Lubricant composition for sewing machine

A lubricant composition, sewing machine technology, applied in the direction of lubricating composition, sewing machine components, sewing equipment, etc., can solve the problems of not being able to achieve wear resistance, not proposed to use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The present invention will be clearly described below with reference to Examples and Comparative Examples.

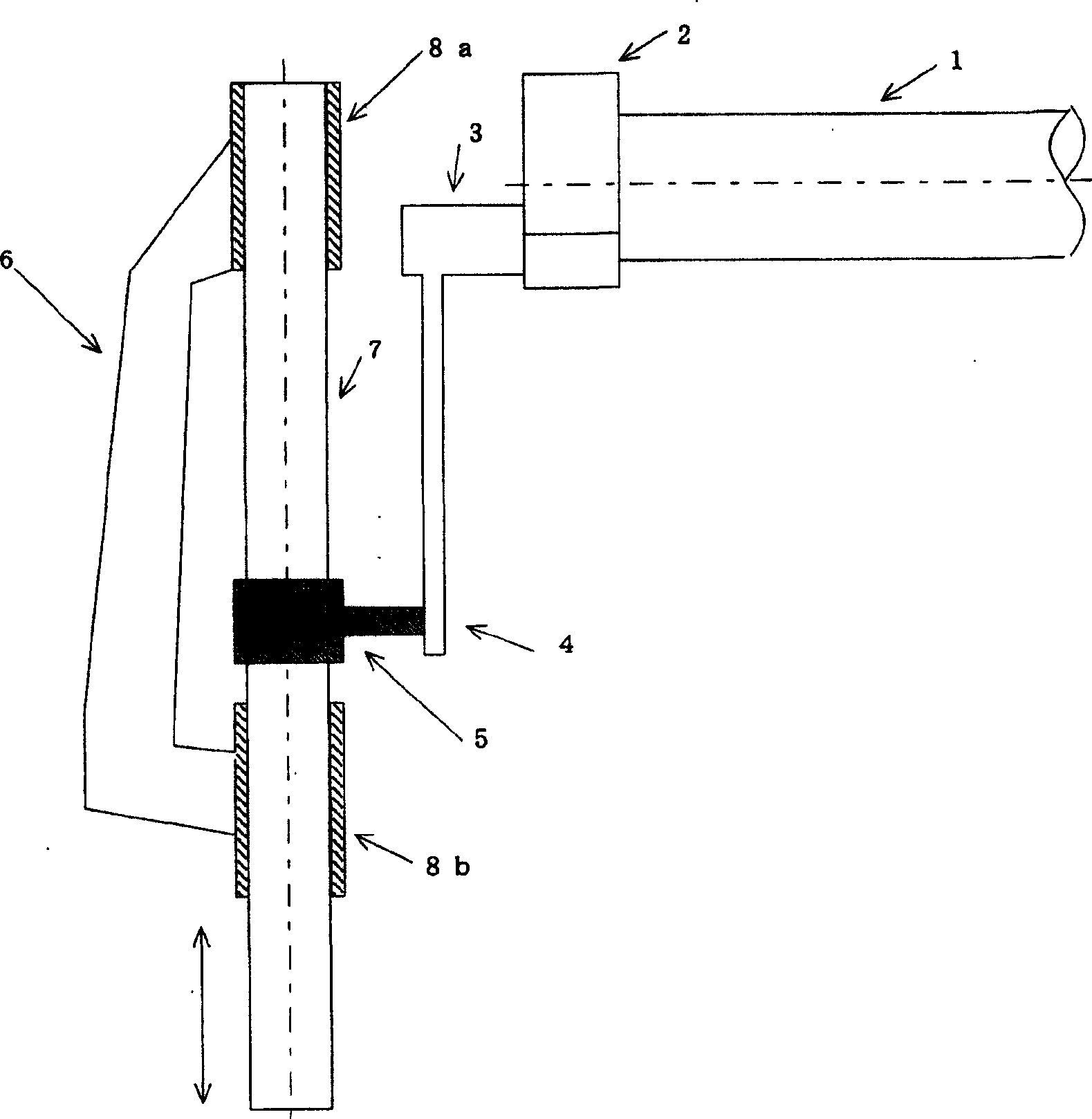

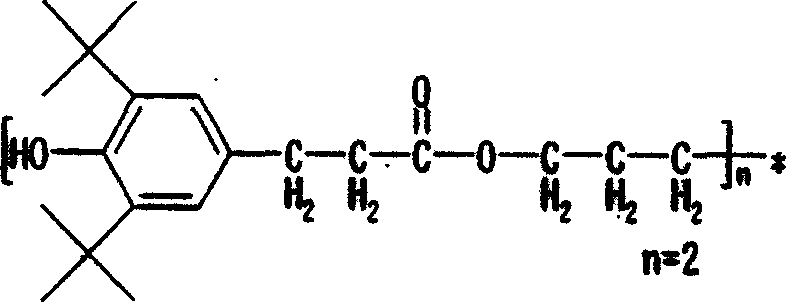

[0048] Using DOS as the base oil, the lubricant compositions for sewing machines shown in Table 1 were prepared. The sewing machine lubricants of Examples 1 to 4 and the lubricants of Comparative Examples 1 to 5 were used with similar figure 1 Structured sewing machine durability tester (spindle speed: 4000rpm, surface pressure: 0.4N / mm 2 , Test time: until the sintering stops), implement the durability test. The amount of lubricant injected into the bearing is about 1 cc, and the test is terminated by controlling the motor current value that rotates the spindle. When an overcurrent exceeding the specified current value occurs, the motor circuit is closed. Also, the injection of the lubricant is only in the initial stage. Table 2 shows the results of the sewing machine durability test. The evaluation criteria (standards of sewing machine manufacturers) for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com