Patents

Literature

61results about How to "Increase fuel supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

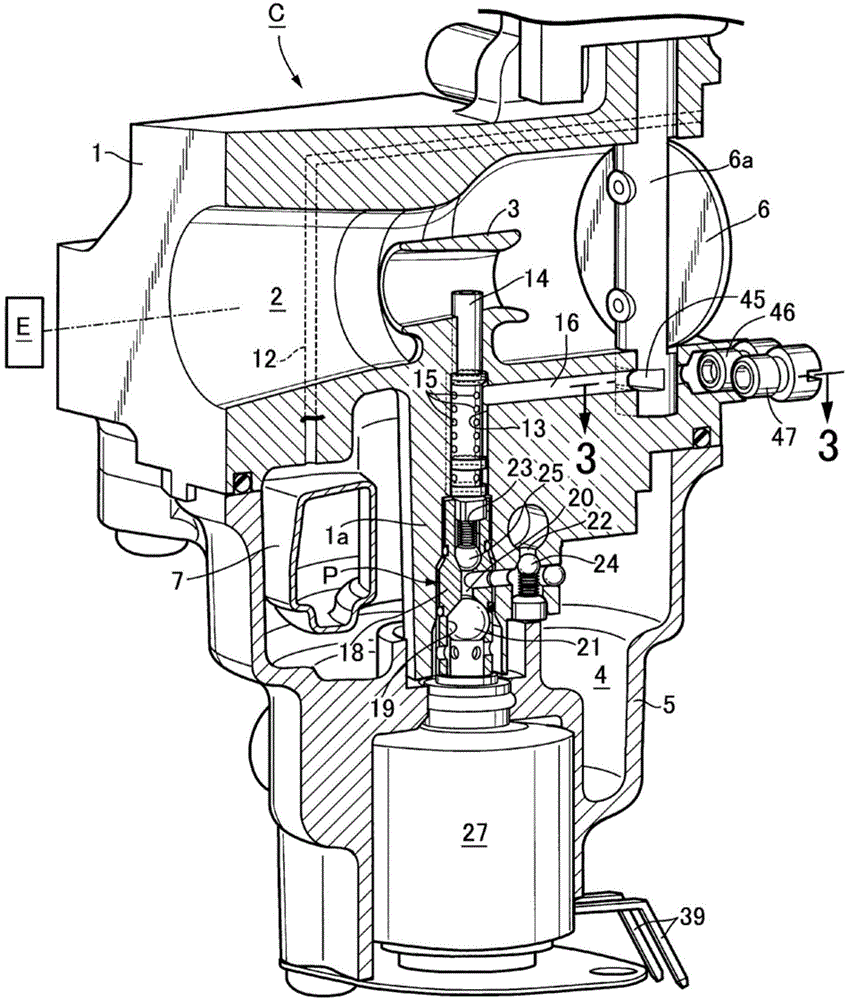

Motorcycle carburetor with reinforced starter

InactiveCN1584317AIncrease fuel supplyIncrease supplyIdling devicesMachines/enginesIdle speedOil well

The present invention relates to a motorcycle carburetor capable of raising starting performance. It includes carburetor self-body, on the carburetor self-body an air bleed jet, an idle discharge port and a transition port are cut, and the interior of the carburetor self-body has an idle fuel well and a float chamber, said idle fuel well is formed from its internal cavity and its external cavity, in the bottom portion of its internal cavity an idle metering jet is cut, and in its upper portion a foam hole is cut. It is characterized by that on the idle metering jet more than one starting concentration-increasing hole can be drilled under the fuel level, so that is can raise starting performance of engine, and can reduce discharge at the same tine of ensuring idle run.

Owner:ZHEJIANG HUAYANG INDAL CARBURETOR

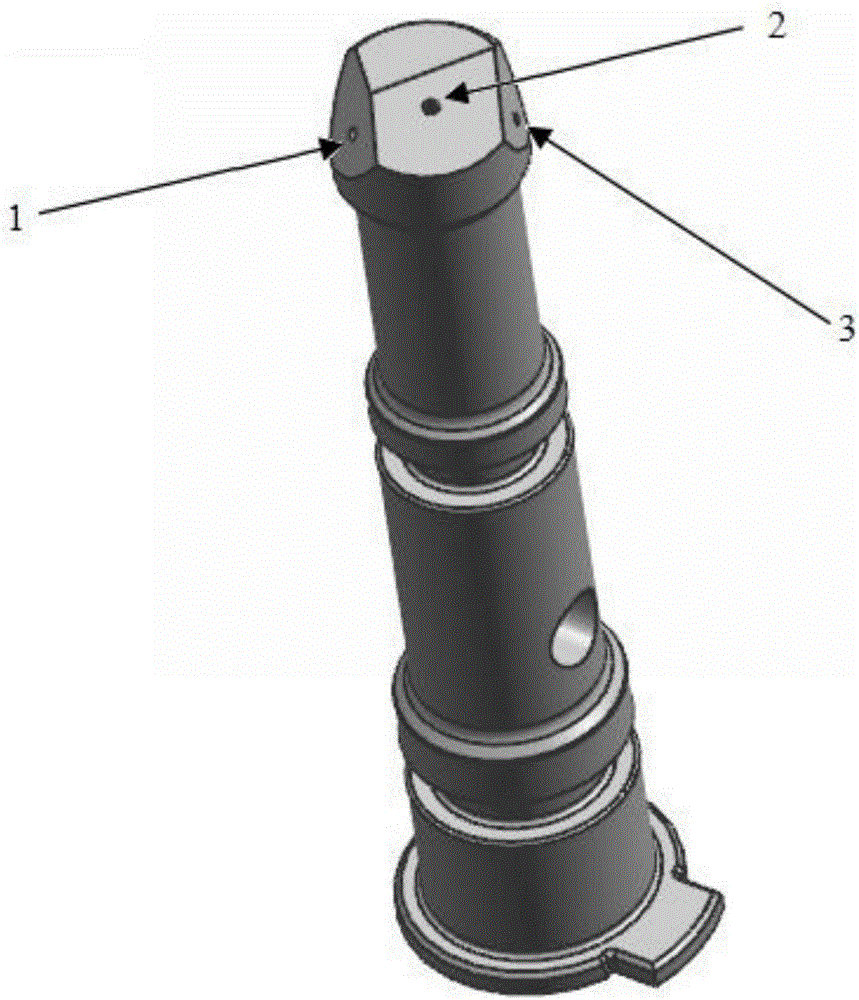

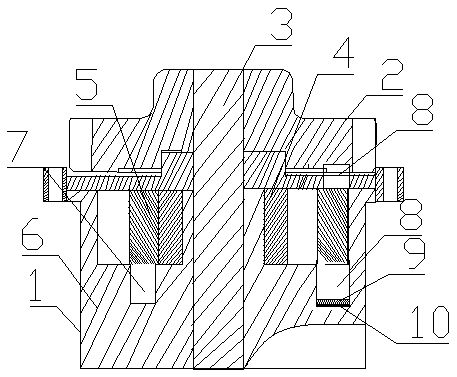

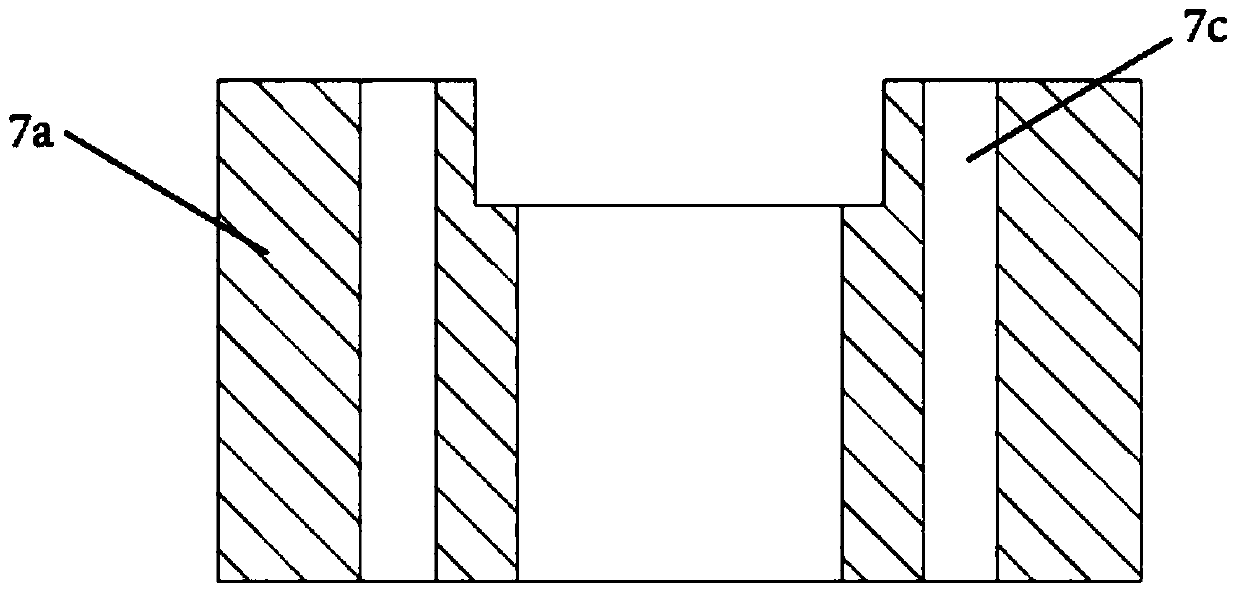

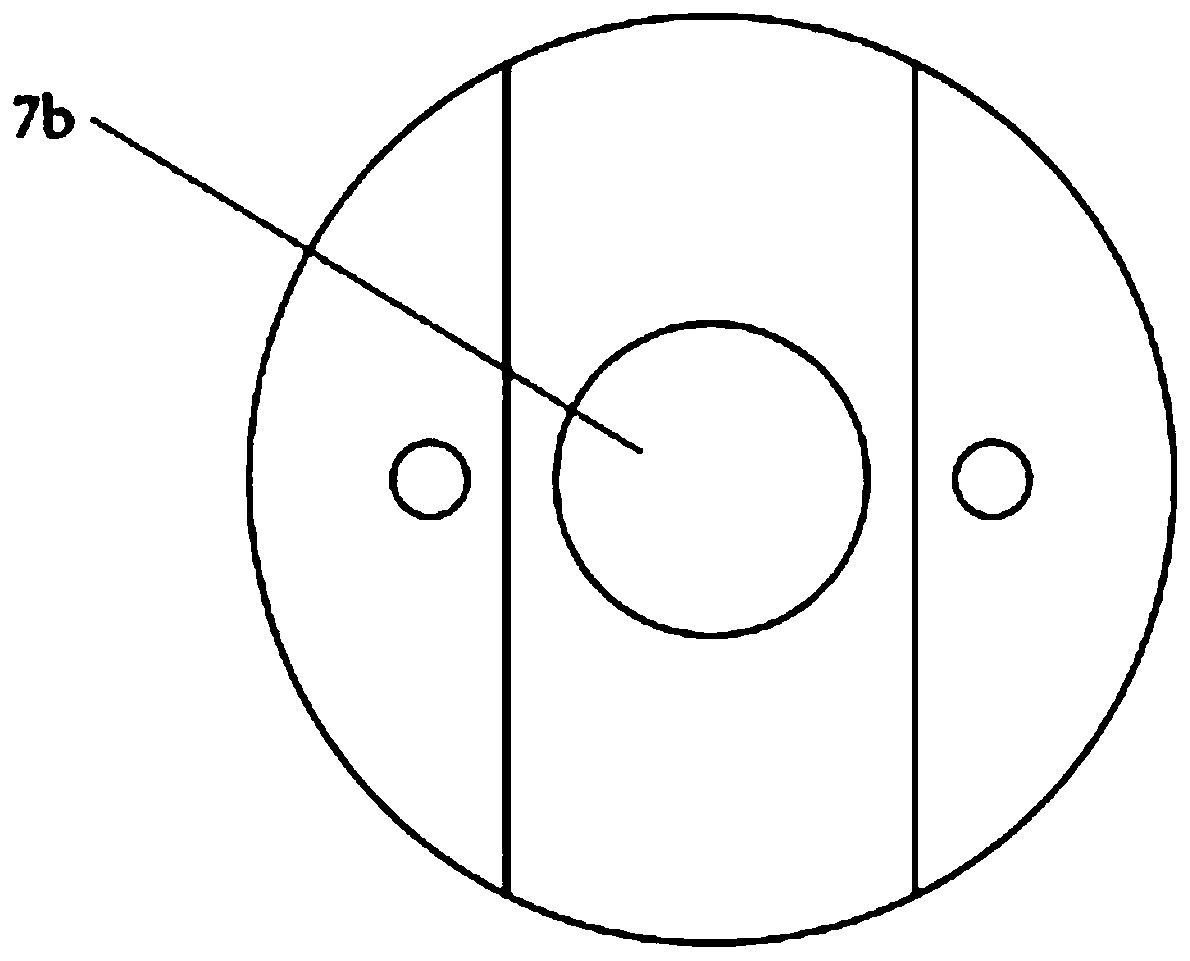

Multipoint radial jetting oil supply nozzle for high-speed and heavy-load bevel gear

ActiveCN106594248AImprove cooling effectBreak through the limit of cooling capacityGear lubrication/coolingSpray nozzlesCooling effectLimit value

The invention relates to a multipoint radial jetting oil supply nozzle for a high-speed and heavy-load bevel gear. A hollow oil chamber, an oil inlet and oil jetting holes are formed in the nozzle. The hollow oil chamber communicates with the oil inlet and the oil jetting holes. A circumferential locating boss is formed at the end of the oil supply nozzle. The oil jetting holes comprise the first oil jetting hole, the second oil jetting hole and the third oil jetting hole. The three oil jetting holes are all formed in the end of the oil supply nozzle, and an independent included angle is formed between each of the three oil jetting holes and the central axis. An upper limit value of the oil supply amount exists for transmission of any gear. When the oil supply amount exceeds the upper limit value, no cooling effect can be achieved for the gear. The upper limit value is called as the valid oil supply amount, and the exceeding part is the invalid oil supply amount. By means of the multipoint radial jetting oil supply nozzle, the valid oil supply amount can be increased, the invalid oil supply amount can be controlled, and the cooling effect can be improved.

Owner:AECC SICHUAN GAS TURBINE RES INST

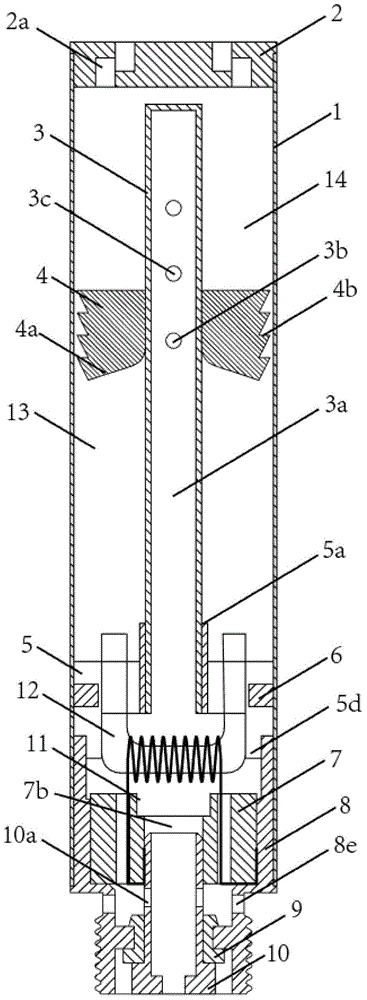

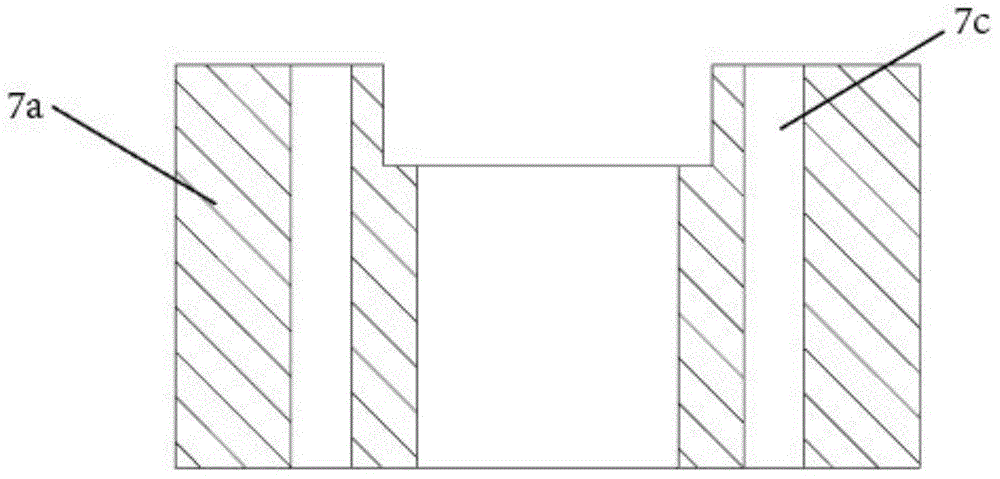

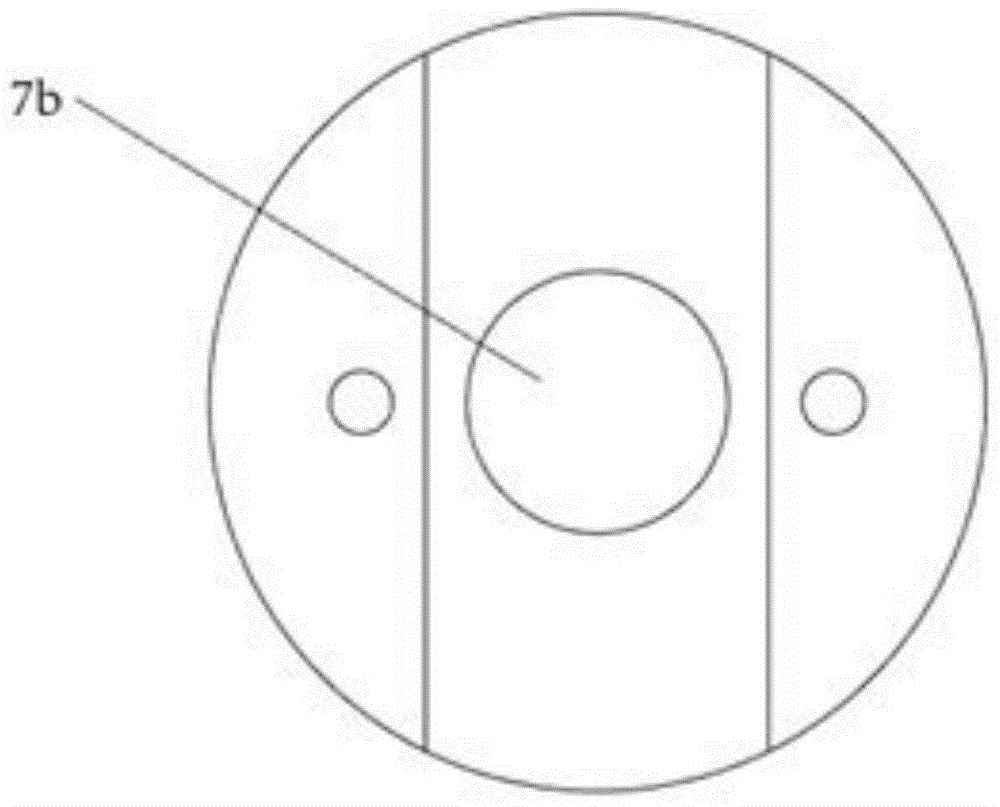

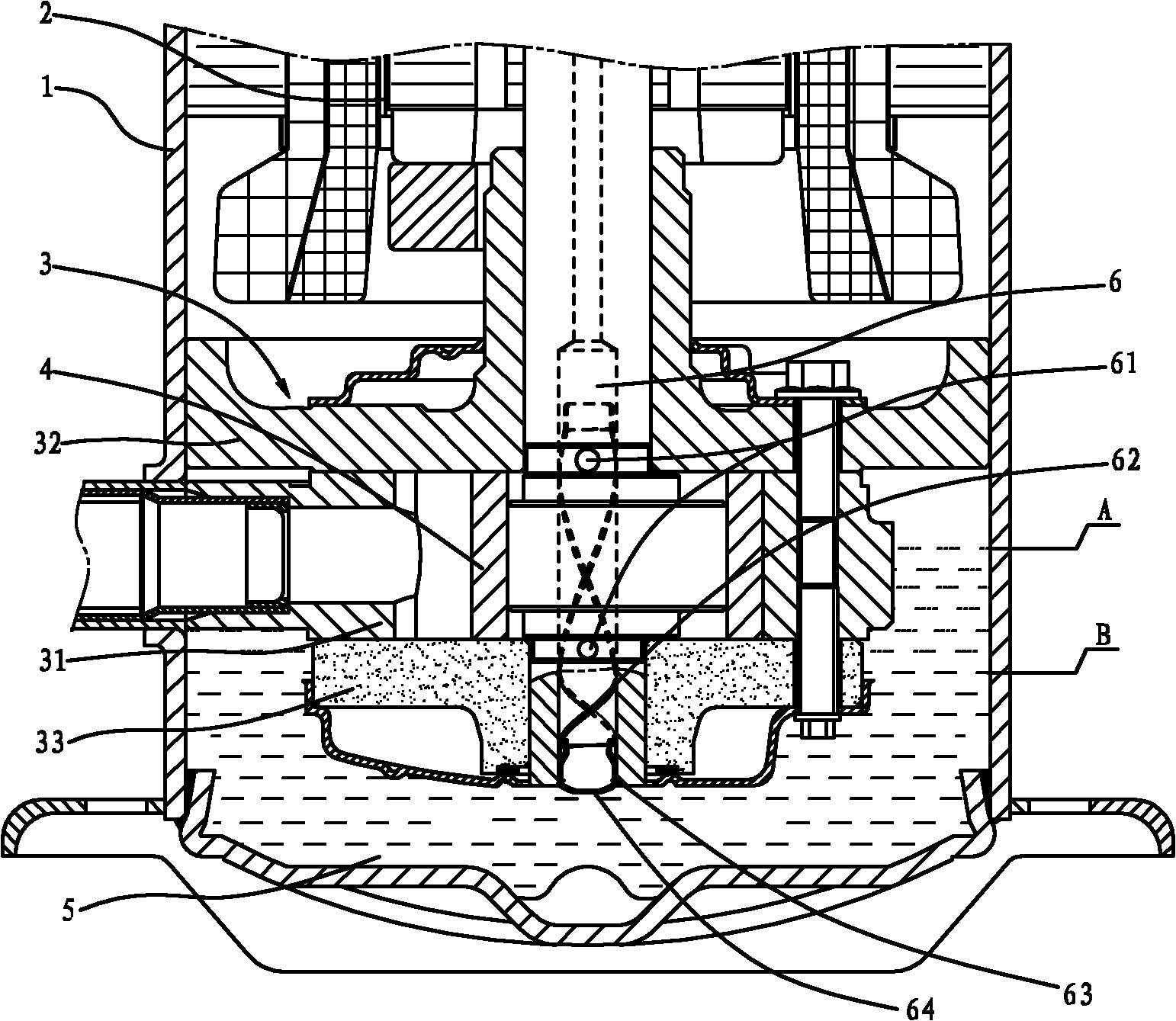

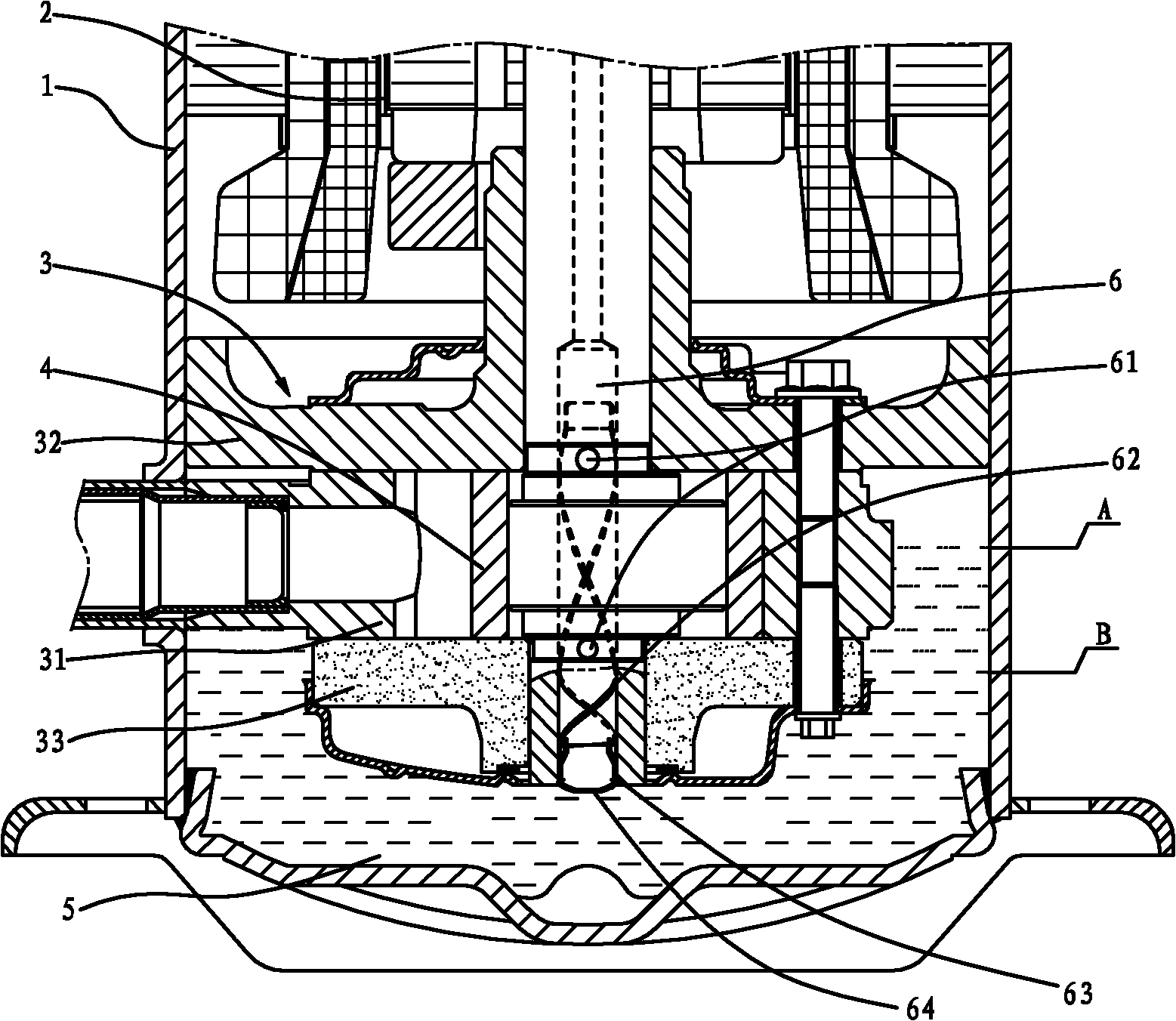

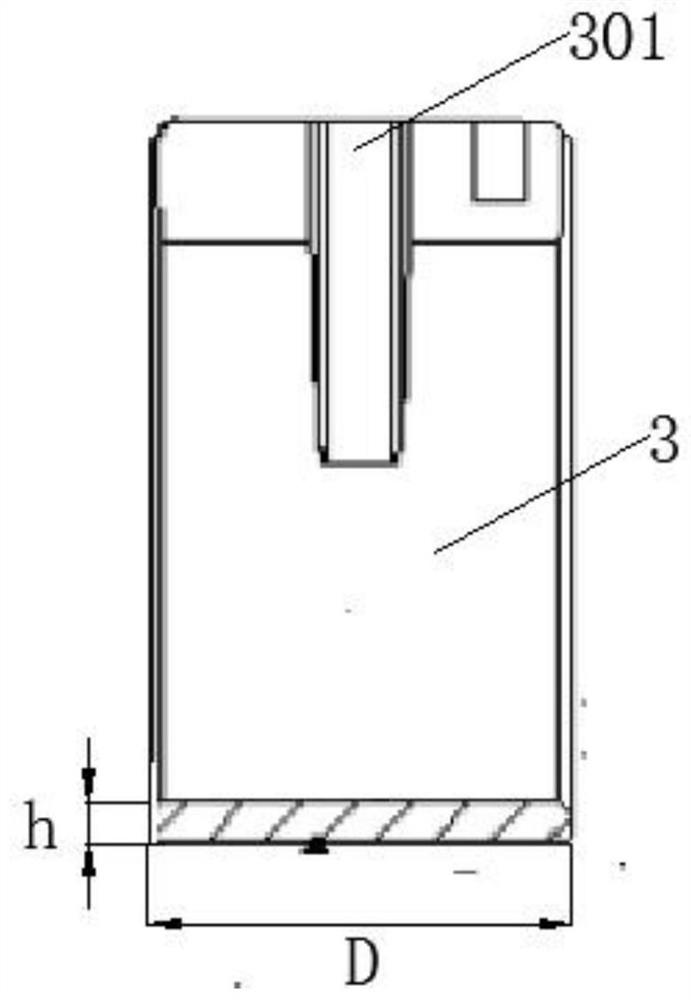

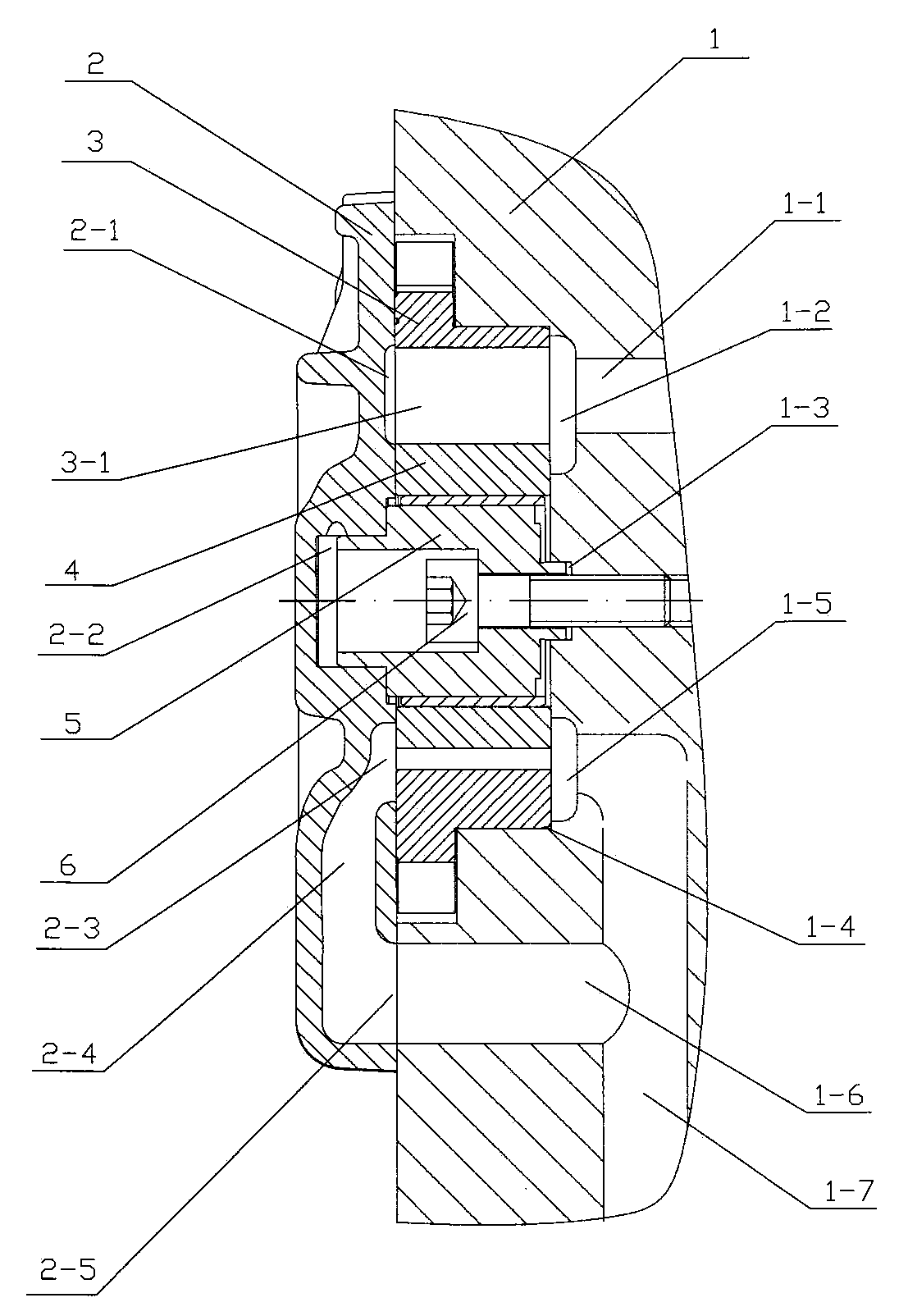

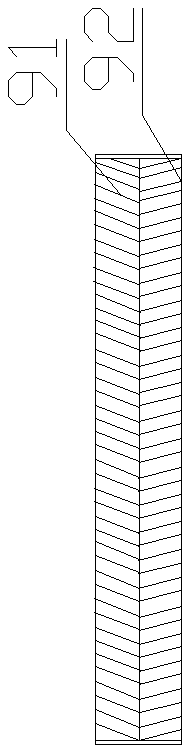

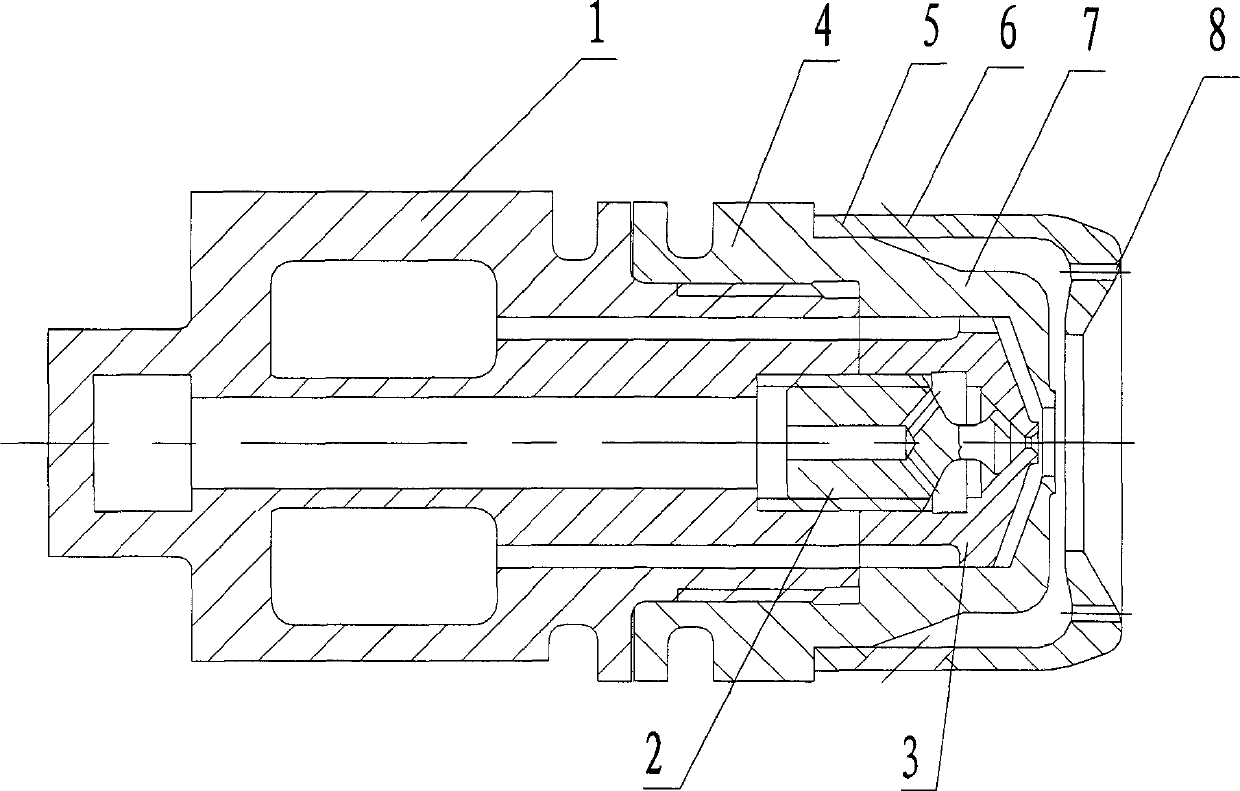

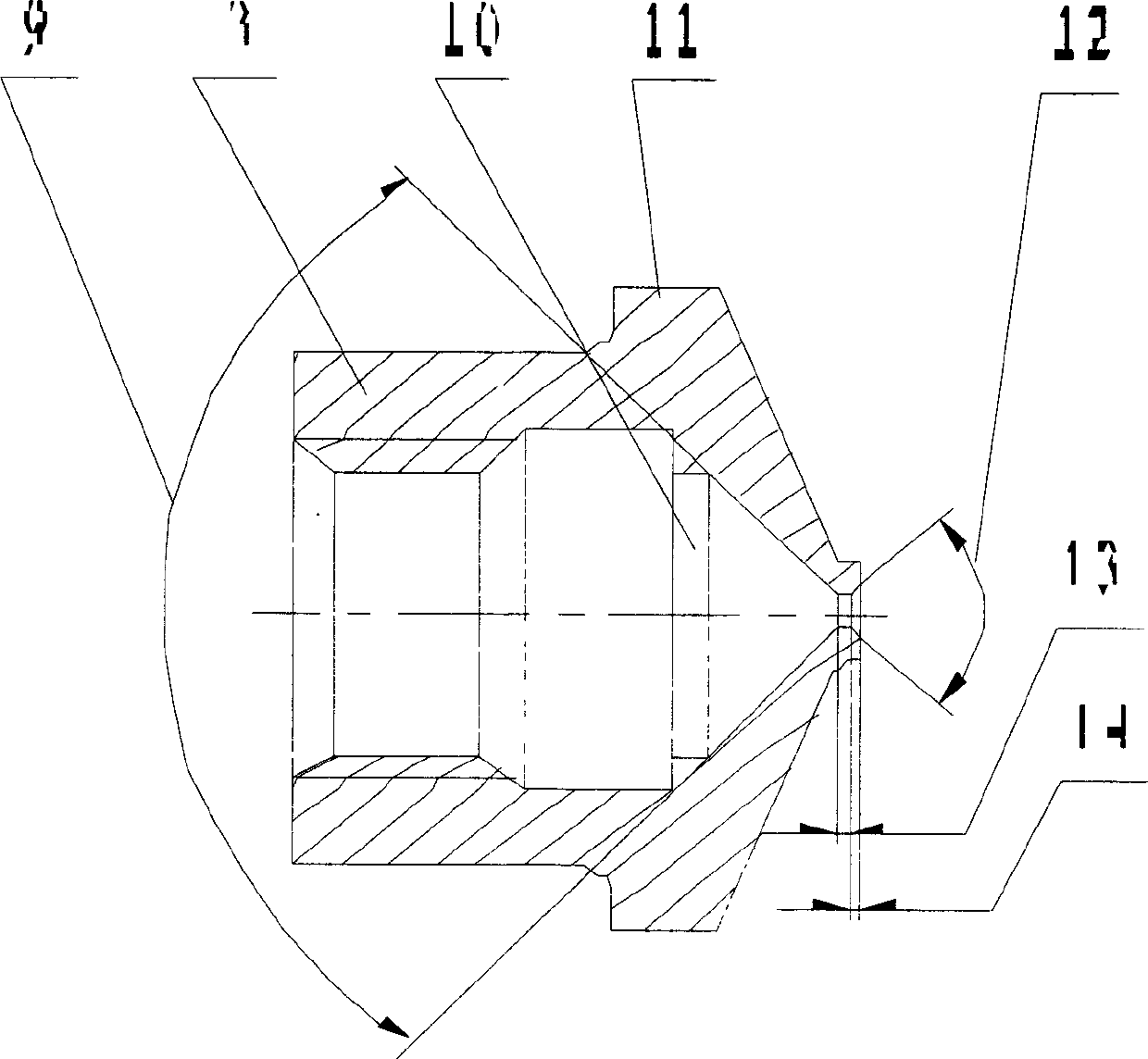

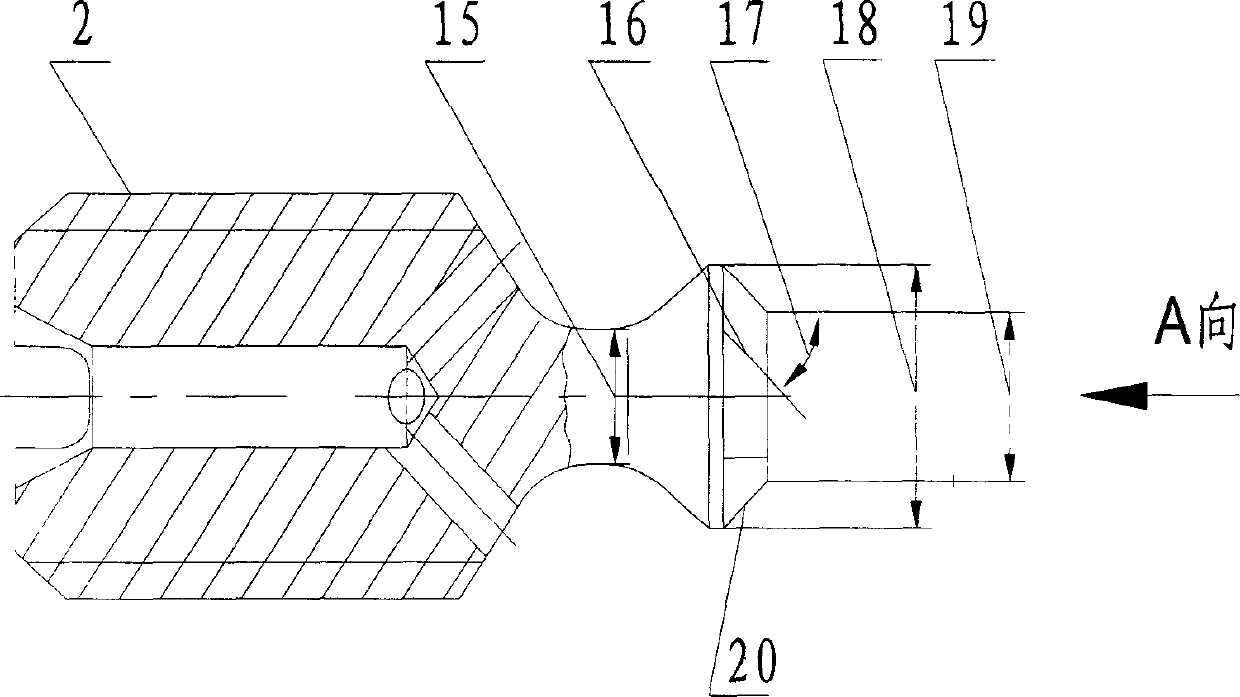

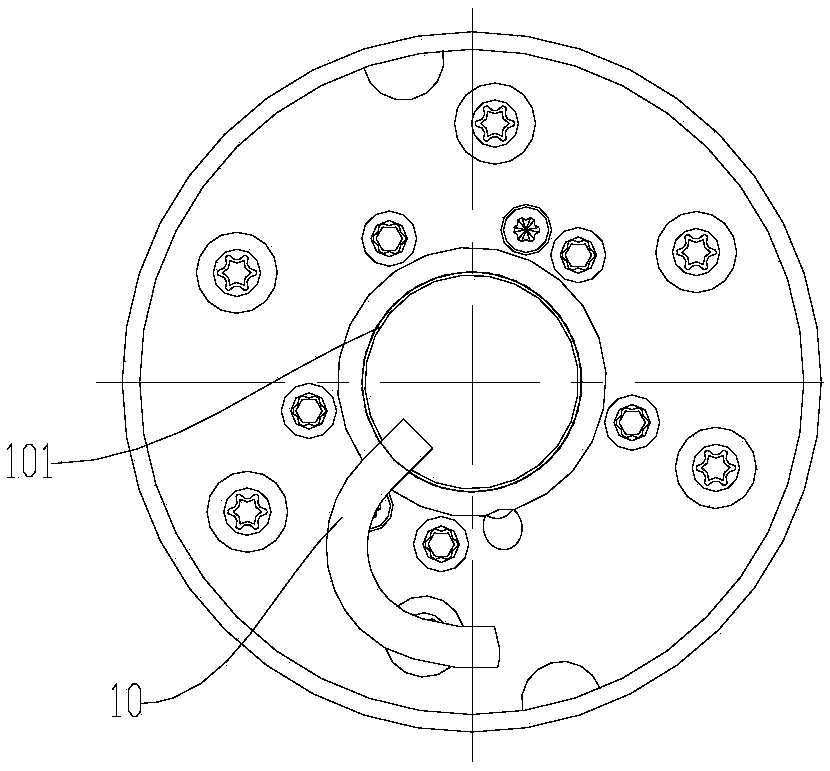

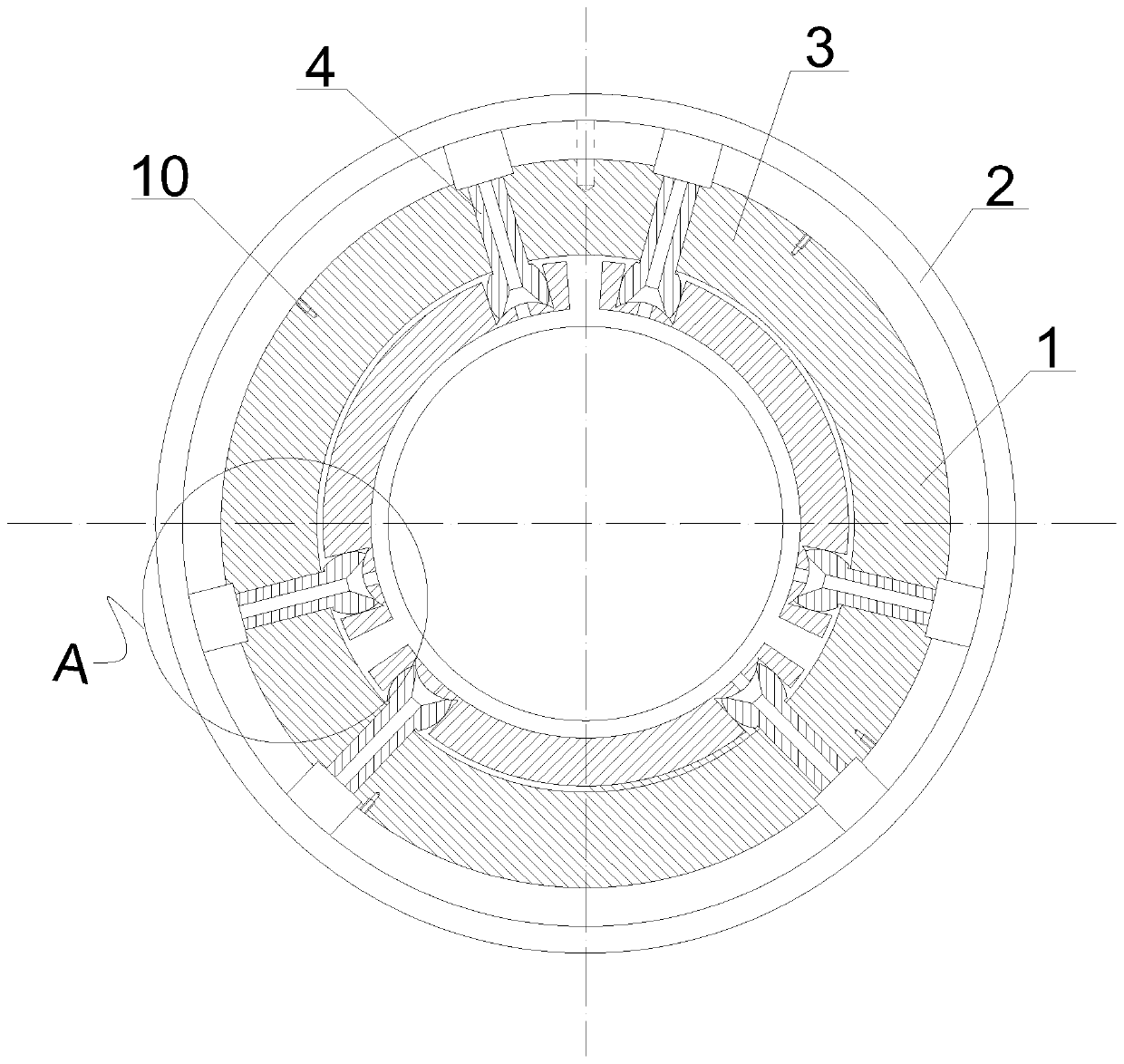

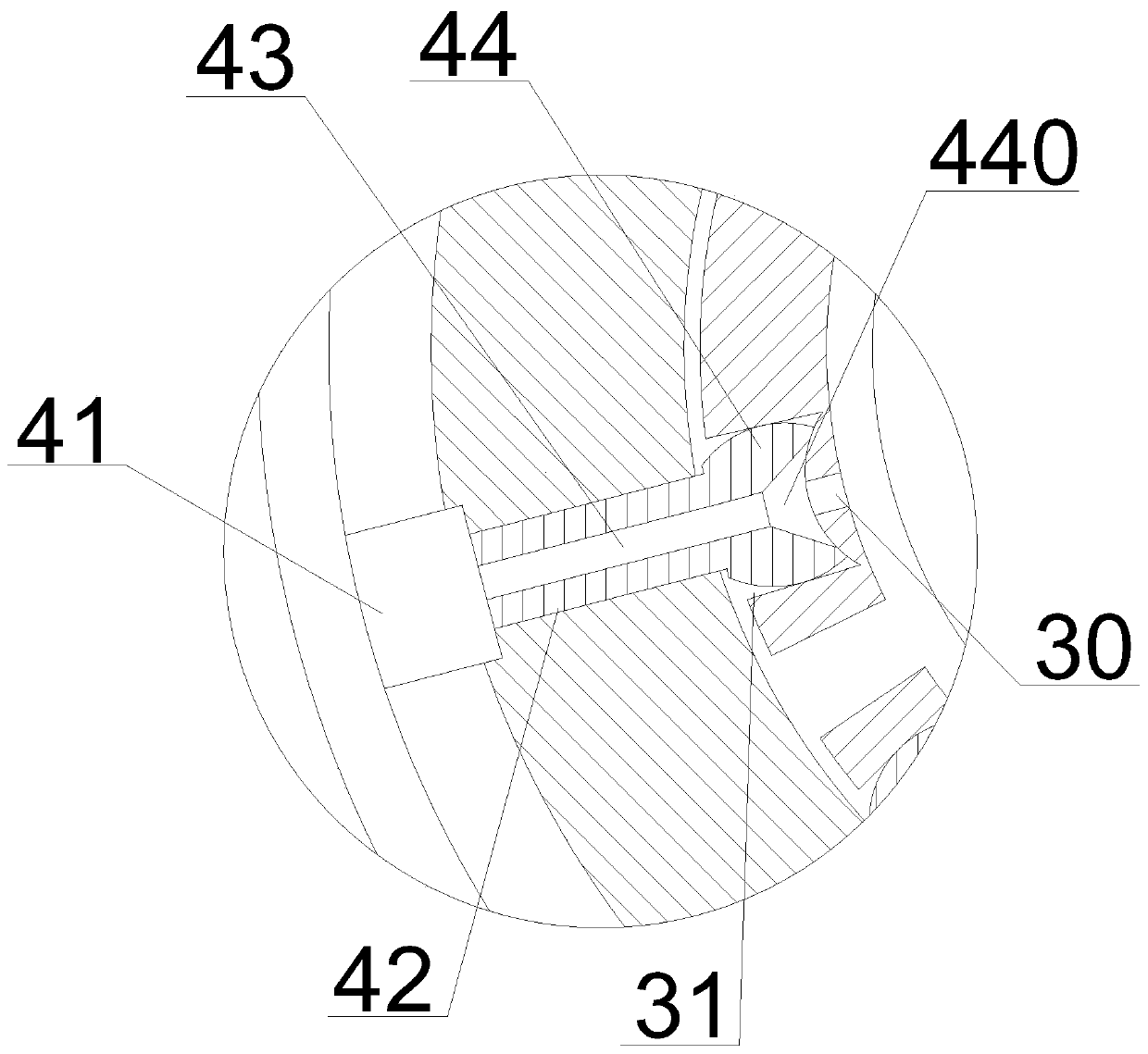

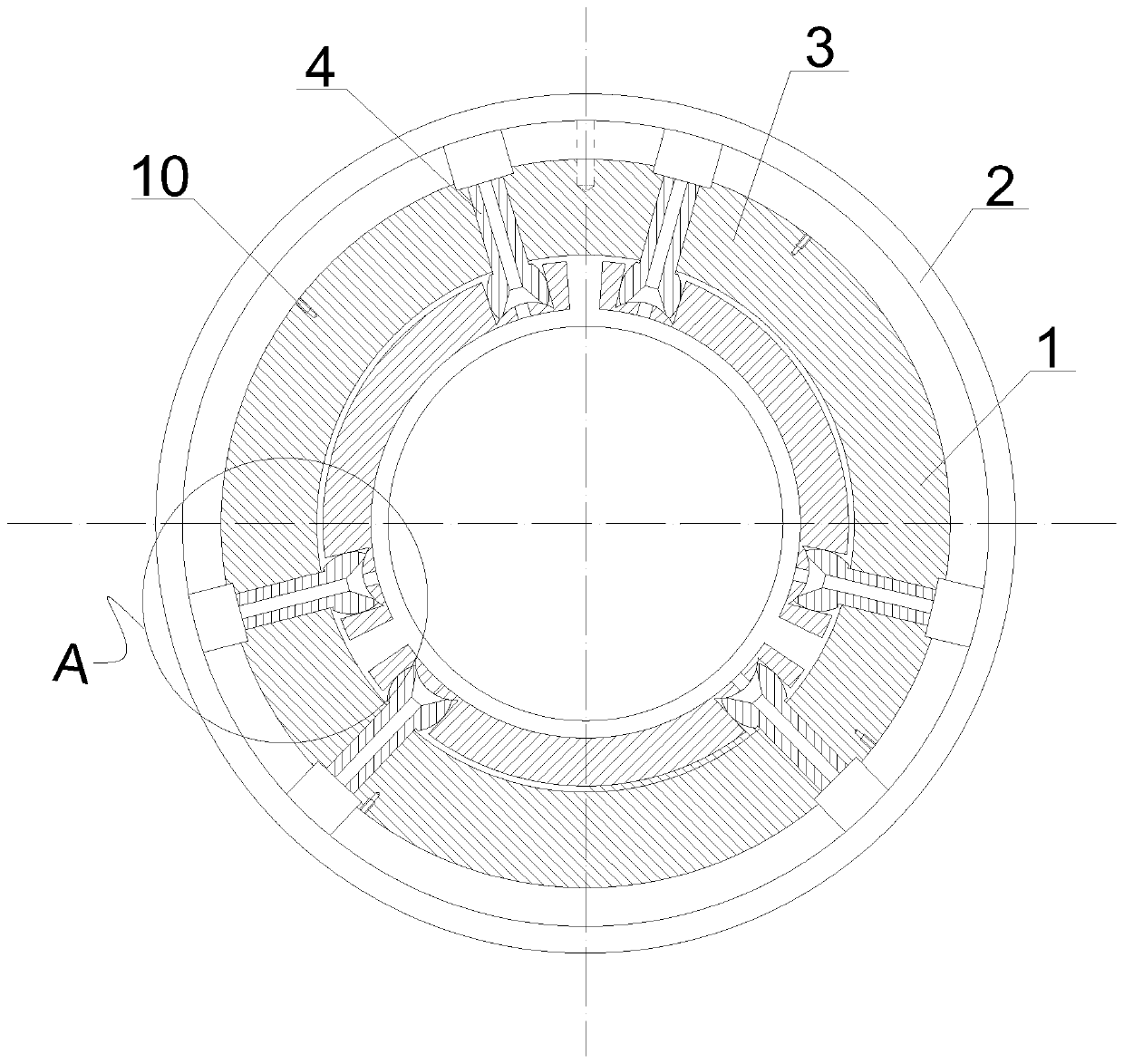

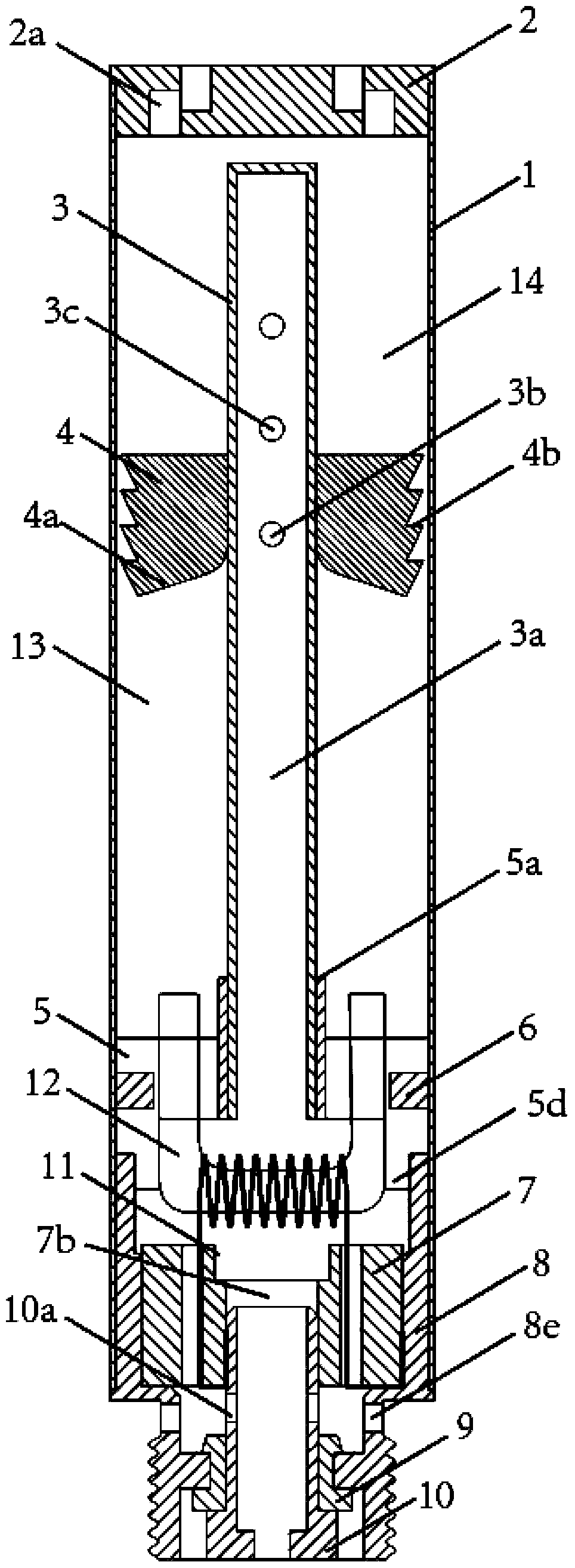

Disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage

A disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage comprises a round-tube-shaped casing (1), an axial smoke tube (3), a cigarette holder cover (2), a tobacco tar isolation rubber gasket (4) and an atomizer assembly, wherein the axial smoke tube (3) is arranged in the inner center of the casing, the cigarette holder cover (2) covers the top of the casing, vent holes (2a) are formed in the cigarette holder cover (2), the tobacco tar isolation rubber gasket (4) is arranged at the middle-upper part in the casing and mounted on the smoke tube in a sleeving manner, and the atomizer assembly is arranged at the lower end of the smoke tube; the tobacco tar isolation rubber gasket divides an inner cavity of the casing into an upper annular cavity (14) for accommodating filtration or flavoring materials and a lower tobacco tar storage cup (13) for storing tobacco tar. No tobacco tar storage cotton is used, bacterium breeding can be effectively avoided, air in the annular tobacco tar storage cup can be completely removed, the problem of tobacco tar leakage is effectively solved, the tobacco tar utilization rate is high, the smoke quantity is large, tobacco tar can be prevented from being sucked into the mouth, and the smoking experience is better.

Owner:云南拓宝科技有限公司

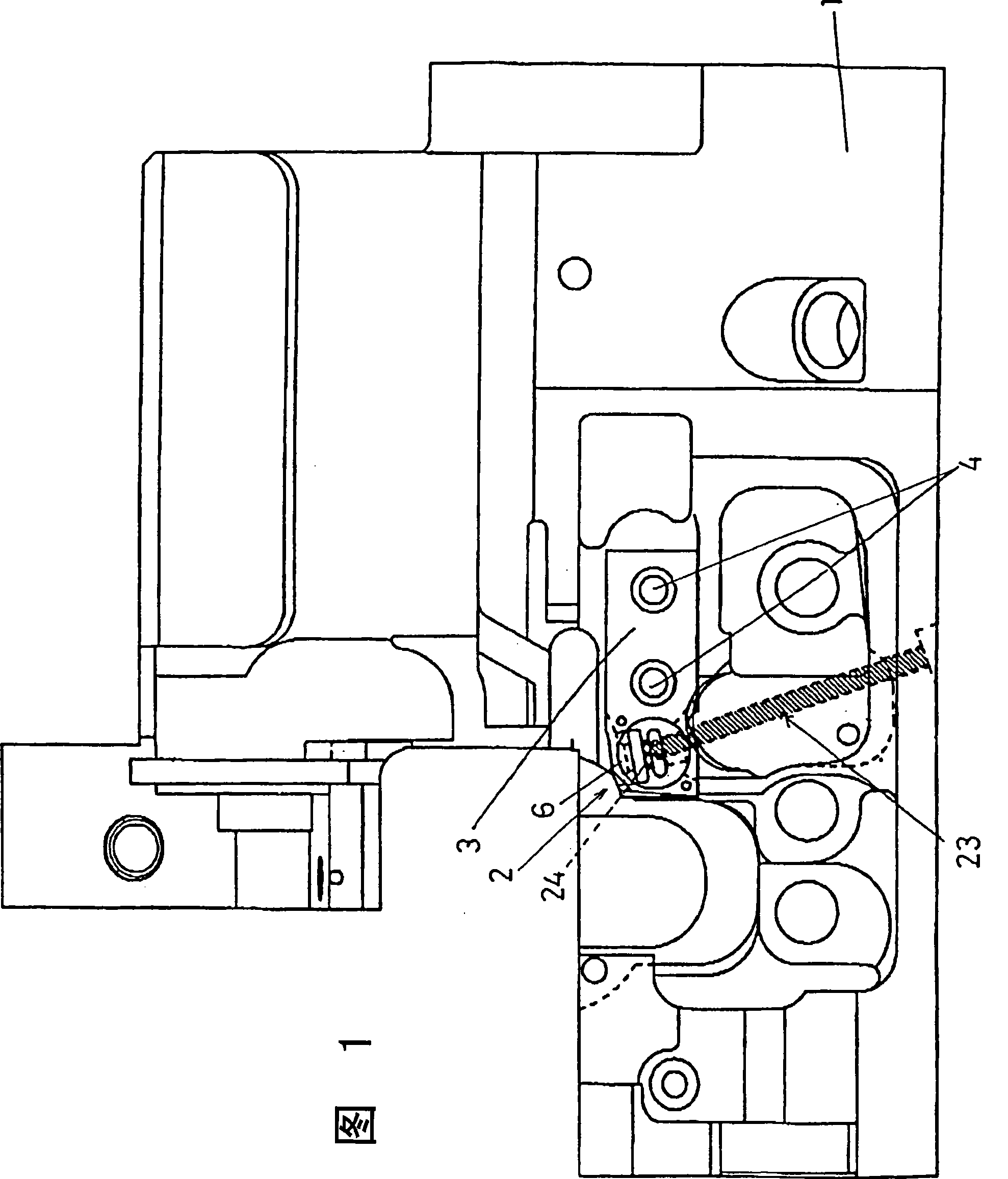

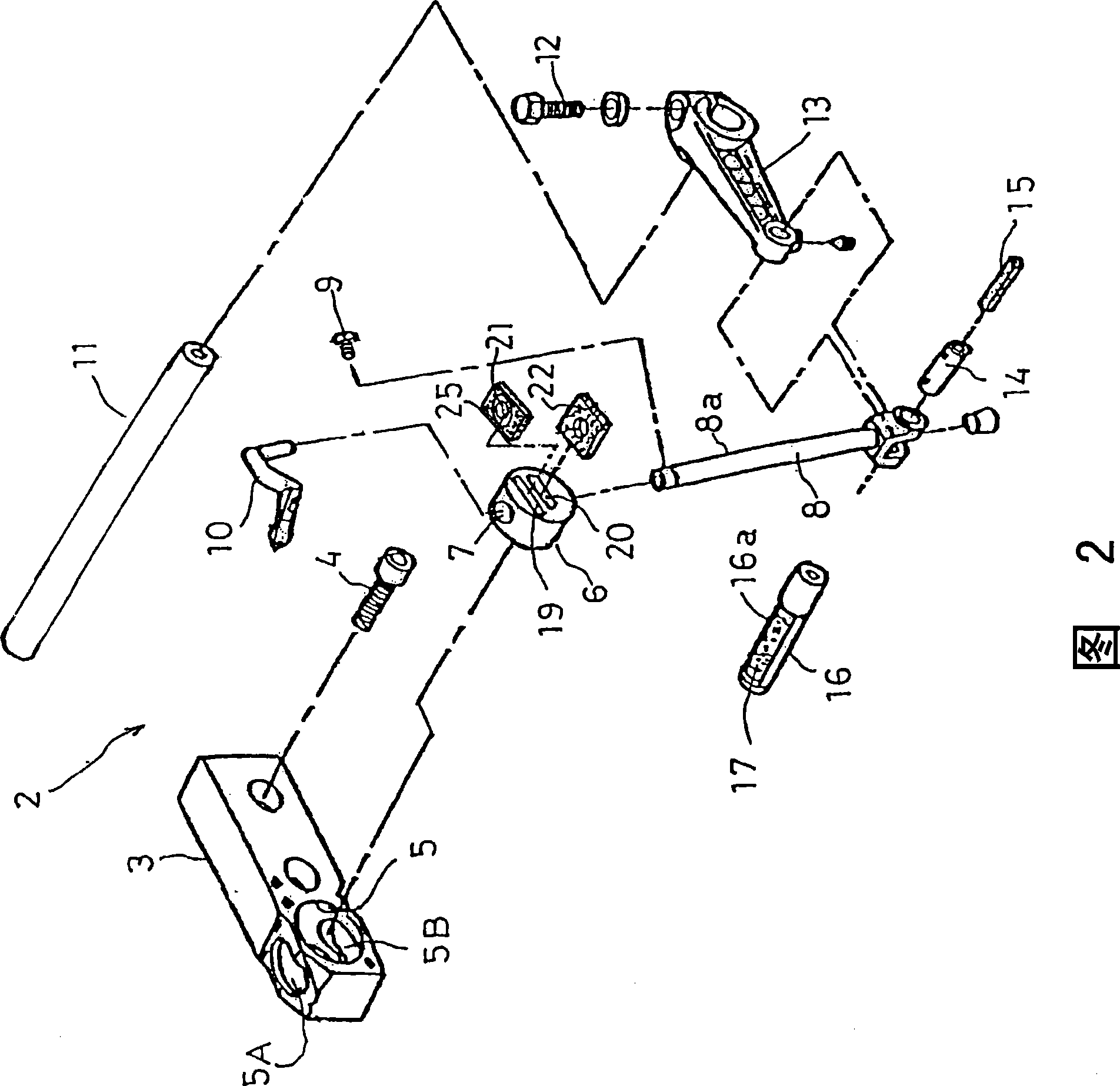

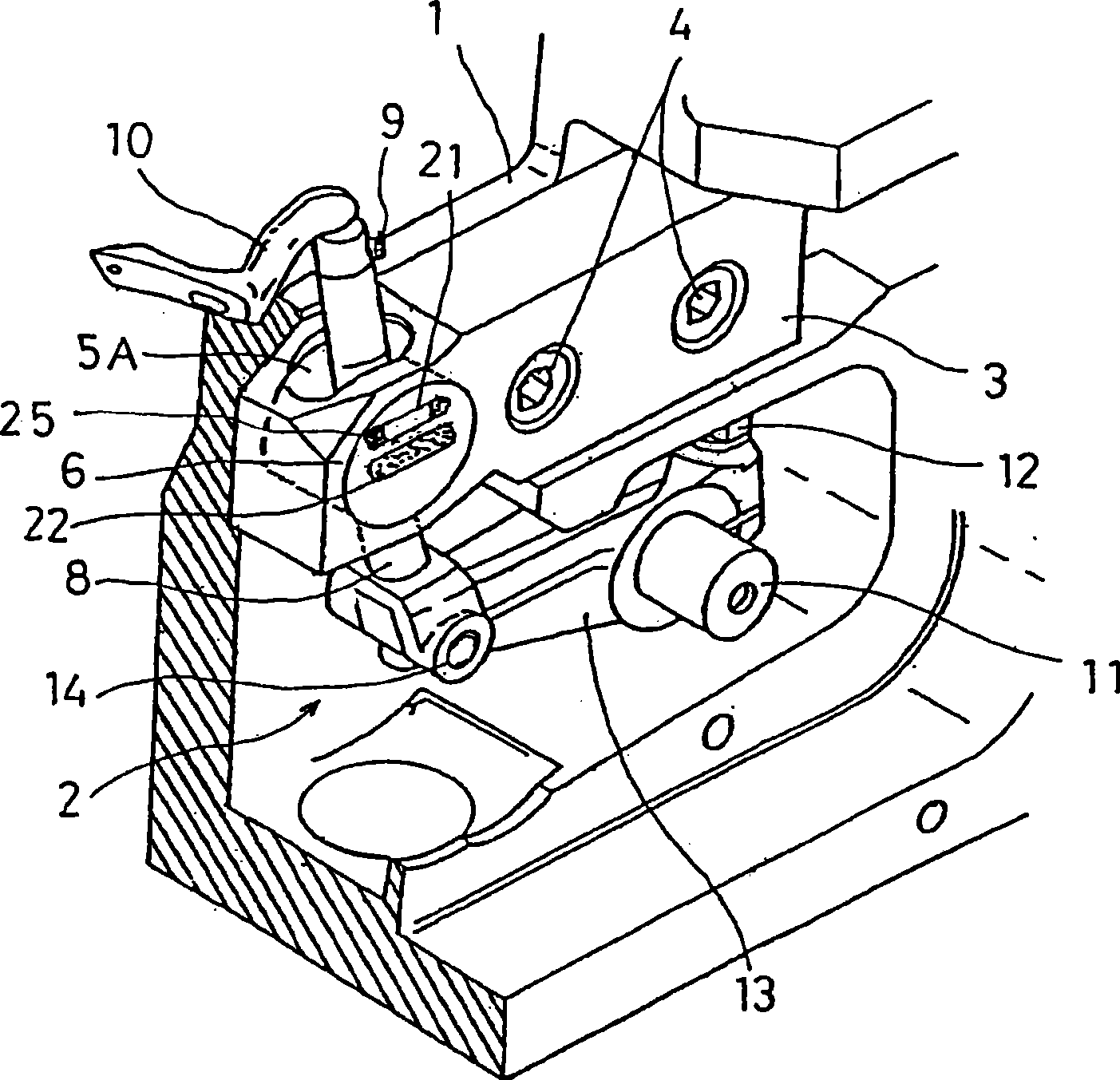

Anti-oil leakage device of top bend needle mechanism

InactiveCN101381933ALong-term and smooth maintenance of lifting motion effectSmoothly maintain the effect of lifting movementLubrication/cooling devicesLubrication elementsFree rotationEngineering

The invention relates to an oil leak preventing device for an upwards curved needle mechanism. A columned upwards curved needle guiding body capable of being freely and rotationally inserted and kept on a circular hole formed on an upwards curved needle guiding component is formed with an upper communicating slotted hole and a lower communicating slotted hole orthogonal with a communicating hole for sliding and lifting of an upwards curved needle table, an oil seal ring elastically and glidingly contacting the outer peripheral face of the upwards curved needle table and provided with a labial part for scraping lubricating oil is inserted in the upper communicating slotted hole, and an oil suction ring capable of sucking and keeping the scraped residual lubricating oil is inserted in the lower communicating slotted hole, therefore, the oil leak preventing device can reliably and favorably exert scraping function of the residual lubricating oil, can reliably prevent the scraped residual lubricating oil from being attached to the outer peripheral face of the upwards curved needle table again to disperse upwards, and can stably maintain the oil link preventing function for a long term.

Owner:YAMATO SEWING MASCH MFG CO LTD

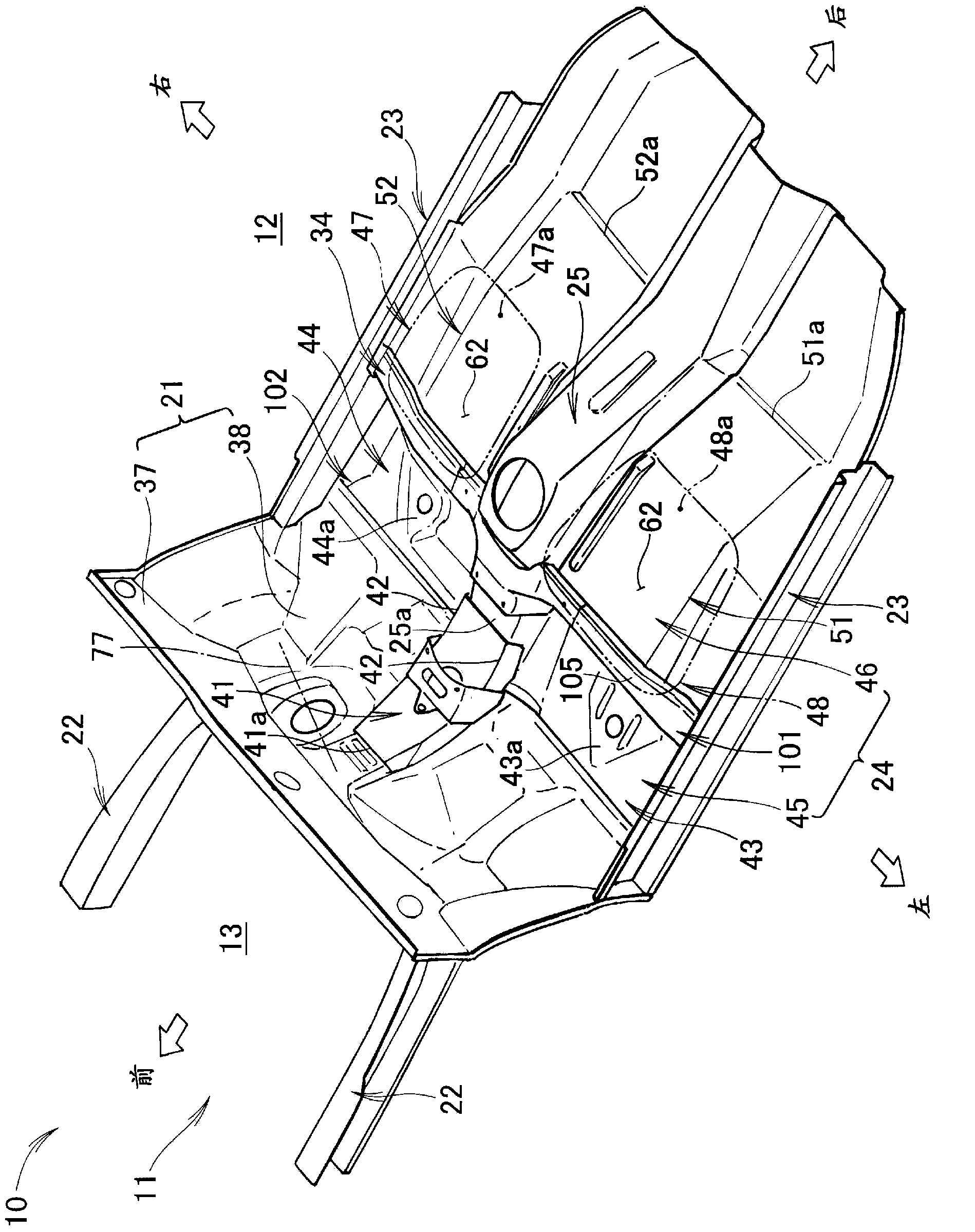

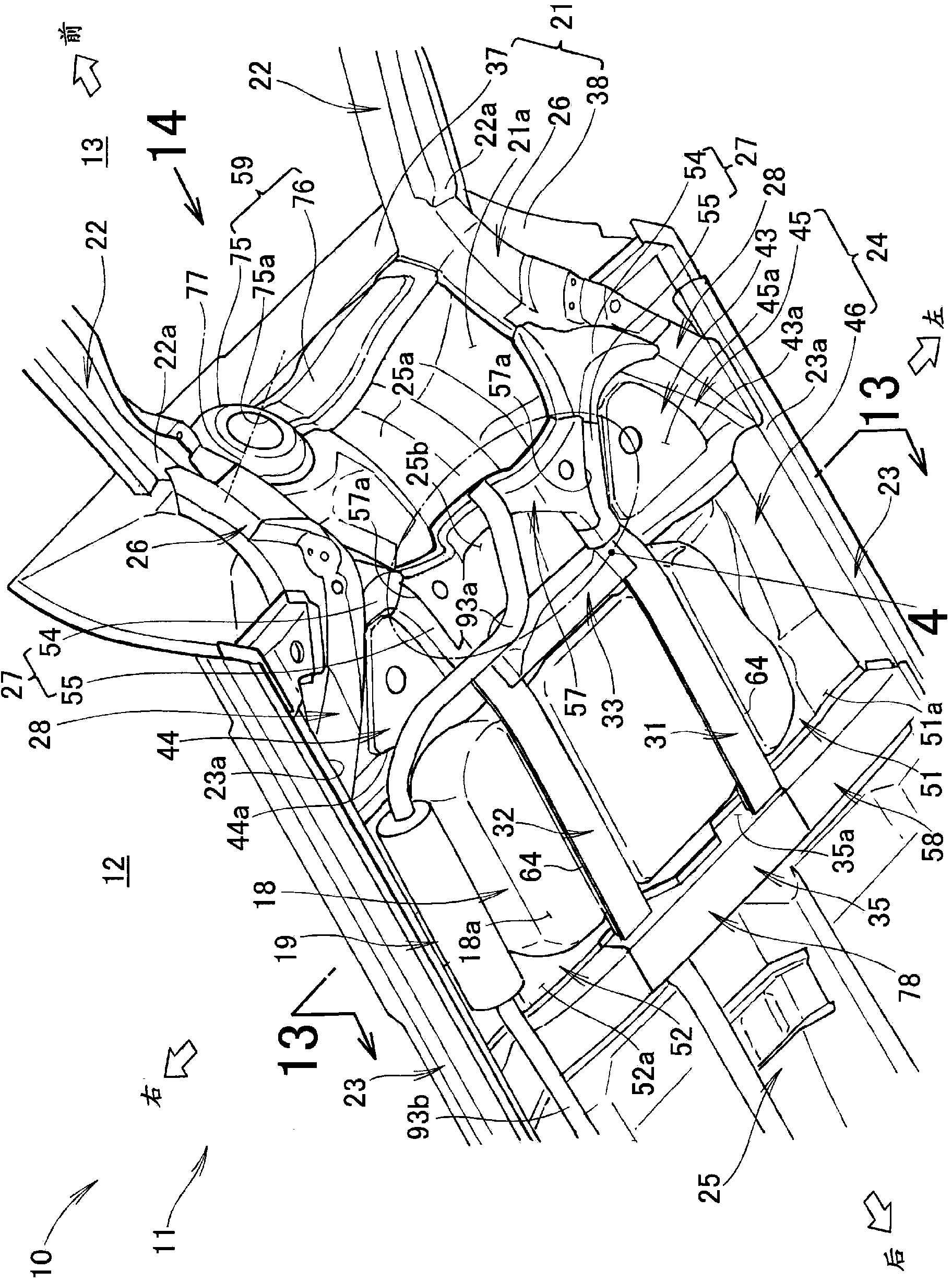

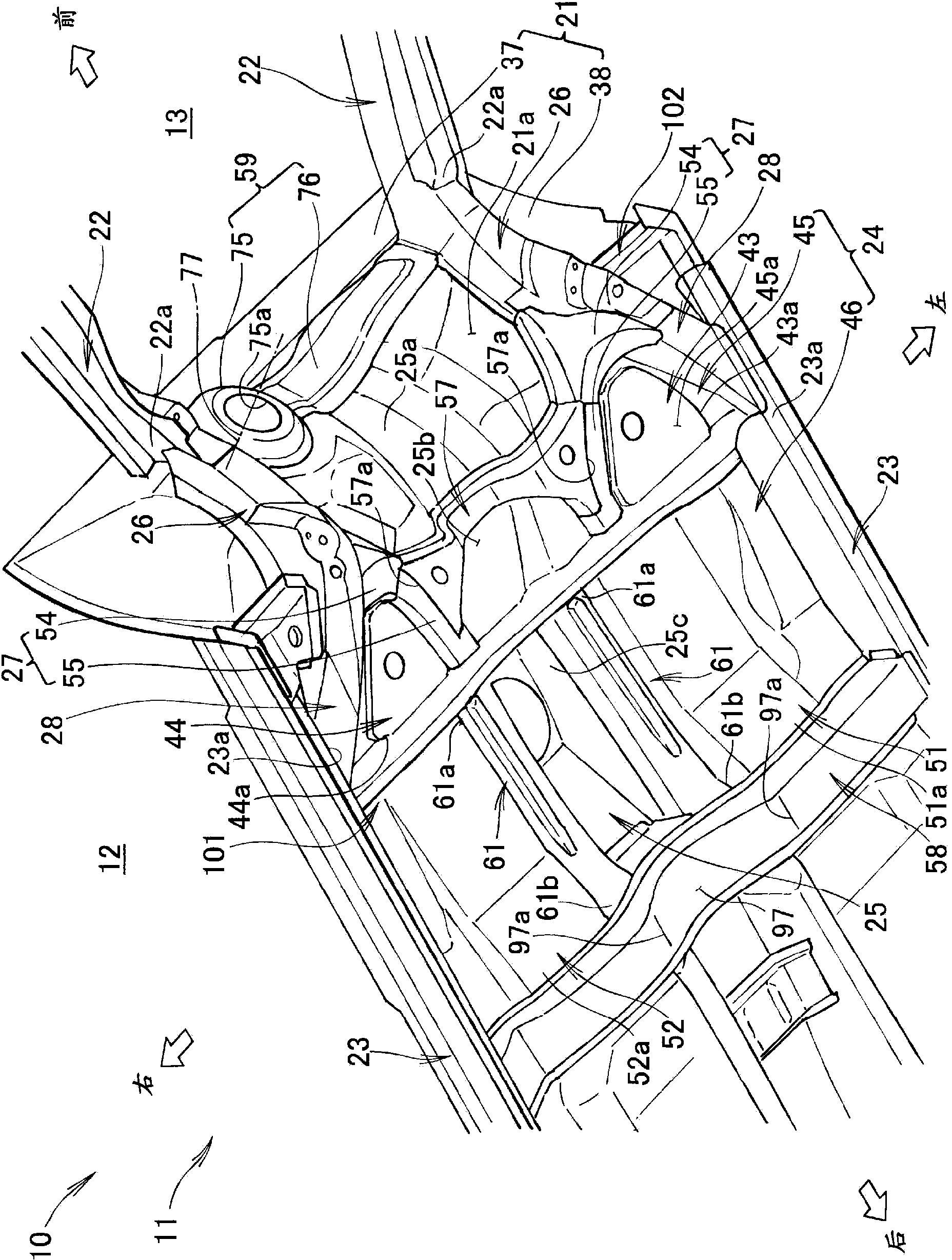

Vehicle body structure

ActiveCN103998273AFreely fixedImprove work efficiencyUnderstructuresVehicle sub-unit featuresDashboardVehicle frame

A floor panel (24) of a vehicle body (11) is provided with bulging sections (51, 52) in which seats (47, 48) are disposed to the left and right of a tunnel section (25), and a rear tunnel cross member (58) extending in the vehicle width direction at the rear ends (51a, 52a) of the bulging sections (51, 52). The vehicle body (11) is provided with left and right floor extensions (27, 27) set further toward the tunnel section (25) along a dashboard lower (21) relative to front side frames (22, 22), floor frames (31, 32) extending so as to span between the floor extensions (27, 27) and the rear tunnel cross member (58) and having a predetermined distance in the vehicle body vertical direction from a rear floor panel (46), and an energy container (18) placed below the bulging sections (51, 52) and supported on the floor frames (31, 32). The floor frames (31, 32) are fixed to the vehicle body (11) so as to be capable of being removed from below the vehicle body.

Owner:HONDA MOTOR CO LTD

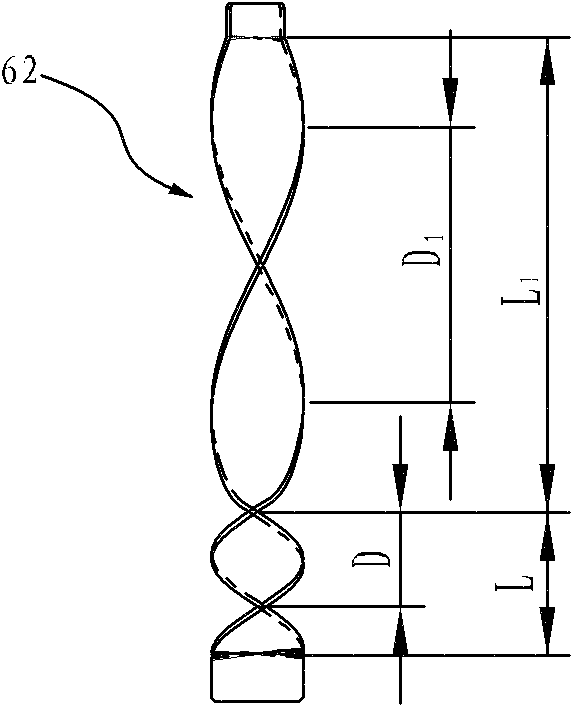

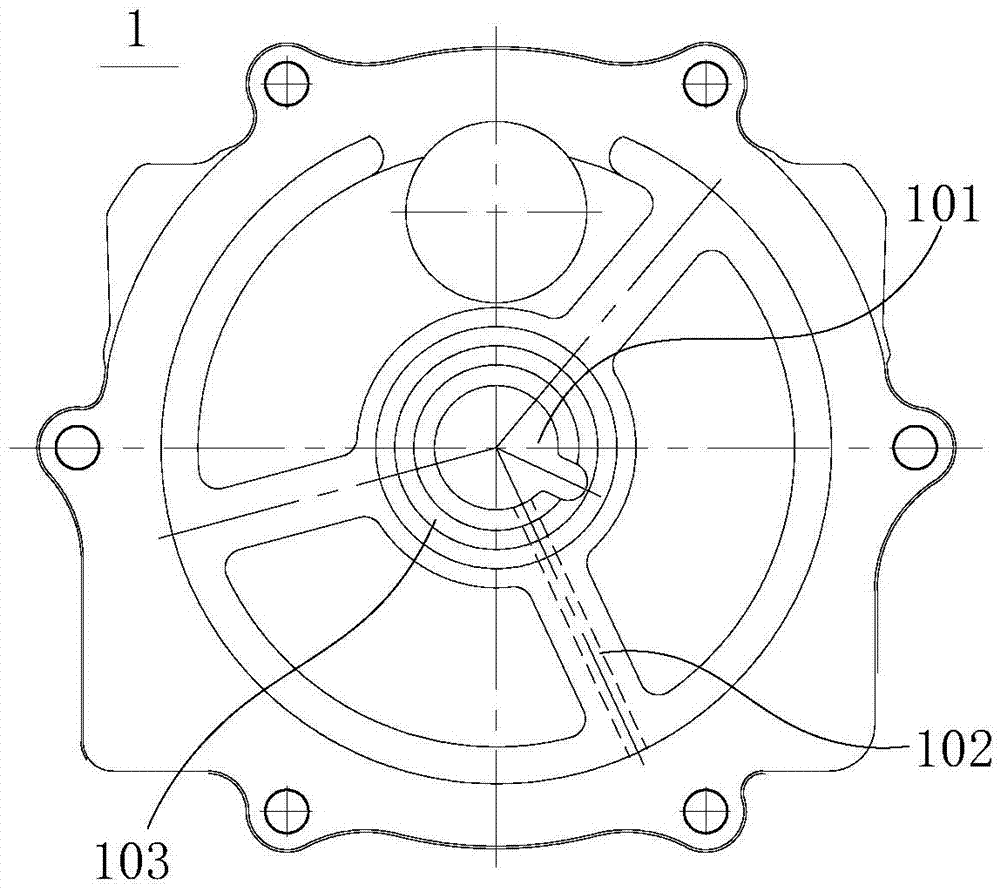

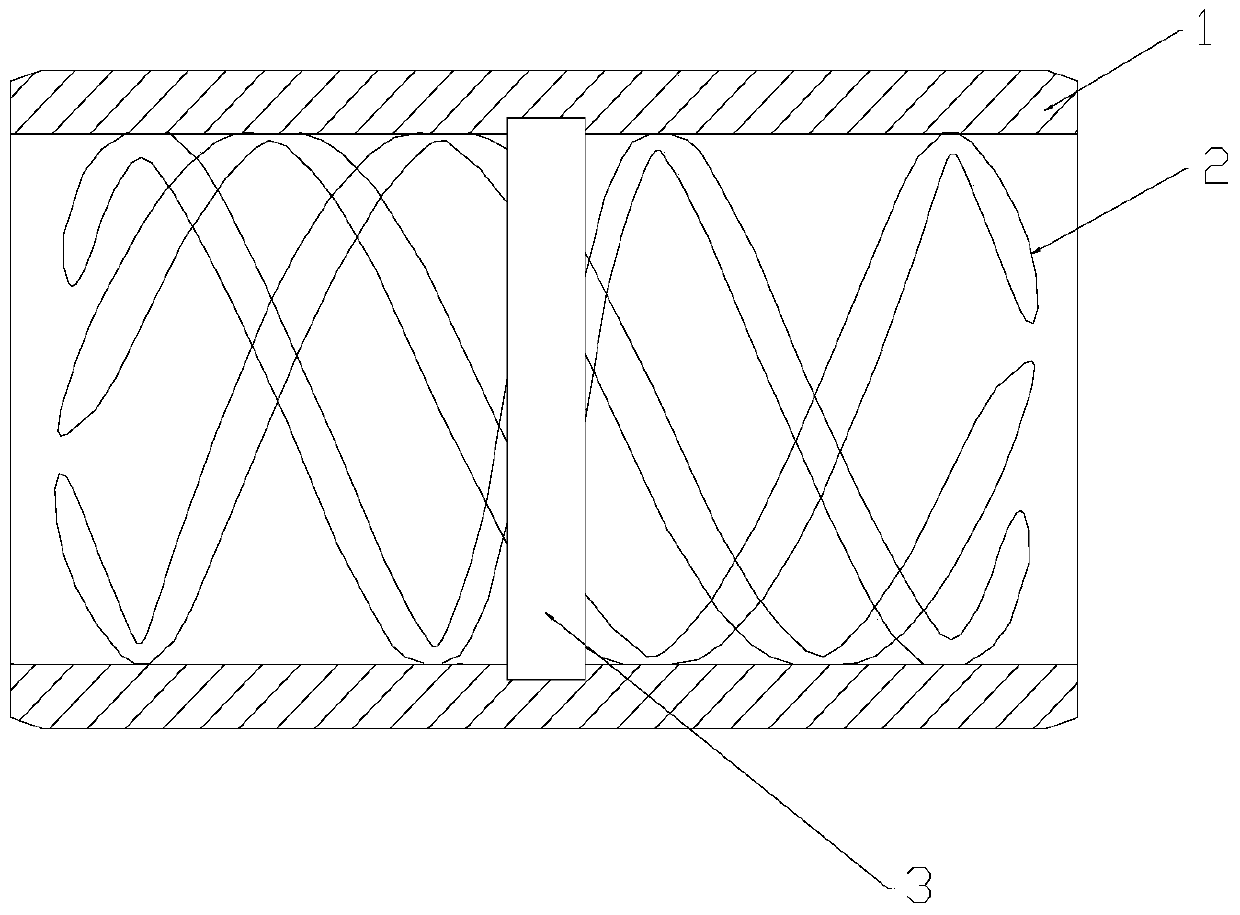

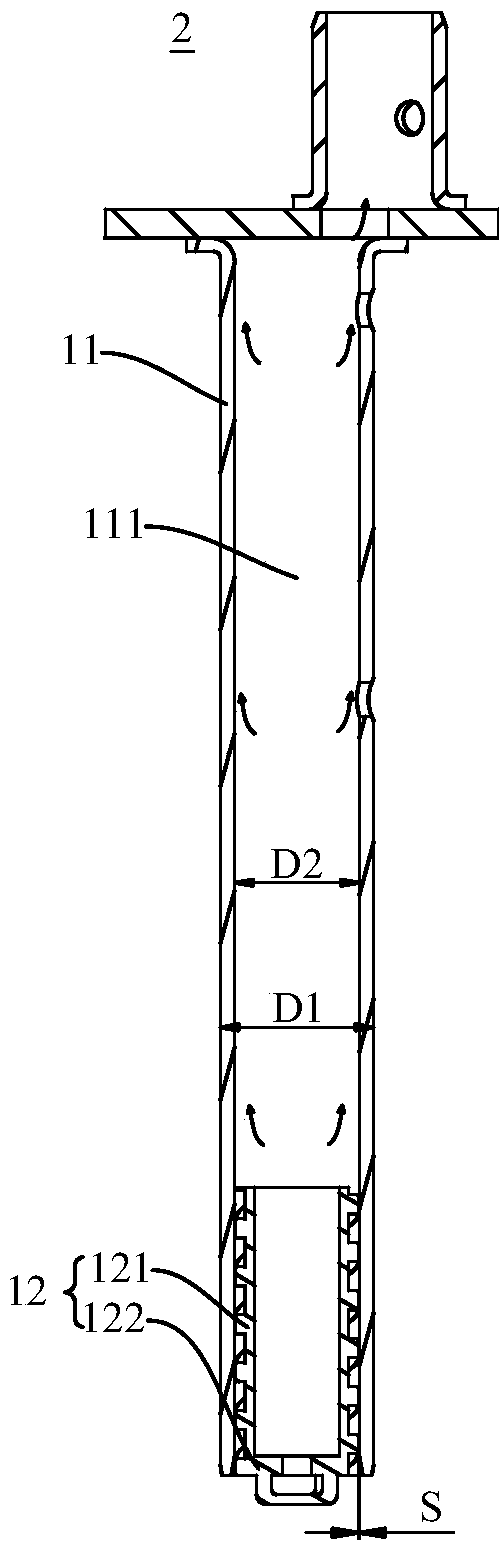

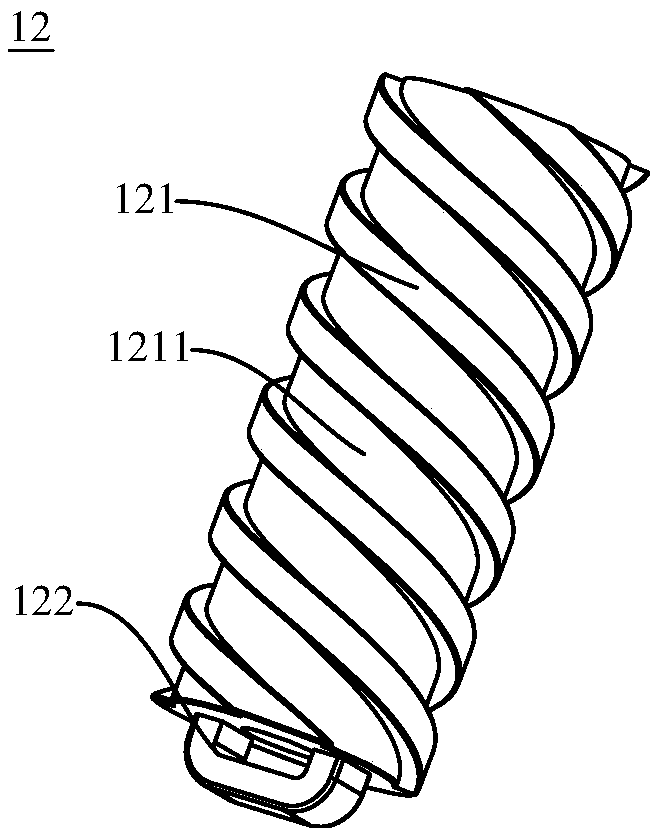

Rotary compressor with spiral oil guide sheet

ActiveCN102062100AGuaranteed reliabilityReduce formationRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorEngineering

The invention relates to the technical field of refrigeration compressors, in particular to a rotary compressor with a spiral oil guide sheet. In the rotary compressor, the lower end of the rotating shaft of a motor is connected to an inner bore oil duct of an oil bath; the inner bore oil duct is provided with the spiral oil guide sheet; the spiral thread pitch of the lower end of the spiral oil guide sheet is less than the thread pitch of the upper side of the spiral oil guide sheet; in the working process of the compressor, when the oil level of lubricating oil in the oil bath is lower, theoil guide sheet at the lower end of the spiral oil guide sheet which has smaller thread pitch is contacted with the lubricating oil in the oil bath, and the working angle of the oil guide sheet is large so as to contribute to increasing the oil supply and oil supply pressure; and in the process of delivering the lubricating oil upwards, the upper spiral sheet of the spiral oil guide sheet has larger thread pitch, so that the formation frequency of eddy of oil flow is reduced, oil supply resistance is reduced, the quantity of oil reaching an oil hole level is high, the quantity of oil enteringa compressor unit from an oil hole is higher, sufficient oil is supplied to the compression unit, and the reliability of the compressor is ensured.

Owner:GREE ELECTRIC APPLIANCES INC +2

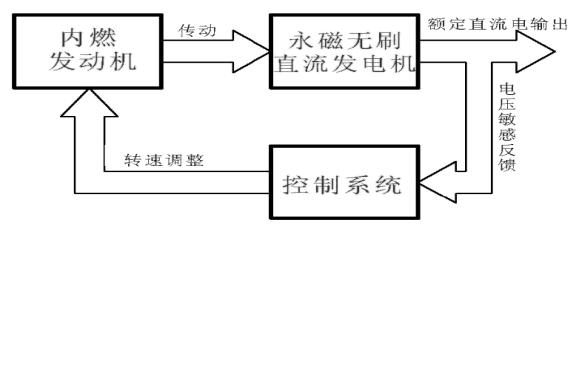

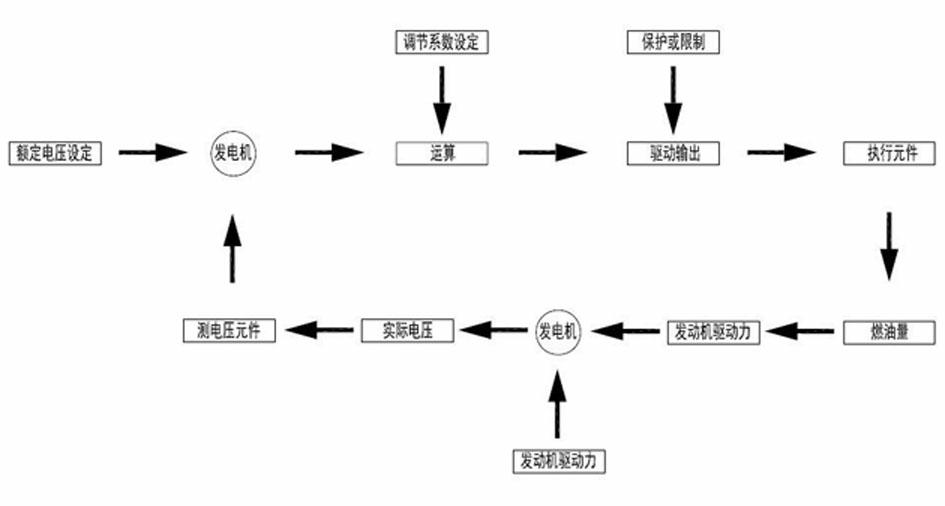

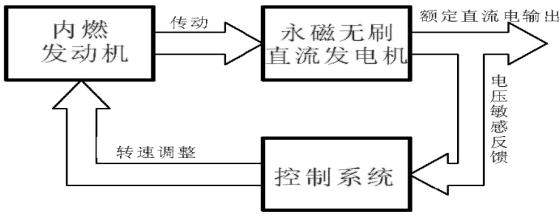

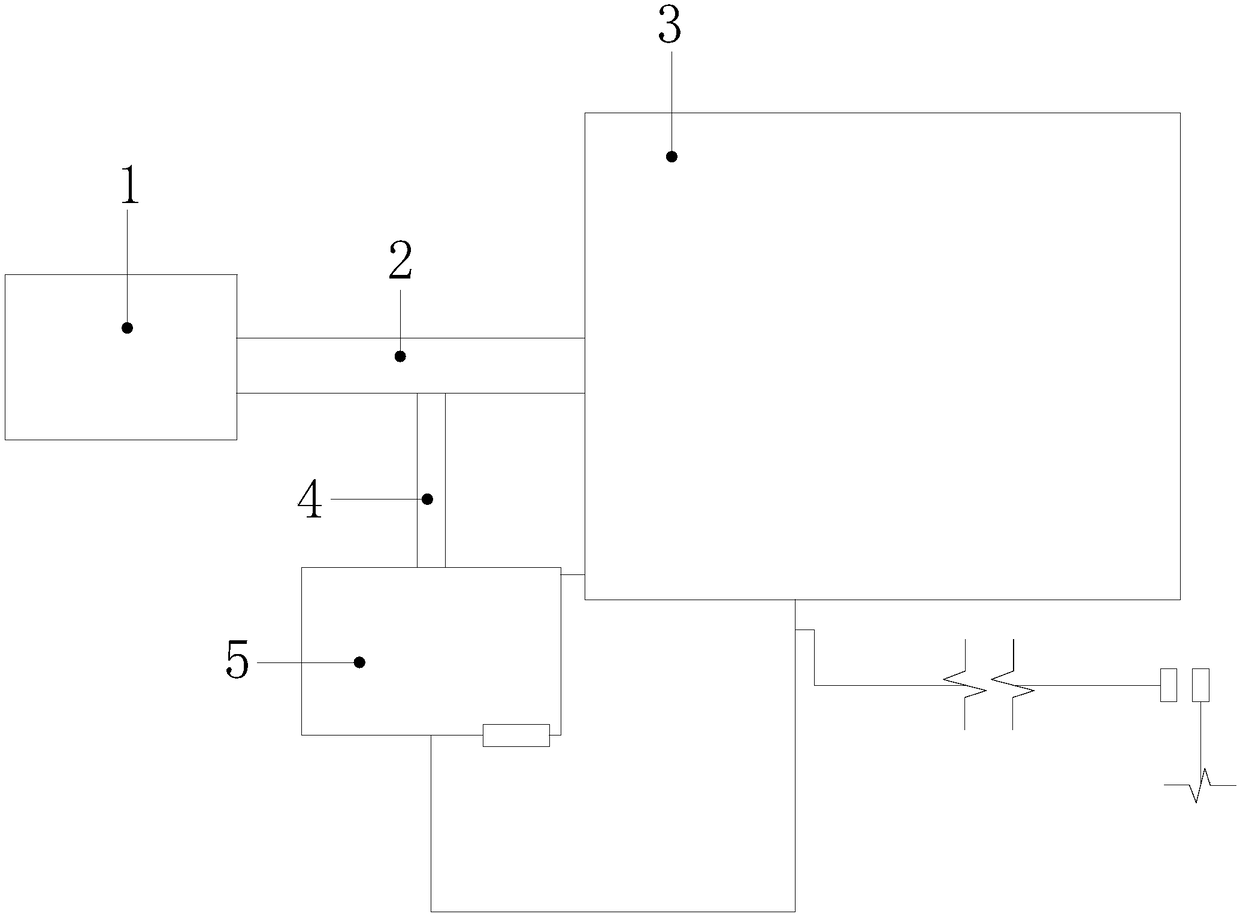

Method for maintaining voltage of direct current power generator set by speed adjustment

ActiveCN102434293AIncrease the output voltageConstant output voltageEngine controllersMachines/enginesControl systemInternal combustion engine

The invention discloses a method for maintaining voltage of a direct current power generator set by speed adjustment. When an electric load is increased, output voltage of the direct current power generator set is linearly reduced, and a control system correspondingly adjusts an accelerator electromagnetic performer in an internal combustion engine according to voltage sensitive feedback information to increase fuel supply quantity to increase rotation speed of the internal combustion engine to increase the output voltage of the direct current power generator set so as to ensure the constant output voltage of the direct current power generator set, and vice versa, namely, the rotation speed of the internal combustion engine is adjusted repeatedly to realize the voltage maintaining effect. Because the control system correspondingly adjusts the accelerator electromagnetic performer in the internal combustion engine according to the voltage sensitive feedback information to increase the fuel supply quantity to increase the rotation speed of the internal combustion engine to increase the output voltage of the direct current power generator set so as to ensure the constant output voltage of the direct current power generator set, and vice versa, the voltage maintaining effect can be realized by adjusting the rotation speed of the internal combustion engine repeatedly.

Owner:FEIERTE ENERGY DONGGUAN CO LTD

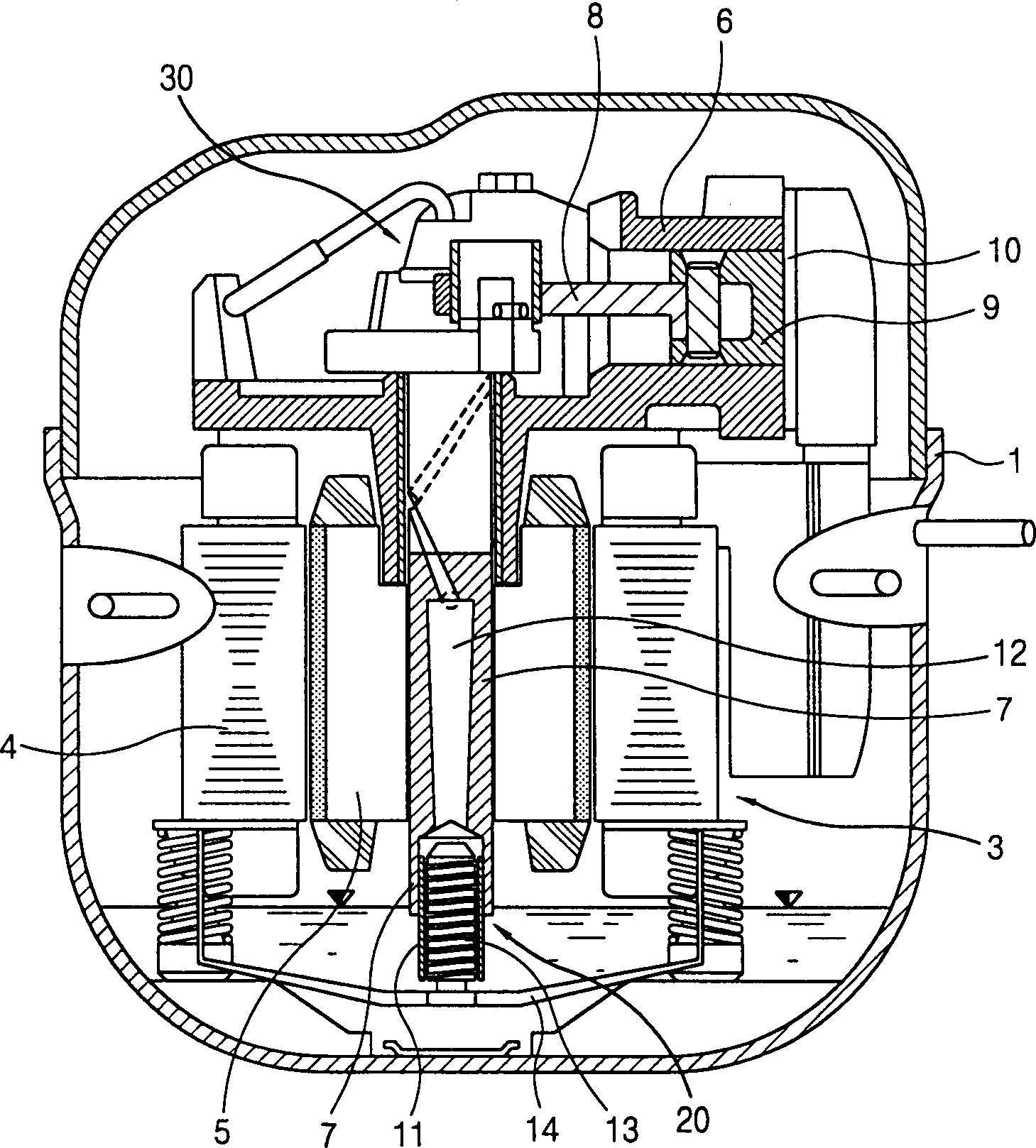

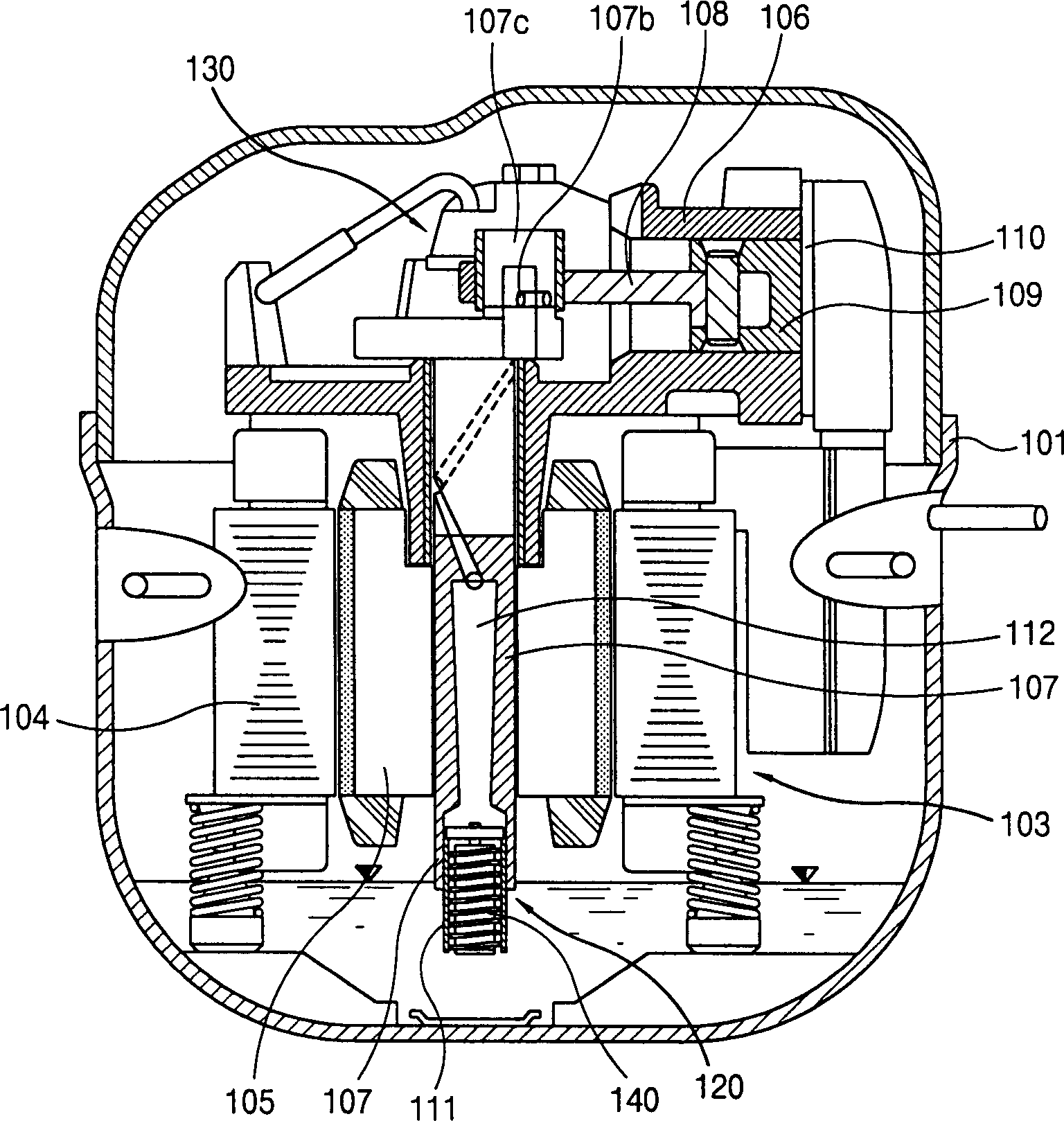

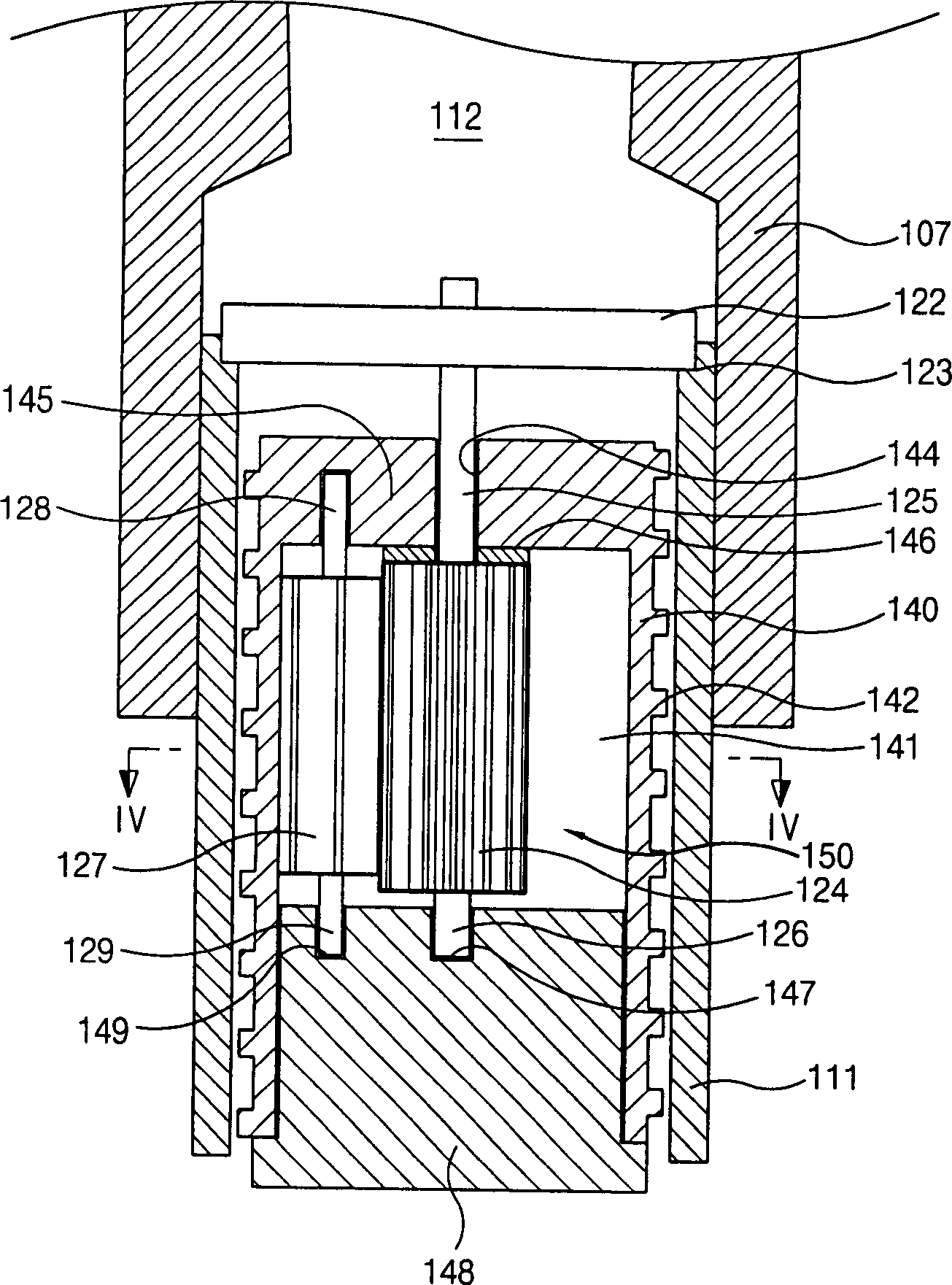

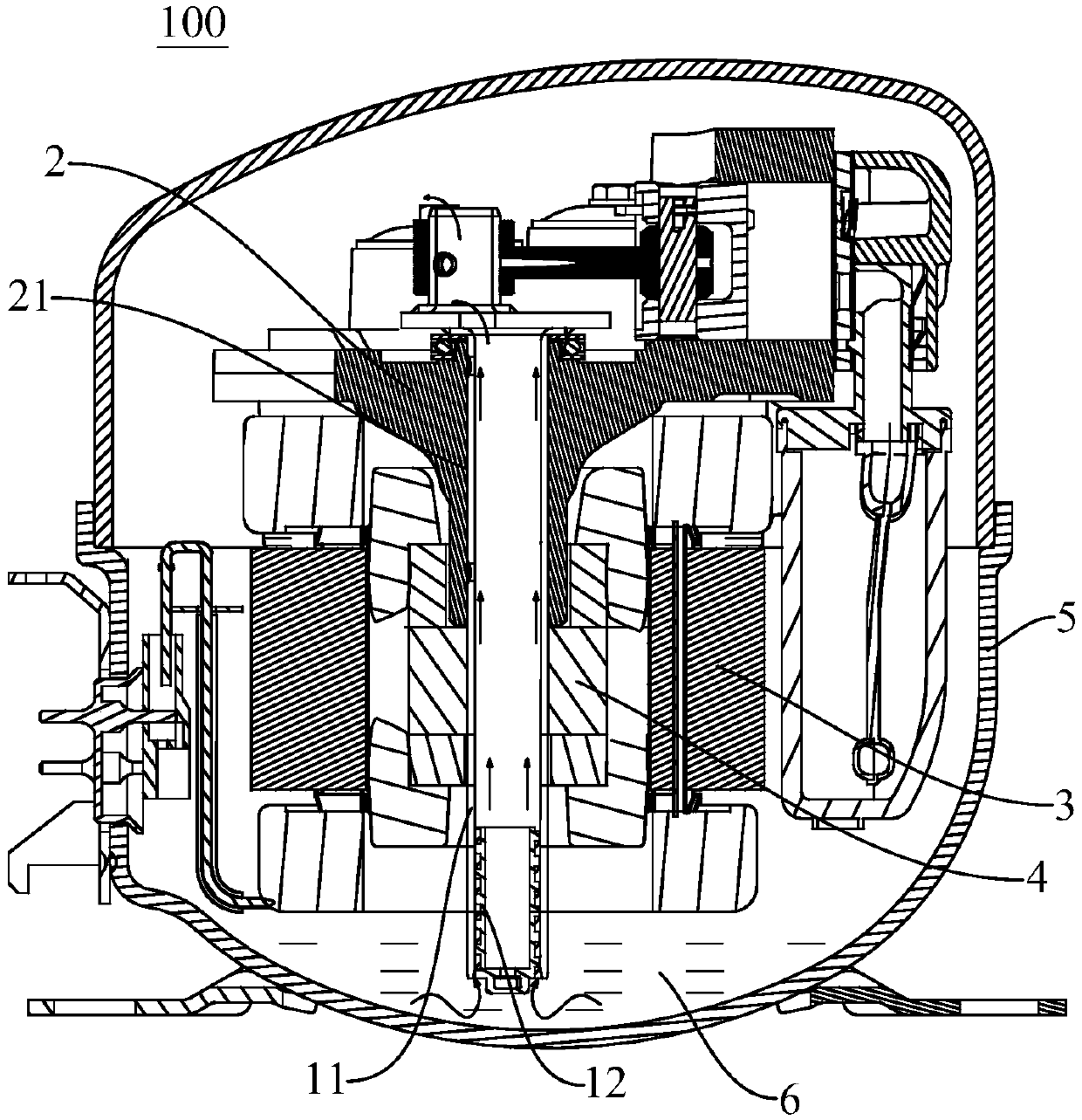

Oil supply device for hermetically sealed compressor

InactiveCN1386981AImprove oil supply capacityImprove performancePositive displacement pump componentsPiston pumpsRotation velocityCrankshaft

An oil supply device for a hermetic compressor, which comprises: a crankshaft connected with the motor rotor so as to rotate together with it and having a lubricating oil passage inside; a sleeve connected with the lower part of the crankshaft for It is integrated with the crankshaft and rotates together; an oil-absorbing member arranged to maintain a uniform interval with the inner peripheral surface of the above-mentioned sleeve, which rotates in the direction opposite to the rotation direction of the sleeve to complete the oil-absorbing work; and an oil-absorbing member for supporting the above-mentioned oil-absorbing member The rotation force transmission device of the component is used to make the oil-absorbing component rotate together with the sleeve, and the device receives the rotational force from the sleeve so that the oil-absorbing component rotates in the direction opposite to the direction in which the sleeve rotates. The increased relative rotational speed between the sleeve and the oil absorbing member increases the amount of oil supplied to the sliding parts and friction parts, thereby improving the lubricating performance of the compressor. When the compressor vibrates, the oil-absorbing member and the sleeve vibrate with the same amplitude, so that the gap between the sleeve and the oil-absorbing member can be kept uniform. Therefore, the present invention can improve the reliability of oil supply.

Owner:LG ELECTRONICS INC

Horizontal vortex compressor

ActiveCN107013462AReliable lubrication and oil supplyIncrease fuel supplyRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringMechanical engineering

The invention provides a horizontal vortex compressor. The horizontal vortex compressor comprises a front shell, a back shell, a hollow shell, a motor, an eccentric crankshaft, an oil pump rotor, a through oil pump shaft, a compressed vortex disc, a main bearing and an auxiliary bearing; the back shell corresponds to the front shell, an oil pump stator and a bearing support are integrated with the back shell; the hollow shell is connected with the front shell and the back shell; the eccentric crankshaft is connected to a rotor of the motor so as to transmit rotating force and comprises a long shaft portion, an eccentric pin hole is formed in the first end of the long shaft portion, an eccentric pin is arranged at the second end of the long shaft portion, and an oil hole is formed in the eccentric crankshaft and penetrates through the eccentric crankshaft in the length direction of the eccentric crankshaft; the oil pump rotor is matched with the oil pump stator to form an oil pump; the two ends of the through oil pump shaft are sleeved with the oil pump rotor and the eccentric pin hole of the long shaft portion respectively; the motor, the oil pump and the auxiliary bearing are all arranged on the low-pressure side of the horizontal vortex compressor for an automobile. According to the horizontal vortex compressor, the requirement that the size of the compressor is small can be met, and the lubricating effect can be enhanced.

Owner:SHANGHAI HIGHLY NEW ENERGY TECH CO LTD

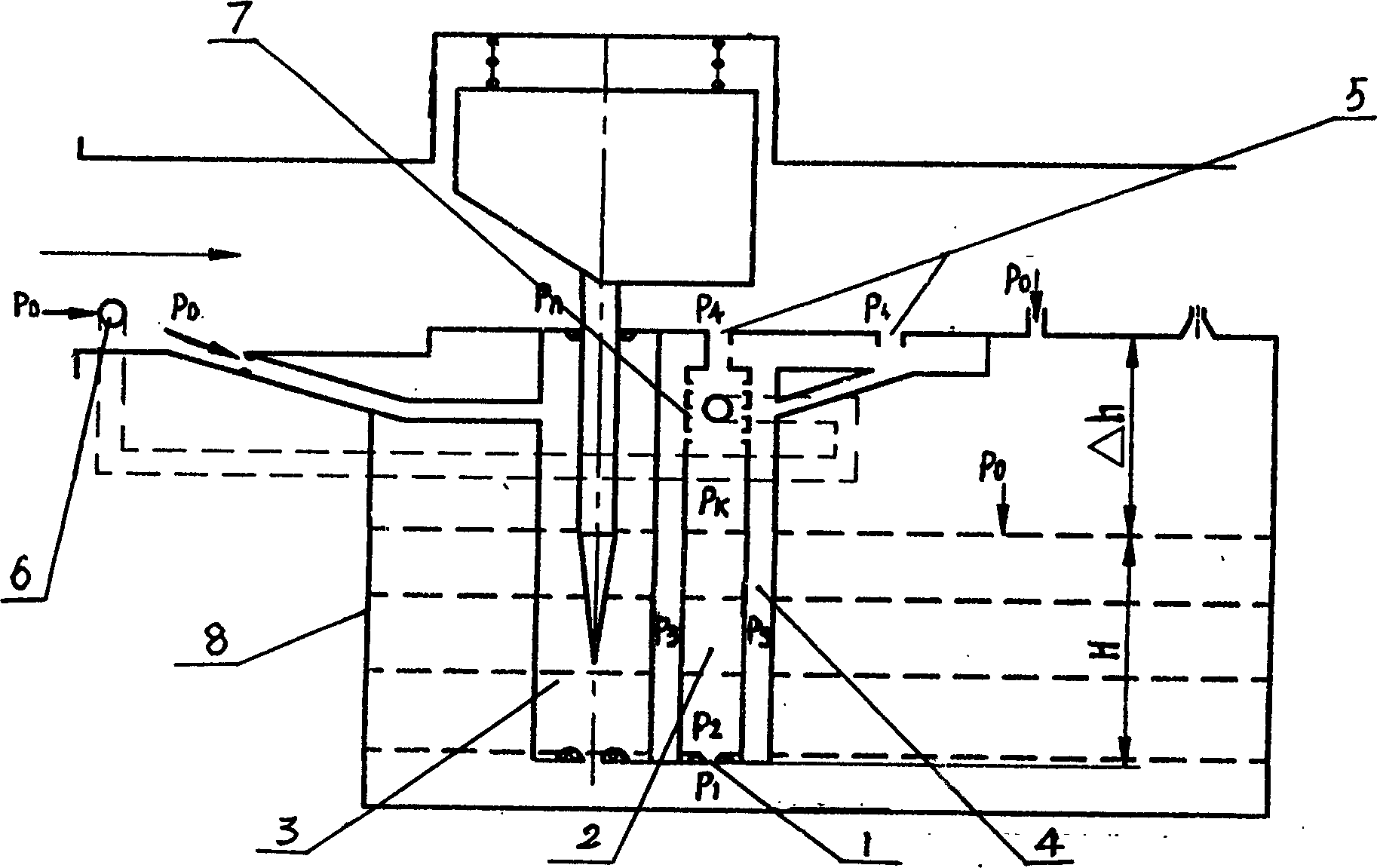

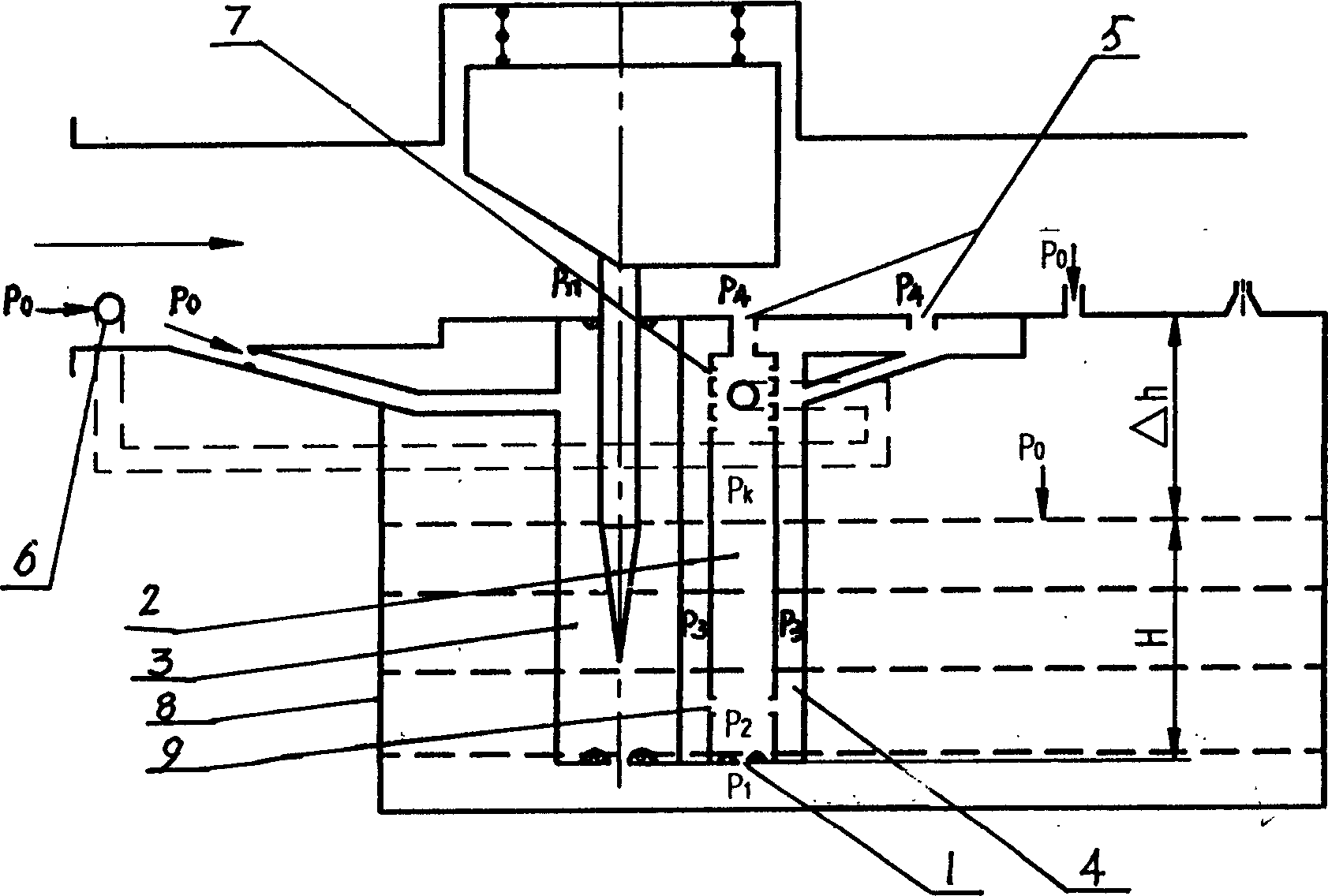

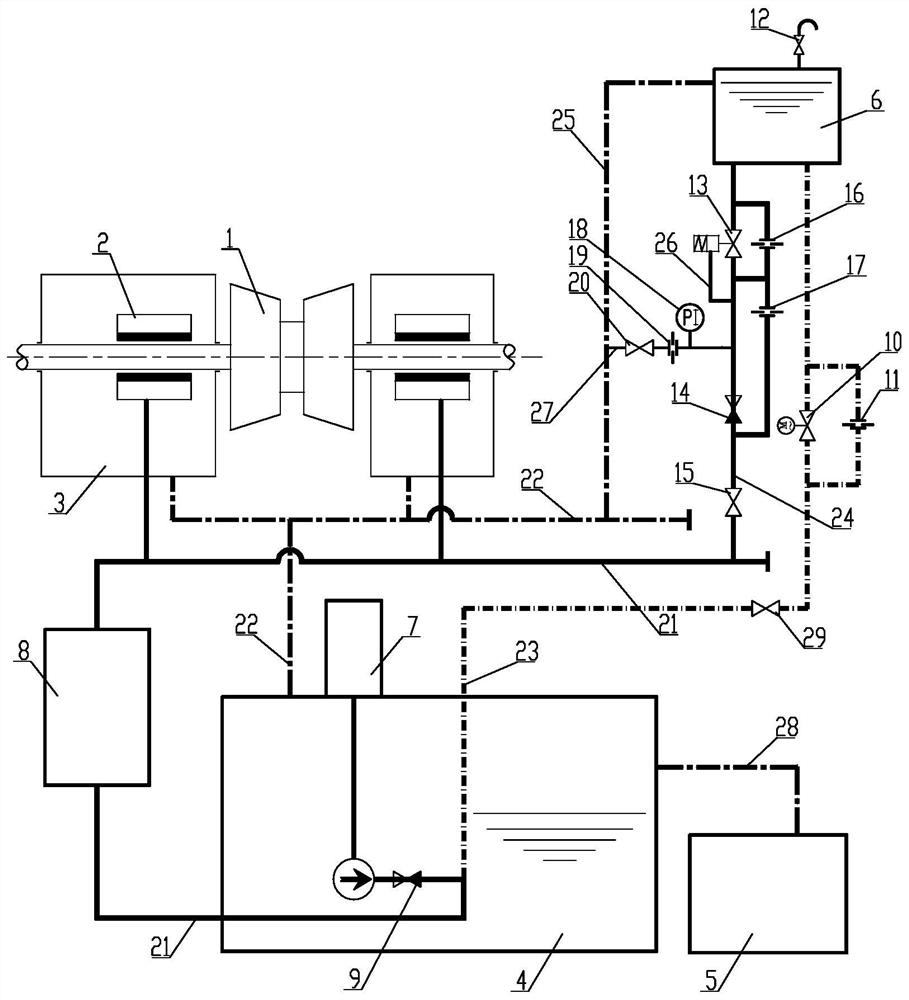

Steam turbine lubricating oil high-level oil tank system

ActiveCN113153460AReduce layout requirementsReduce capacity requirementsMachines/enginesEngine componentsProcess engineeringOil temperature

The invention discloses a steam turbine lubricating oil high-level oil tank system. The steam turbine lubricating oil high-level oil tank system comprises a main oil tank, an oil pump, an oil supply pipeline, a bearing box and an oil return pipeline which sequentially communicate with each other according to a lubricating oil circulation sequence, the oil supply pipeline communicates with an oil cooler and communicates with an oil charging pipeline, the oil charging pipeline communicates with a high-level oil tank, and a high-level oil supply pipeline communicates between the high-level oil tank and the bearing box. The steam turbine lubricating oil high-level oil tank system has the beneficial effects that an existing system does not depend on an electrical system, can automatically and stably control the oil supply pressure, only has the requirement for the lowest arrangement height of the oil tank, has no requirement for the structural form, can maintain the oil temperature and the oil level of the high-level oil tank, and has an online testing function. According to the steam turbine lubricating oil high-level oil tank system, the volume of the high-level oil tank can be effectively reduced, the arrangement requirement of the high-level oil tank is lowered, regular tests can be carried out, the safety of a unit lubricating oil system is enhanced, and oil cut-off and bush burning accidents are avoided.

Owner:DONGFANG TURBINE CO LTD

Engine body delayed oil supply lubricating system

The invention relates to an engine lubricating system, in particular to an engine body delayed oil supply lubricating system. The engine body delayed oil supply lubricating system comprises a main journal, an upper bearing bush, a lower bearing bush, a journal oil duct and an engine body; an engine body oil storage tank is formed in a bearing seat; a lower oil storage tank is downwards formed in the inner circumference of the lower bearing bush from the parting surface of the lower bearing bush and the upper bearing bush; and the tail ends of the lower oil storage tank and an upper oil storagetank are communicated. The engine body oil storage tank is additionally arranged in a bearing seat hole in the engine body, so that pressure attenuation is delayed; and oil tanks are formed in the left parting surface and the right parting surface of the lower bearing bush, so that the oil supply duration angle is increased, and bush burning faults are reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

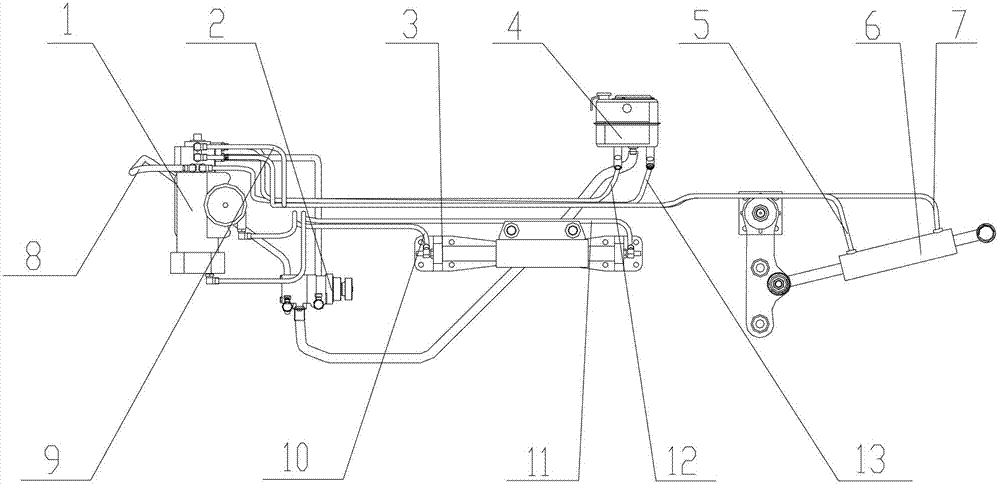

Steering pump, steering device, steering system and automobile

The invention provides a steering pump. The steering pump is provided with a steering pump oil inlet and two steering pump oil outlets, wherein the steering pump oil inlet is connected with an oil tank, and the two steering pump oil outlets are connected with a steering device. The invention further provides the steering device comprising two steering device oil inlets, two steering device oil outlets and two boosting cylinder connectors, wherein the two steering device oil inlets are used for connecting with the steering pump, the two steering device oil outlets are connected with the oil tank, and the two boosting cylinder connectors are used for connecting with boosting cylinders. A rotary valve used for controlling oilway flow direction is arranged on the steering device. In addition, the invention provides a steering system comprising the steering device, the steering pump, the oil tank, the first boosting cylinder and the second boosting cylinder. The steering system solves the problem that the automobile is heavy in turning and slow-moving in steering. Finally, the invention provides the automobile comprising the steering system.

Owner:SANY AUTOMOBILE MFG CO LTD

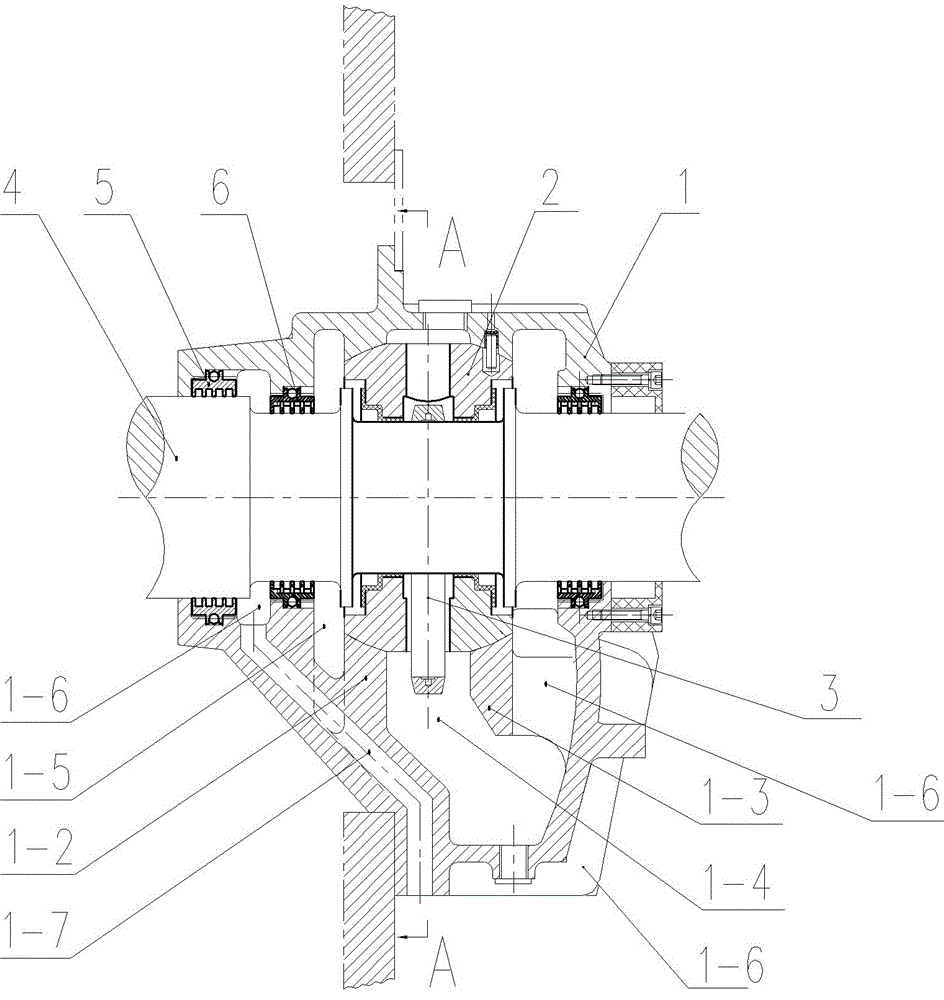

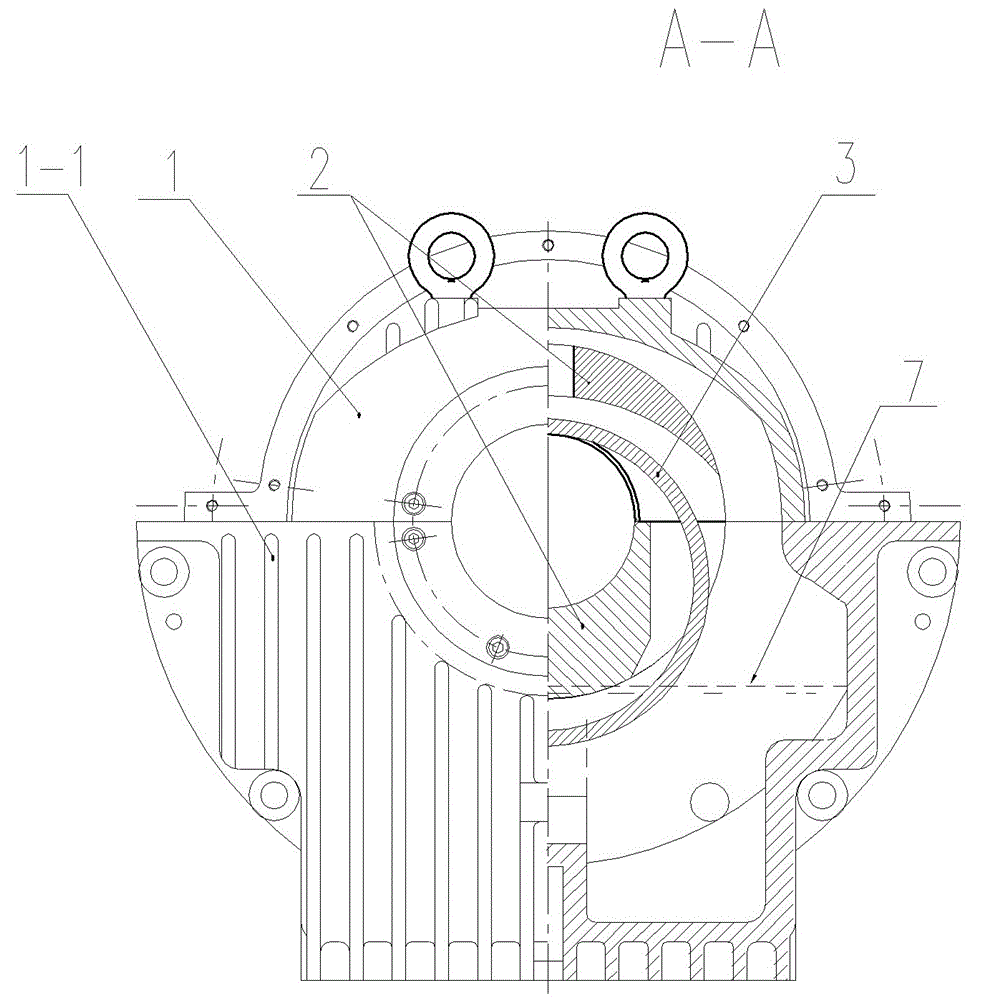

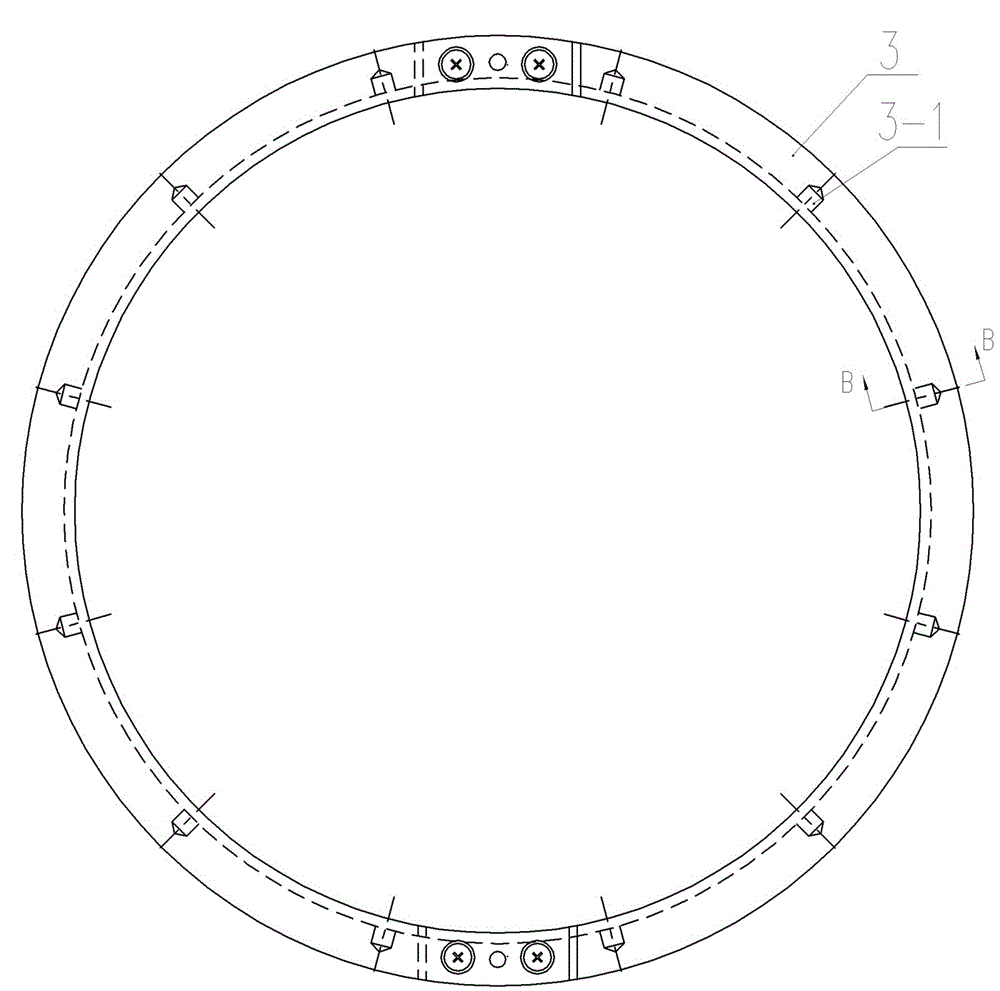

Self-lubricating sliding bearing for high-speed large-power motor

ActiveCN102983663AIncrease fuel supplyReduce the temperatureSupports/enclosures/casingsAir bearingSlider bearing

The invention discloses a self-lubricating sliding bearing for a high-speed large-power motor. A bearing box adopts a D-shaped large oil cavity structure; and cooling fins are cast at the periphery of the oil cavity. The structure inside the bearing box can avoid the situation that the high-temperature lubricating oil leaked from the inner end and the outer end of a bearing bush is directly introduced to a lubricating clearance between a shaft and the bearing bush by an oil ring, and ensure that the lubricating oil supplied by the oil ring to the bearing bush is efficiently-cooled low-temperature lubricating oil, so as to reduce the temperature of the bearing. The improved structure of the oil ring can enlarge the amount of the bearing lubricating oil, enhance the lubrication of the bearing bush, and reduce the friction loss of the bearing bush. An air passage is cast in the bearing box to compensate air that is sucked by the local part of the bearing box by the air outside the bearing box. A cavity inside the bearing box is partially sealed, so that the partial negative pressure that is naturally formed when the gas is expanded isothermally and by the equal volume can counteract the negative pressure inside the motor, which ensures that the sliding bearing is free from the leakage hidden trouble. The sliding bearing has the advantages of reasonable structure and design, strong bearing radiating capability, reliability in lubrication, good sealing performance and the like.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

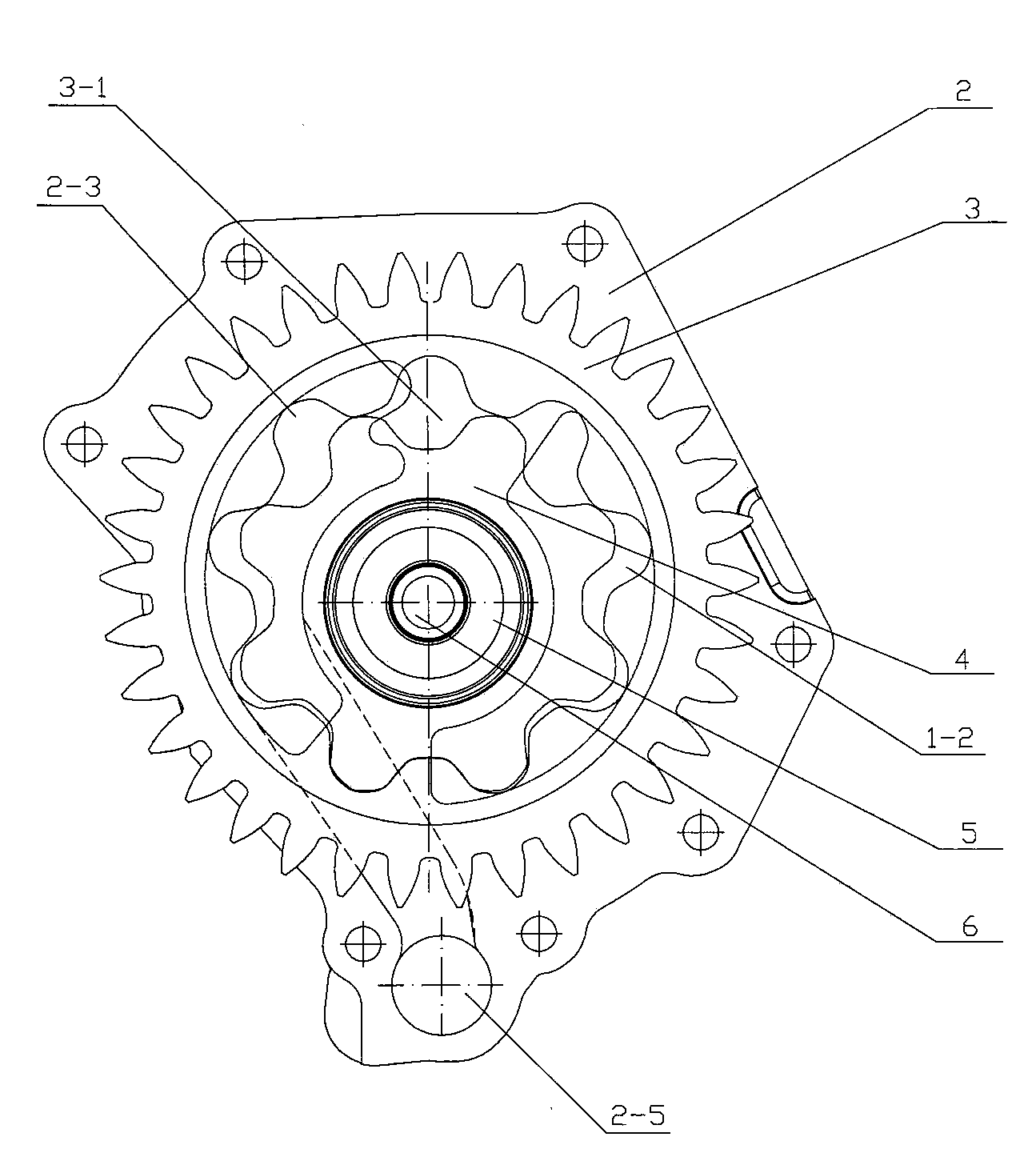

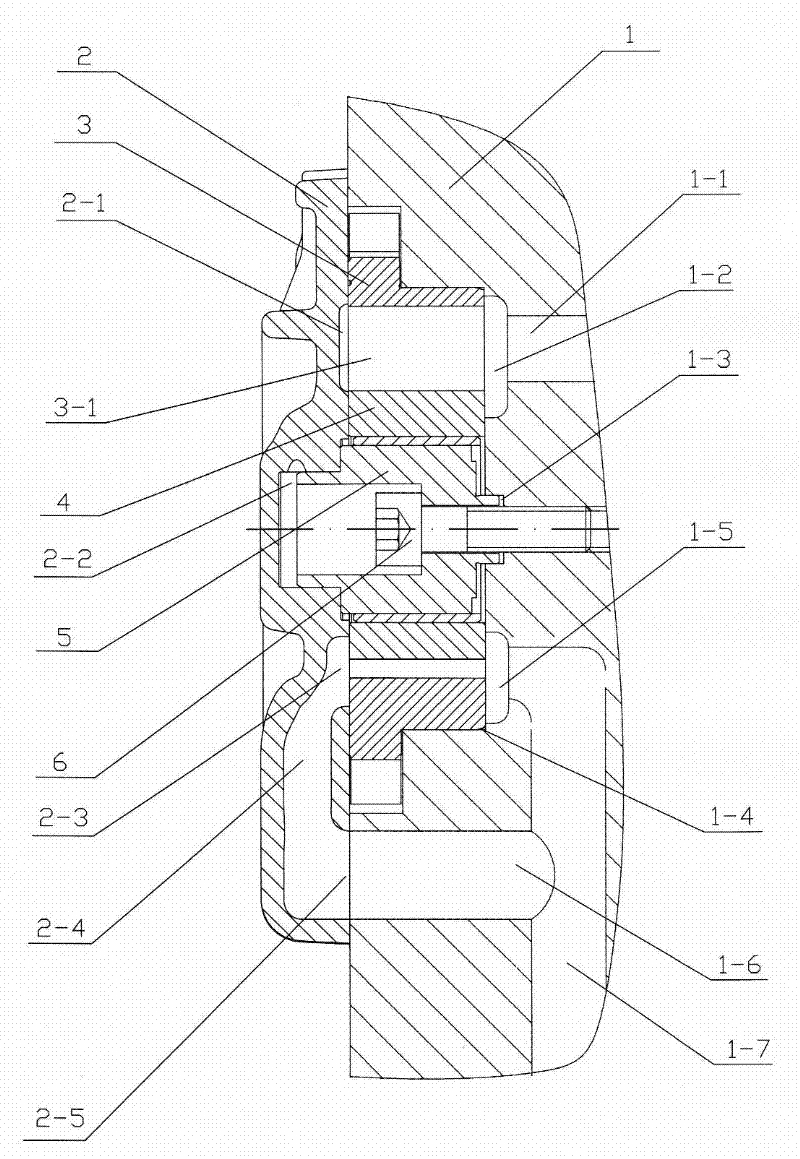

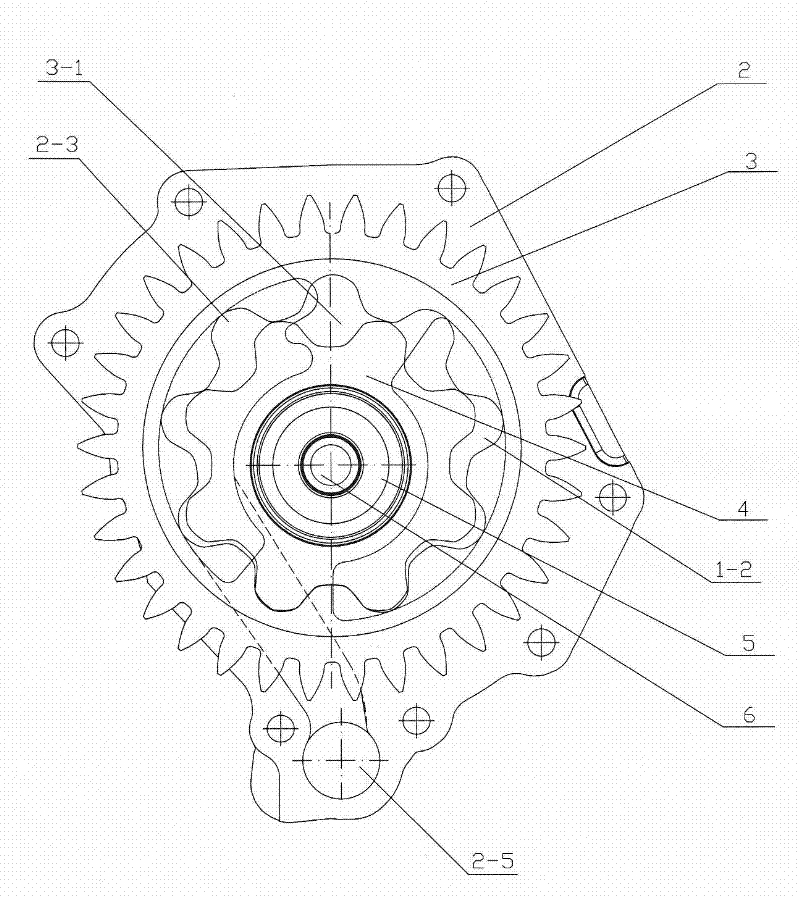

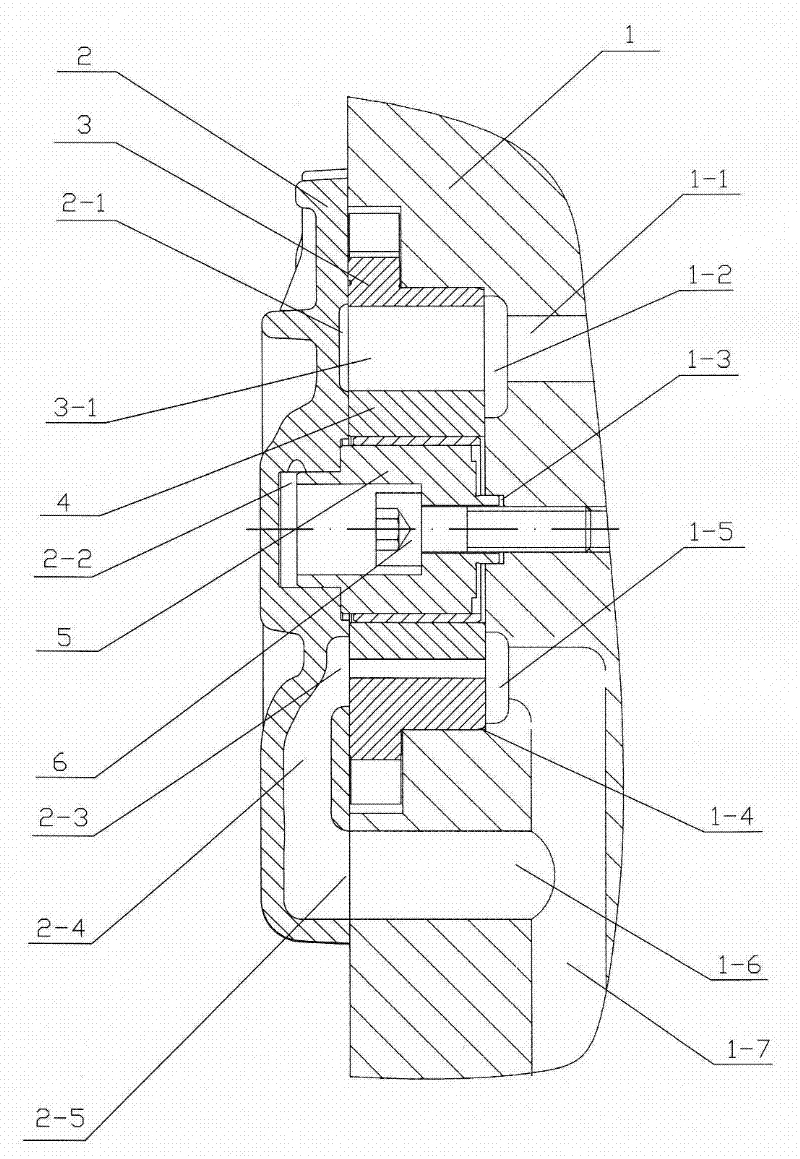

Outer rotor gear driven lubricating oil pump

ActiveCN102200215BImprove transmission efficiencyReduce weightLubricating pumpsPressure lubrication with lubrication pumpGear driveGear wheel

The invention discloses an outer rotor gear driven lubricating oil pump, which comprises a body pump body, a pump cover, an outer rotor gear, an inner rotor, a boss pump shaft and an inner hexagon screw, wherein the bottom surface of a rotor hole of the body pump body is provided with an oil inlet passage, an oil inlet cavity, an oil outlet cavity, an oil outlet hole and an oil path hole; the plane of the pump cover is provided with an oil inlet cavity, a tunnel type oil passage, an oil inlet and an oil outlet cavity; the boss pump shaft is arranged on the bottom surface of the rotor hole at the front end of the body pump body by using the inner hexagon screw; a cylindrical small boss on the boss pump shaft is matched with an axle hole on the bottom surface of the rotor hole at the front end of the body pump body; the outer rotor gear is arranged in a rotor hole at the front end of the body pump body; the inner rotor is arranged on the boss pump shaft in a movable fit mode and is engaged with inner teeth of the outer rotor gear; the pump cover is arranged on a shell of the body pump body through bolts; and a cylindrical large boss on the boss pump shaft is matched with the axle hole on the pump cover. After the pump cover is arranged on the shell of the body pump body, flexibility of rotation of the inner rotor and the outer rotor gear can be guaranteed.

Owner:HUNAN OIL PUMP

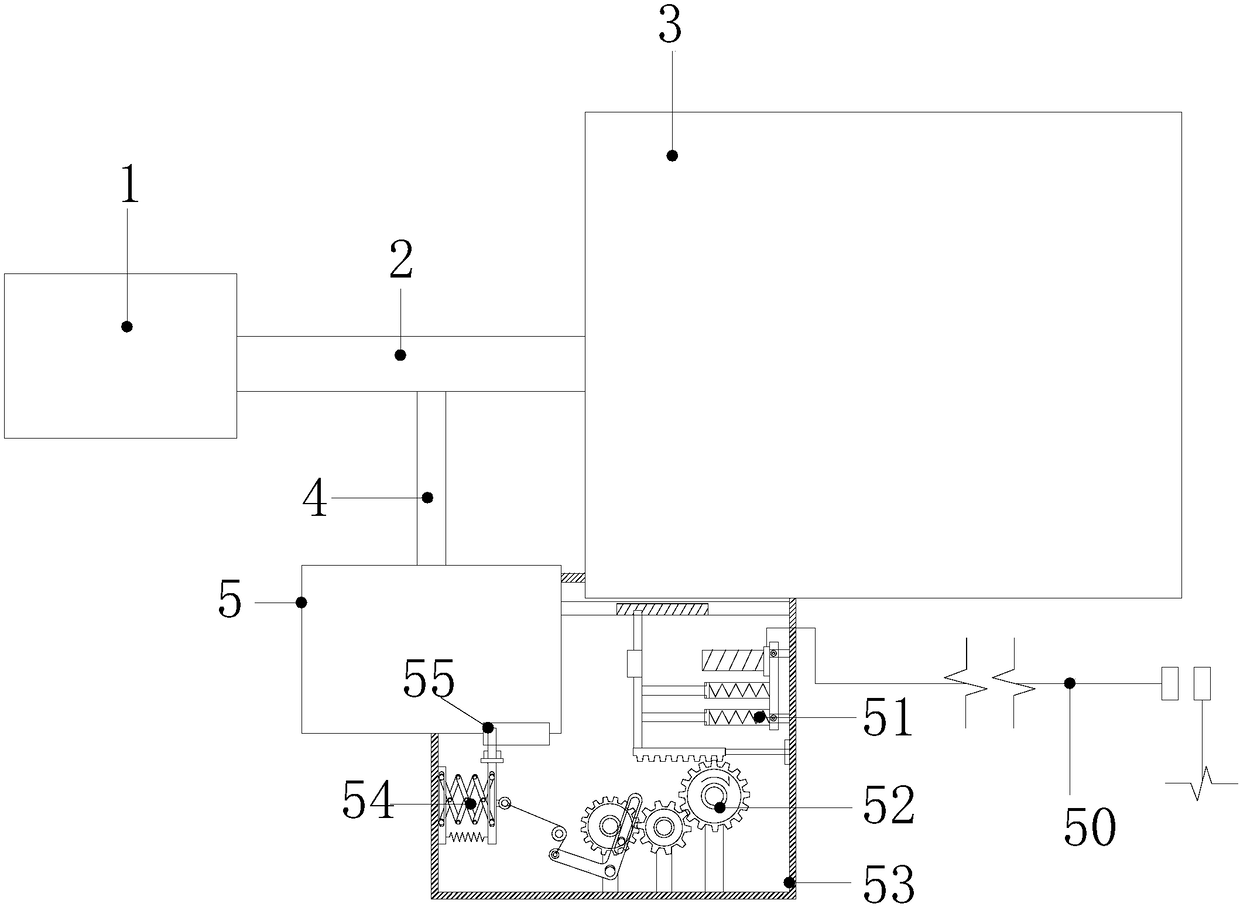

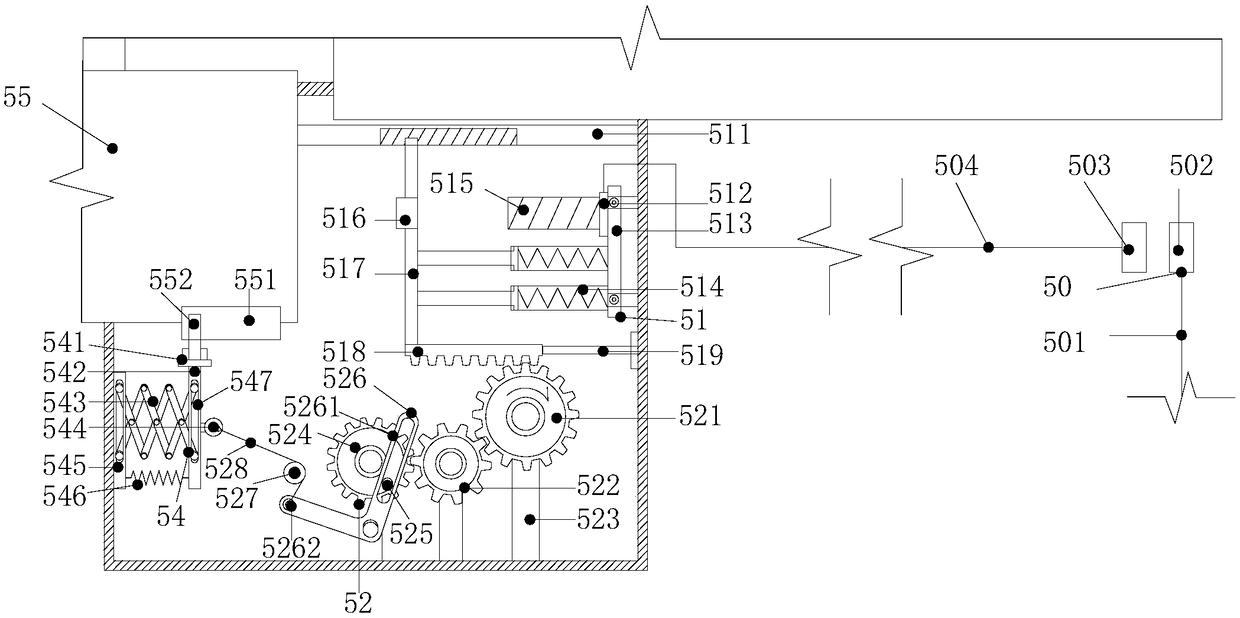

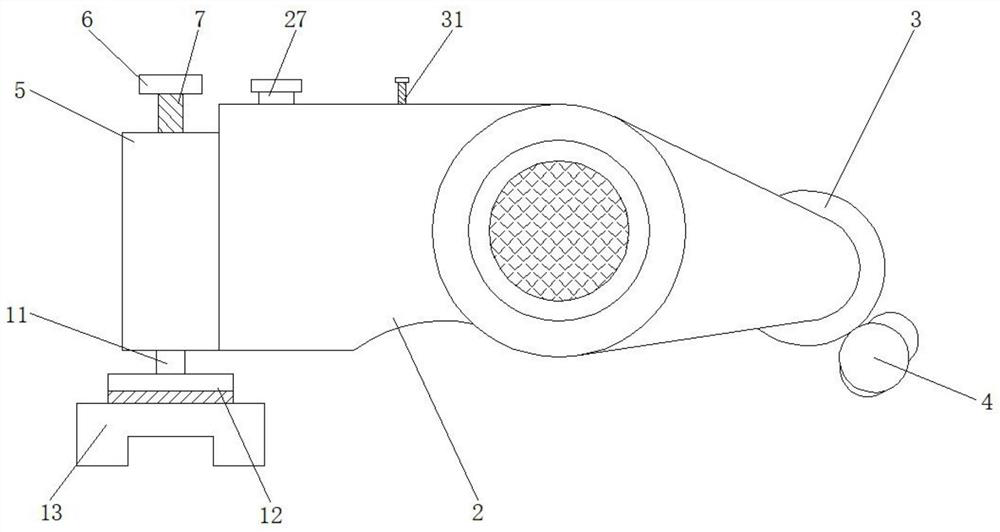

Upslope booster for turbocharging diesel car

InactiveCN108506082APlay a supporting roleImprove climbing abilityInternal combustion piston enginesEngine componentsAtmospheric pressureFlange

The invention discloses an upslope booster for a turbocharging diesel car. The upslope booster comprises a supercharging compensator, a connecting air inlet pipe, an engine body, a supercharging air pipe and a boosting supercharging device. The supercharging compensator is closely connected with one end of the connecting air inlet pipe in a penetrating mode. The engine body is connected with the other end of the connecting air inlet pipe. One end of the supercharging air pipe is embedded in the connecting air inlet pipe and is fixed in a screwed mode by a connecting flange. The boosting supercharging device is connected with the supercharging air pipe in a screwed mode by a connecting hole with threads. The boosting supercharging device consists of a contact starting device, an electromagnetic coil device, a gear transmission device, a protection shell, a switch connecting mechanism and a supercharging pump device. According to the upslope booster for the turbocharging diesel car, theboosting supercharging device is arranged to enable the turbocharging diesel car to increase air pressure in the connecting air inlet pipe when the car climbs a slope, diesel supply volume of the supercharging compensator is increased; finally, power of the car is increased, a boosting function is conducted on the car, so that the upslope ability of the car is improved.

Owner:莆田市荔城区任西贸易有限公司

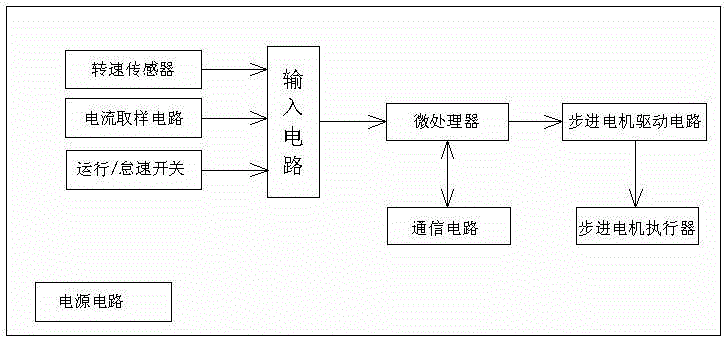

Precognition type electronic speed regulator of generator set and speed regulating method thereof

ActiveCN102797566BIncrease fuel supplyIncrease loading capacityFuel-injection pumpsMachines/enginesSynchronous motorPower flow

Owner:CHONGQING JIAJING ELECTRONICS EQUIP

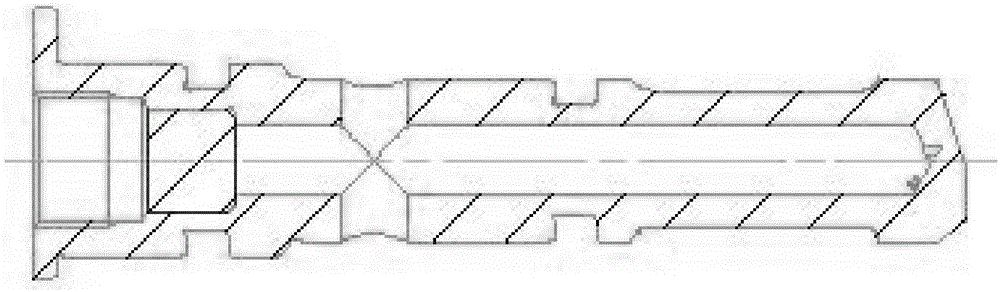

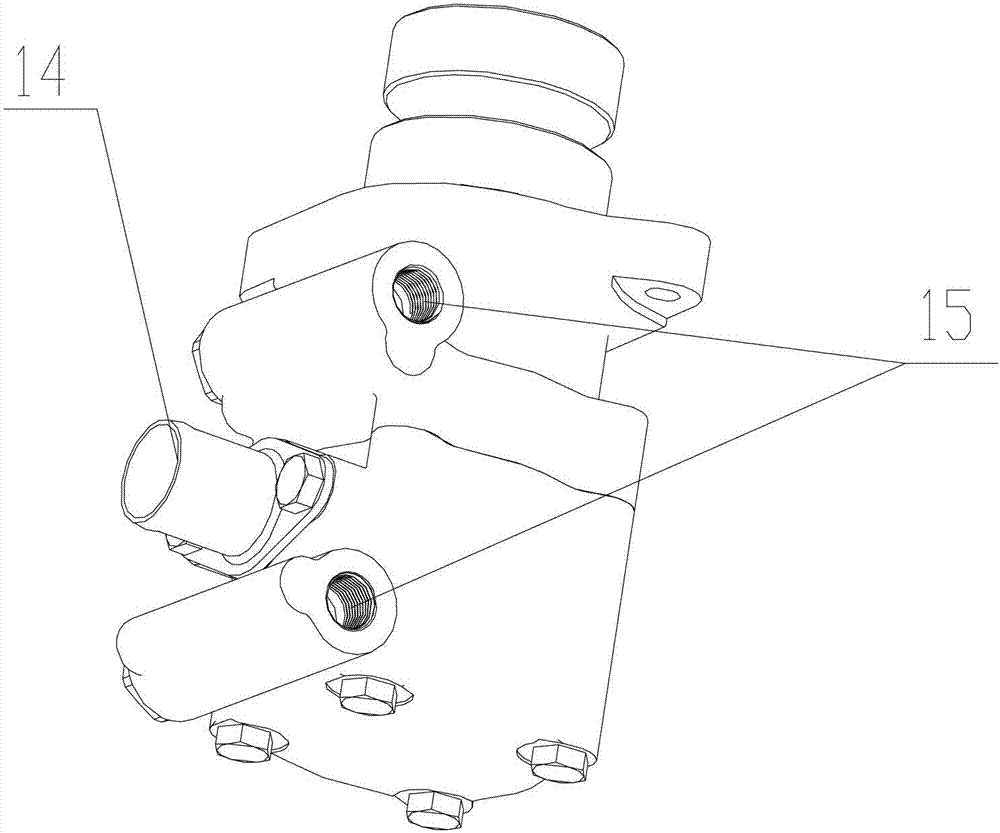

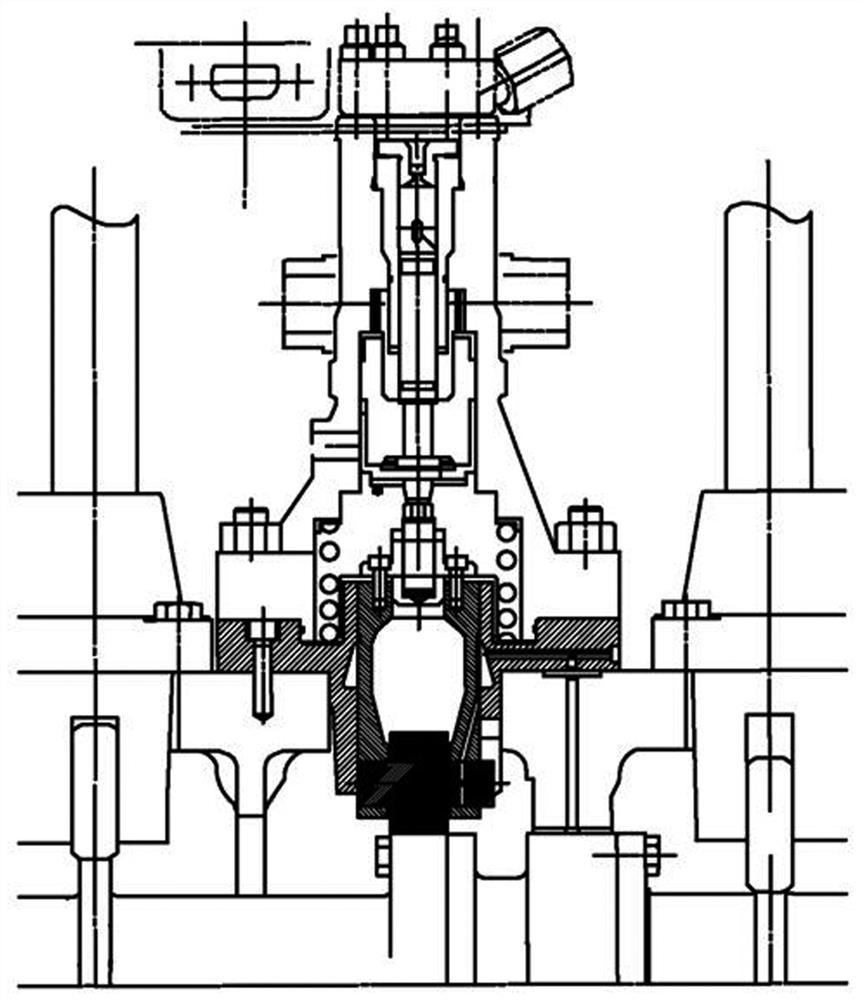

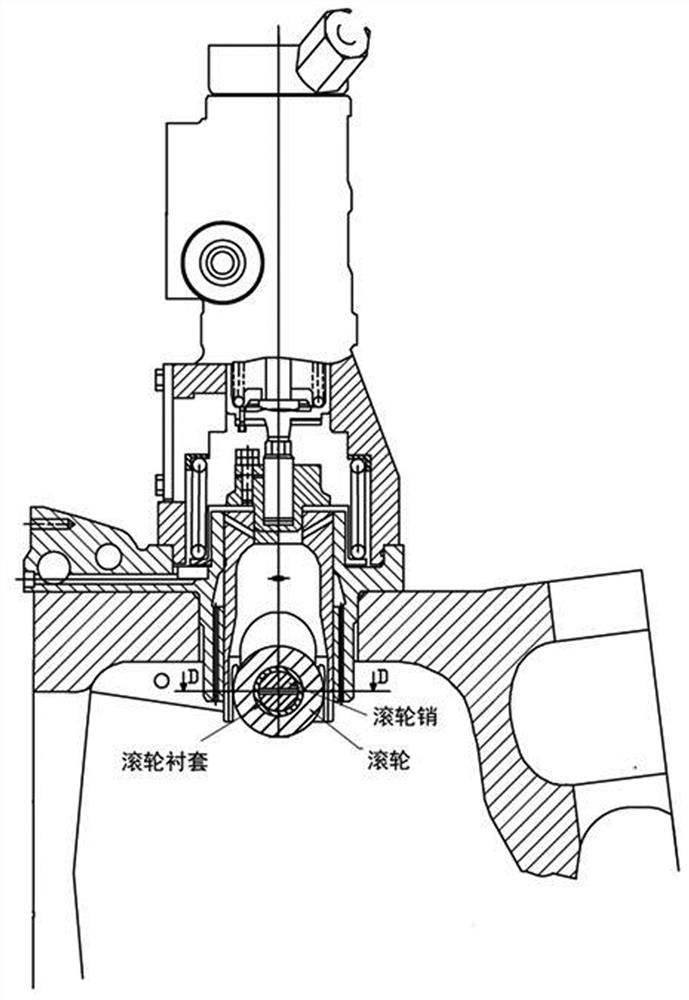

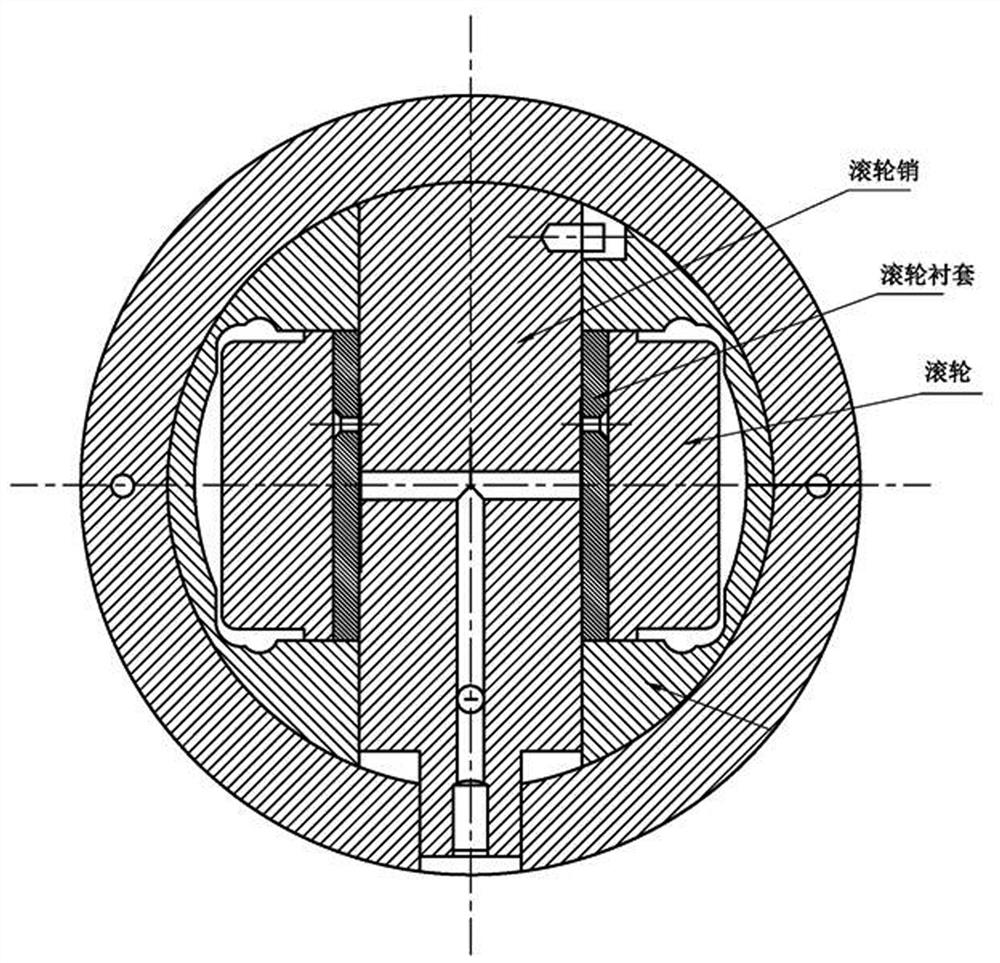

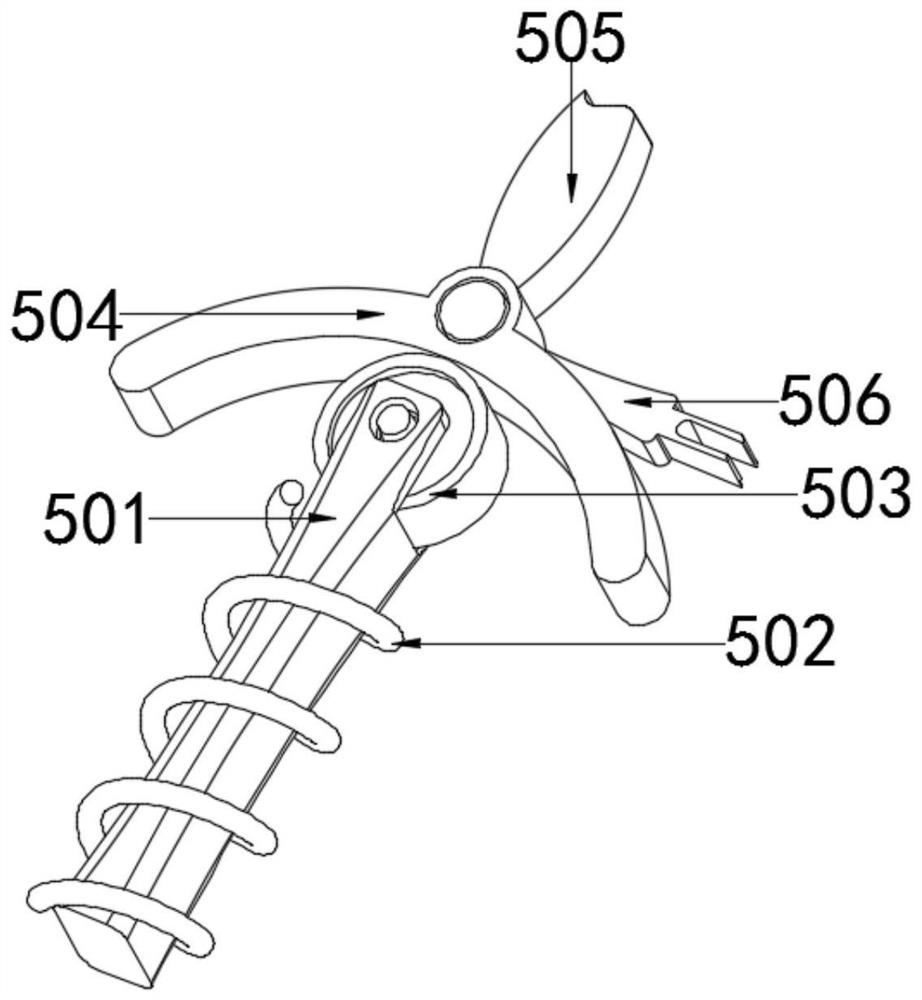

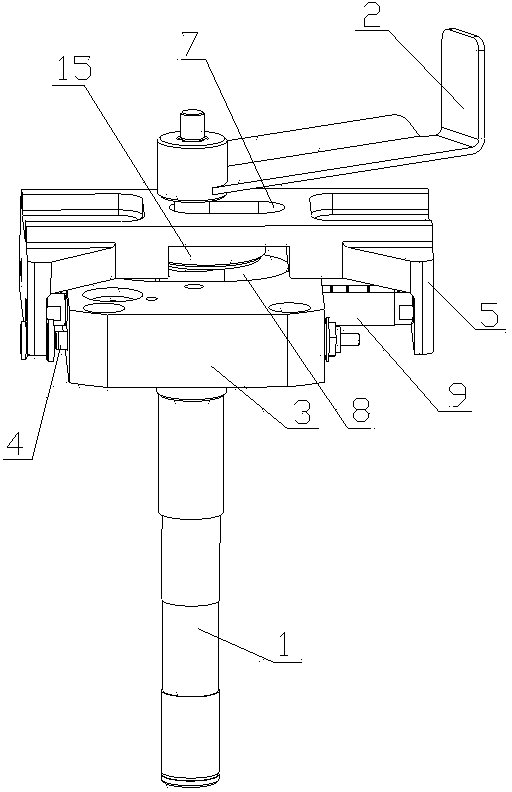

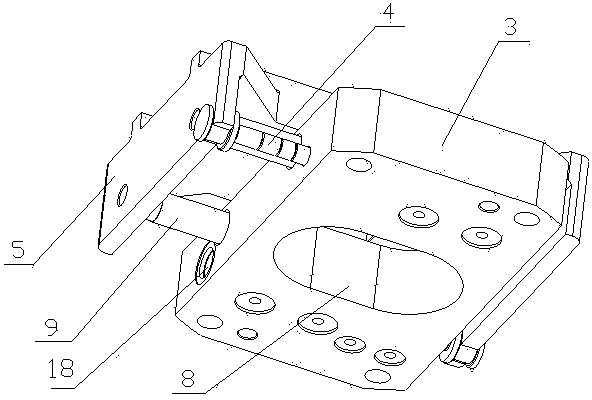

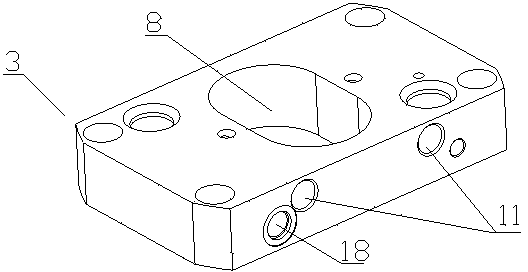

Fuel injection pump driving device of diesel engine

PendingCN112780469AReliable flushIncrease fuel supplyPositive displacement pump componentsFuel injecting pumpsDieselingOil distribution

The invention discloses a fuel injection pump driving device of a diesel engine. The fuel injection pump driving device comprises a rolling wheel assembly and a tappet; the rolling wheel assembly comprises a rolling wheel pin, a rolling wheel lining and a rolling wheel; the rolling wheel pin is provided with an oil distribution groove; and a plurality of oil distribution holes are additionally formed in the middle of the rolling wheel lining in the circumferential direction. The fuel injection pump driving device disclosed by the invention can solve the problem that there is insufficient oil supply when fit clearances between the rolling wheel and the lining and between the lining and the rolling wheel reach two end faces of the rolling wheel, the problem about uneven oil supply caused when the fit clearances between the rolling wheel and the lining and between the lining and the rolling wheel pin reach the two end faces of the rolling wheel due to form and location tolerance of parts, and the problem about abnormal wear without changing the overall structure of the fuel driving mechanism.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

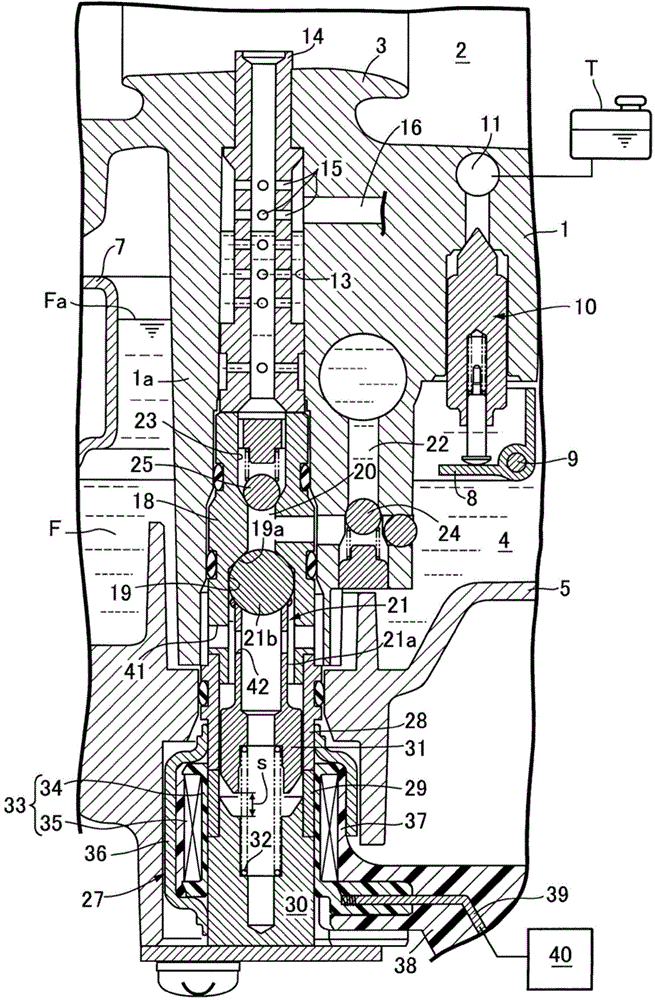

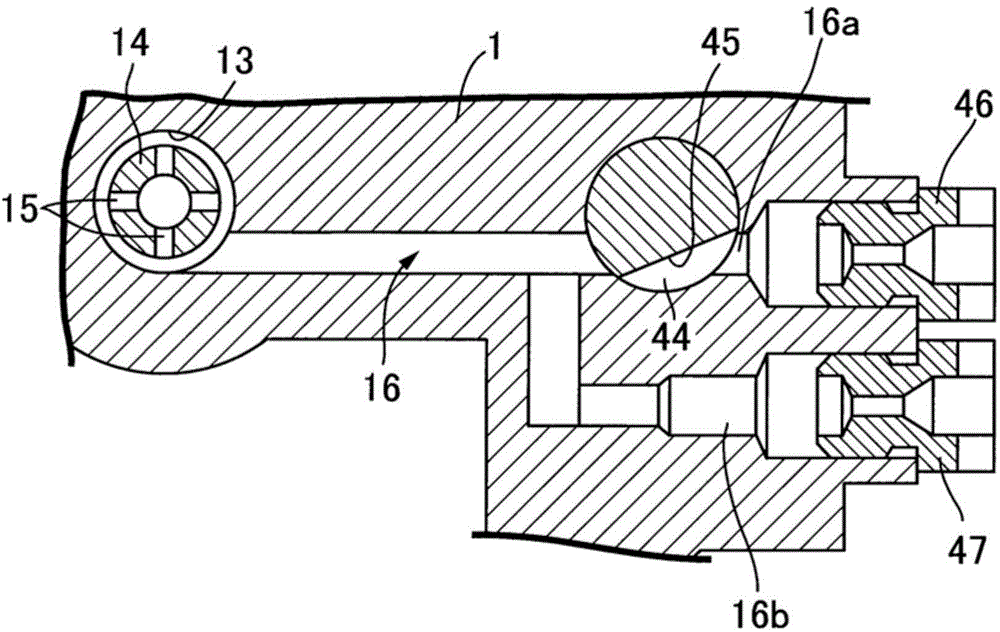

Carburetor

InactiveCN104421047ANo vapor lockReduce power consumptionFloat-controlled apparatusMachines/enginesCarburetorEngineering

A carburetor comprises an intake path, a constant volume fuel chamber and a fuel nozzle. The intake path is connected to an intake port of an engine, and is opened and closed by a throttle valve. The constant volume fuel chamber is provided below the intake path, constantly stores a certain amount of fuel, and has an upper space connected to an air vent. An upper end of the fuel nozzle opens to the intake path to spray fuel of the constant volume fuel chamber to the intake path. The fuel nozzle is connected to a fuel passage communicating to the underneath of a fuel level of the constant volume fuel chamber, and a fuel pump which feeds fuel to the fuel nozzle is interposed in the fuel passage.

Owner:KEIHIN CORP

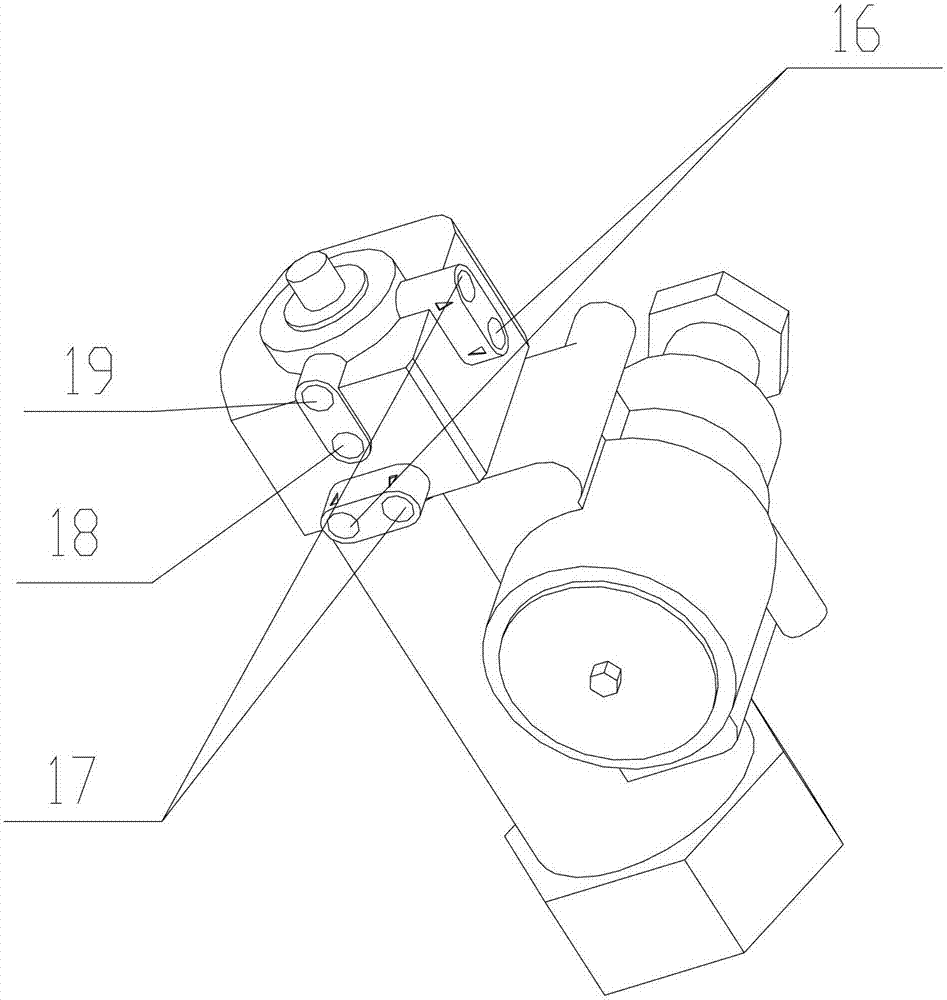

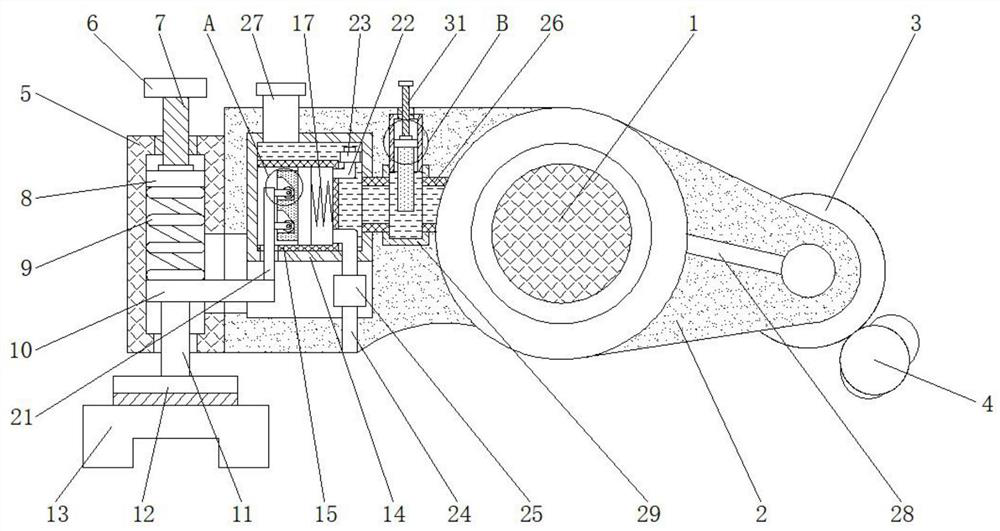

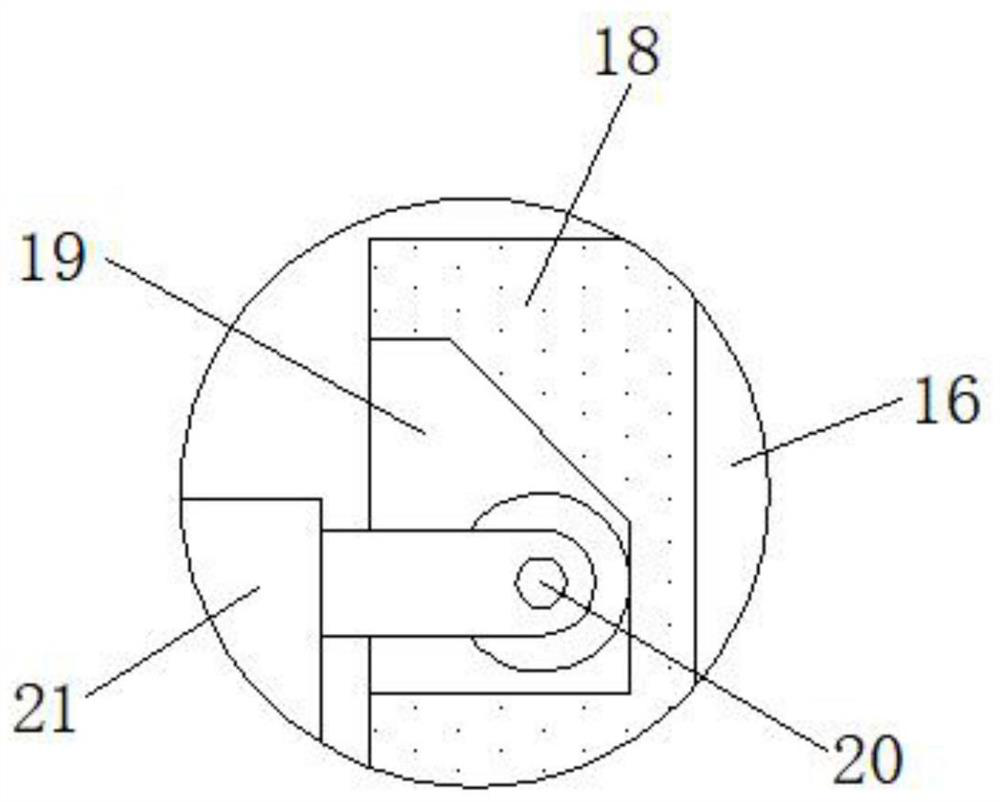

Novel brake rocker arm and control method thereof

ActiveCN113623043AImprove the lubrication effectIncrease fuel supplyValve arrangementsLubrication of auxillariesCamControl theory

The invention discloses a novel brake rocker arm and a control method thereof. The novel brake rocker arm comprises a rocker arm shaft, wherein the surface of the rocker arm shaft is sleeved with a brake rocker arm body, the right side of the brake rocker arm body is movably connected with a roller, the bottom of the roller is provided with a cam, the left side of the brake rocker arm body is fixedly connected with a brake execution box, the top of the brake execution box is provided with a rotary knob, the bottom of the rotary knob is fixedly connected with a threaded rod, and the bottom of the threaded rod penetrates into an inner cavity of the brake execution box and is movably connected with a pressing plate. According to the brake rocker arm, by arranging an oil outlet shell, a rubber sealing plate, a reset spring, a control block, adjusting grooves, extrusion wheels, a pull rod, an exhaust pipe, a first one-way valve, an air inlet pipe, a second one-way valve and an oil outlet pipe, the problems that an existing brake rocker arm is small in lubricating oil supply amount and poor in lubricating effect, and low brake precision is likely to be caused are solved. The brake rocker arm has the advantages that the lubricating oil supply amount is large, the lubricating effect is good, and the brake rocker arm is worthy of popularization.

Owner:ZHEJIANG YUEJIN FORGING

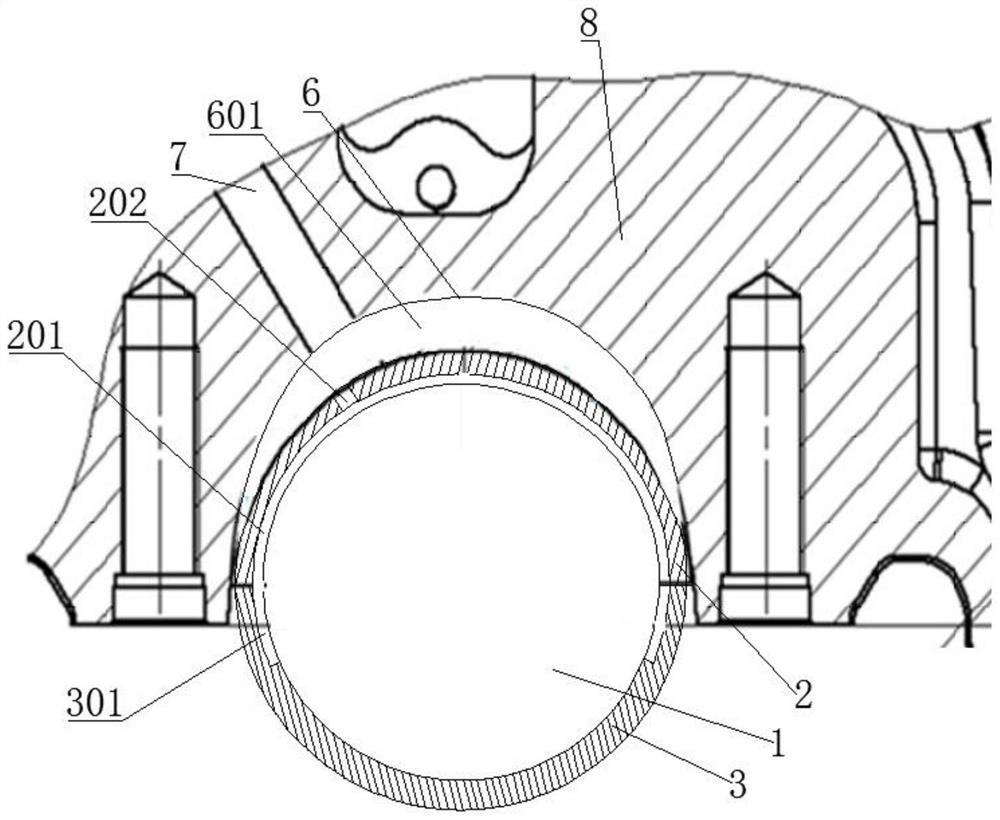

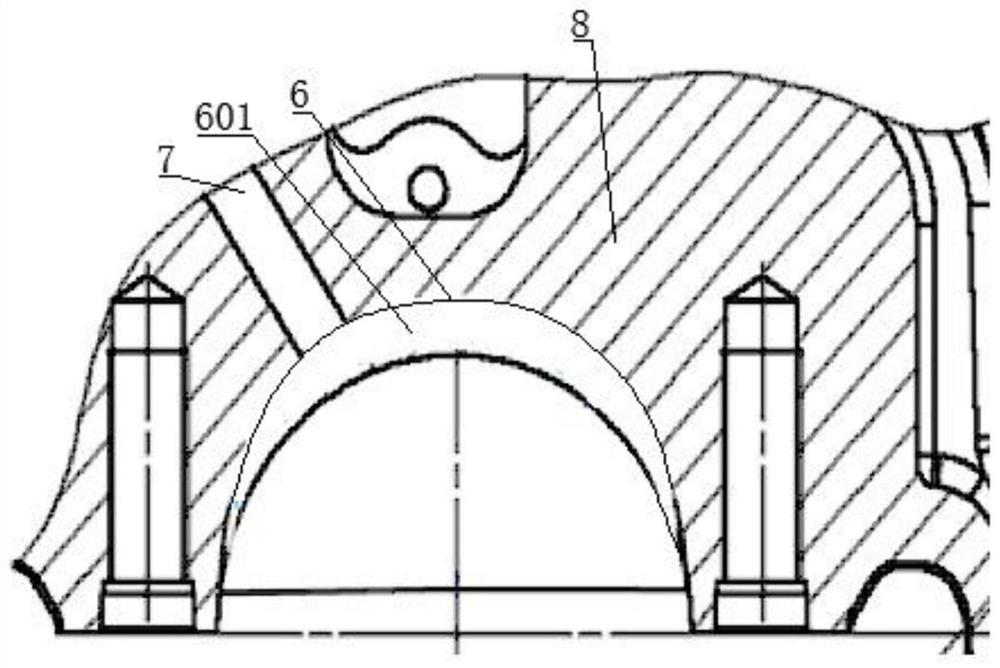

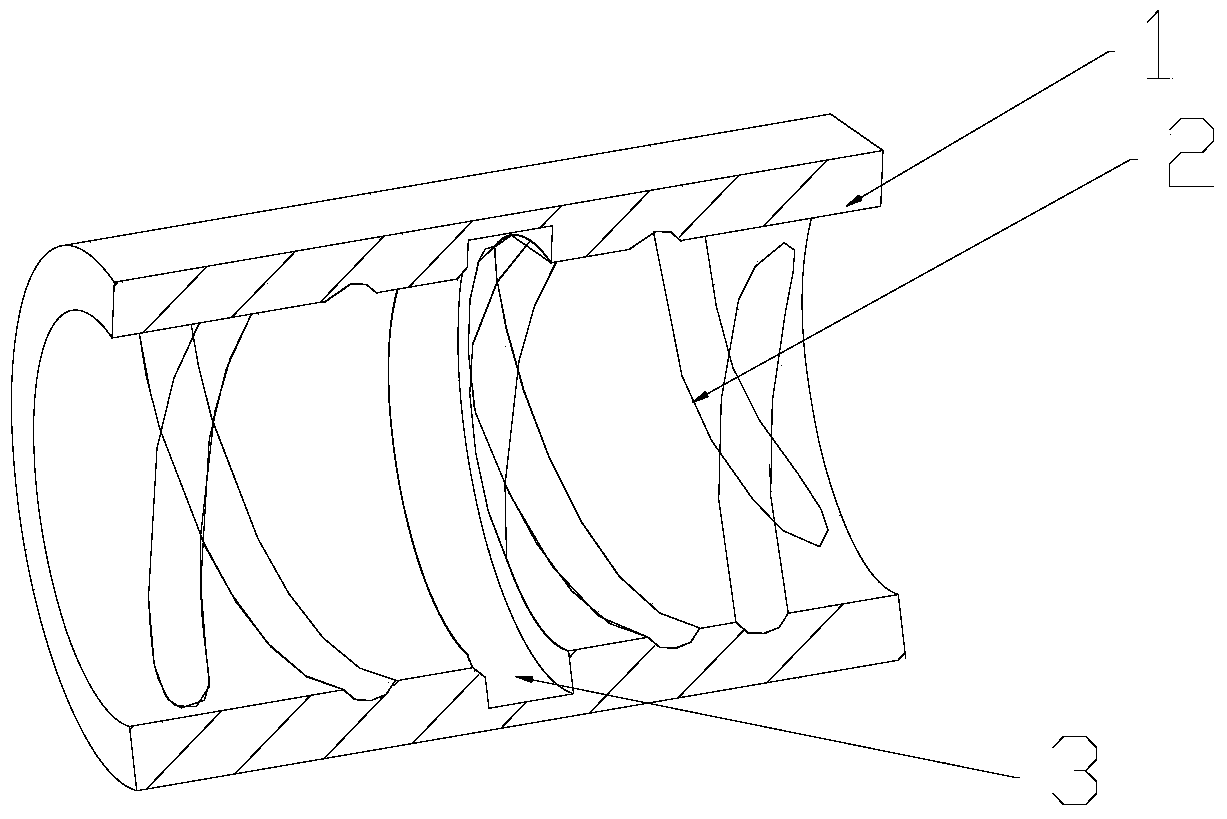

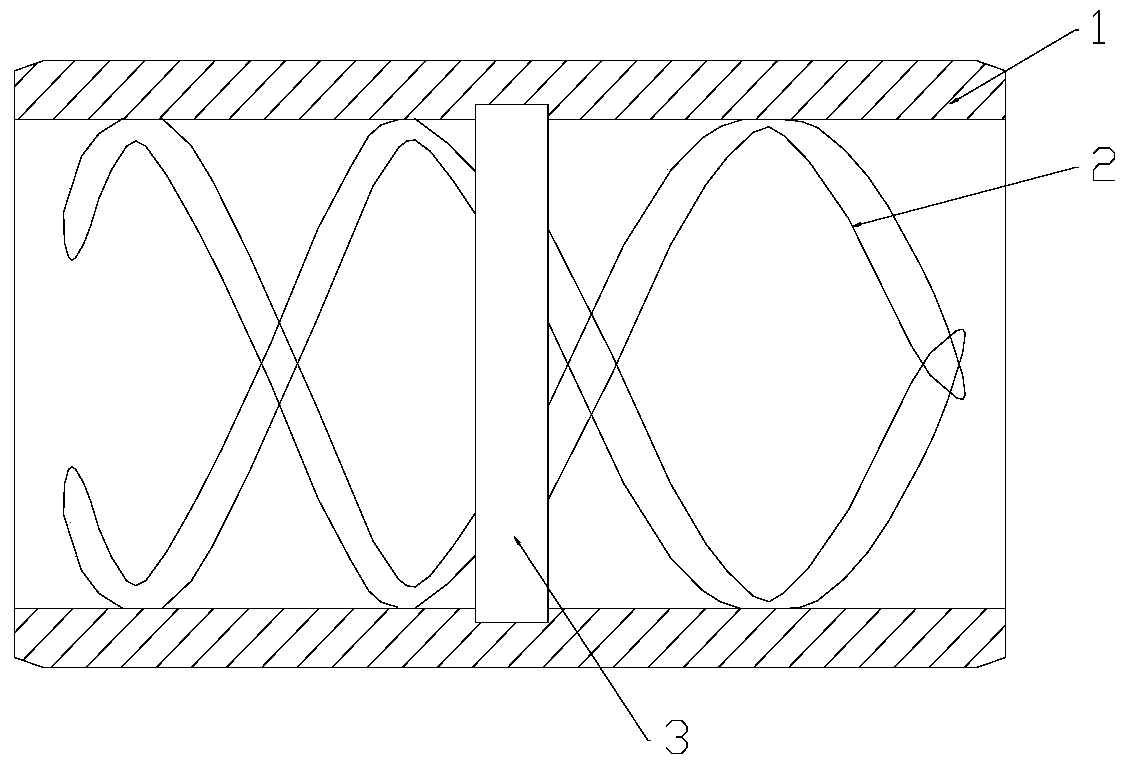

wear bushing

ActiveCN104389907BEvenly distributedIncrease fuel supplyBearing componentsEngine lubricationRotational axisEngineering

The invention provides a wear-resistant bush, which relates to the field of mechanical parts. The wear-resistant bush includes a bush main body, and the inner wall of the bush main body is provided with a plurality of lubricating oil passages extending in a spiral shape; a plurality of The starting ends of the lubricating oil passages are evenly arranged along the circumference of the bushing body; the pitches of the plurality of lubricating oil passages are respectively equal; the plurality of lubricating oil passages intersect each other; the plurality of lubricating oil passages The beginning and the end of the passage are closed respectively; the bushing body is also provided with an annular oil storage passage, and the rotation axis of the oil storage passage is collinear with the rotation axis of the bushing main body; the oil storage passage and the The plurality of lubricating oil passages are connected through respectively. The wear-resistant bush provided by the invention solves the technical problems of the traditional bush such as uneven distribution of oil passages, insufficient oil supply and poor sealing performance.

Owner:ENSIGN HEAVY IND

Oil pump

InactiveCN105546313ACompact structureSmooth circulationLubricating pumpsLubrication elementsForeign matterOil can

The invention provides an oil pump. The oil pump comprises a pump body, a pump cover, a pump shaft, an inner rotor and an outer rotor. The pump cover is arranged on the pump body, and an oil cavity is formed between the pump cover and the pump body; the pump shaft penetrates the pump shaft to extend to the interior of the oil cavity, and is sleeved with the inner rotor; the inner rotor is arranged inside the outer rotor, and the inner rotor and the outer rotor are arranged inside the oil cavity; and an oil outlet cavity is formed in the left end of the bottom of the oil cavity, and an oil inlet cavity is formed in the right end of the bottom of the oil cavity. A filter device is arranged at the bottom of the oil inlet cavity, a suction filter and an oil outlet hole are arranged inside the pump body, the suction filter is communicated with the oil inlet cavity, and the oil outlet hole is connected with the oil outlet cavity. The oil pump is simple and compact in structure, foreign matter in oil can be filtered in time, the oil can flow smoothly, normal work of the oil pump is ensured, and the working efficiency is improved.

Owner:CHONGQING YUNHAI MACHINERY MFG

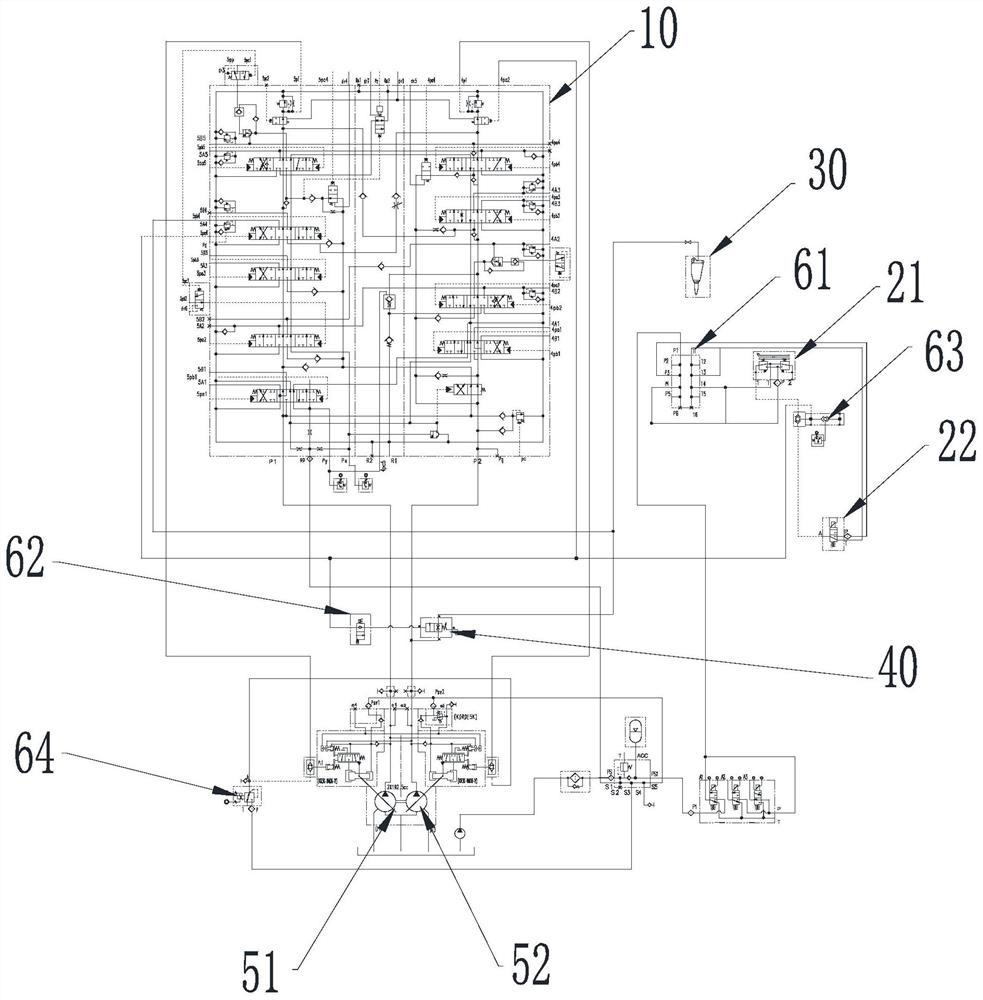

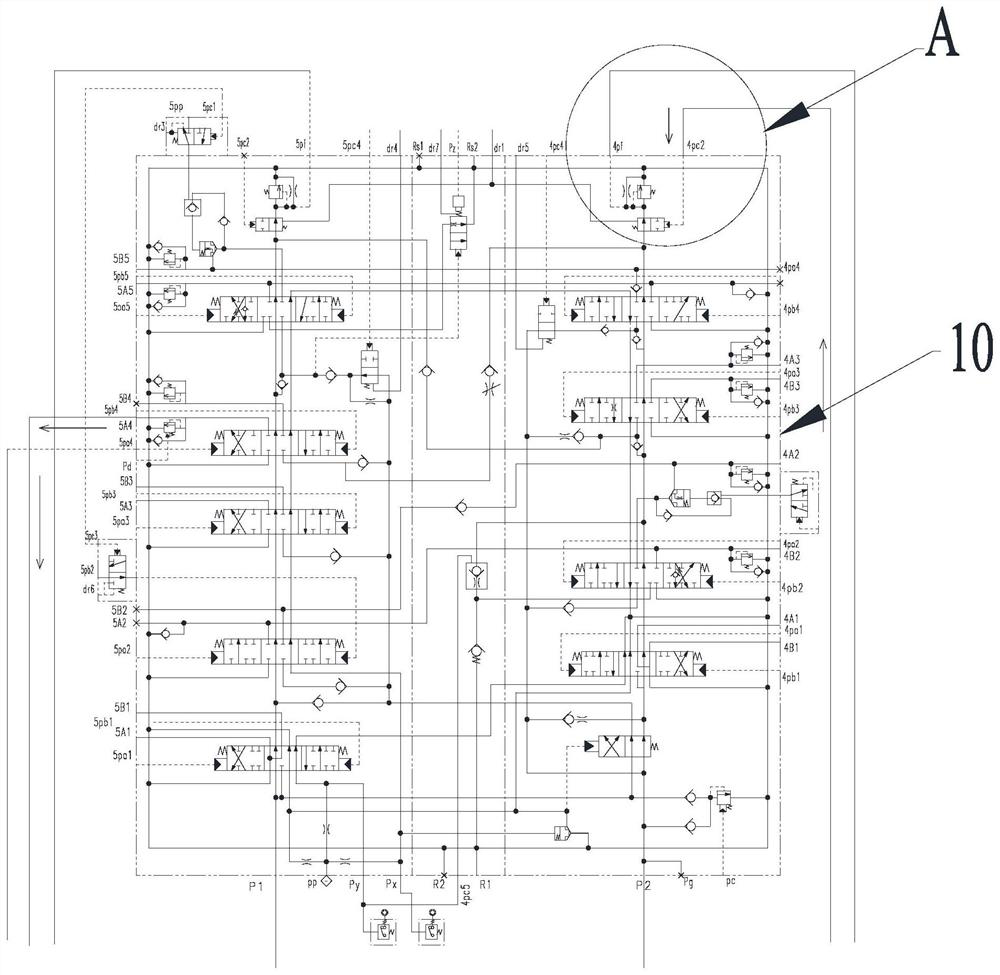

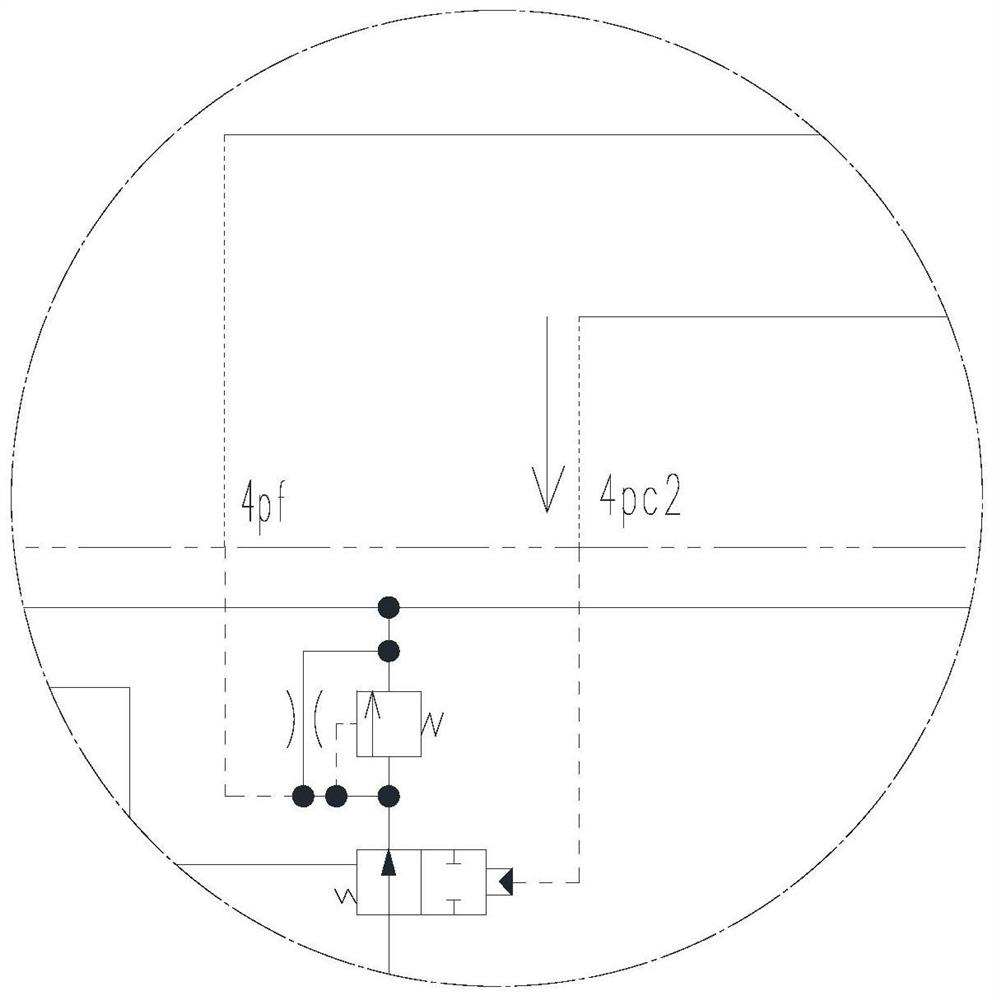

Double-pump confluence hydraulic system and excavator

ActiveCN112012268AIncrease fuel supplySimplify pipeline structureSoil-shifting machines/dredgersOil supplyExcavator

A double-pump confluence hydraulic system relates to the technical field of excavators and comprises a pumping module, a breaking hammer starting module, a main valve and a breaking hammer, wherein the pumping module comprises a first pumping mechanism and a second pumping mechanism, the first pumping mechanism communicates with a first valve block group of the main valve, and the second pumping mechanism communicates with a second valve block group of the main valve; the breaking hammer starting module communicates with a pilot oil pipeline; the pilot oil pipeline respectively communicates with a converging valve and a negative flow signal cut-off valve in the main valve; the breaking hammer communicates with a breaking hammer oil supply pipeline, the breaking hammer oil supply pipeline communicates with the first pumping mechanism in the pumping module through the main valve, and the breaking hammer oil supply pipeline communicates with the second pumping mechanism in the pumping module through the converging valve. When the double-pump confluence hydraulic system supplies oil to the breaking hammer, the first pumping mechanism supplies oil through the main valve, the second pumping mechanism supplies oil through the converging valve, the oil does not need to flow through the main valve, and the energy loss of the oil is reduced while the oil supply amount is increased through double-pump oil supply.

Owner:SHANDONG LINGONG CONSTR MACHINERY

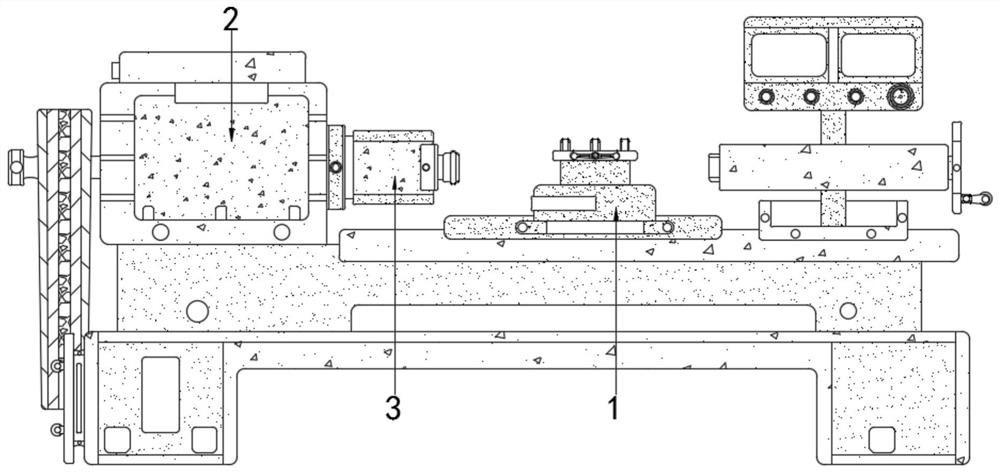

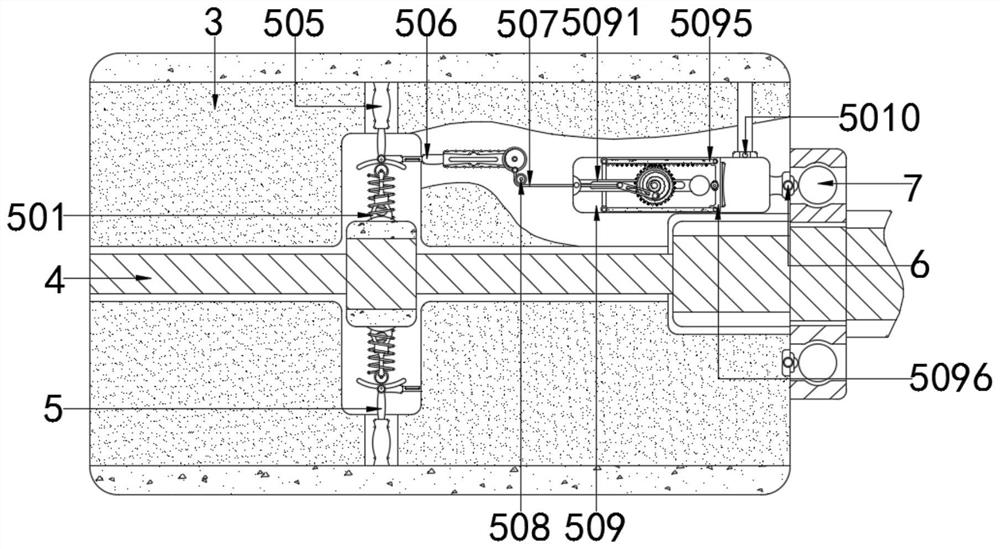

Lubrication control system and method for numerical control machine tool and capable of automatically adjusting lubrication according to needs

InactiveCN113182928AIncrease speedIncrease fuel supplyMaintainance and safety accessoriesNumerical controlControl system

The invention relates to the technical field of numerical control lathes, and discloses a lubrication control system for a numerical control machine tool and capable of automatically adjusting lubrication according to needs. The lubrication control system comprises a tool table, a self-lubricating assembly and a nozzle assembly; a control seat is fixedly mounted on the left side of the tool table; a clamping seat is fixedly mounted on the right side of the control seat; a rotating shaft is movably connected to the inner wall of the clamping seat; and the inner wall of the clamping seat is movably connected with the outer wall of the self-lubricating assembly. According to the lubrication control system and method for the numerical control machine tool and capable of automatically adjusting lubrication according to needs, a user supplies power to a motor; when the rotating shaft changes from a low speed to a high speed, the eccentricity of the rotating shaft is increased, then a telescopic rod drives a pressing wheel to move outwards under the assistance of a reset spring; fixed-point rotation of a gear disc enables an oil pushing plate to slide along the inner wall of an oil storage cavity, and finally the oil pushing plate cooperates with the nozzle assembly to continuously supply oil to a roller on the inner wall of a bearing, so that the effect of lubricating oil of different magnitudes under different rotating speeds of the numerical control machine tool is improved.

Owner:新昌县善力机械科技有限公司

Double-oil-circuit fuel nozzle

ActiveCN103134079BPerformance unchangedIncrease fuel supplyContinuous combustion chamberCombustion chamberCombustor

The invention relates to a double-oil-circuit fuel nozzle, in particular to a double-oil-circuit large-spray-cone-angle fuel nozzle. The double-oil-circuit fuel nozzle mainly comprises a nozzle shell body, a main oil circuit nozzle, a main oil circuit swirler and a vice oil circuit swirler. A main oil circuit swirling chamber is formed by the main oil circuit swirl and an inner cavity of the main oil circuit nozzle, a vice oil circuit swirling chamber is formed by a head cone-shaped body of the vice oil circuit swirler and a convergence taper angle of the inner cavity of the main oil circuit swirler, and a cooling air channel is designed on the main oil circuit nozzle. The problem that an aero-engine combustor is wide in fuel supply range is well resolved, a spray cone angle of the fuel nozzle is increased by 10 degrees to 15 degrees, and the effects of nozzle cooling and nozzle surface carbon deposition blowing down are achieved.

Owner:中国航发贵阳发动机设计研究所

Outer rotor gear driven lubricating oil pump

ActiveCN102200215AImprove efficiencyIncrease fuel supplyLubricating pumpsPressure lubrication with lubrication pumpGear driveGear wheel

The invention discloses an outer rotor gear driven lubricating oil pump, which comprises a body pump body, a pump cover, an outer rotor gear, an inner rotor, a boss pump shaft and an inner hexagon screw, wherein the bottom surface of a rotor hole of the body pump body is provided with an oil inlet passage, an oil inlet cavity, an oil outlet cavity, an oil outlet hole and an oil path hole; the plane of the pump cover is provided with an oil inlet cavity, a tunnel type oil passage, an oil inlet and an oil outlet cavity; the boss pump shaft is arranged on the bottom surface of the rotor hole at the front end of the body pump body by using the inner hexagon screw; a cylindrical small boss on the boss pump shaft is matched with an axle hole on the bottom surface of the rotor hole at the front end of the body pump body; the outer rotor gear is arranged in a rotor hole at the front end of the body pump body; the inner rotor is arranged on the boss pump shaft in a movable fit mode and is engaged with inner teeth of the outer rotor gear; the pump cover is arranged on a shell of the body pump body through bolts; and a cylindrical large boss on the boss pump shaft is matched with the axle hole on the pump cover. After the pump cover is arranged on the shell of the body pump body, flexibility of rotation of the inner rotor and the outer rotor gear can be guaranteed.

Owner:HUNAN OIL PUMP

Oil supply structure for compressor and compressor with oil supply structure

ActiveCN111271254AIncrease fuel supplyImprove efficiency and reliabilityPositive displacement pump componentsPositive-displacement liquid enginesOil supplyCrankshaft

The invention discloses an oil supply structure for a compressor and the compressor with the oil supply structure. The oil supply structure for the compressor comprises a crankshaft, wherein the crankshaft is arranged vertically and is provided with a central hole; and an oil pump piece, wherein the oil pump piece is matched at the lower part of the central hole, a gap is reserved between the outer peripheral wall of the oil pump piece and the inner peripheral wall of the central hole, and the oil pump piece can rotate relative to the crankshaft. According to the oil supply structure for the compressor according to the embodiment of the invention, the oil supply amounts of various components of the compressor are increased on the premise of thinning the diameter of the crankshaft; and theefficiency and the reliability of the compressor are improved.

Owner:ANHUI MEIZHI COMPRESSOR

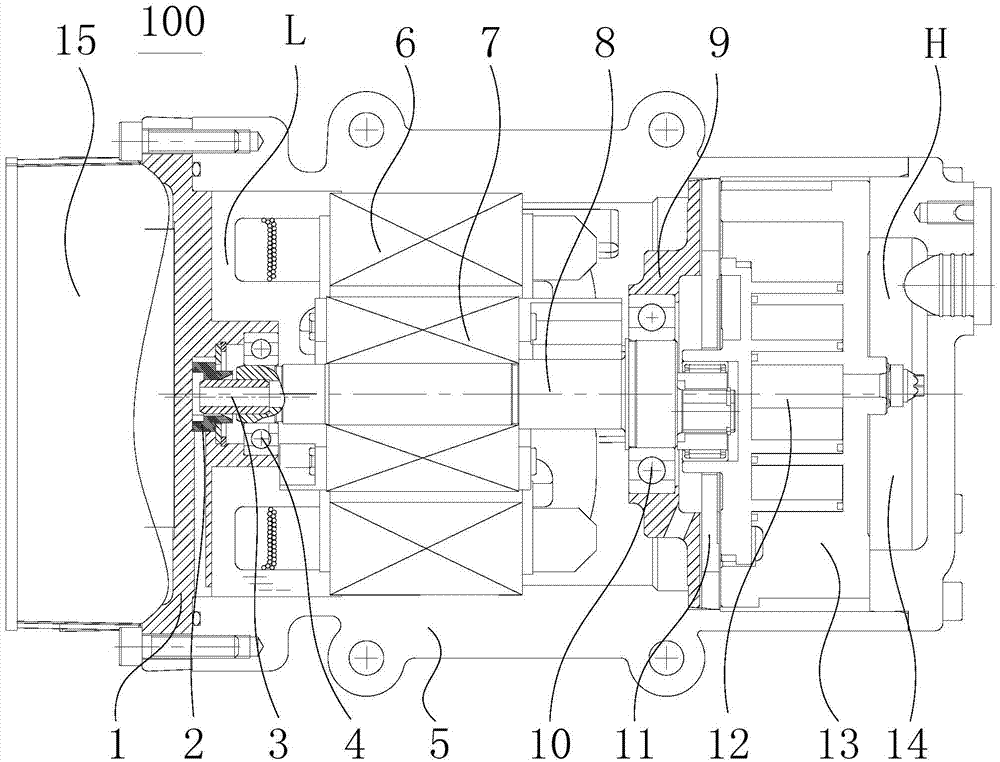

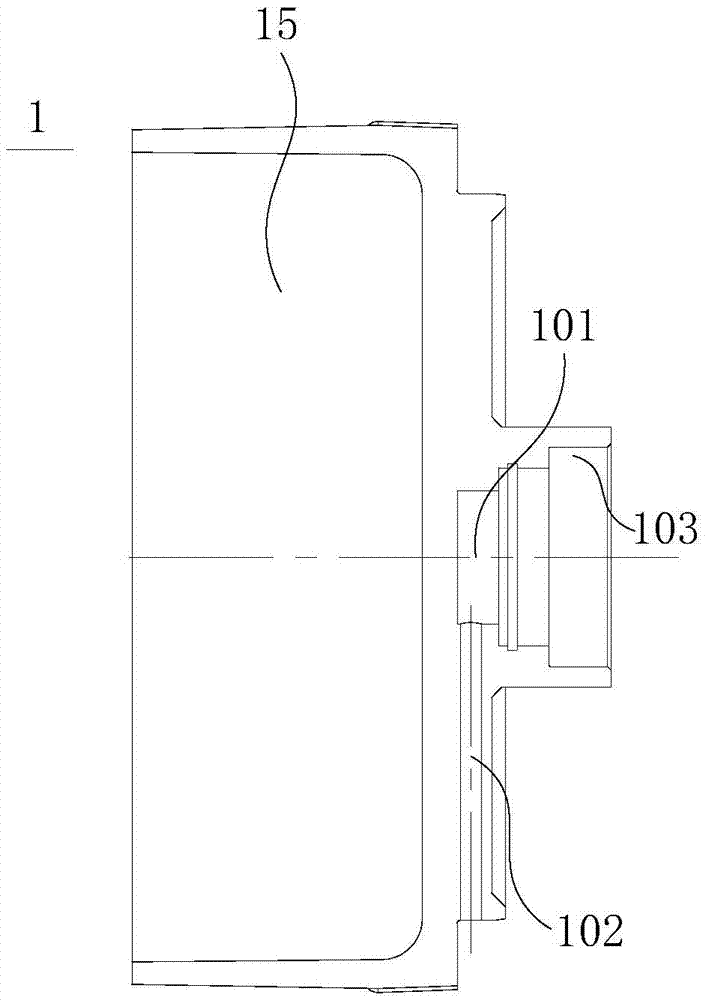

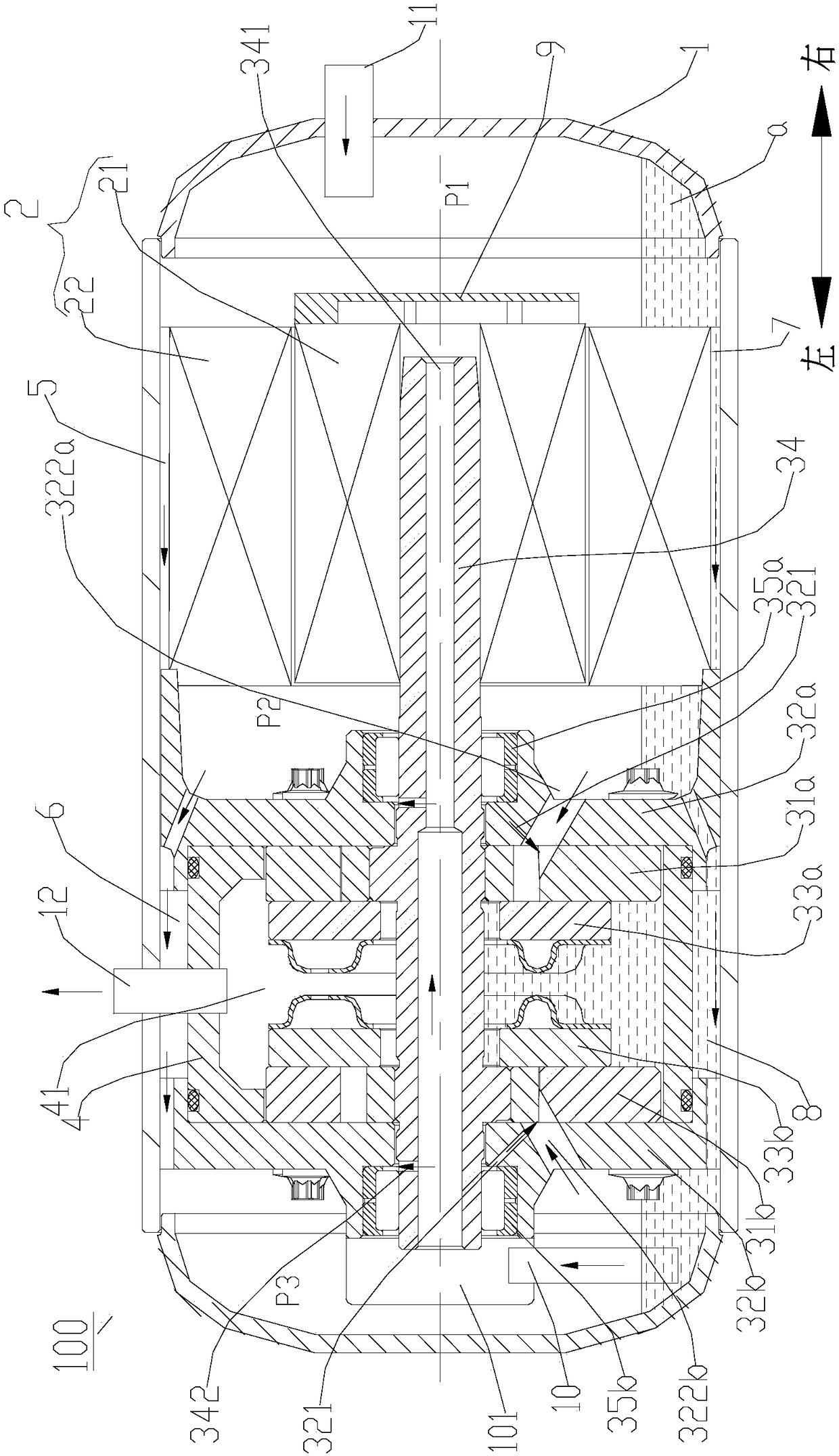

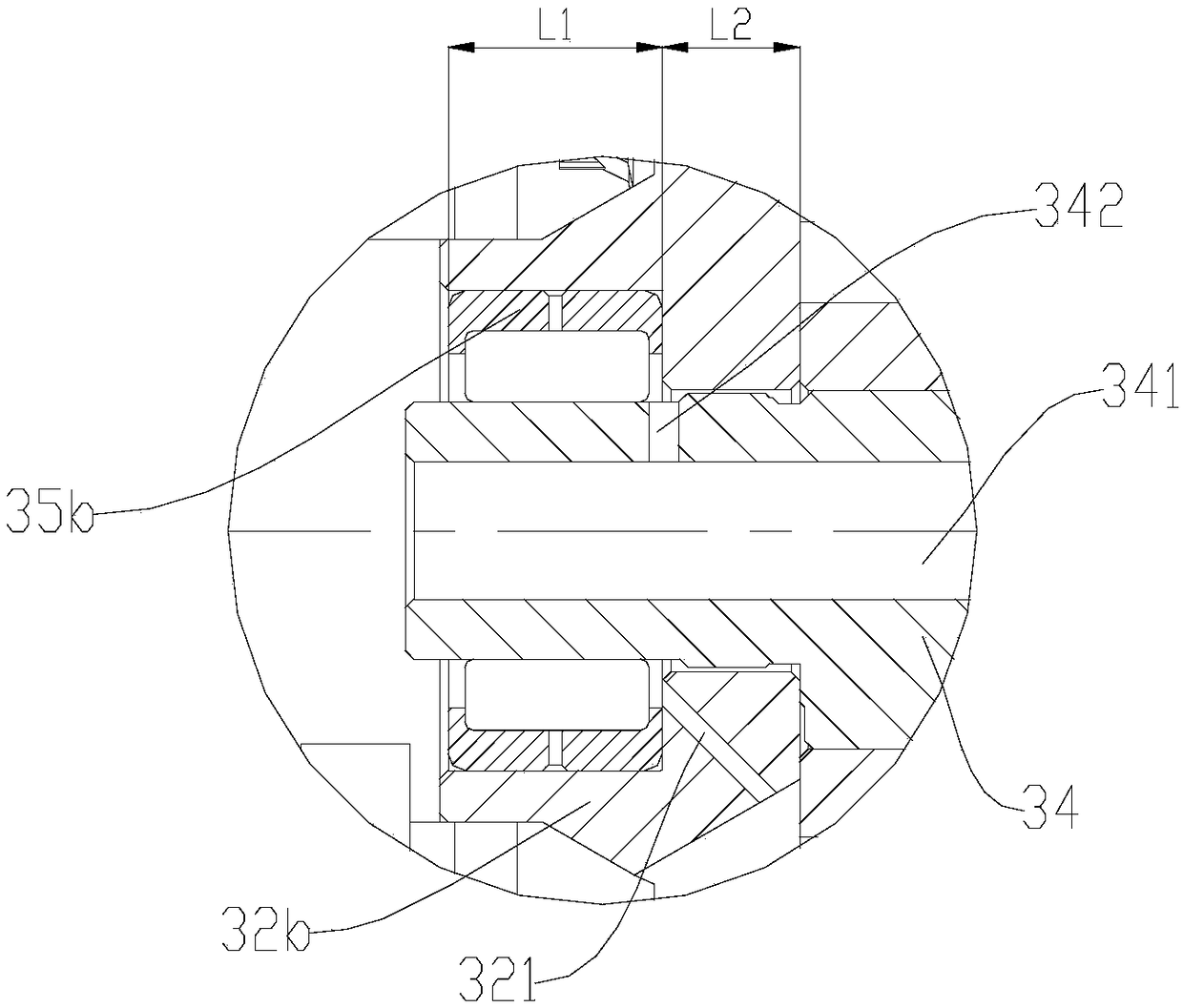

Low back pressure horizontal compressor and refrigeration system

ActiveCN106286298BIncrease fuel supplyReduce wearRotary/oscillating piston combinations for elastic fluidsCrankshaftsRolling-element bearingEngineering

The invention discloses a low-back-pressure horizontal compressor and a refrigerating system. The compressor comprises a shell and a compressing mechanism, wherein the shell is provided with an air suction pipe and an air discharging pipe, and a low-pressure oil pool is arranged at the bottom of the shell; the compressing mechanism comprises two air cylinder, two fitted bearings, two cover plates, a crankshaft and a rolling bearing, the cover plates are respectively arranged at the sides, facing to each other, of the two air cylinders, the two fitted bearings are connected through a retainer to define a closed air discharging cavity, the crankshaft is matched with the two fitted bearings, the rolling bearing is arranged between at least one fitted bearing and the crankshaft, the part, which is provided with the rolling bearing, of the fitted bearing is matched with the crankshaft in a sliding manner, a central hole is formed in the crankshaft, a plurality of radial holes are formed in the crankshaft and are communicated with the central hole, the central hole is communicated with the low-pressure oil pool through an oil supplying pipe, and each fitted bearing and at least one radial hole are correspondingly arranged. The compressor provided by the invention is beneficial to increasing oil supplying amount and alleviating the abrasion of the fitted bearings.

Owner:GUANGDONG MEIZHI COMPRESSOR

Double-fulcrum sliding bearing

ActiveCN111120506AAchieve hybridImprove carrying capacityBearing componentsSliding contact bearingsSlider bearingEngineering

The invention discloses a double-fulcrum sliding bearing, and relates to the field of sliding bearings. The bearing comprises a bearing inner ring. A bearing outer ring is arranged on the outer portion of the bearing inner ring in a sleeving manner. The bearing outer ring and the bearing inner ring are fixed through pins. Multiple bearing bush blocks are fixed to the inner layer of the bearing inner ring. The multiple bearing bush blocks are combined and arranged in a circular, uniform-distribution and surrounding manner. Each bearing bush block is connected with the bearing inner ring and thebearing outer ring through two mechanical supports. The mechanical supports are adopted for the bearing and used as oil spraying devices, and therefore materials are saved, the bearing capacity can be improved, and loss and oil consumption of the positions of fulcrums are reduced.

Owner:HEBEI UNIV OF ENG

Grease plunger pump

InactiveCN102135229BSimplify Transition PartsCompact and reasonable structureLubricating pumpsReciprocating motionEngineering

The invention relates to a grease plunger pump. The grease plunger pump comprises a driving device, a grease stirring device, and a grease absorption and discharging device, wherein the grease absorption and discharging device comprises a pump body and a swing device; the pump body comprises a cylinder and a plunger movably arranged in a plunger chamber of the cylinder; the swing device comprises a swing main body which can do reciprocating motion axially relative to the plunger chamber of the cylinder; and a non working end face of the plunger is fixed on the swing main body and do reciprocating motion synchronously in the plunger chamber along with the reciprocating motion of the swing main body so as to absorb and discharge the grease. The swing main body is provided with a first through hole which is parallel to a rotation shaft of the driving device; the cylinder is provided with a second through hole which is parallel to the rotation shaft of the driving device; the rotation shaft of the driving device passes through the first through hole and the second through hole; and the end part drives the grease stirring device to circumferentially rotate so as to stir the grease. The connection parts between the driving device and the grease stirring device are simplified, the structure of the plunger pump is more compact and reasonable, the loss of the energy is reduced, the structure of the grease absorption and discharging device is not influenced, and the plunger pump has large grease supply.

Owner:BEIJING CMRC SCI & TECH DEV

A large-capacity disposable electronic cigarette cartridge that prevents oil leakage

A disposable high-capacity electronic cigarette cartridge capable of preventing tobacco tar leakage comprises a round-tube-shaped casing (1), an axial smoke tube (3), a cigarette holder cover (2), a tobacco tar isolation rubber gasket (4) and an atomizer assembly, wherein the axial smoke tube (3) is arranged in the inner center of the casing, the cigarette holder cover (2) covers the top of the casing, vent holes (2a) are formed in the cigarette holder cover (2), the tobacco tar isolation rubber gasket (4) is arranged at the middle-upper part in the casing and mounted on the smoke tube in a sleeving manner, and the atomizer assembly is arranged at the lower end of the smoke tube; the tobacco tar isolation rubber gasket divides an inner cavity of the casing into an upper annular cavity (14) for accommodating filtration or flavoring materials and a lower tobacco tar storage cup (13) for storing tobacco tar. No tobacco tar storage cotton is used, bacterium breeding can be effectively avoided, air in the annular tobacco tar storage cup can be completely removed, the problem of tobacco tar leakage is effectively solved, the tobacco tar utilization rate is high, the smoke quantity is large, tobacco tar can be prevented from being sucked into the mouth, and the smoking experience is better.

Owner:云南拓宝科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com