Oil supply structure for compressor and compressor with oil supply structure

A compressor and oil supply technology, which is applied in the field of compressors, can solve problems such as reduced oil supply capacity and affect the normal operation of refrigeration compressors, and achieve the effects of increasing oil supply, good lubrication, and improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

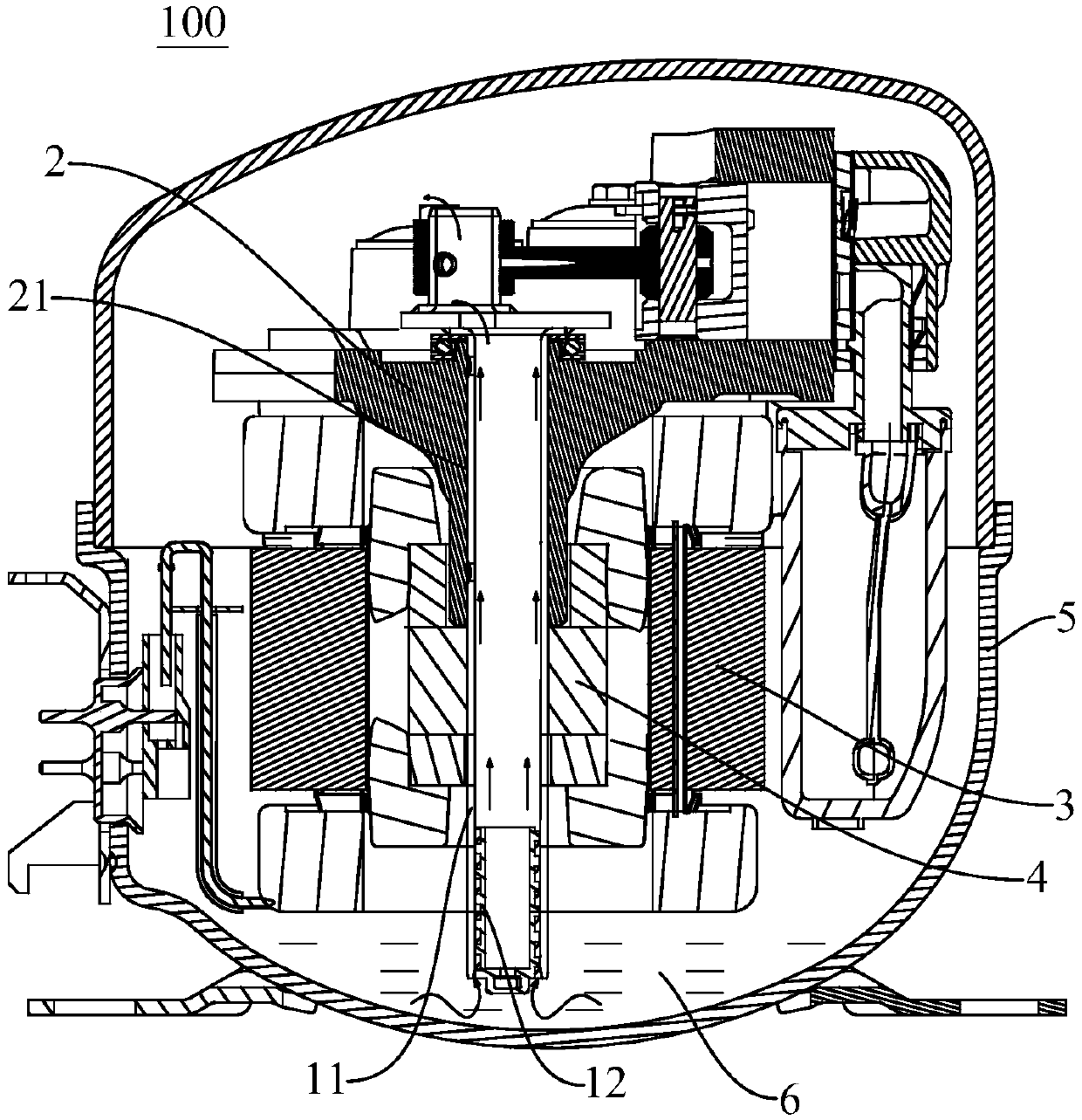

[0063] Refer below Figure 1-Figure 5 A compressor 100 according to a specific embodiment of the present application is described.

[0064] Such as figure 1 As mentioned above, the compressor 100 of this embodiment includes an oil supply structure 1 , a frame 2 , a stator 3 , a rotor 4 and a casing 5 .

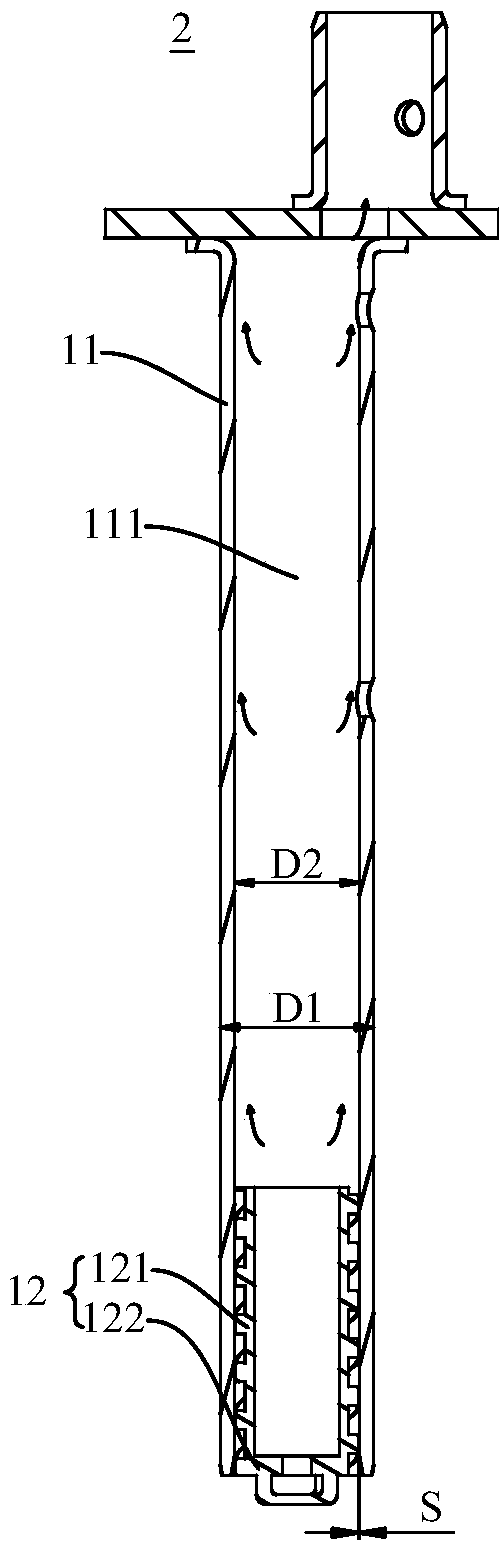

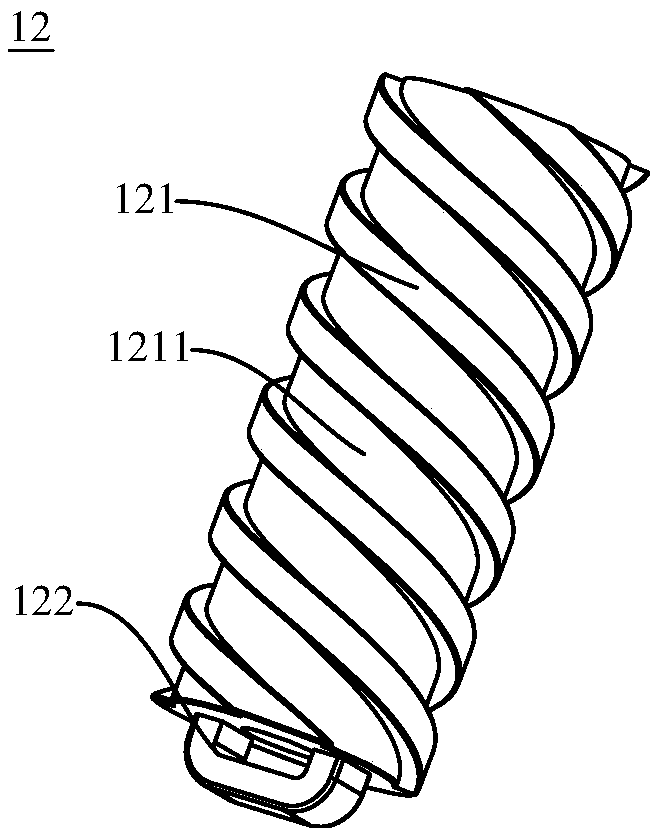

[0065] The oil supply structure 1 includes a crankshaft 11 and an oil pump part 12. The crankshaft 11 is arranged vertically. The crankshaft 11 has a central hole 111. The oil pump part 12 fits in the lower part of the central hole 111. Between the outer peripheral wall of the oil pump part 12 and the inner peripheral wall of the central hole 111 There is a gap between them, and the oil pump part 12 can rotate relative to the crankshaft 11. The width of the gap between the outer peripheral wall of the oil pump member 12 and the inner peripheral wall of the central hole 111 is S, and S satisfies the relational formula: 0.04mm≤S≤0.2mm. A spiral oil groove 1211 extending along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com