Double-pump confluence hydraulic system and excavator

A hydraulic system and double-pump confluence technology, applied in the field of double-pump confluence hydraulic system and excavator, can solve the problems of energy waste, high heat generation, large pressure loss, etc., and achieve short flow distance, small energy loss and small pressure loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

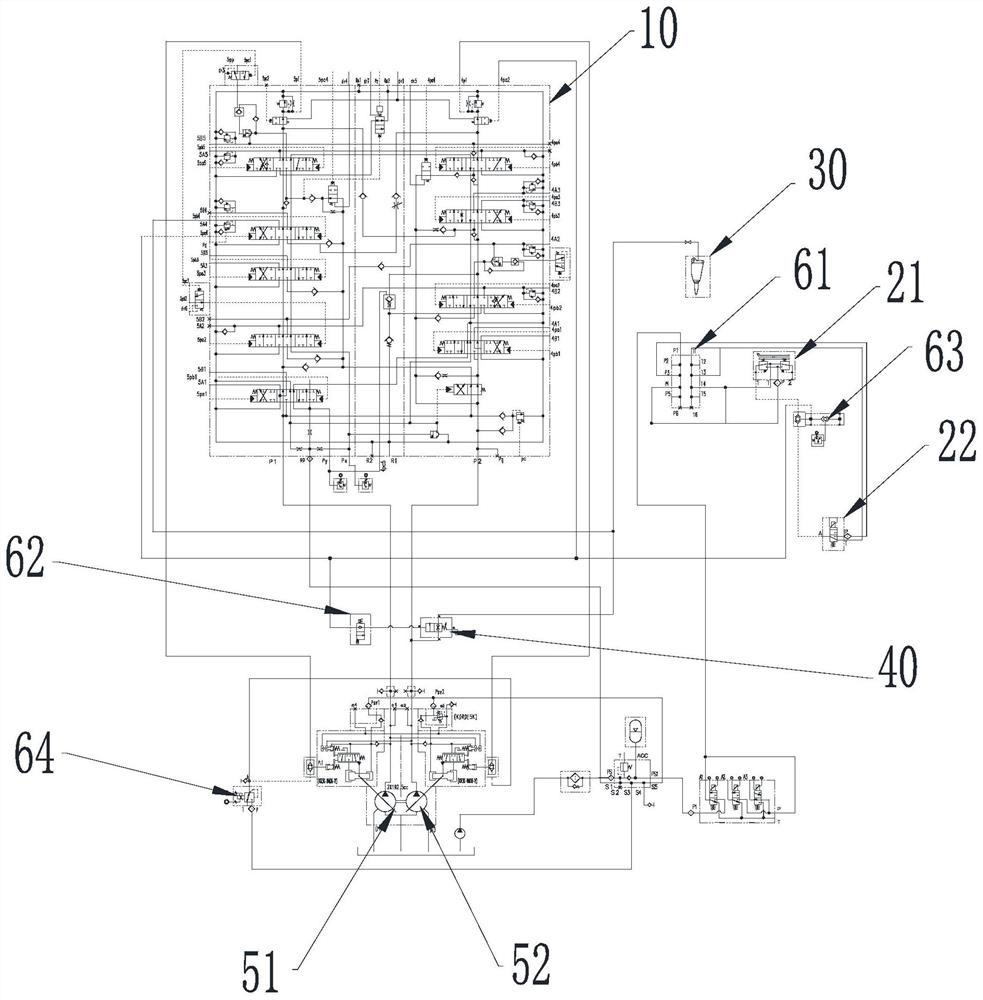

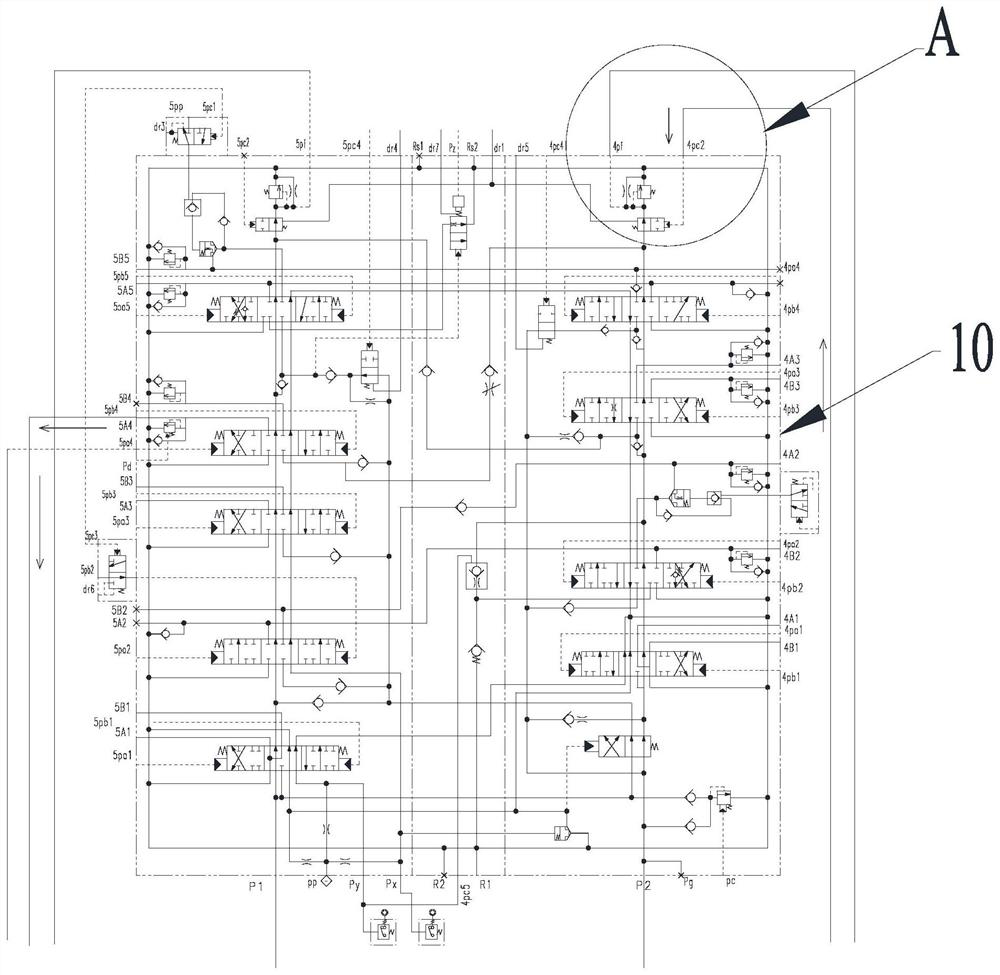

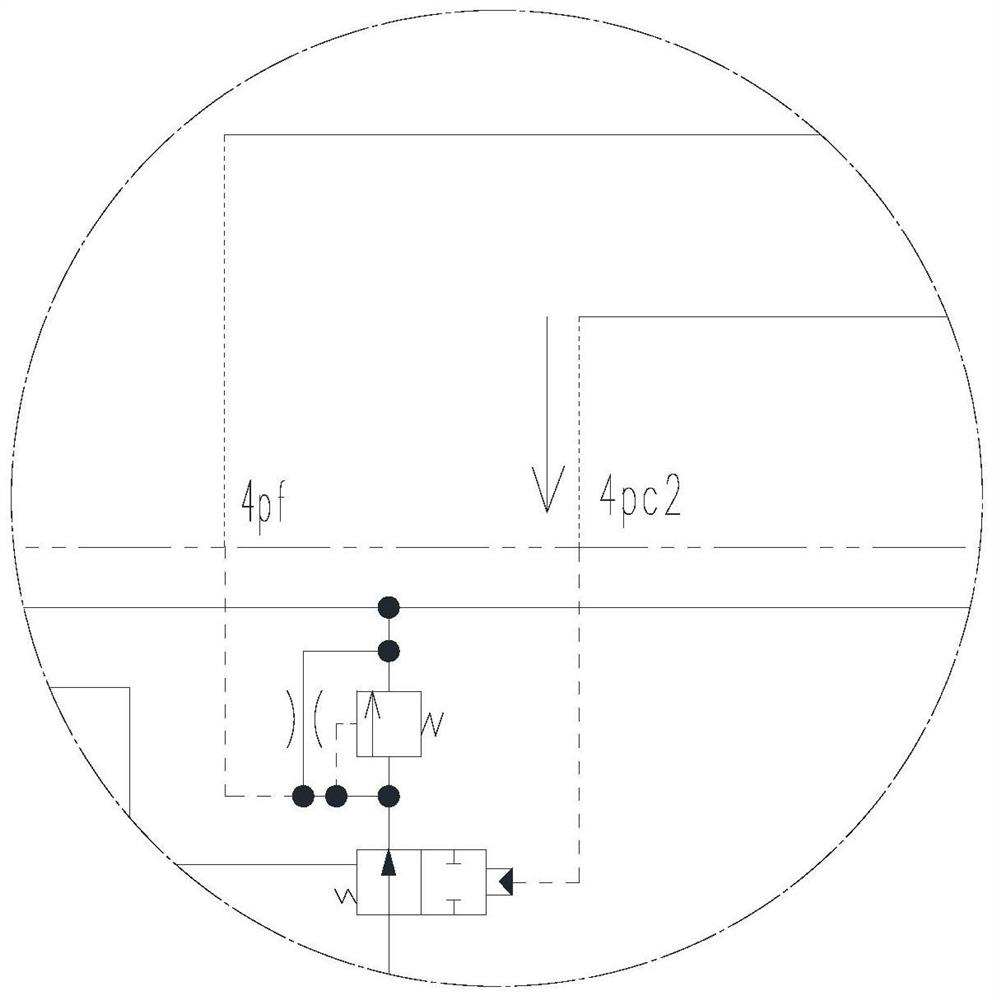

[0048] Please refer to figure 1 - Figure 5 , this embodiment provides a dual-pump confluence hydraulic system, which includes a pumping module, a breaker starting module, a main valve 10 and a breaker 30, wherein:

[0049] The pumping module includes a first pumping mechanism 51 and a second pumping mechanism 52, the main valve 10 includes a first valve block group and a second valve block group, the first pumping mechanism 51 and the first valve block group of the main valve 10 communicated, the second pumping mechanism 52 communicates with the second valve block group of the main valve 10; figure 1 Among them, the first valve block group is a row of valve blocks on the left side of the main valve 10, and the second valve block group is a row of valve blocks on the right side of the main valve 10. Each valve block in the main valve 10 is used to communicate with various mechanisms in the excavator to supply oil to the various mechanisms in the excavator.

[0050] The star...

no. 2 example

[0072] This embodiment provides an excavator, which includes the dual-pump confluence hydraulic system provided by the above-mentioned first embodiment.

[0073] Further, in the excavator provided in this embodiment, a control system is also included, and the control system is connected to the double-pump confluence hydraulic system.

[0074]Specifically, the control system is connected to the pressure switch in the double-pump confluence hydraulic system, and the pressure in the pilot oil pipeline is detected through the pressure switch to determine whether the pilot oil pipeline is connected, so as to determine whether the breaker starting module is activated. When the breaking hammer starting module is started, the control system switches the excavator to the crushing mode, and when the breaking hammer starting module is not started, the control system switches the excavator to the digging mode. Specifically, in the crushing mode, the control system controls the engine in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com