Carburetor

A technology for carburetors and air intake passages, applied to carburetors, machines/engines, engine components, etc., can solve problems such as difficulty in passing exhaust emission regulations, inability to perform fuel metering and supply correctly, and increased costs, so as to reduce power consumption low power consumption, simple structure, and improved output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below based on the drawings.

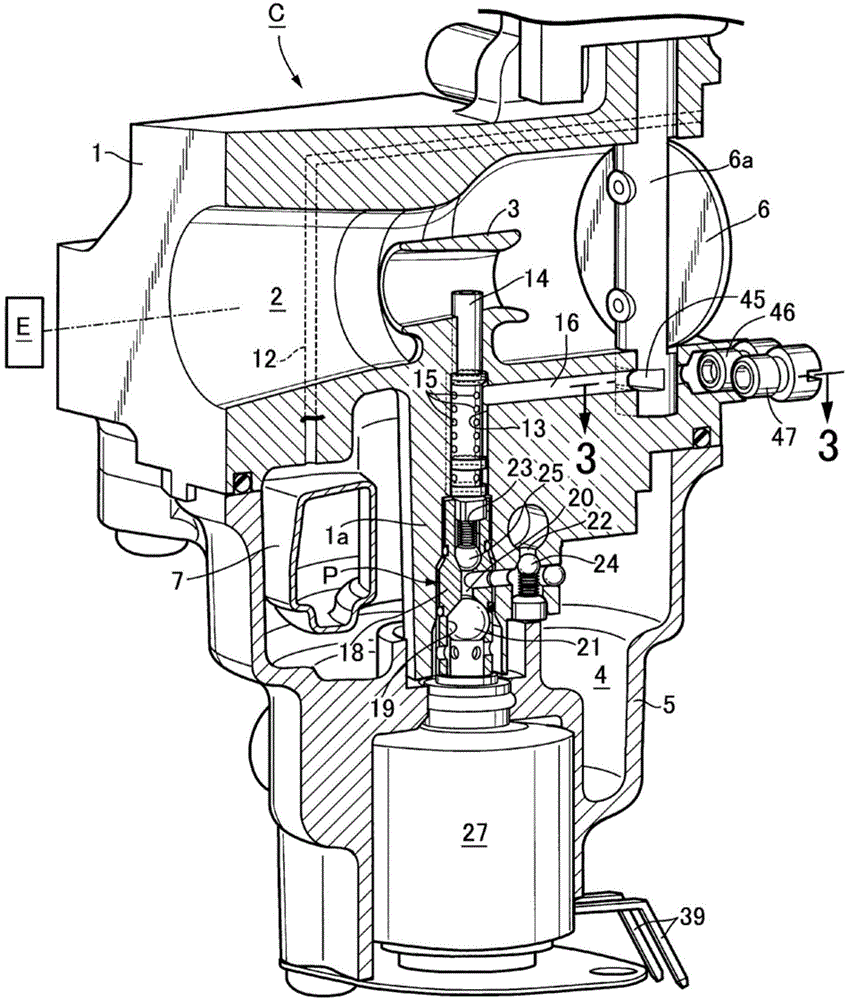

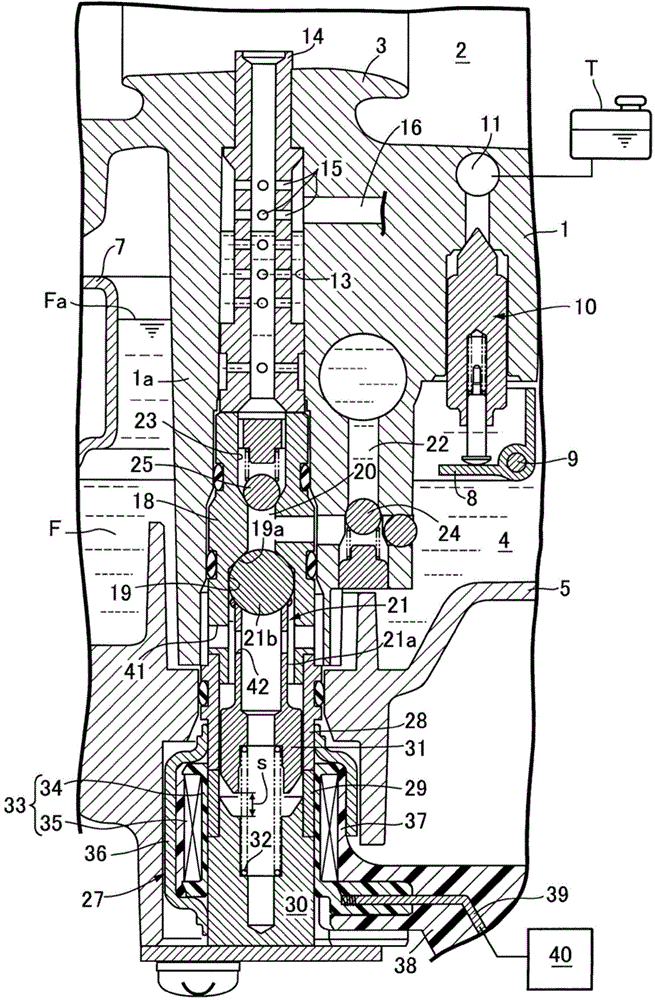

[0029] First, in figure 1 and figure 2 Among them, the carburetor C is used for a single-cylinder engine, or is provided for each cylinder of a multi-cylinder engine. The carburetor C includes a carburetor body 1 having a horizontal air intake passage 2 connected to the air intake port of the engine E, and a float room (float room) that is airtightly joined to the lower end surface of the carburetor body 1 and partitioned therebetween. 4 of the float chamber body 5. The float chamber body 5 is detachably fastened on the carburetor body 1 by bolts.

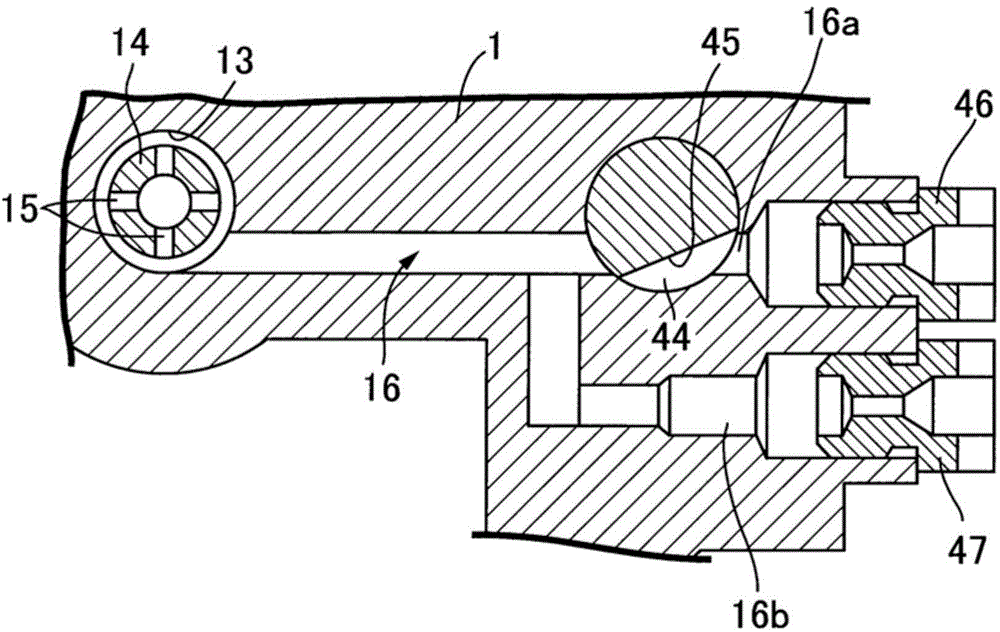

[0030] In the intake passage 2 , a Venturi tube 3 is disposed at the center thereof, and a butterfly valve-type throttle valve 6 is disposed upstream of the Venturi tube 3 .

[0031] The carburetor body 1 integrally has a fuel boss (boss) 1a protruding into the float chamber 4 from the central part of the lower surface thereof, and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com