Cloth feeding mechanism of sewing machine

A cloth feeding device and sewing machine technology, applied in the direction of sewing machine components, cloth feeding mechanism, sewing equipment, etc., can solve the problems of disordered cloth feeding, damage to sewing quality, connection and removal troubles, etc., to achieve accurate cloth feeding, The effect of reducing the distance and reducing the sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

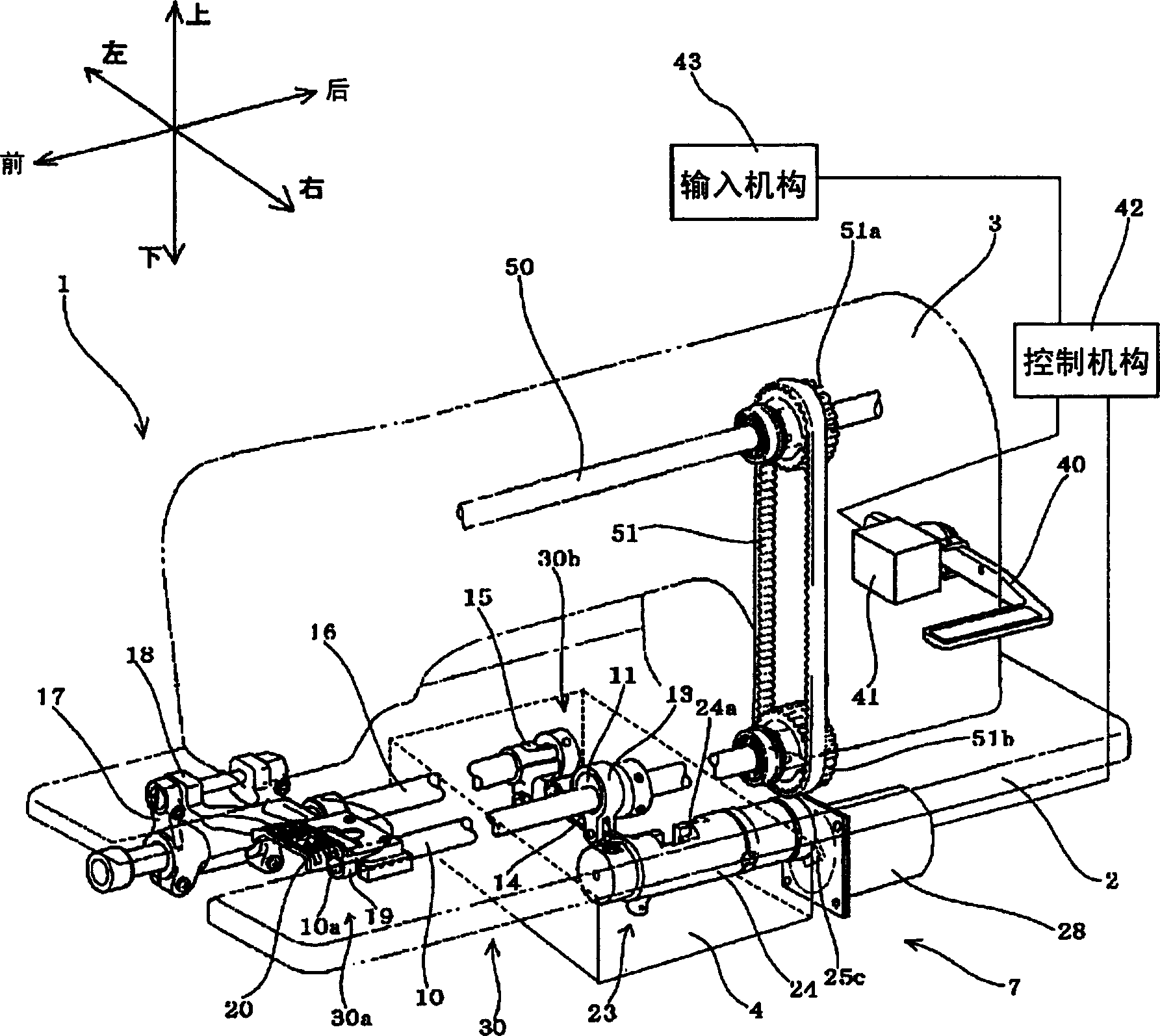

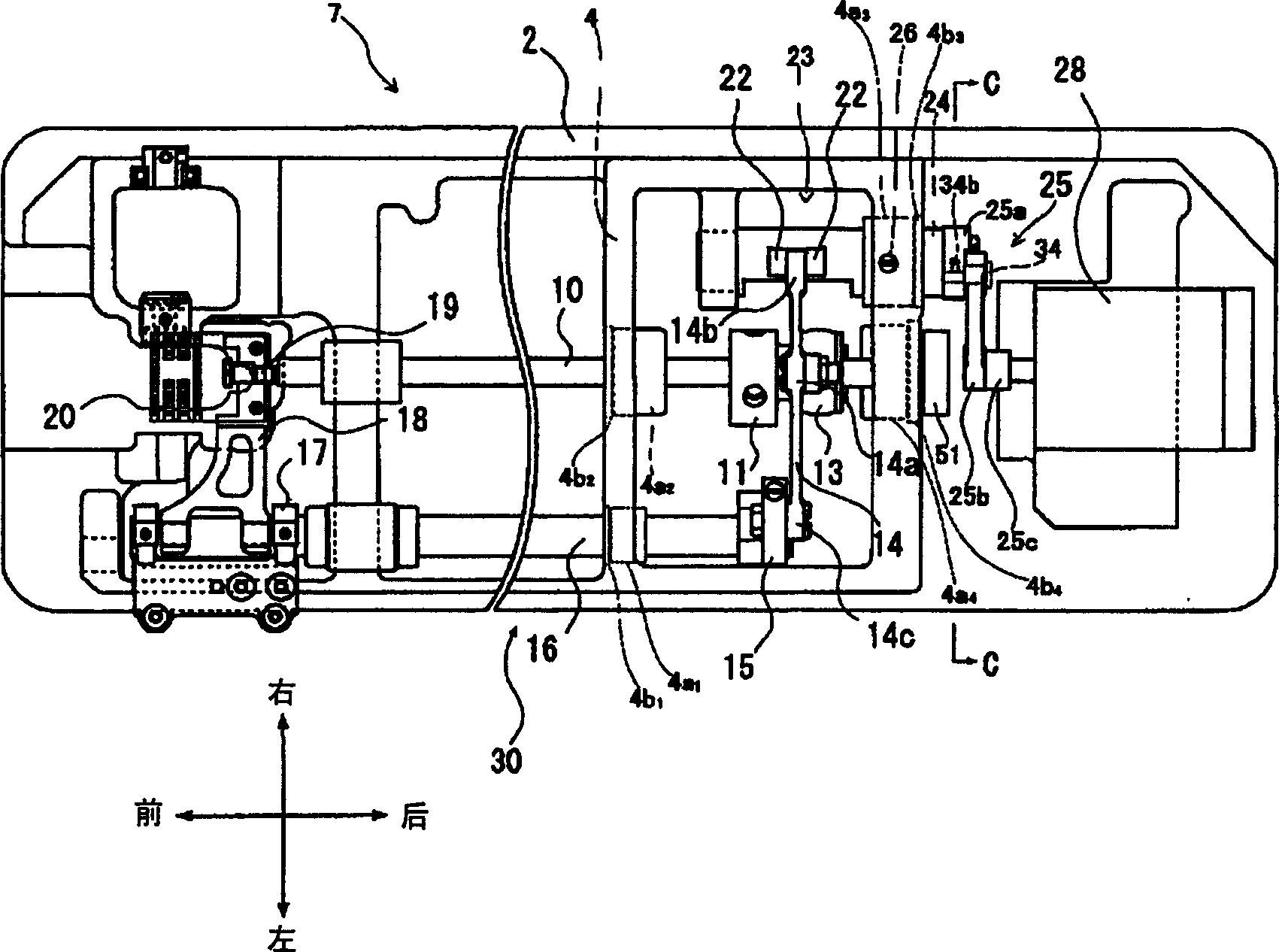

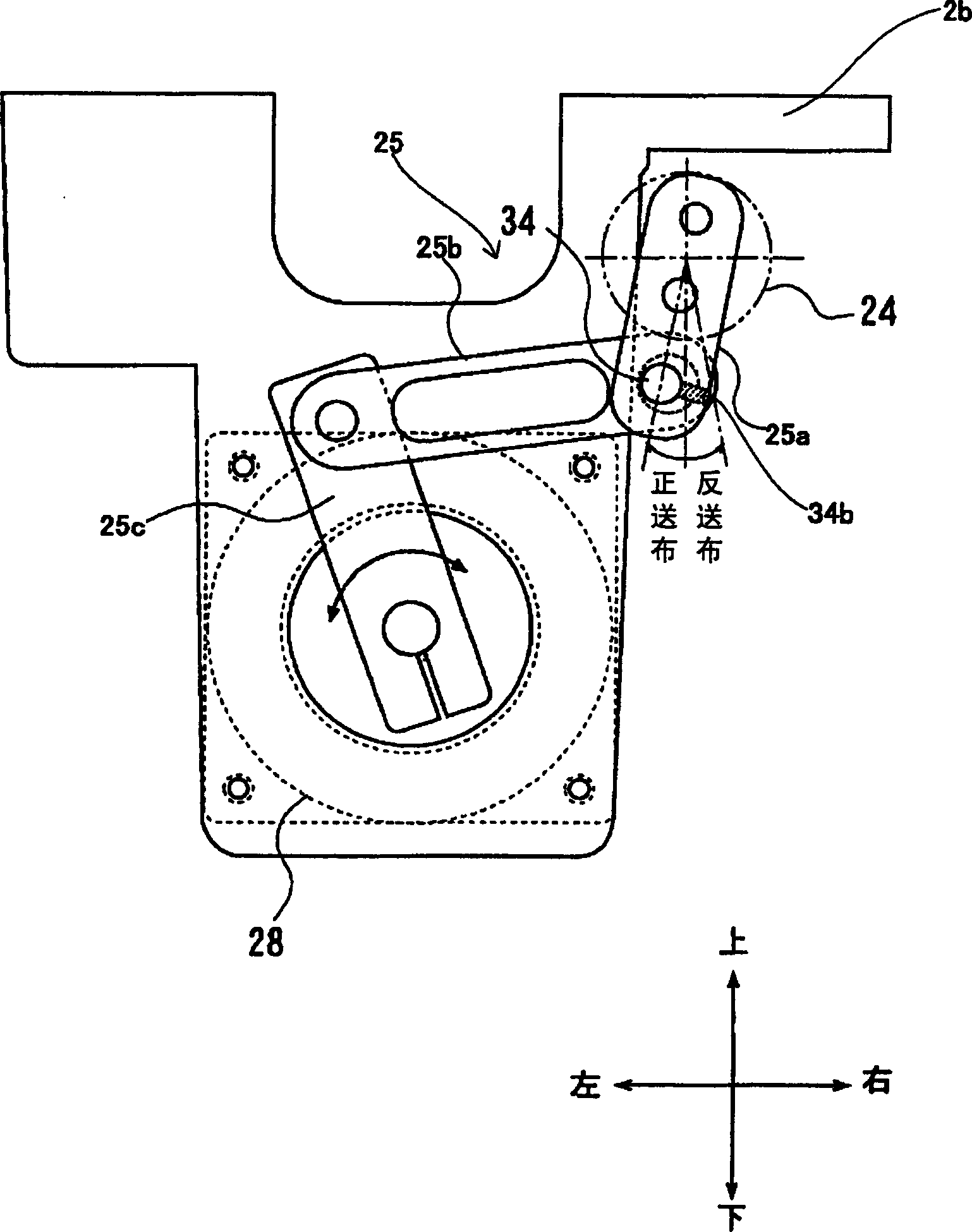

[0051] Hereinafter, specific embodiments of the cloth feeding device of the present invention will be described with reference to the drawings. In addition, in figure 1 , 2 In the structure shown, the feed dog 20, the feed table 18, the feed transfer mechanism 30 (the upper and lower feed mechanism 30a (the lower shaft eccentric part 10a, the upper and lower feed link 19, etc.), the horizontal feed mechanism 30b (horizontal Feed cam 11, horizontal feed lever 13, horizontal feed connecting rod 14, horizontal feed arm 15, horizontal feed shaft 16, (slider 22, groove 24a, etc.), feed amount changing mechanism 23 (feed Adjusting body 24, slider 22, etc.) is almost the same as the conventional structure, so its detailed description is omitted.

[0052] exist figure 1 , 2 Among them, the main shaft 50 extending in the front-back direction is rotatably supported on the sewing machine head, and the main shaft 50 is rotated in conjunction with a drive source (not shown), and is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com