Straight sock looping machine

A technology for sewing head machines and socks, which is applied to sewing machine components, sewing equipment, and knitting machines for connecting knitted fabrics, etc. Oil convenience, reduced maintenance costs, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

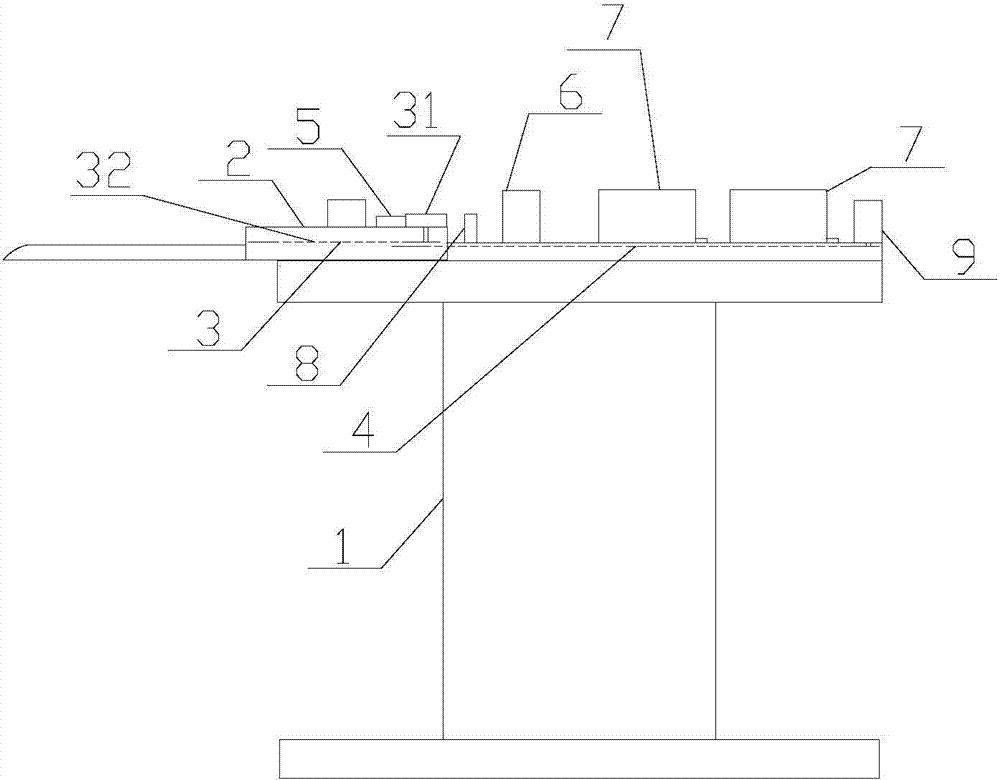

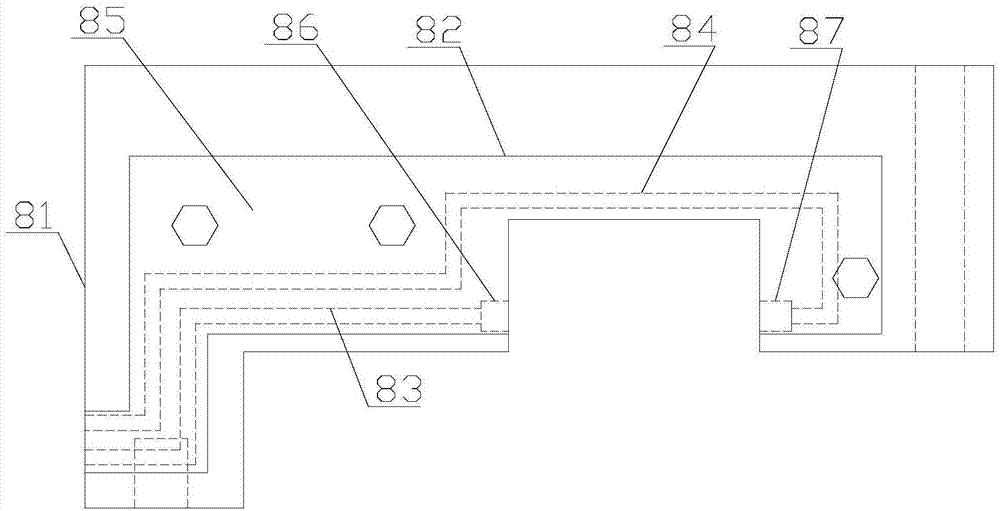

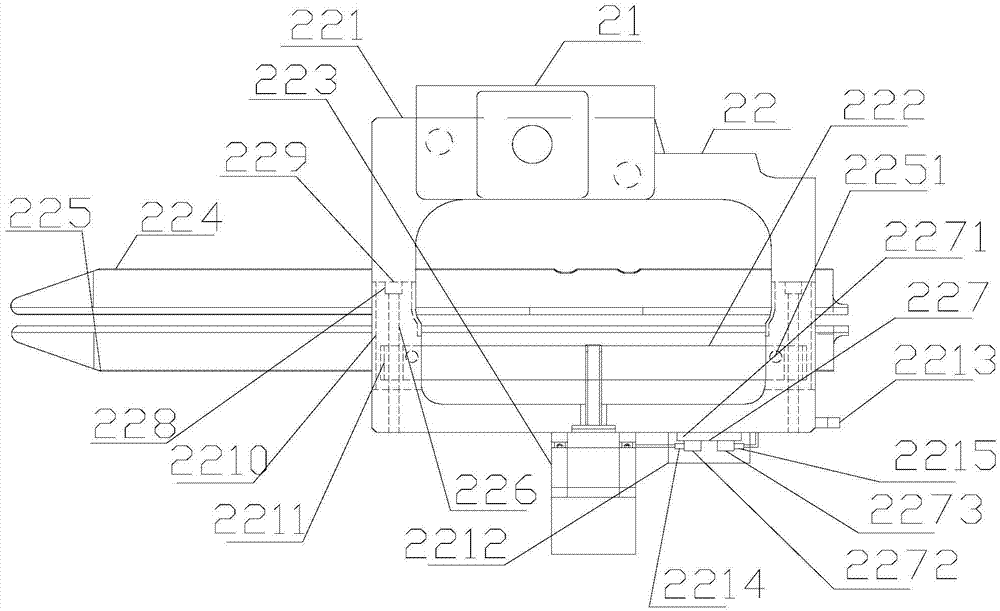

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a straight sock sewing machine of the present invention, comprising a frame 1, a material guide device 2, a conveying chain device 3, a second conveying chain 4, a main motor 5, a cutter 6, an elevator head 7, a horse riding 8 and a second Transmission box 9, the front portion of the platform of the frame 1 is provided with a guide device 2 and a conveyor chain device 3, and the platform of the frame 1 is successively provided with a horse riding 8, a cutter 6, and a lift at the rear of the material guide device 2 Head 7 and the second transmission box 9, the platform of the frame 1 is provided with the second conveying chain 4, and the second conveying chain 4 is positioned at the cutting knife 6, the lifting machine head 7, the riding 8 and the second transmission box 9 Below, the second transmission box 9 is in transmission connection with the second conveying chain 4, and the main motor 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com