Steam turbine lubricating oil high-level oil tank system

A high-level fuel tank and lubricating oil technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as restricting the application of high-level fuel tanks and operating risks of the unit, so as to achieve short effective fuel supply time, large fuel supply, and reduced fuel consumption. The effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

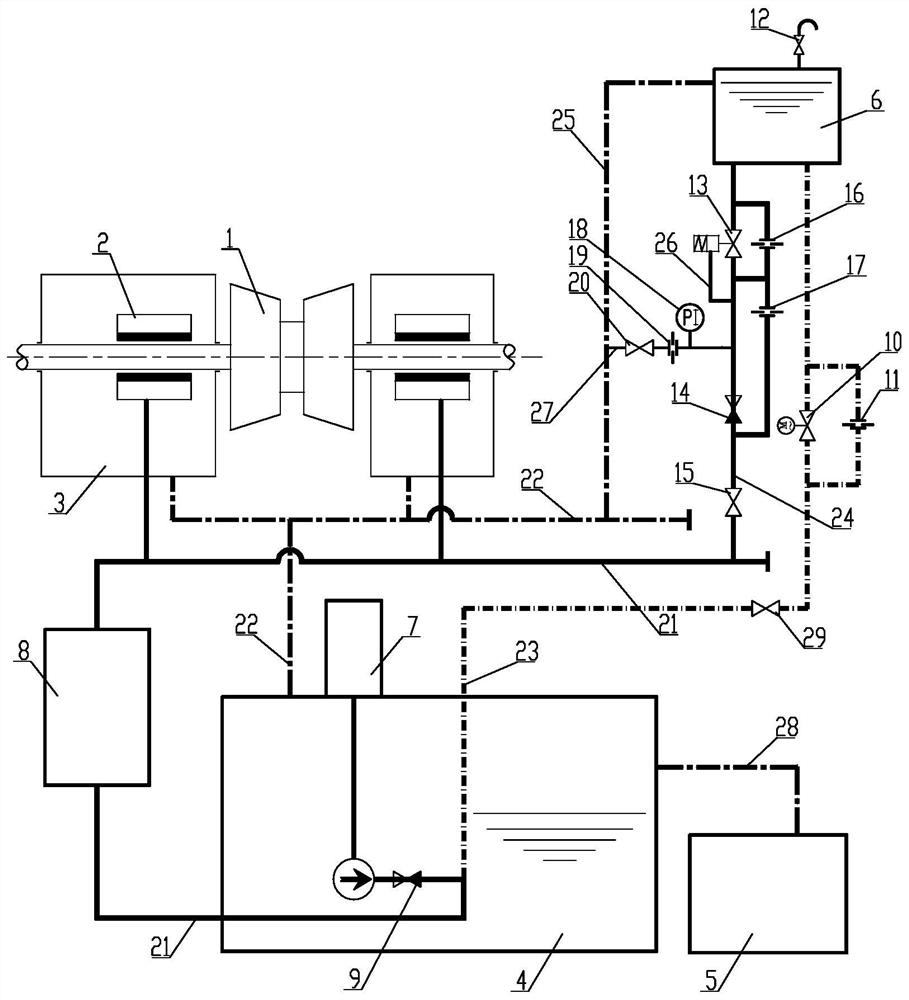

[0027] Such as figure 1 As shown, in this embodiment, a steam turbine lubricating oil high-level oil tank system includes a main oil tank 4, an oil pump 7, an oil supply pipeline 21, a bearing housing 3 and an oil return pipeline 22 connected sequentially in accordance with the flow sequence of lubricating oil, and the oil supply The pipeline 21 is connected with an oil cooler 8, the oil supply pipeline 21 is connected with an oil filling pipeline 23, the oil filling pipeline 23 is connected with a high-level oil tank 6, and a high-level oil supply line is connected between the high-level oil tank 6 and the bearing housing 3 Line 24.

[0028] The unit is in the working condition before starting, the oil pump 7 is running, the lubricating oil passes through the oil pump check valve 9 behind the oil pump 7, and one way passes through the oil supply pipeline 21 and the oil cooler 8 to supply oil to the bearing 2; the other way passes through the oil filling pipeline 23 Fill the ...

Embodiment 2

[0032] On the basis of the above embodiments, in this embodiment, the oil filling pipeline 23 is provided with an A isolation valve 29 and an electric oil filling valve 10 in sequence according to the flow direction of lubricating oil; the electric oil filling valve 10 is connected in parallel with an oil temperature hole plate 11. The electric oil filling valve 10 can control the communication or closing of the oil filling pipeline 23, so as to open when oil filling is required and close after filling.

Embodiment 3

[0034] On the basis of the above embodiments, in this embodiment, the high-level oil supply pipeline 24 is sequentially provided with a self-operated regulating valve 13, an oil discharge check valve 14, and a B isolation valve 15 according to the flow direction of lubricating oil. The pipeline between the self-operated regulating valve 13 and the oil discharge check valve 14 is communicated with a pressure introduction pipe 26 communicated with the self-operated regulating valve 13 .

[0035] In this embodiment, when the unit lubricating oil fails, the oil pump 7 stops, the pressure of the lubricating oil supply pipeline 21 decreases, the oil discharge check valve 14 automatically opens under the pressure difference, and the lubricating oil in the high oil tank 6 passes through The self-operated regulating valve 13 and the oil supply orifice 16 supply oil to the bearing 2. The actuator of the self-operated regulating valve 13 automatically adjusts the opening through the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com