Anti-oil leakage device of top bend needle mechanism

A bending needle and oil leakage technology, applied in safety devices, engine lubrication, lubrication/cooling devices, etc., can solve the problems of oil leakage, unable to maintain the oil leakage prevention function with good stability for a long time, and achieve less wear, The effect of reliable stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described below with reference to the drawings.

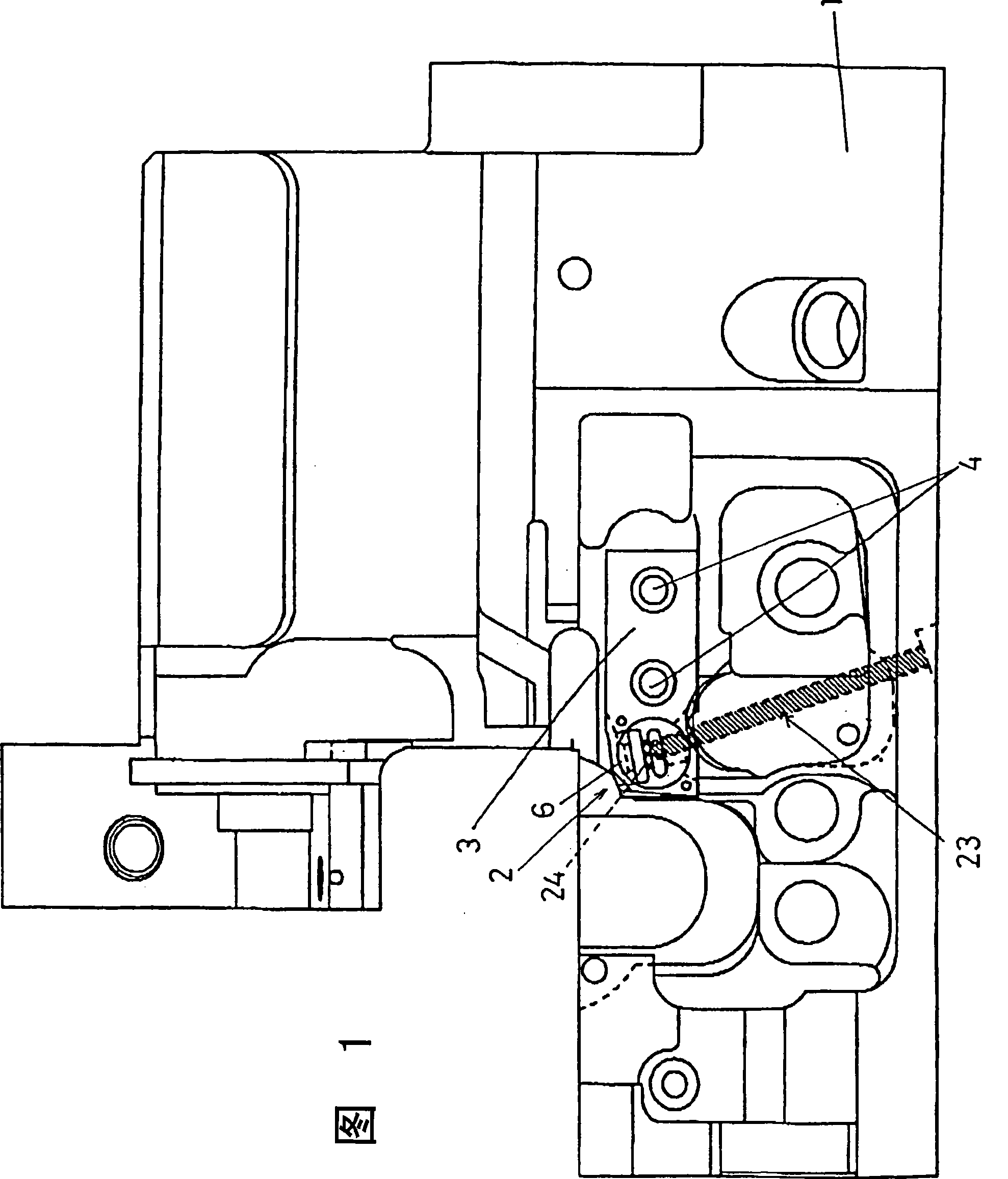

[0036] Fig. 1 shows a sewing machine frame in an overlock sewing machine equipped with an oil leakage prevention device for an upper looper mechanism according to a first embodiment of the present invention in a state where the front cover (not shown) mounted on the sewing machine frame 1 is removed. 1 overall front view, showing the upper looper mechanism 2 in front of the sewing machine frame 1.

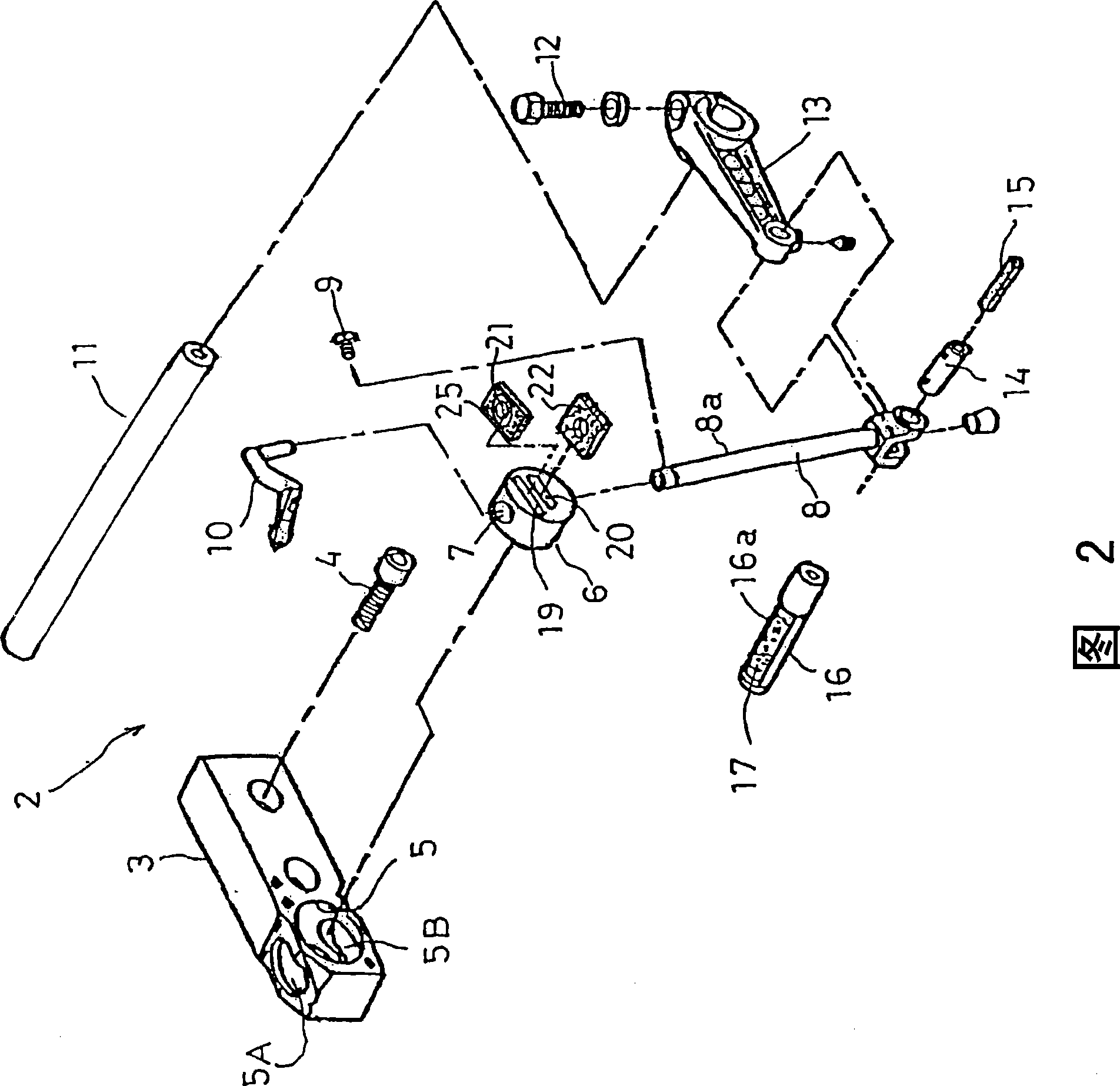

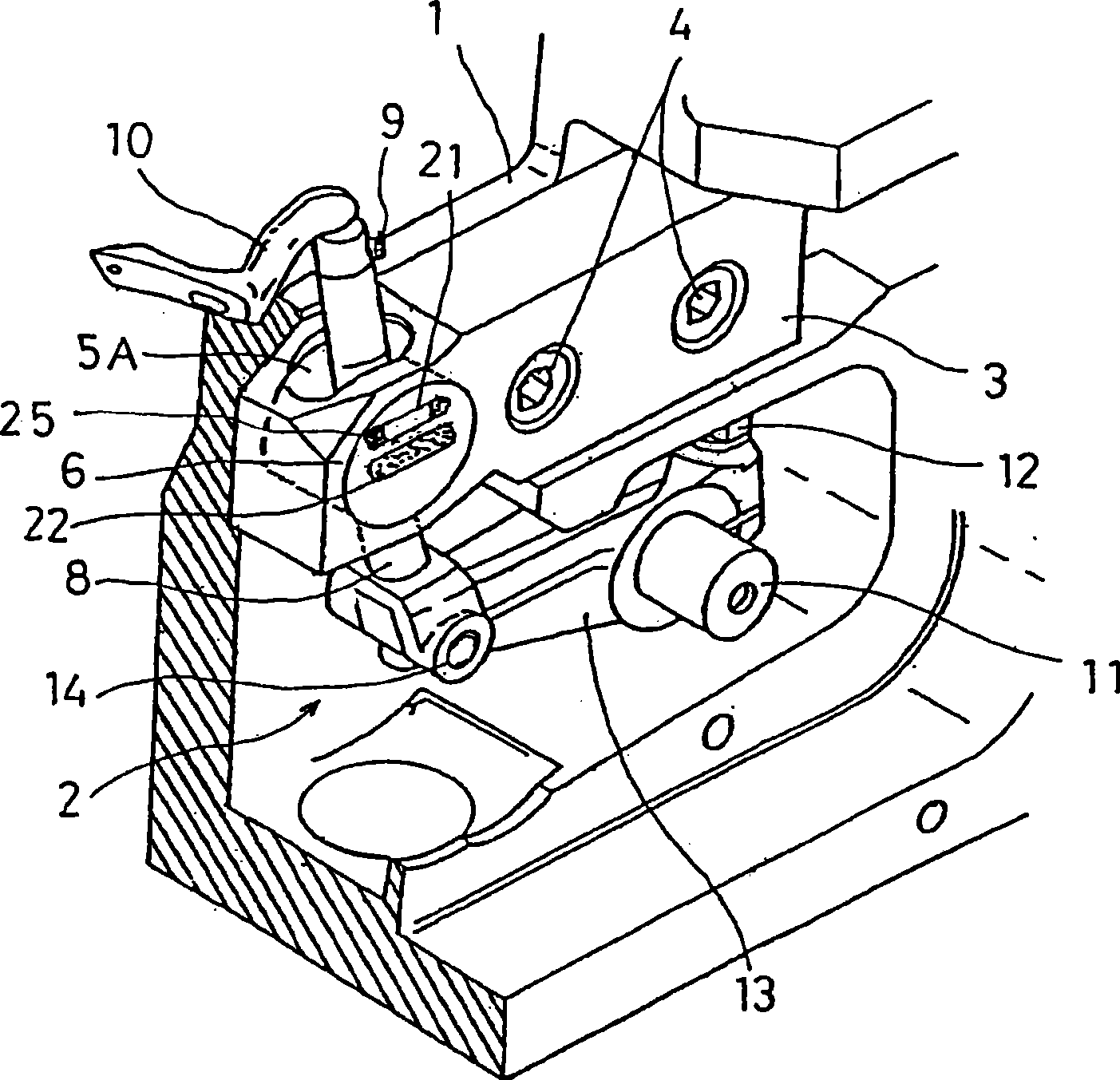

[0037] Fig. 2 is an exploded perspective view of the upper looper mechanism 2, image 3 It is an assembly perspective view of the upper looper mechanism 2, Figure 4 It is the front view of the upper looper mechanism 2. In these figures, symbol 3 is an upper looper guide member fixed on the front of the sewing machine frame 1 by a set screw 4, and a circular hole 5 along the cloth feeding direction is formed at the front end of the upper looper guide member 3. The shaped hole 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com