Outer rotor gear driven lubricating oil pump

A technology for external rotors and gears, which is applied to engine components, engine lubrication, and lubrication pumps. It can solve the problems of transmission stability, safety and reliability, low installation and positioning accuracy, and large space occupation. The effect of mass production, simplified connection structure and supporting parts, and reduced occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

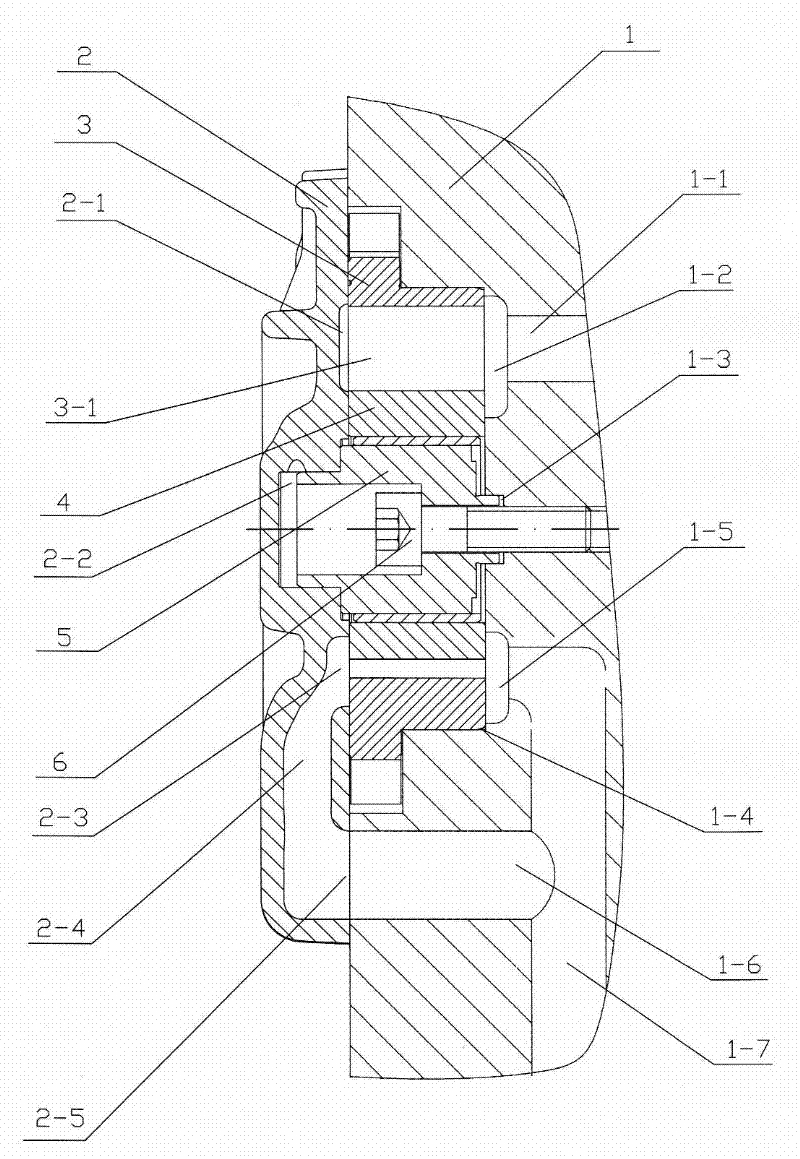

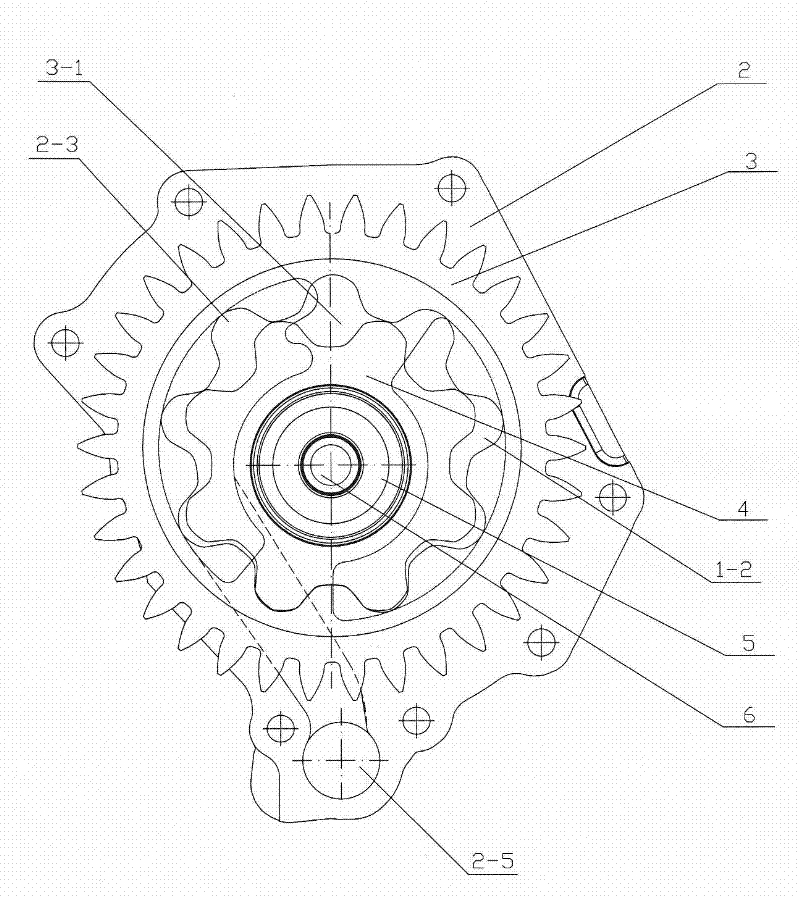

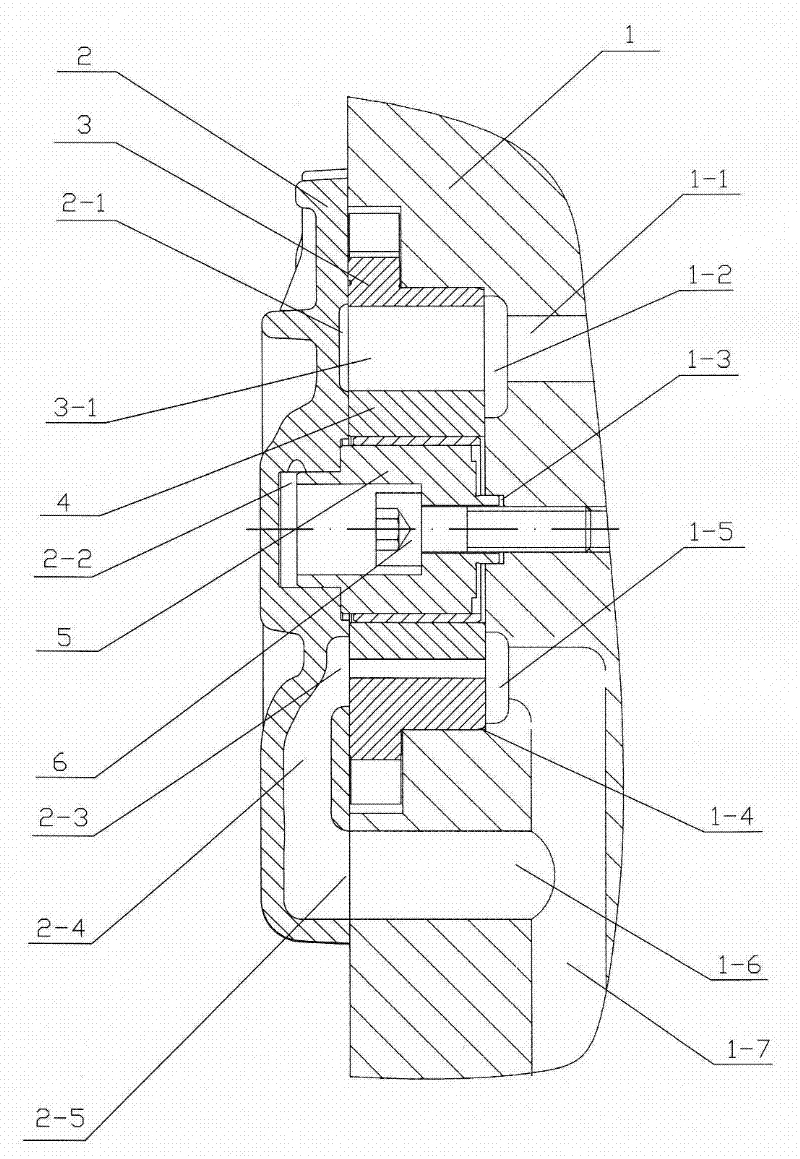

[0015] An outer rotor gear transmission oil pump comprises a body pump body 1, a pump cover 2, an outer rotor gear 3, an inner rotor 4, a boss pump shaft 5 and an inner hexagon screw 6. The bottom surface of the rotor hole 1-4 of the body pump body 1 is provided with an oil inlet passage 1-7, an oil inlet chamber 1-5, an oil outlet chamber 1-2, an oil outlet hole 1-1 and an oil passage hole 1-6 . The oil inlet chamber 1-5 and the oil passage hole 1-6 communicate with the oil inlet passage 1-7, and the oil outlet chamber 1-2 communicates with the oil outlet hole 1-1. The plane of the pump cover 2 is provided with an oil inlet chamber 2-3, a tunnel oil passage 2-4, an oil inlet 2-5 and an oil outlet chamber 2-1, wherein the oil inlet chamber 2-3 passes through the tunnel oil passage 2 -4 communicates with oil inlet 2-5.

[0016] The boss pump shaft 5 is installed on the bottom surface of the rotor hole 1-4 at the front end of the body pump body 1 with a hexagon socket head scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com