Driving device for cutter of sewing machine

A technology for driving devices and sewing machines, which can be used in the direction of sewing machine control devices, sewing machine components, and mechanisms for cutting threads in sewing machines, and can solve problems such as inability to lubricate, hinder high-speed operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

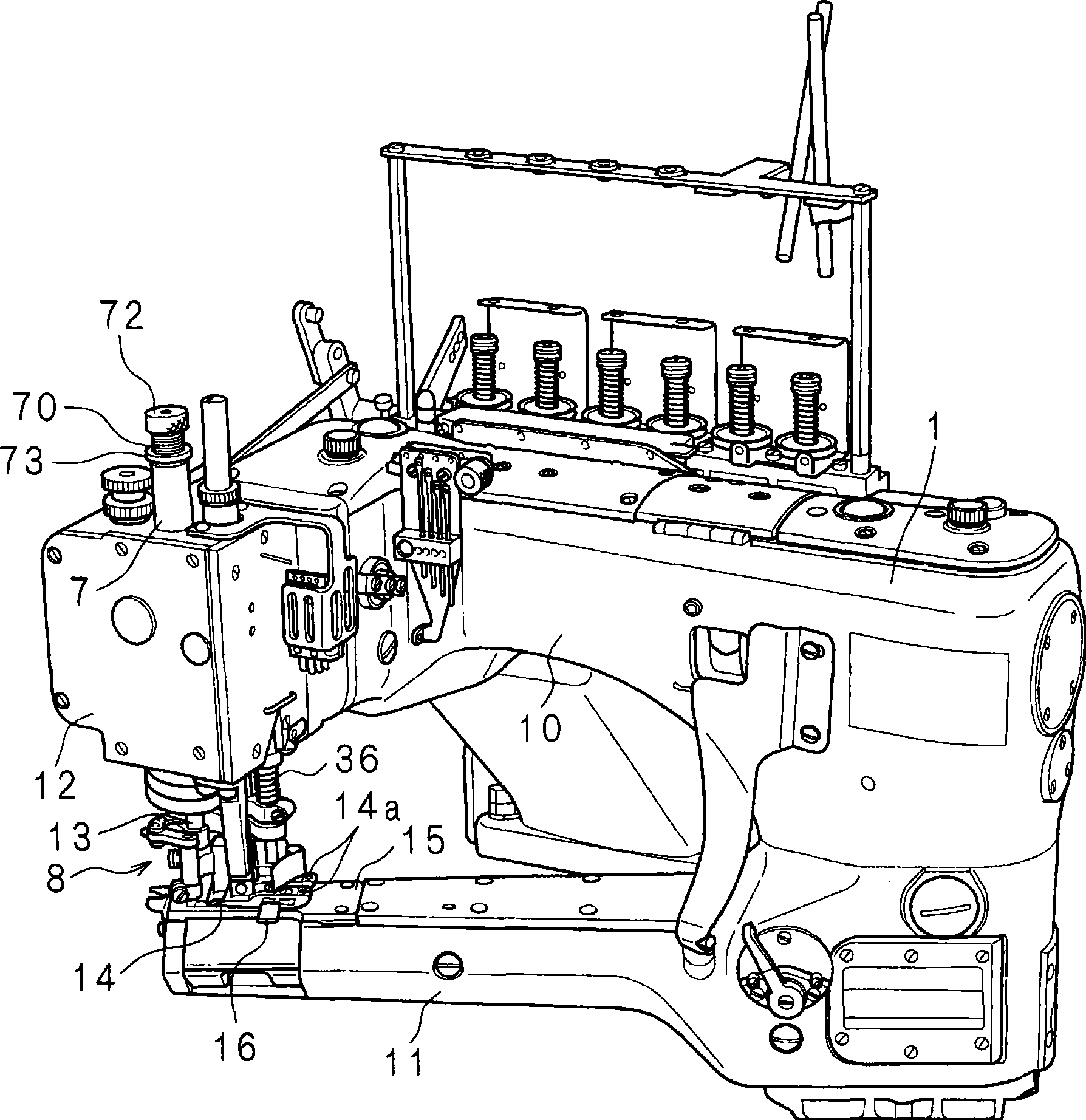

[0023] Hereinafter, the present invention will be described in detail based on the accompanying drawings showing preferred embodiments. figure 1 It is a perspective view showing the overall configuration of a bed lockstitch sewing machine including the knife driving device according to the present invention.

[0024] As shown in the figure, the clamp lockstitch sewing machine includes a sewing machine arm 10 extending in one direction on the upper part of the sewing machine frame 1, and a narrow cylindrical sewing machine table extending in a different direction from the sewing machine arm 10 on the lower part of the sewing machine frame 1 11. The end portion of the sewing machine arm 10 is connected with a hollow rectangular block-shaped head 12 along a direction substantially perpendicular to the sewing machine arm 10 .

[0025] The pressing rod 13 is supported by the head 12 . A presser foot 14 is attached to a lower end portion of a presser bar 13 extending toward an end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com