A flip-chip white light LED device and manufacturing method thereof

A technology of LED devices and manufacturing methods, which is applied to semiconductor devices, electrical components, circuits, etc., and can solve the problems of reliability, manufacturing cost and price of light emitting effects, high temperature resistance, air tightness defects, and easy coating of fluorescent materials. Uniformity and other issues, to achieve the effects of large-scale integrated packaging, good light output, and saving powder and glue consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

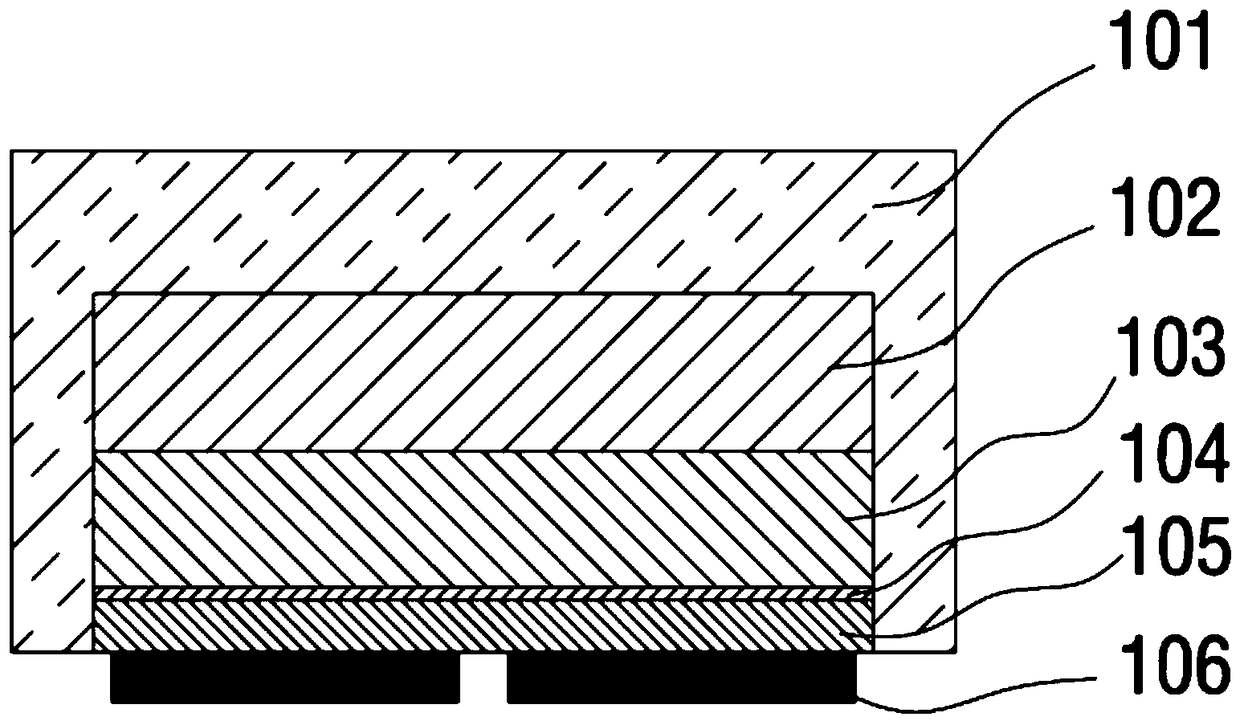

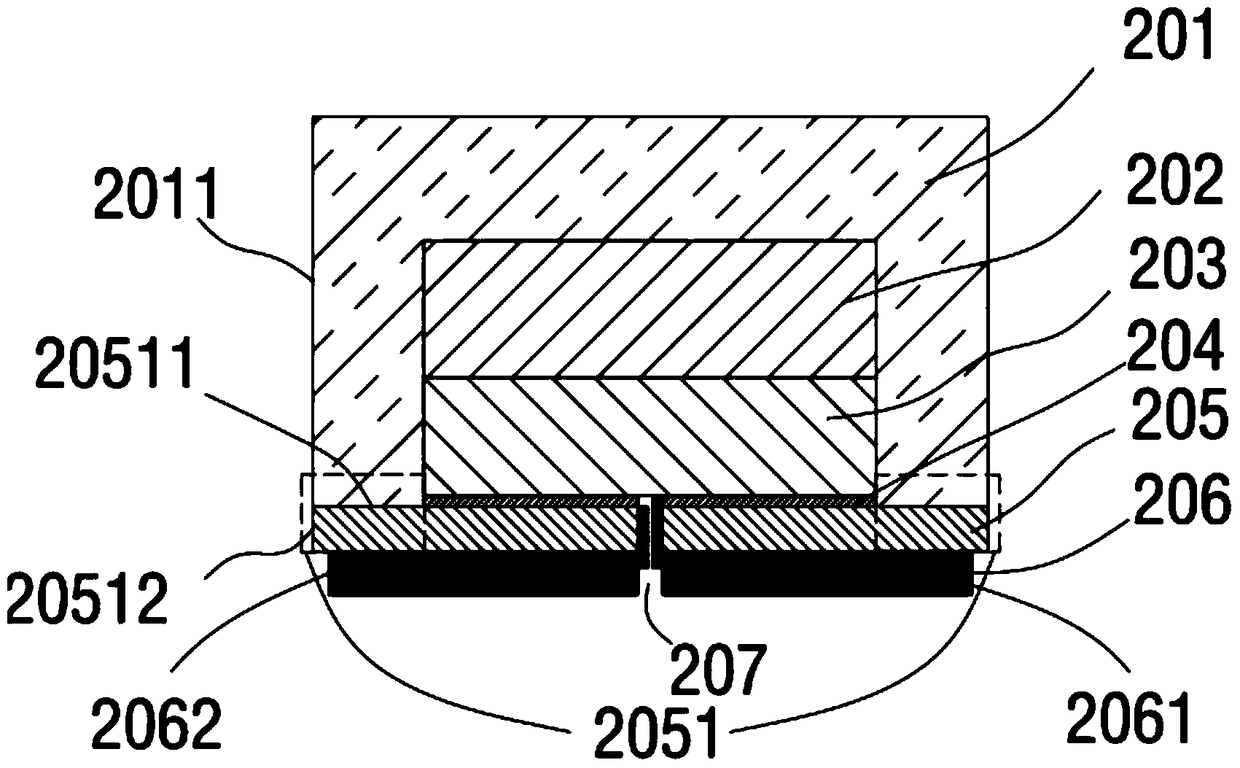

[0054] Such as figure 2 , Figure 3a As shown, this embodiment provides a flip-chip white LED device, the white LED device includes a wavelength conversion layer 201 and a light emitting unit 208, the light emitting unit 208 includes an epitaxial layer substrate 202, which is sequentially stacked and grown on the epitaxial layer substrate 202 The first semiconductor layer 203 , the active layer 204 , the second semiconductor layer 205 and the conventional electrode metal layer 206 , that is, the light emitting unit 208 have a flip-chip structure.

[0055] In particular, the second semiconductor layer 205 extends outward to form a protruding portion 2051 , so that the light emitting unit 208 has an inverted T structure.

[0056] In particular, the wavelength conversion layer 201 completely covers the epitaxial layer substrate 202, the first semiconductor layer 203, the active layer 204, up to the upper surface 20511 of the protrusion, and the wavelength conversion layer 201 d...

Embodiment 2

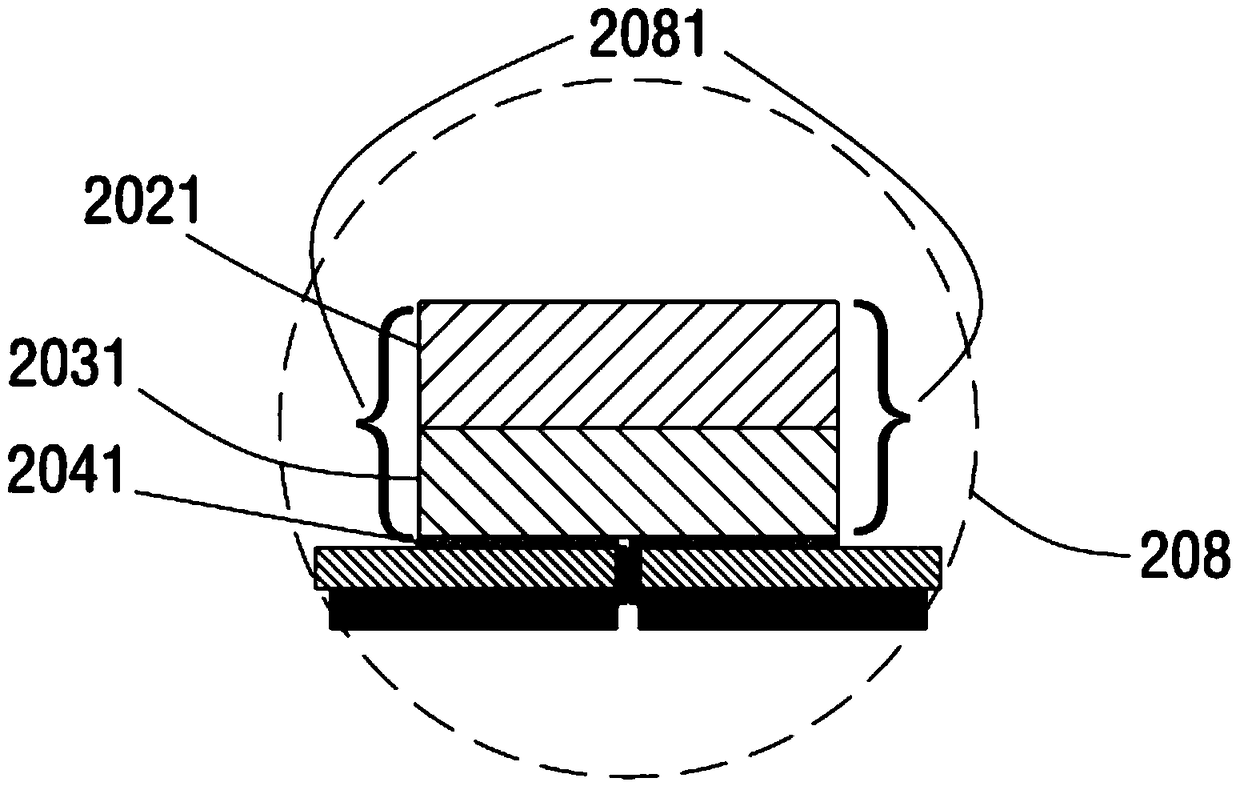

[0078] 1. A flip-chip white light LED device provided in this embodiment, such as Figure 4 As shown, the structural differences from Embodiment 1 are only: the third sidewall boundary 2021 on the epitaxial layer substrate 202, the fourth sidewall boundary 2031 on the first semiconductor layer 203, and the first sidewall boundary 2031 on the active layer 204. The sixth sidewall boundary 2081 formed by the five sidewall boundaries 2041 is inclined, so that the overall appearance of the light emitting unit 208 is trapezoidal.

[0079] Since the second side wall boundary 20512 of the protrusion 2051 is not covered by the wavelength conversion layer 201, there is a certain risk of blue light leakage. When the sixth side wall boundary 2081 is inclined, when the light with the first wavelength is reflected by the reflective layer and passes through the wavelength conversion layer 201, the probability of the light with the first wavelength passing through the side wall 20512 of the p...

Embodiment 3

[0084]1. A flip-chip white light LED device provided in this embodiment, such as Figure 5 As shown, the structural difference from Embodiment 2 is only that: the white LED device further includes a transparent adhesive layer 401 covering the wavelength conversion layer 201 .

[0085] Same as Embodiment 2, the sixth side wall boundary 2081 in this embodiment is also inclined, with an inclination angle 402 .

[0086] Wherein, the thickness of the wavelength conversion layer 201 ranges from 5 to 15 microns, so that the thickness of the wavelength conversion layer 201 is in a thinner and better range, so as to ensure that the white light LED device has better light color uniformity. However, the thickness of the wavelength conversion layer 201 is not limited to this thickness range, and the specific thickness is determined according to the needs of actual products.

[0087] 2. The manufacturing method of the flip-chip white LED device provided in this embodiment differs from Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com