Novel sewing machine rotating shuttle structure

A sewing machine, a new type of technology, applied in the direction of the sewing machine ring mechanism, sewing machine components, sewing equipment, etc., can solve the problems of high friction resistance between the shuttle frame guide rail and the shuttle bed, difficulty in controlling the amount of refueling, and affecting the sewing quality, so as to improve work efficiency. The effect of stability, avoiding unsmooth outlet, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

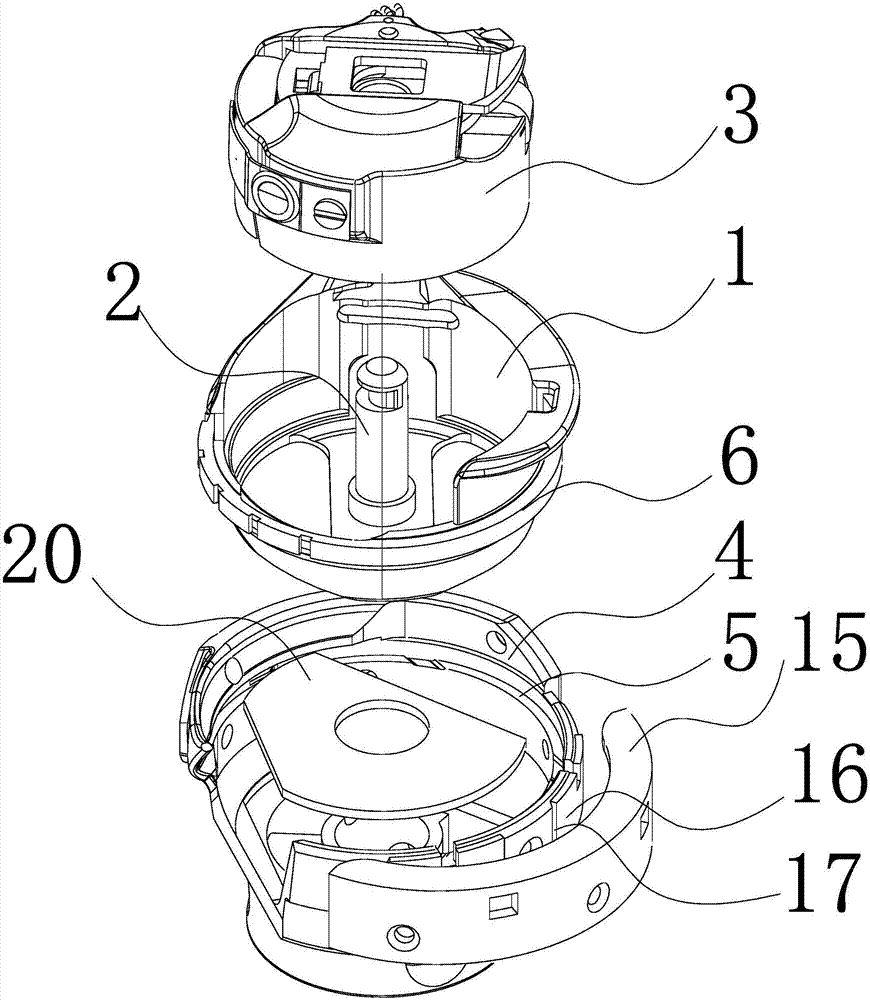

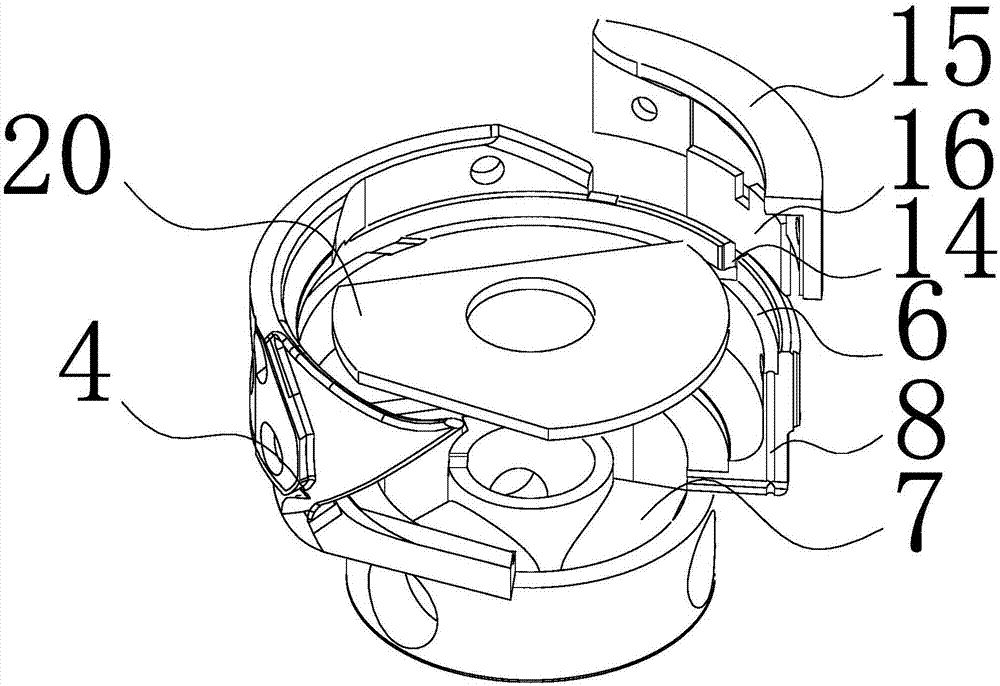

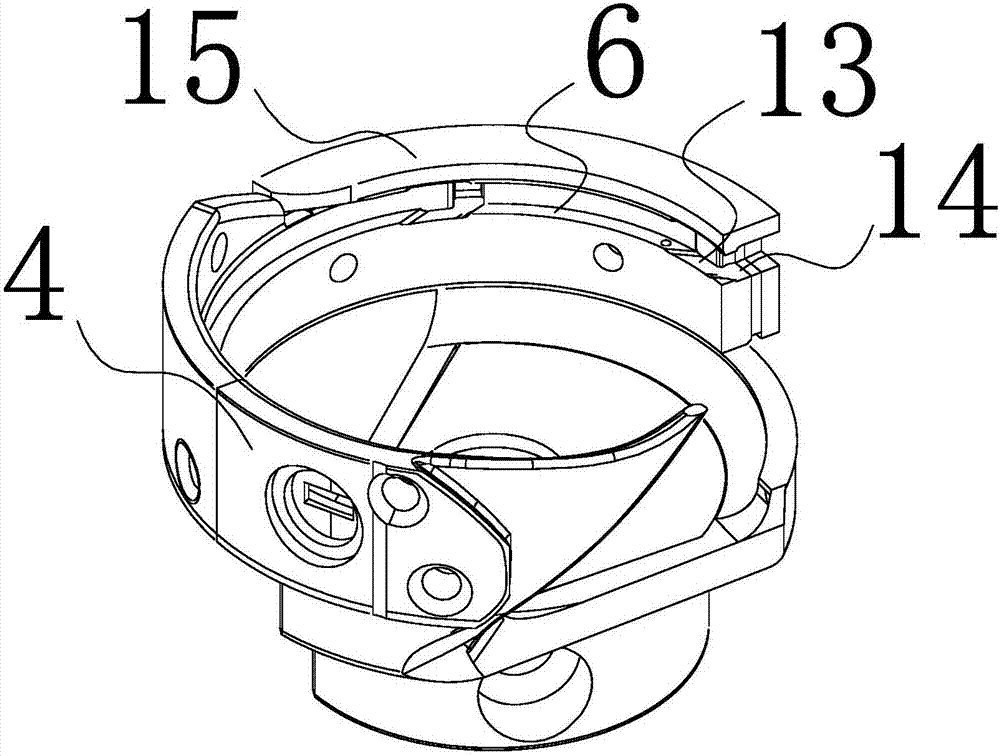

[0028] Such as figure 1 As shown, a novel sewing machine rotary hook structure of the present invention includes a bobbin frame 1 and a button cover fixed on the bobbin case 3 on the bobbin frame core 2 in the upper port of the bobbin frame 1, and the lower end of the bobbin frame 1 is matched with a cover. The shuttle bed 4 that can be rotated relative to the center of the shuttle frame core 2 is adorned, and the shuttle frame core 2 is a circular truncated shape with a small upper part and a larger lower part, such as Image 6 As shown, in the middle part of the bobbin case 3, there is a conical truncated bobbin case positioning hole 18 that matches each other, and the shuttle frame core 2 is inserted and fixed in the bobbin case positioning hole 18, as shown in FIG. figure 2 with image 3 As shown, on the outer ring surface of the shuttle bed 4, a moon ring 15 is interfitted with two left and right fixing screws, and a piece of wool felt 16 is sandwiched between the moon ...

Embodiment 2

[0030] Such as Figure 7 As shown, a passing steel wire 22 is embedded in the passing steel sheet limiting groove 12, the inner end of the passing steel wire 22 is fixed in the passing steel sheet limiting groove 12 by a rivet 23, and the outer end extends to the outside of the gap. All the other parts are identical to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com