outer sleeve 13, the clamping ring 14, and the centering ring 15 in sequence; The bit ring 151 contacts; the third step puts the packaged LED base 12, including the LED chip 121, the reflective bowl 122, the radiator 123, the chip lead 124 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com