Lower shaft driving mechanism of sewing machine

A technology of sewing machine and shaft drive, applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

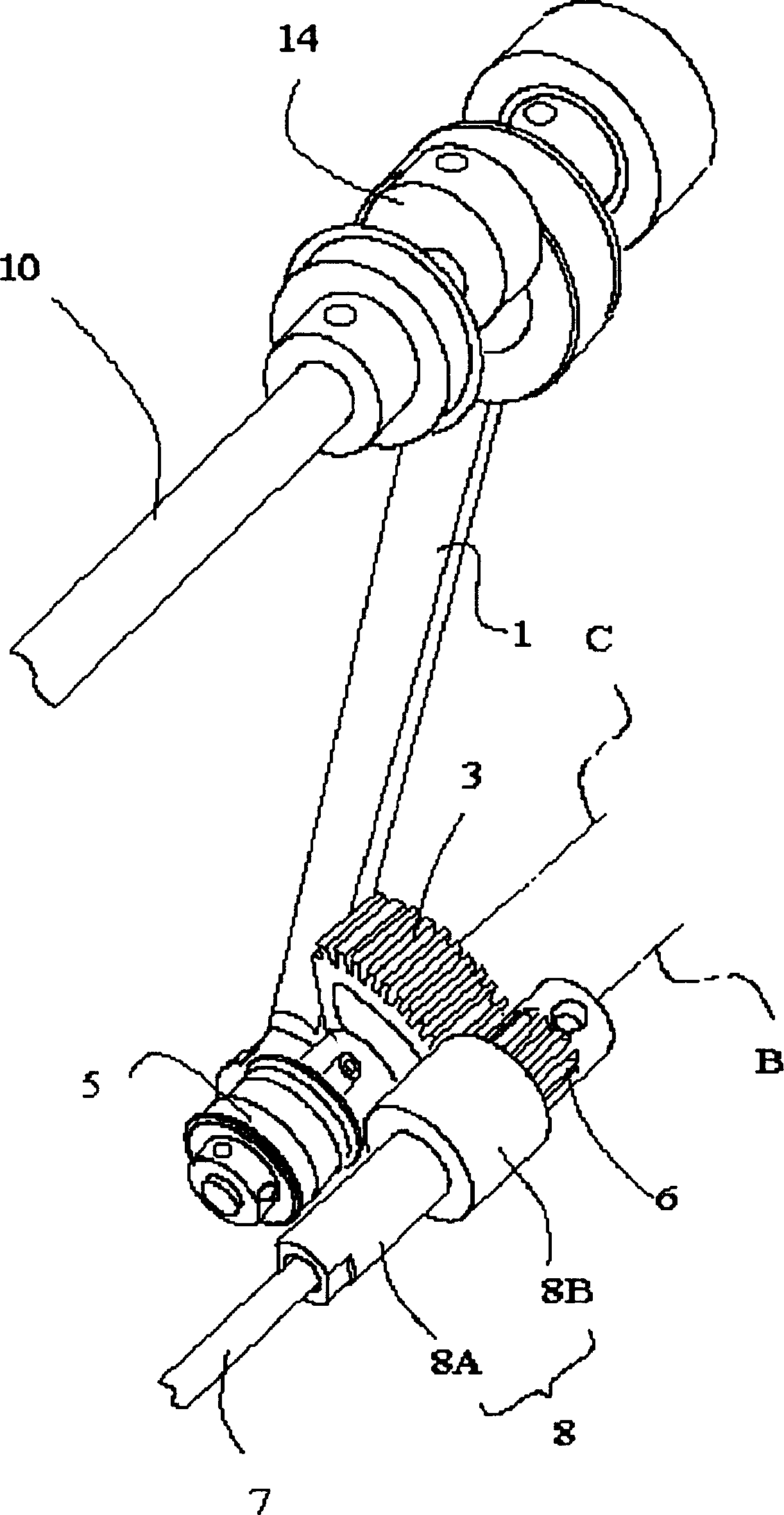

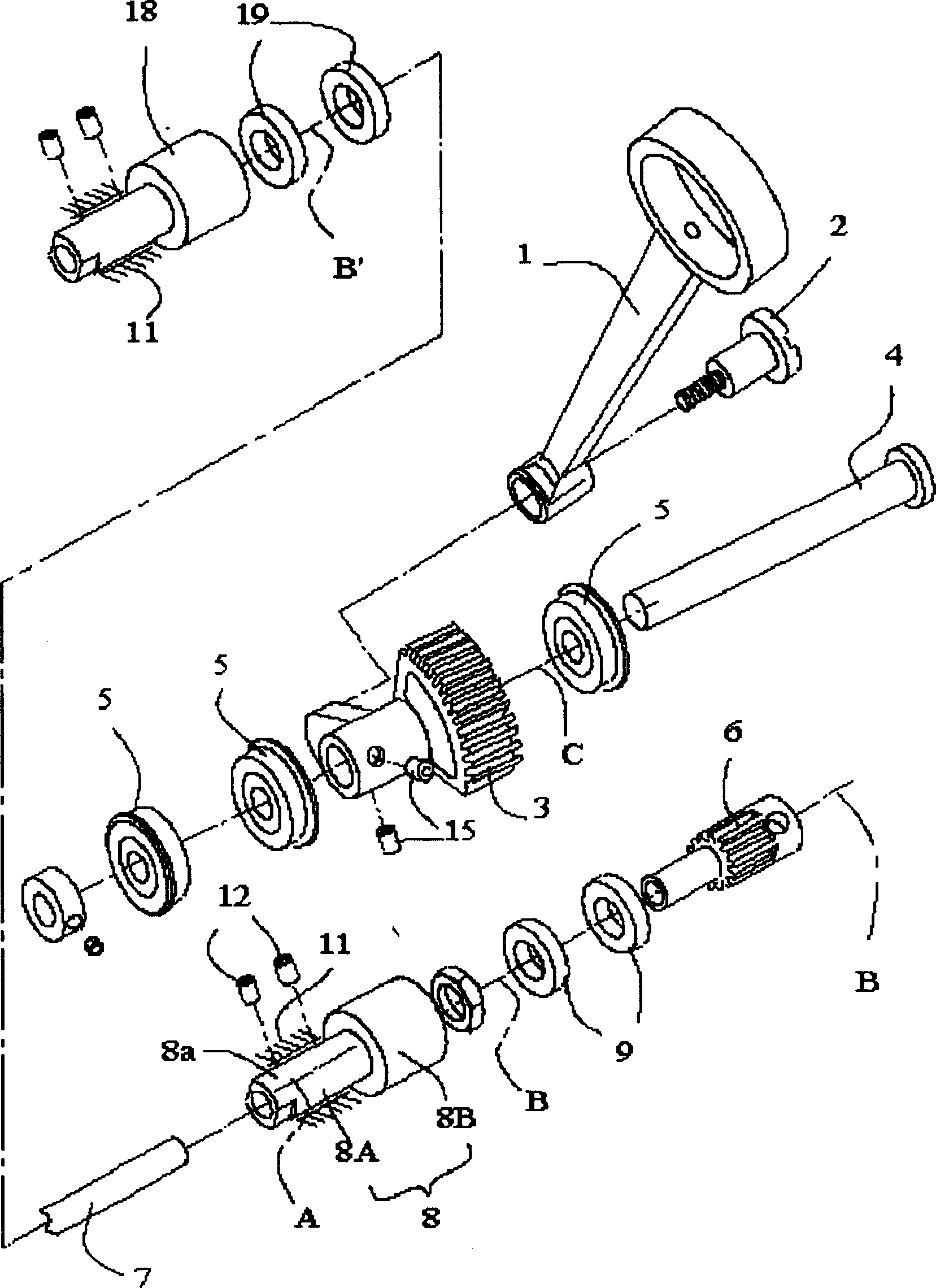

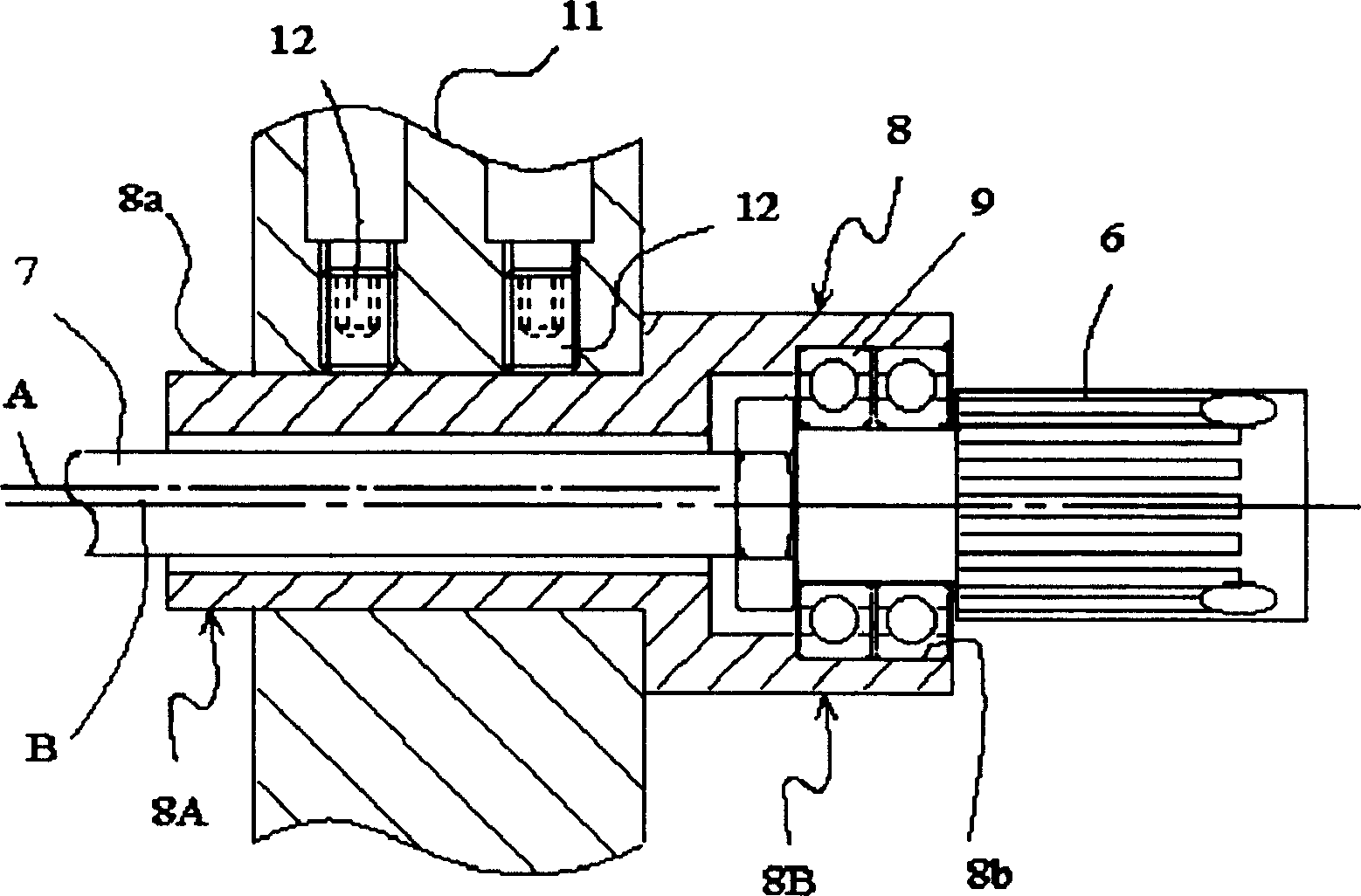

[0025] Below, refer to figure 1 — Figure 4 Specific examples of the present invention will be described. According to the lower shaft driving mechanism of the sewing machine of the present embodiment, there are crank rod (conversion mechanism) 1, large swing pin 2, large swing gear 3, large swing shaft 4, large swing bearing 5, lower shaft gear 6, lower shaft 7, Lower shaft sleeve 8, lower shaft bearing 9 and upper shaft 10 etc. This sewing machine is a semi-rotary rotary hook sewing machine, and its lower shaft 7 does not rotate in a full circle, but swings and rotates in a range of more than 200 degrees, for example, 220 degrees.

[0026] The upper end of the crank rod 1 is connected to the upper shaft 10 through the eccentric cam 14 , and the lower end is swingably connected to the large swing gear 3 through the large swing pin 2 . The large swing gear 3 is fixed on the large swing shaft 4 with fastening screws 15, and the two ends of the large swing shaft 4 are swinga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com