Oil supplying mechanism for rotating shuttle of sewing machine and sewing machine

A technology for rotary hook oil supply and sewing machines, which is applied to sewing machine components, sewing equipment, textiles and papermaking, etc. It can solve the problems of no sealing structure, slow adjustment speed, and inability to seal the lubricating oil, etc., and achieve simple adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

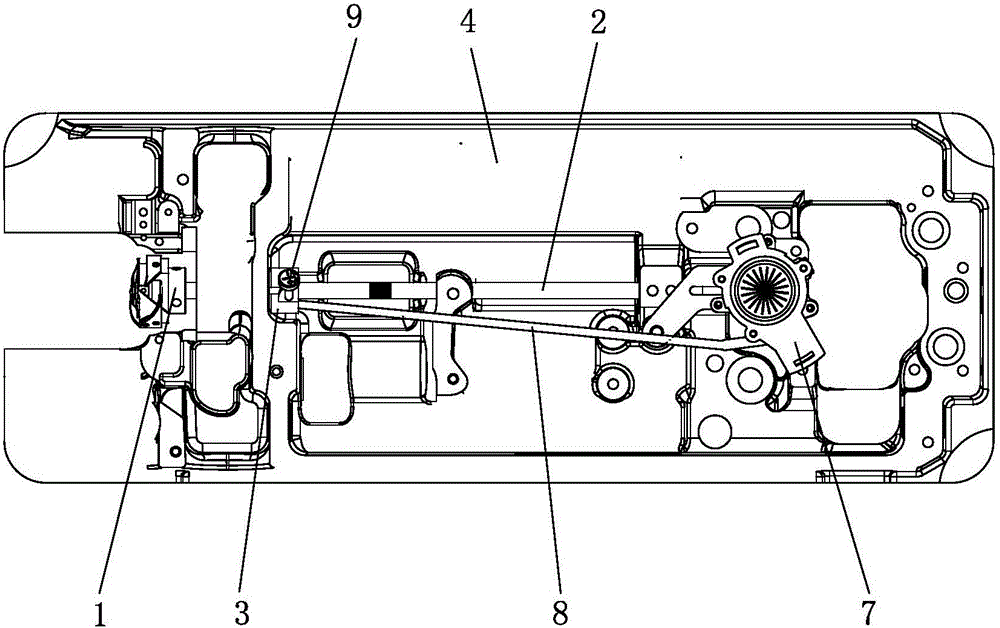

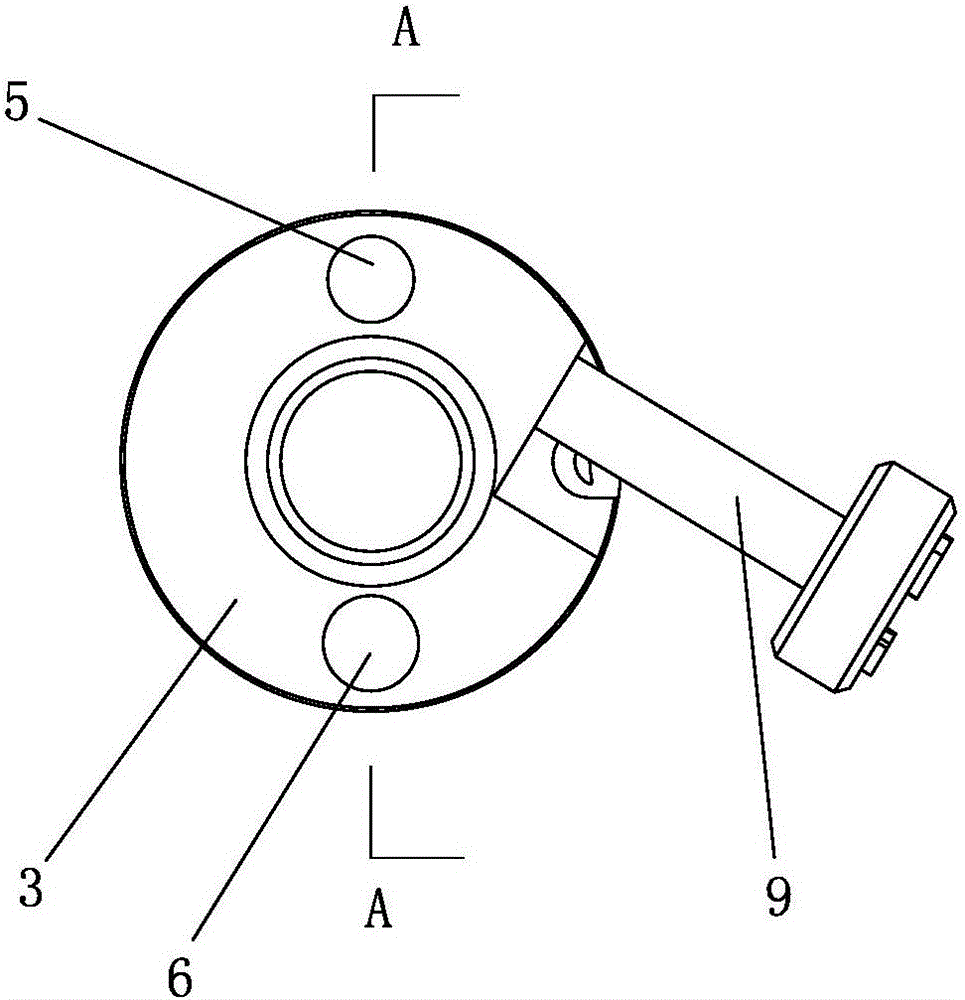

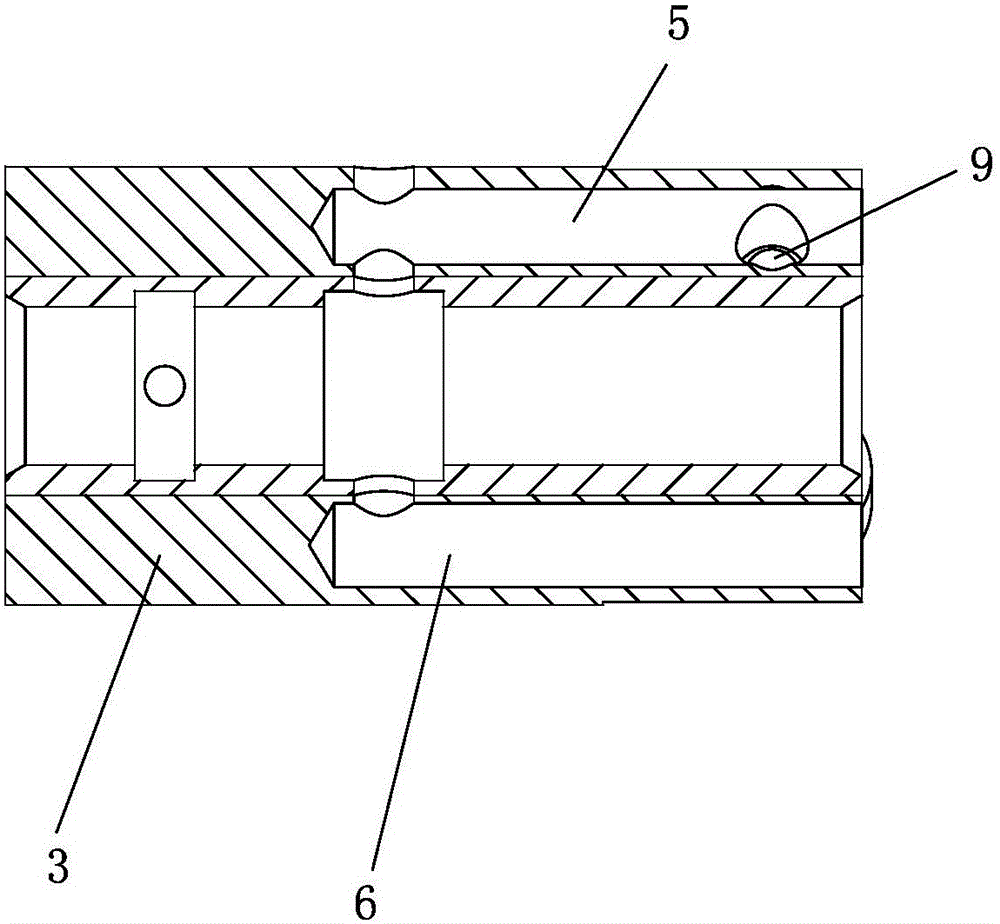

[0030] The present invention will be further described below with specific embodiment, see Figure 4 -8:

[0031] A rotary hook oil supply mechanism of a sewing machine is provided with a rotary hook 11 at one end of a lower shaft 10, a lower shaft front cover 12 is also provided on the lower shaft 10, and a sealing oil seal 13 is provided at both ends of the lower shaft front cover 12, and the lower shaft front cover 12 is provided with a sealing oil seal 13, The shaft front sleeve 12 is also provided with an oil inlet 14 and an oil return hole 15, the oil inlet 14 communicates with the oil return hole 15, the oil inlet 14 is connected with an oil supply pipe 16, and the oil supply pipe 16 is connected with an oil pump 17, The sealing oil seal 13 is used to prevent lubricating oil from leaking outwards from the two ends of the lower shaft front sleeve 12. The oil inlet hole 14 or the oil return hole 15 is connected to the threaded hole 18 of the oil volume adjustment screw, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com