Grease plunger pump

A plunger pump and dry oil technology, applied in the field of lubrication, can solve the problems of insufficient oil supply, large number of oil stirring parts, high power consumption, etc., achieve large oil supply, compact and reasonable structure, and shorten service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

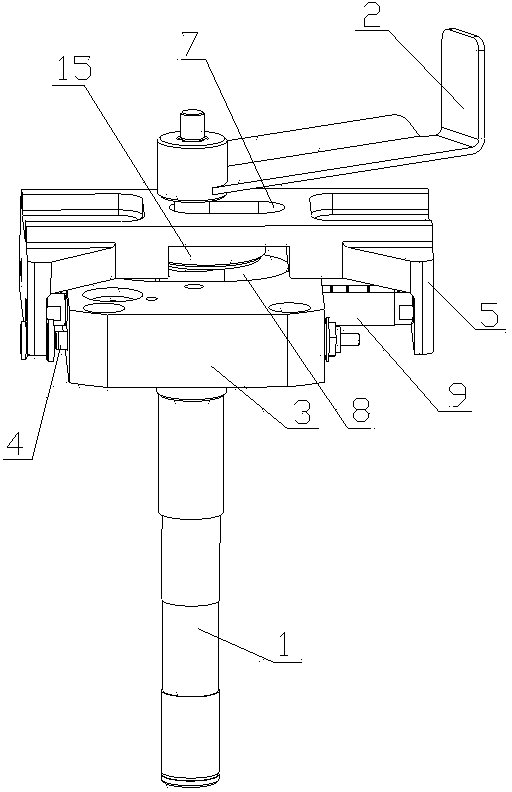

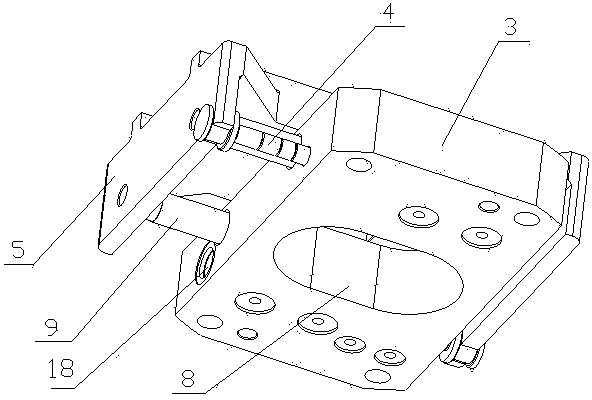

[0059] Combine figure 1 , 2 , 3 and 5, the dry oil plunger pump of the present invention includes a driving device 1, an oil stirring device 2, and an oil suction and discharge device. The driving device 1 provides power for the plunger pump to absorb, discharge and stir oil. The oil stirring device 2 is placed in the oil storage barrel and rotates circularly under the drive of the drive device 1 to achieve oil stirring. The oil suction and discharge device undertakes the oil suction of the plunger pump Working with oil discharge, it includes a pump body and a swing device.

[0060] The pump body includes a cylinder 3 and a plunger 4 fixed in the plunger pump. The cylinder 3 is equipped with suction and discharge channels. The end of the cylinder 3 is provided with an oil suction port and an oil discharge port. The side of the cylinder 3 is provided with a plunger chamber 18. The oil suction and discharge passage connects the oil suction port, the oil discharge port and the plun...

Embodiment 2

[0065] Combine Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the driving device 1 is placed horizontally, and the rotation axis of the driving device 1 is perpendicular to the rotation axis of the oil stirring device 2. The rotating shaft of the driving device 1 passes through the first through hole 7 opened in the swing body 5 and the second through hole 8 opened in the cylinder 3, and the end is connected to the oil stirring device 2 through the reversing gear set 13 and drives the oil stirring device 2 Stir the dry oil continuously in the storage tank. By setting the gear ratio of the meshing gears in the reversing gear set, the reduction transmission can be realized, so that the oil stirring speed is slower than the pump oil speed, and the generation of air bubbles during the oil stirring process is effectively reduced.

[0066] In this embodiment, the driving device and the oil suction and discharge device are easier to separate or combi...

Embodiment 3

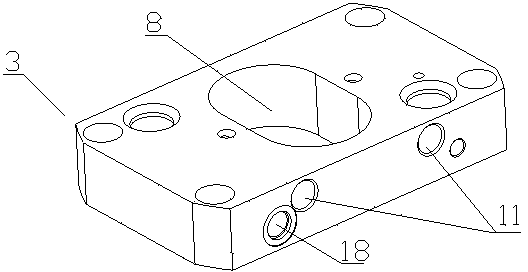

[0068] Combine image 3 As shown, the difference between this embodiment and embodiment 1 is that the second through hole 8 opened in the oil cylinder 3 is a waist-shaped through hole. The size of the waist-shaped through hole is such that the rotating shaft and the eccentric wheel of the driving device 1 are installed and disassembled. As a whole, 15 can easily pass through the second through hole 8, which effectively simplifies the installation and disassembly process of the equipment. Or as Figure 4 As shown, the second through hole 8 can also be set as an eccentric through hole to reduce the area of the through hole on the cylinder 3. When the rotating shaft of the driving device 1 and the eccentric wheel 15 are in the range of the eccentric through hole, the driving device 1 The rotating shaft and the eccentric wheel 15 as a whole can easily pass through the second through hole 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com