Pollution-free lubrication system of sewing machine

A lubrication system and pollution-free technology, which is applied in the direction of sewing machine components, sewing equipment, lubrication/cooling devices, etc., can solve the problems of cloth and sewing thread pollution, poor lubrication effect, etc., and achieve the effect of preventing pollution and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

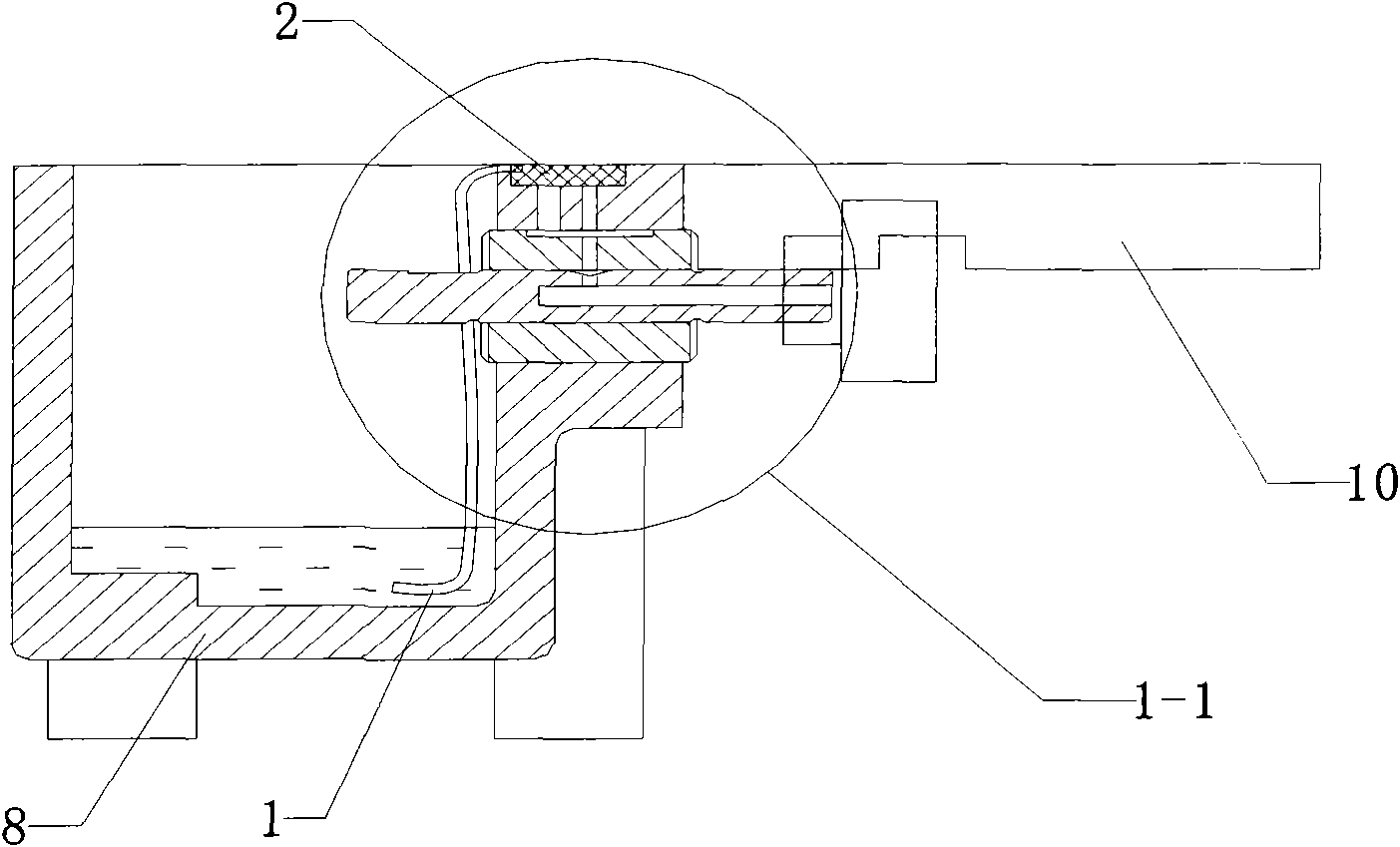

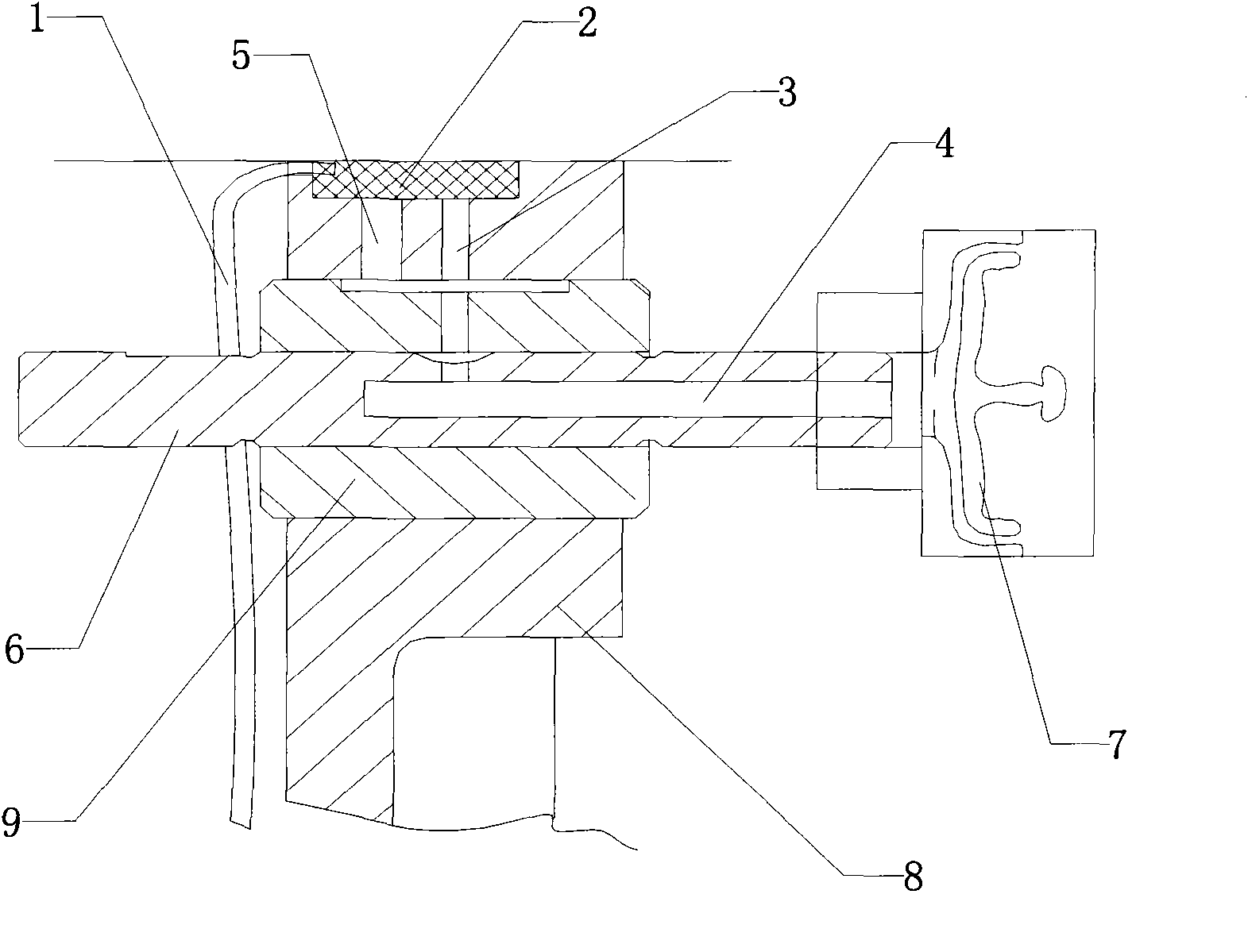

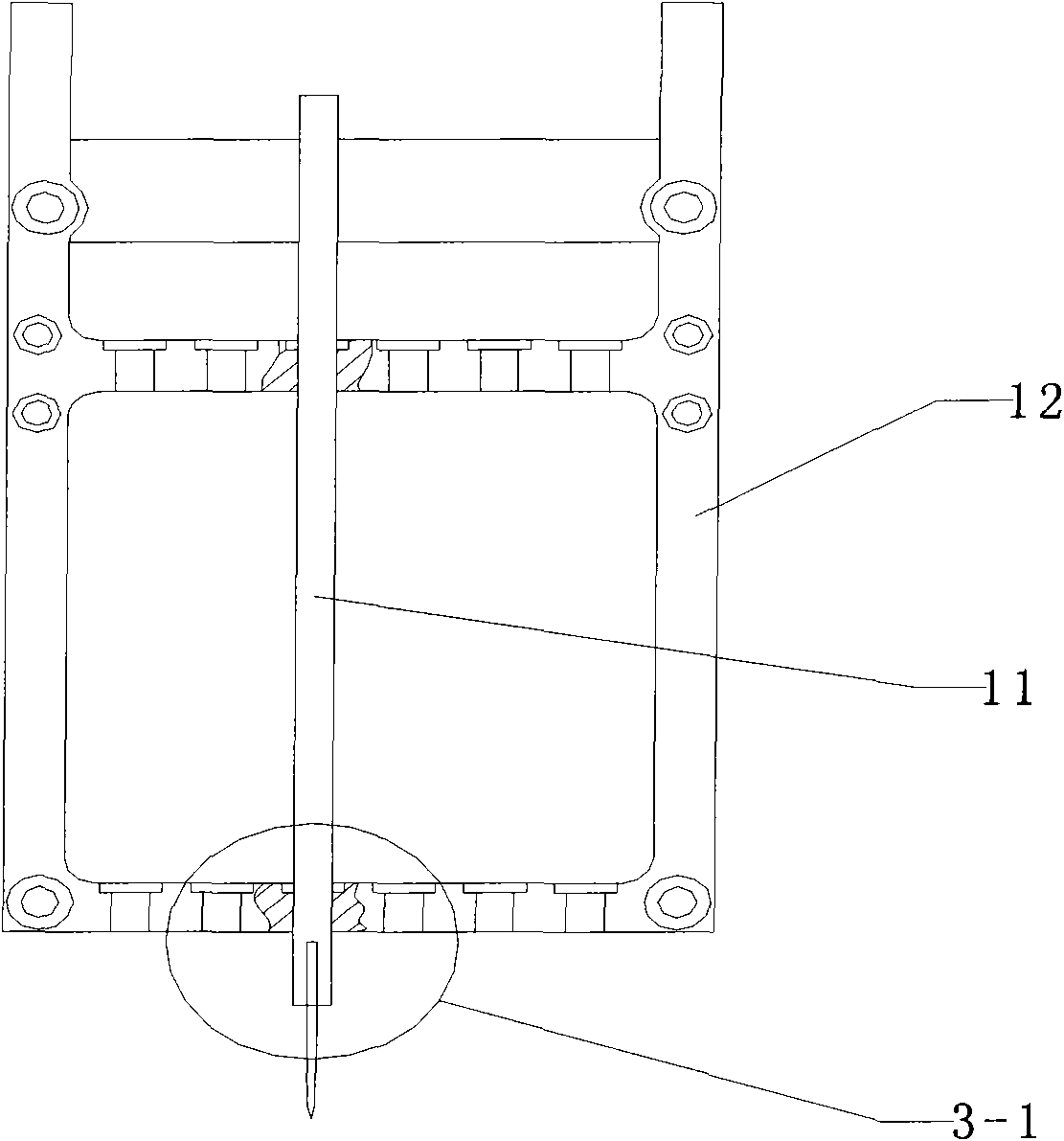

[0015] The pollution-free lubricating system of the sewing machine described in the embodiment of the present invention includes a rotary hook part and a needle bar part, such as Figure 1-2 As shown, the rotary hook part includes oil suction line 1, oil storage felt 2, hollow rotary hook shaft 6, high-speed rotary hook mechanism 7, the outer side of the hollow rotary hook shaft 6 is provided with a rotary hook cover 9, and the hollow rotary hook shaft 6 The inner cavity of the inner cavity is provided with an oil-gas mixture through hole 4, and the top of the upper oil tank body 8 of the rotary hook cover 9 is provided with an oil storage felt 2, and the bottom side of the oil storage felt 2 is provided with two through holes for the oil hole 5 to communicate with the oil-gas mixture. The ports of hole 4 and oil hole 5 communicate with the middle part of compressed air hole 3, and the bottom end of compressed air hole 3 communicates with the inside of oil-air mixture through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com