Novel barrel type sewing machine

A sewing machine, barrel-type technology, which is applied to sewing machine components, needle holders for sewing machines, and bobbin winding in sewing machines, etc., can solve problems such as affecting product quality, increasing production costs, and unstable upper thread tension, and ensuring normal stability. It can run smoothly, prolong the service life, and ensure the effect of full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

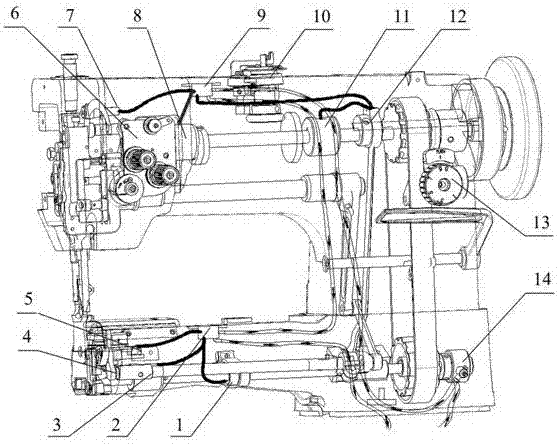

[0028] Refer to Figure 1 to Figure 8 , A new type of cylinder sewing machine, including the sewing machine body, oil tank and cloth feeding mechanism 4, stitch length locking mechanism 13, pre-winding device 10, double thread clamp 6, automatic lubrication system provided on the sewing machine body,

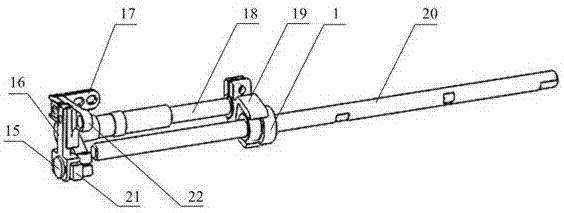

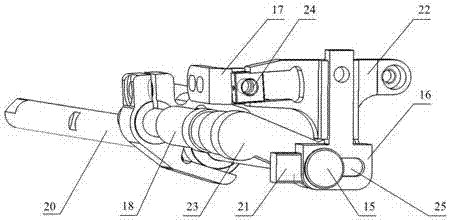

[0029] The cloth feeding mechanism 4 includes a lower shaft 20, a lifting cam 1, a lifting fork 19, a lifting shaft 18, a feeding dog guide 22, a feeding dog guide slider 24, a feeding dog frame 16, and a cloth feeding The tooth frame shaft 15, the cloth feeding frame slider 21, and the cloth feeding frame positioning plate 17. The tooth lifting cam 1 is sleeved in the middle of the lower shaft 20 and is fixedly connected to the lower shaft 20. The tooth lifting shaft 18 One end of the sprocket is rotatably connected with the sprocket cam 1 through the sprocket 19, the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com