Automatic pattern sewing machine

A sewing machine and pattern technology, applied in the field of automatic pattern sewing machines, can solve the problems of poor pattern surface quality, poor stability of sewing mechanism and needle plate mechanism, and unstable pattern stitches, so as to improve surface quality, improve stability, and ensure stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

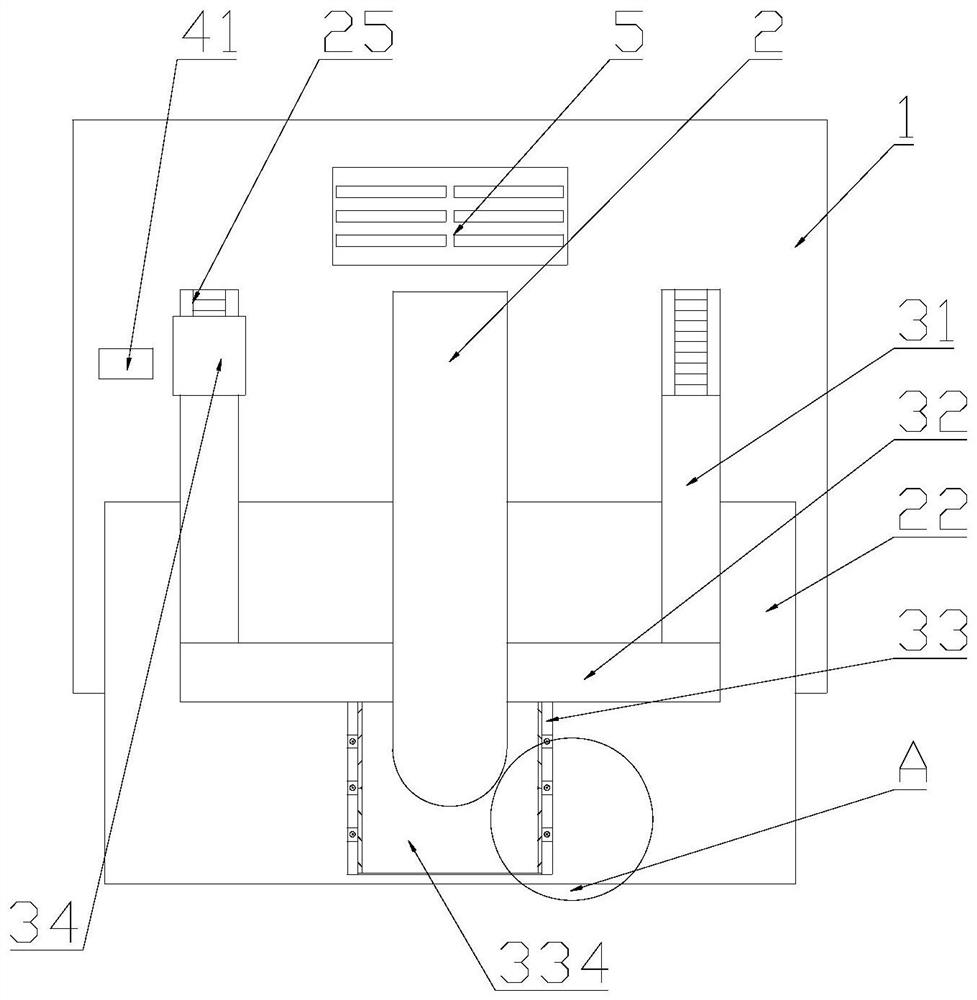

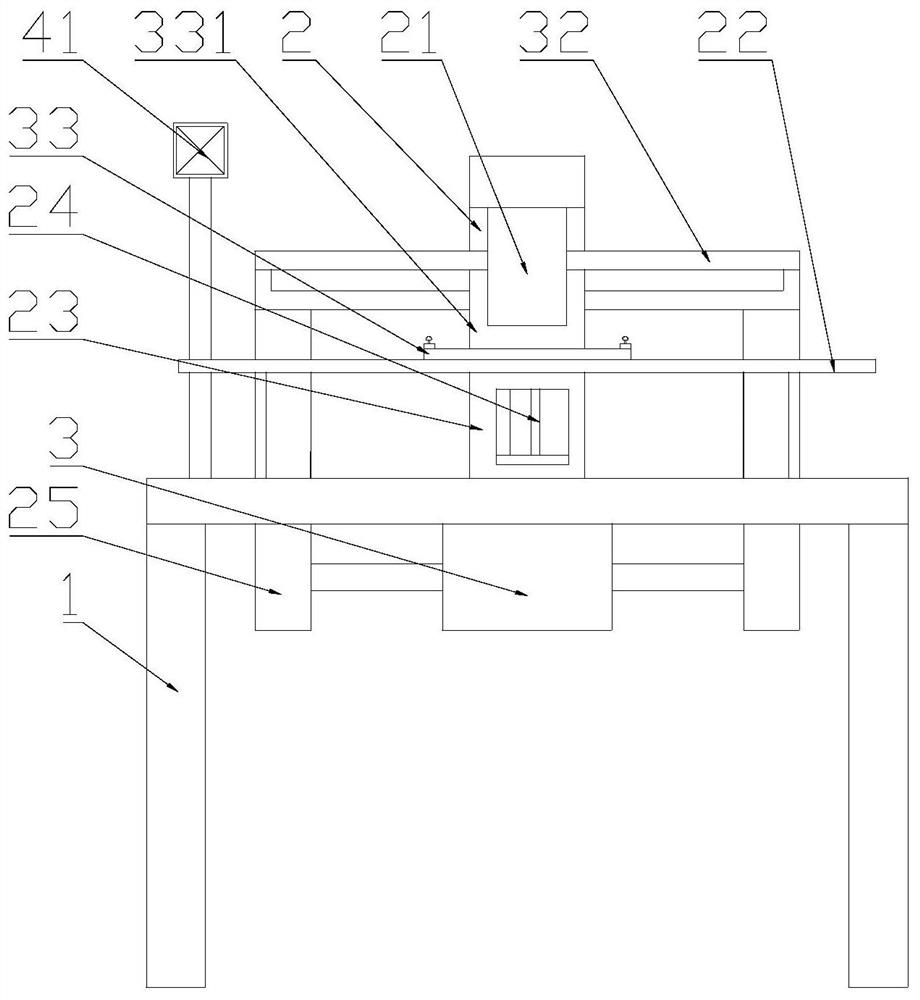

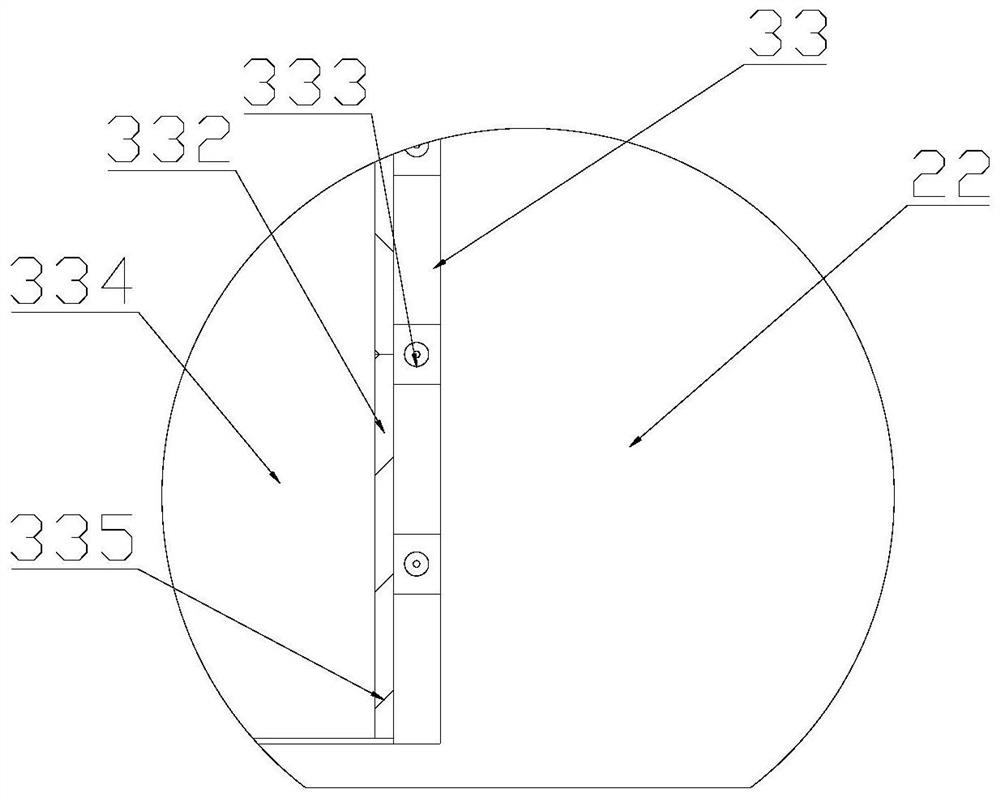

[0024] Such as figure 1 , figure 2 and image 3 As shown, a pattern automatic sewing machine includes a frame 1, a sewing support 2 is provided on one side of the top of the frame 1, a sewing mechanism 21 is provided under the end of the sewing support 2, and a sewing mechanism 21 is provided on the other side of the top of the frame 1. 21 corresponds to the work panel 22, the work panel 22 is provided with a needle plate mechanism corresponding to the sewing mechanism 21, the frame 1 is provided with a bobbin fixing mechanism 23 corresponding to the needle plate mechanism, and the bobbin fixing mechanism 23 is provided with a needle plate mechanism. Mechanism corresponding lead mechanism 24.

[0025] The frame 1 on both sides of the sewing support 2 is respectively provided with a transmission mechanism 25, the bottom of the frame 1 is provided with the first driving motor 3 axially connected with the two transmission mechanisms 25, and the tops of the two transmission mec...

Embodiment 2

[0033] Such as Figure 4 and Figure 5 As shown, compared with Embodiment 1, the difference is that the side of the second bracket 32 is provided with a second drive motor 34 axially connected to the second transmission mechanism, and the rest are the same as Embodiment 1, here There is no special limitation, and they all belong to the protection scope of the present invention. Its production process is also the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com