Patents

Literature

80 results about "Bell nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

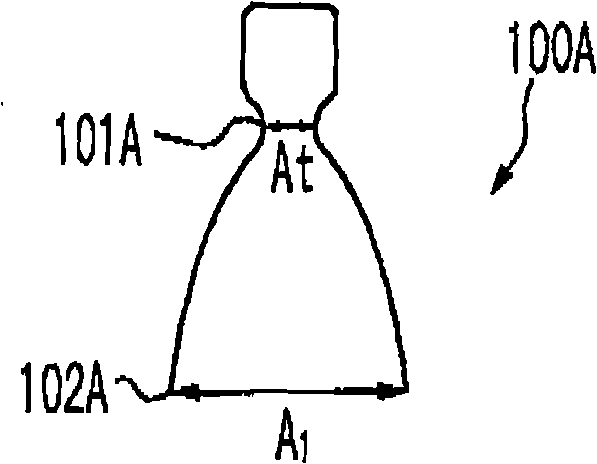

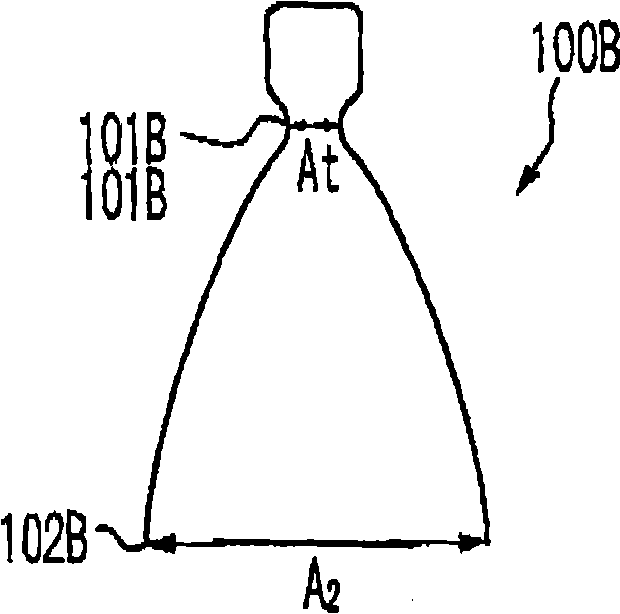

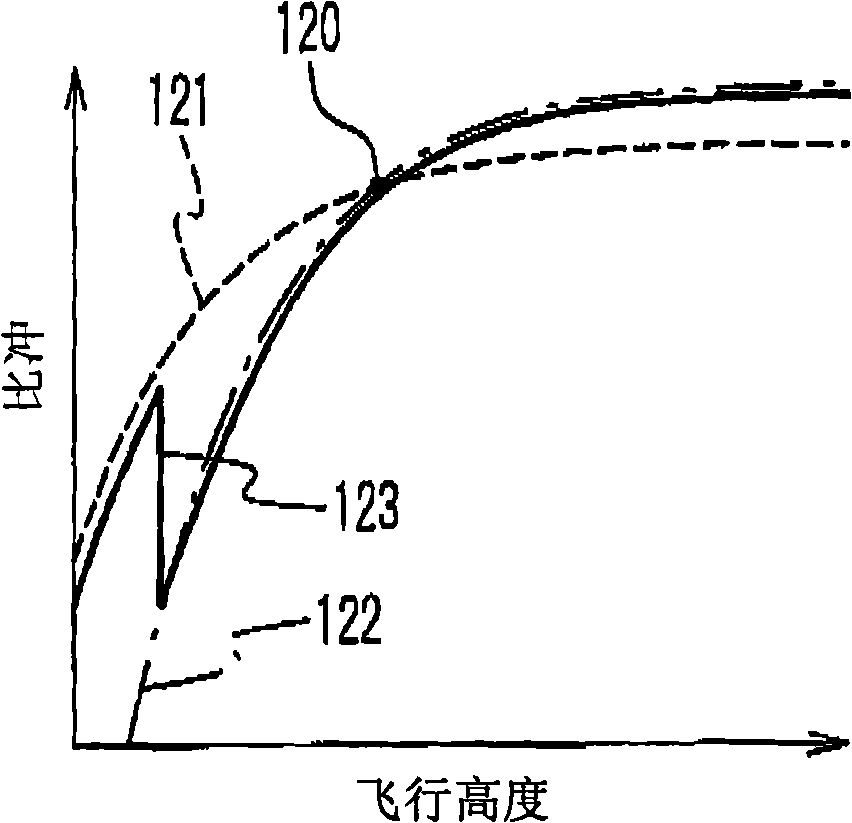

The Bell-shaped or contour nozzle is probably the most commonly used shaped rocket engine nozzle. It has a high angle expansion section (20 to 50 degrees) right behind the nozzle throat; this is followed by a gradual reversal of nozzle contour slope so that at the nozzle exit the divergence angle is small, usually less than a 10 degree half angle.

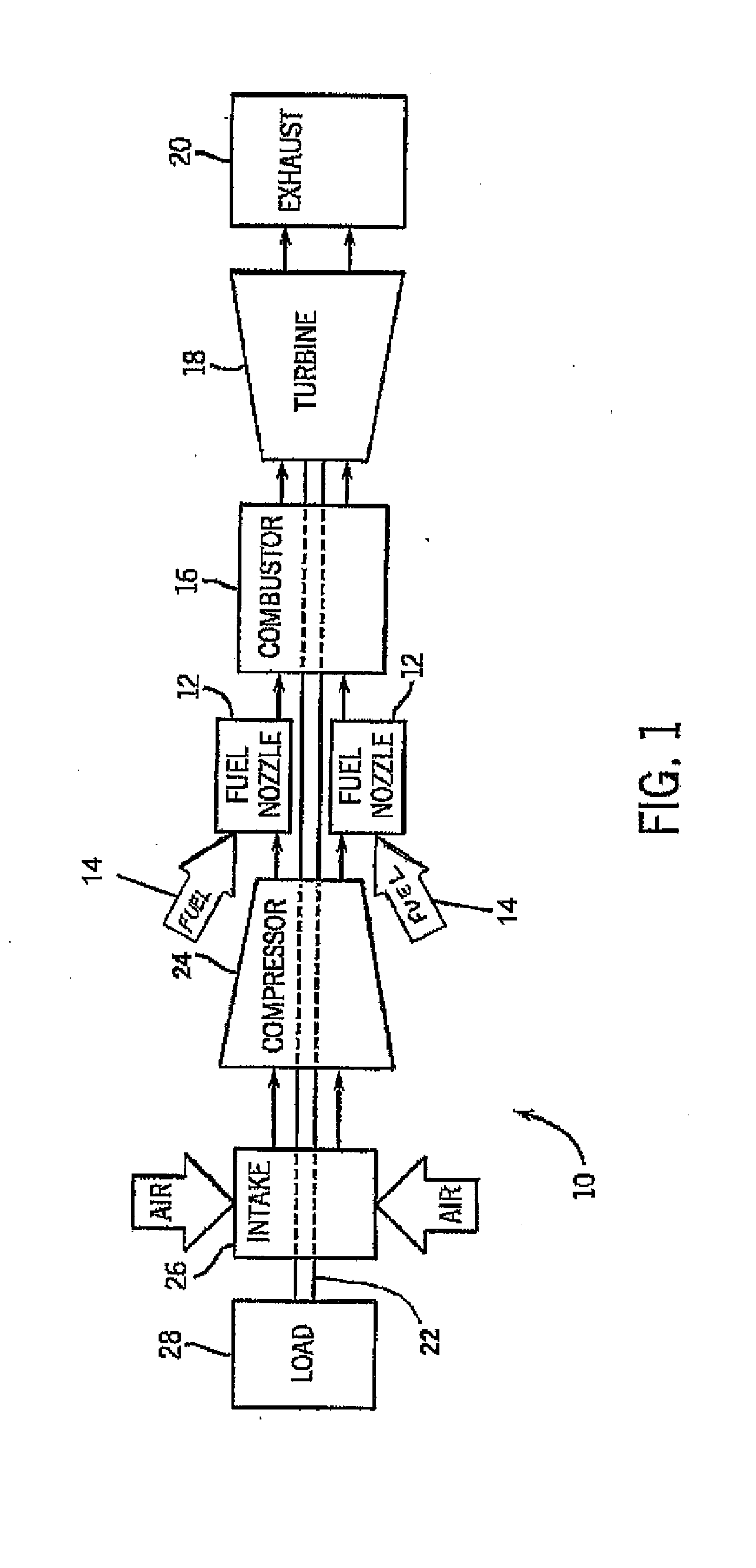

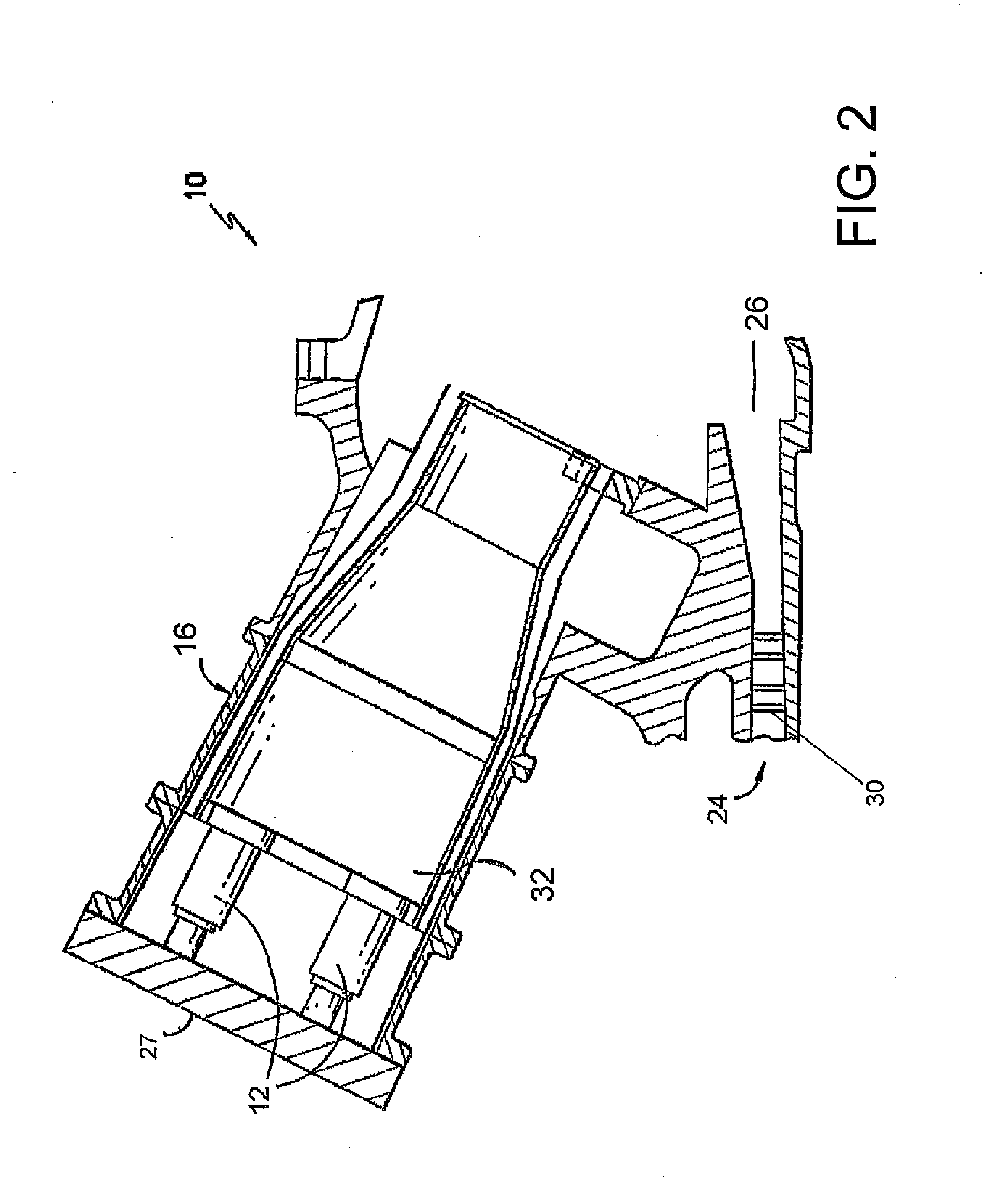

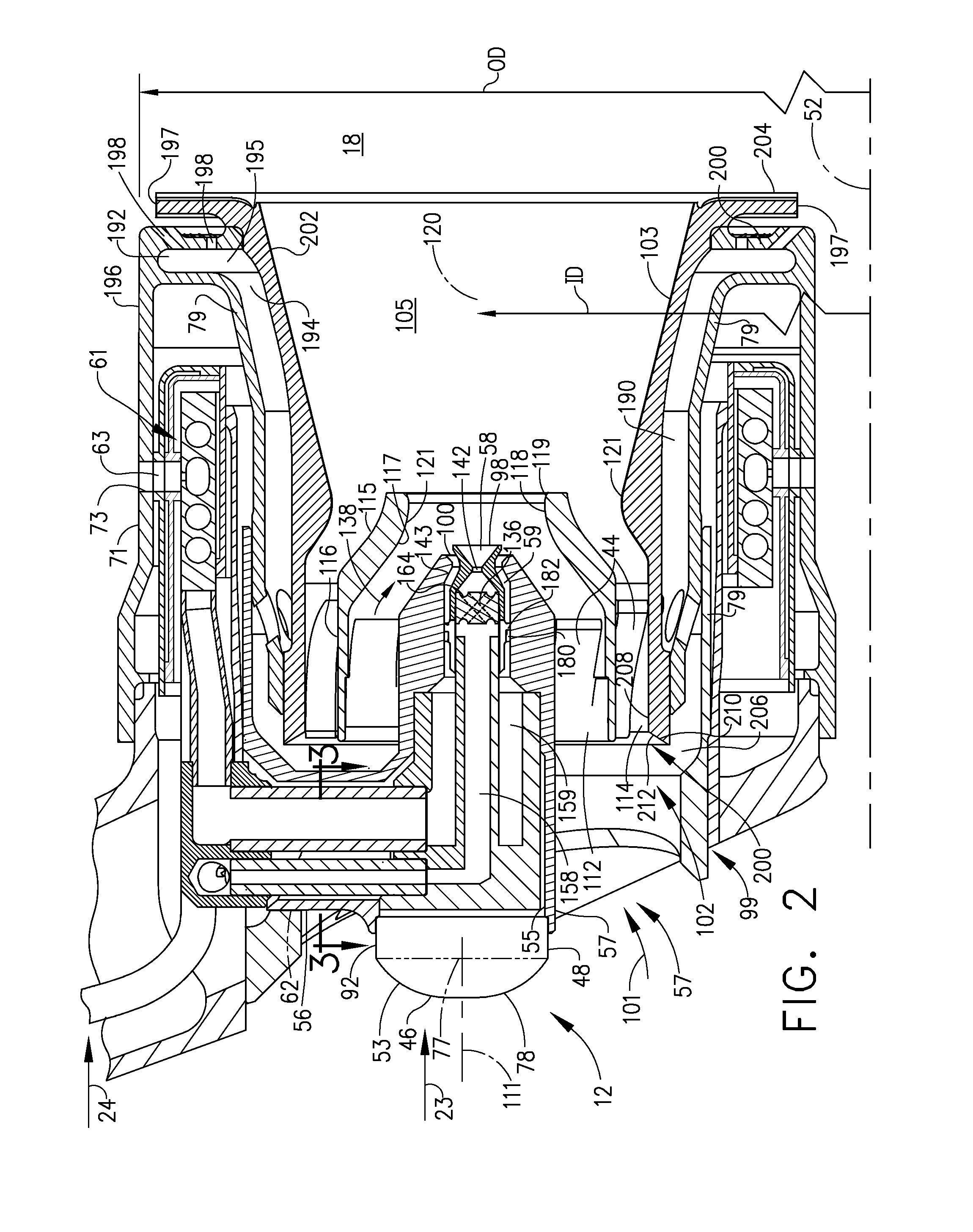

Dual fuel nozzle tip assembly

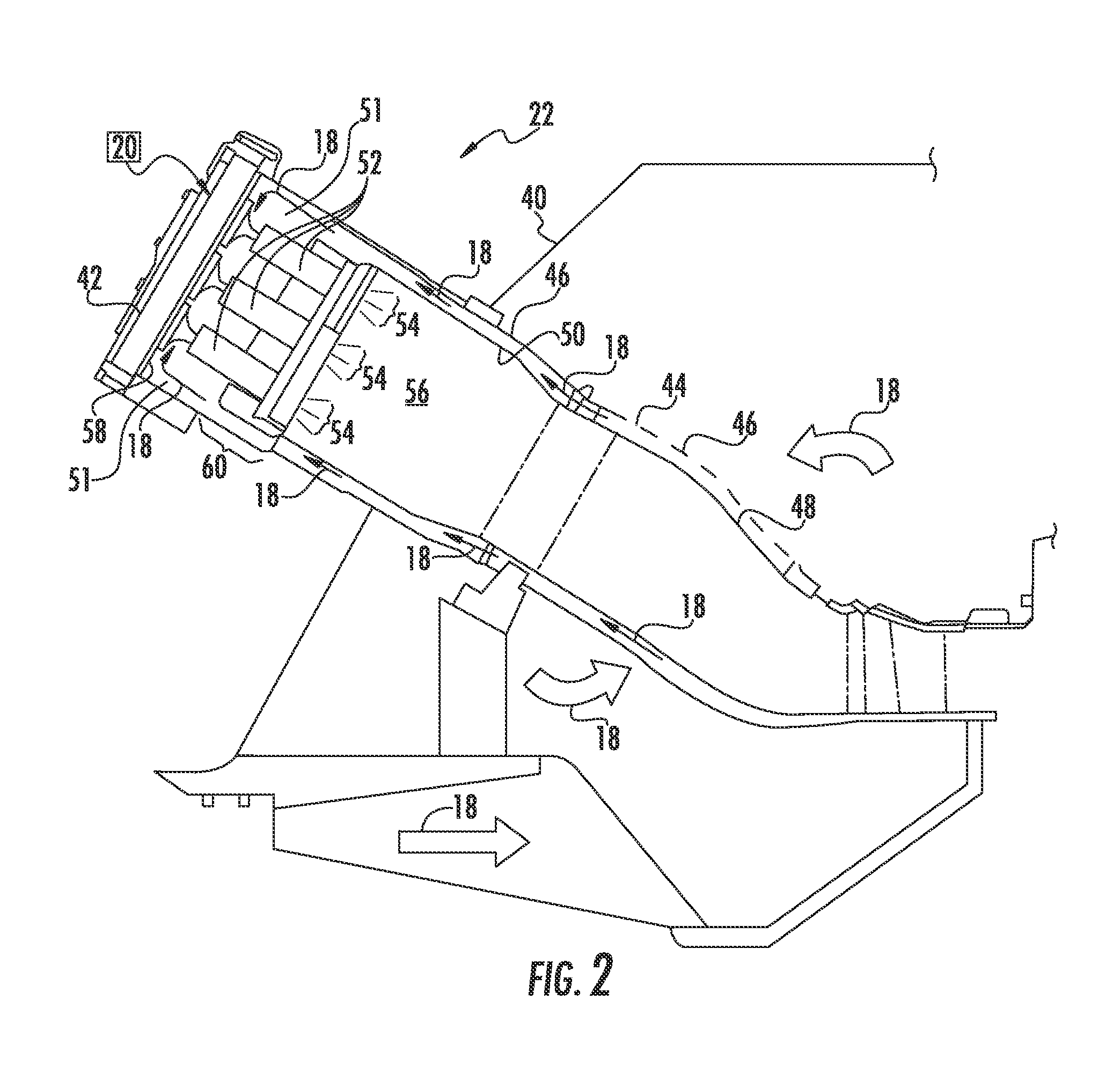

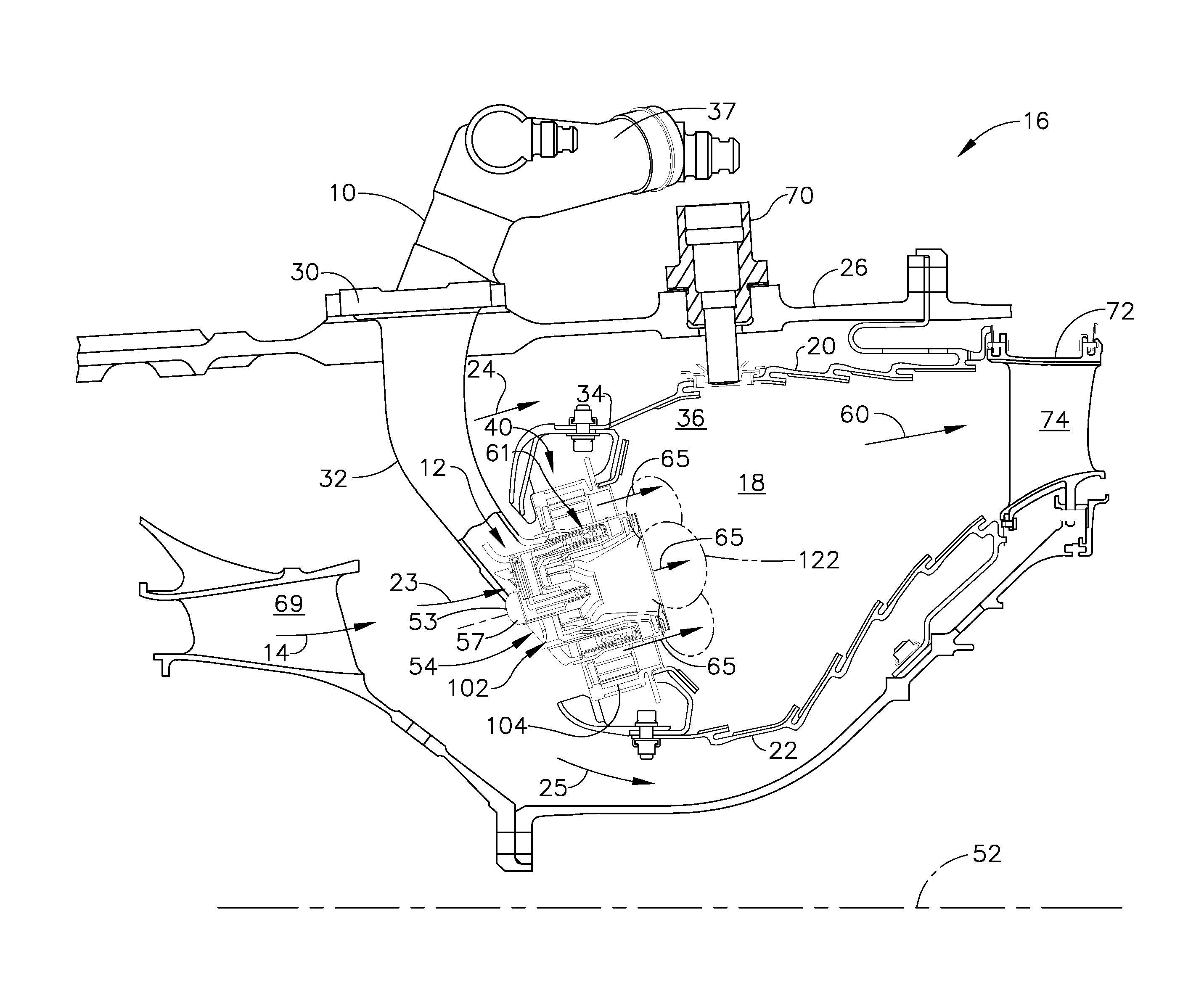

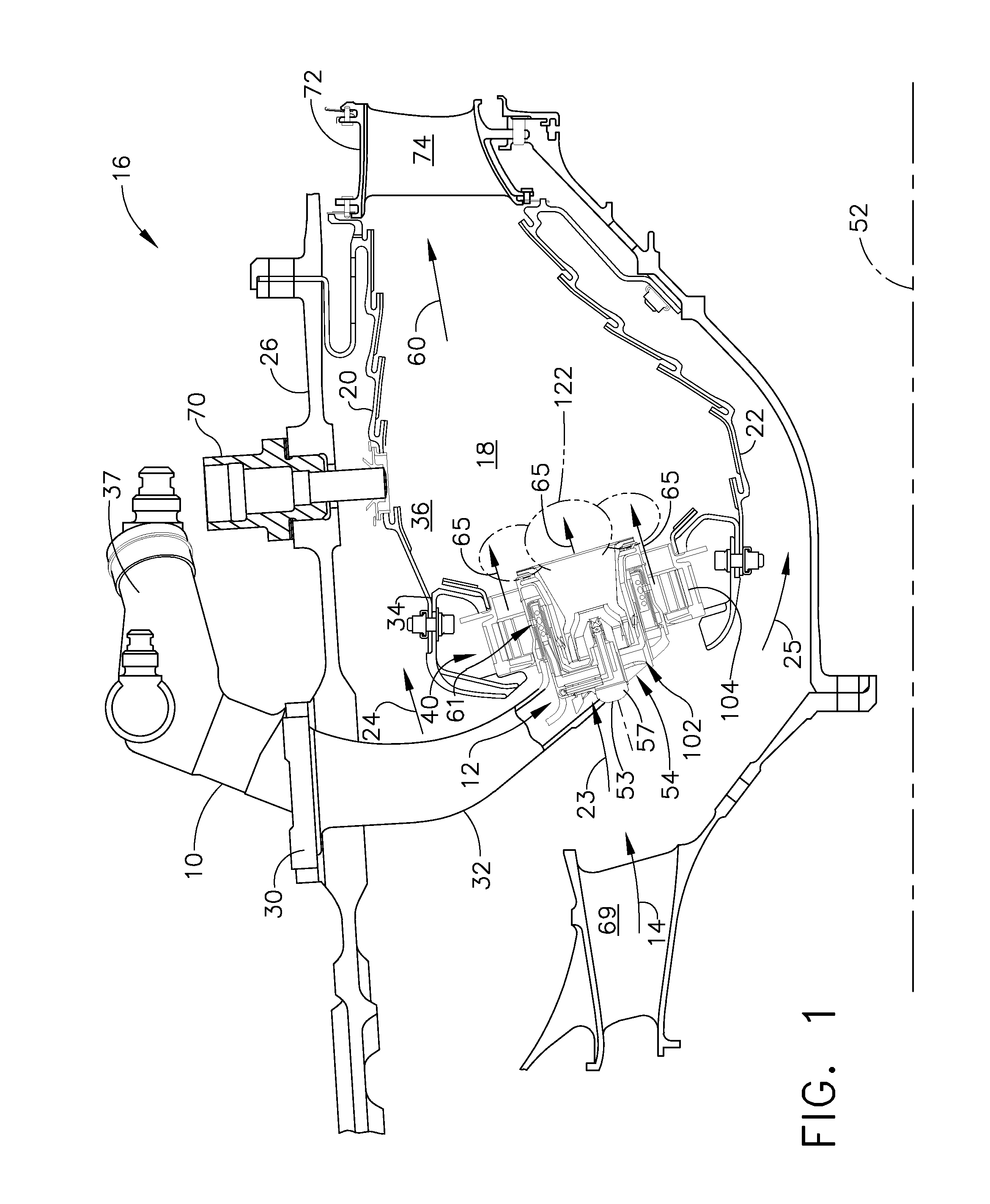

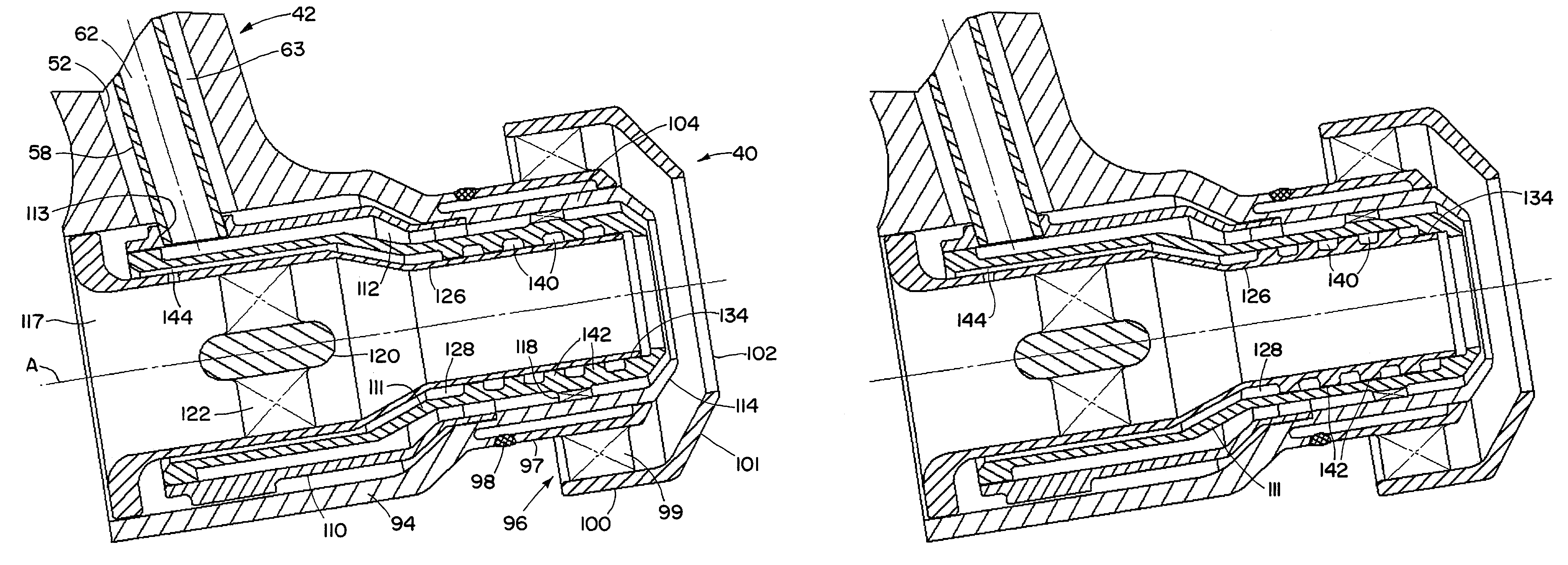

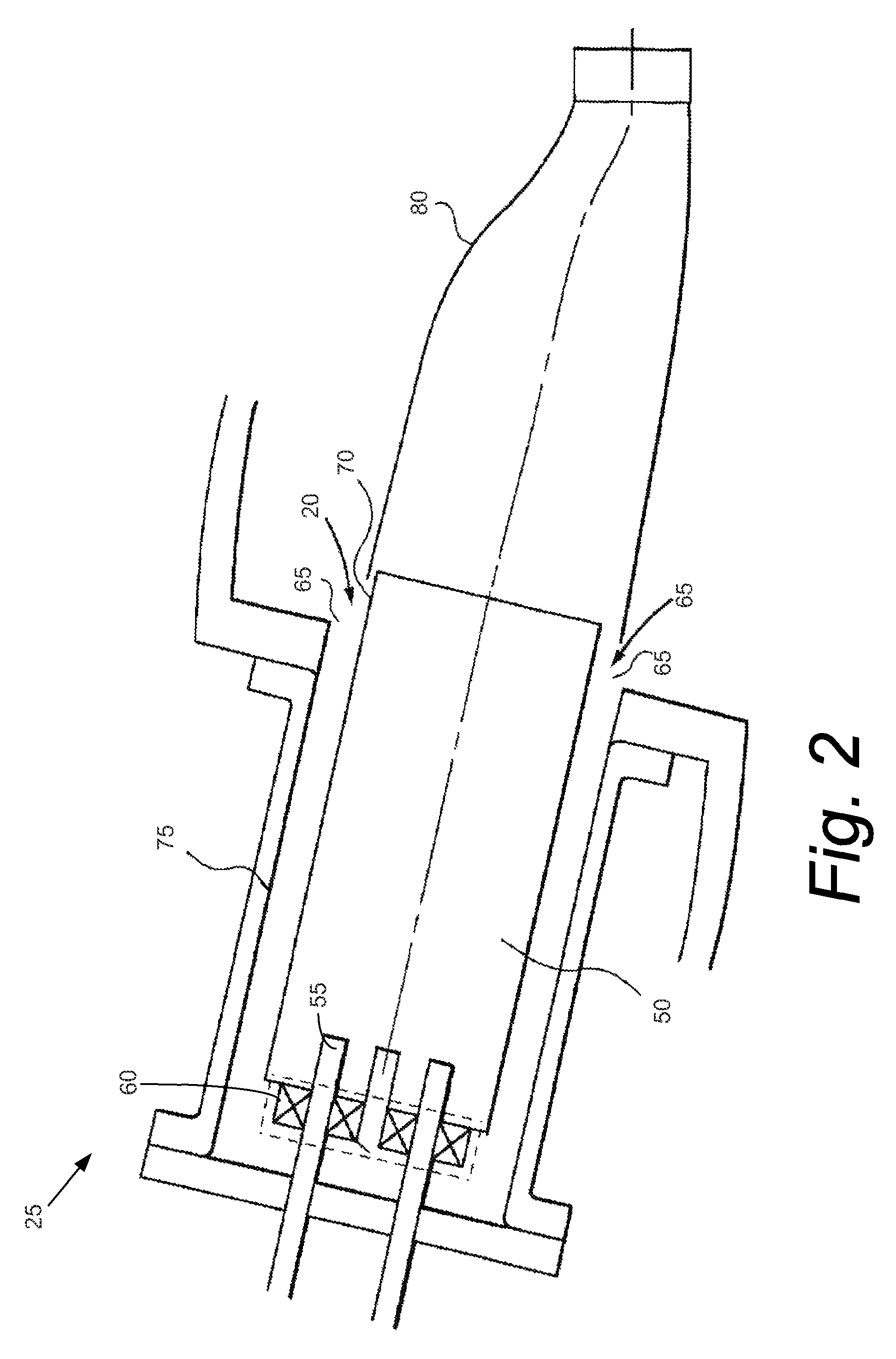

A fuel nozzle for a combustor includes a burner tube and a center nozzle assembly disposed within the burner tube. The center nozzle assembly includes a center body that at least partially defines a cooling air flow passage through the center nozzle assembly. A premix flow passage is defined between the burner tube and the center nozzle assembly. A tip assembly is disposed at a downstream end of the center body. The tip assembly includes an impingement plate, and a cap that is disposed downstream from the impingement plate. The impingement plate and the cap at least partially define a cooling plenum therebetween. An insert passage extends through the impingement plate and a cooling flow outlet extends through the cap. A plurality of cooling ports extends through the impingement plate to provide for fluid communication between the cooling air flow passage and the cooling plenum.

Owner:GENERAL ELECTRIC CO

Annular premixed pilot in fuel nozzle

InactiveUS20130219899A1Increase in NOxMinimizationContinuous combustion chamberGas turbine plantsCombustorGas turbines

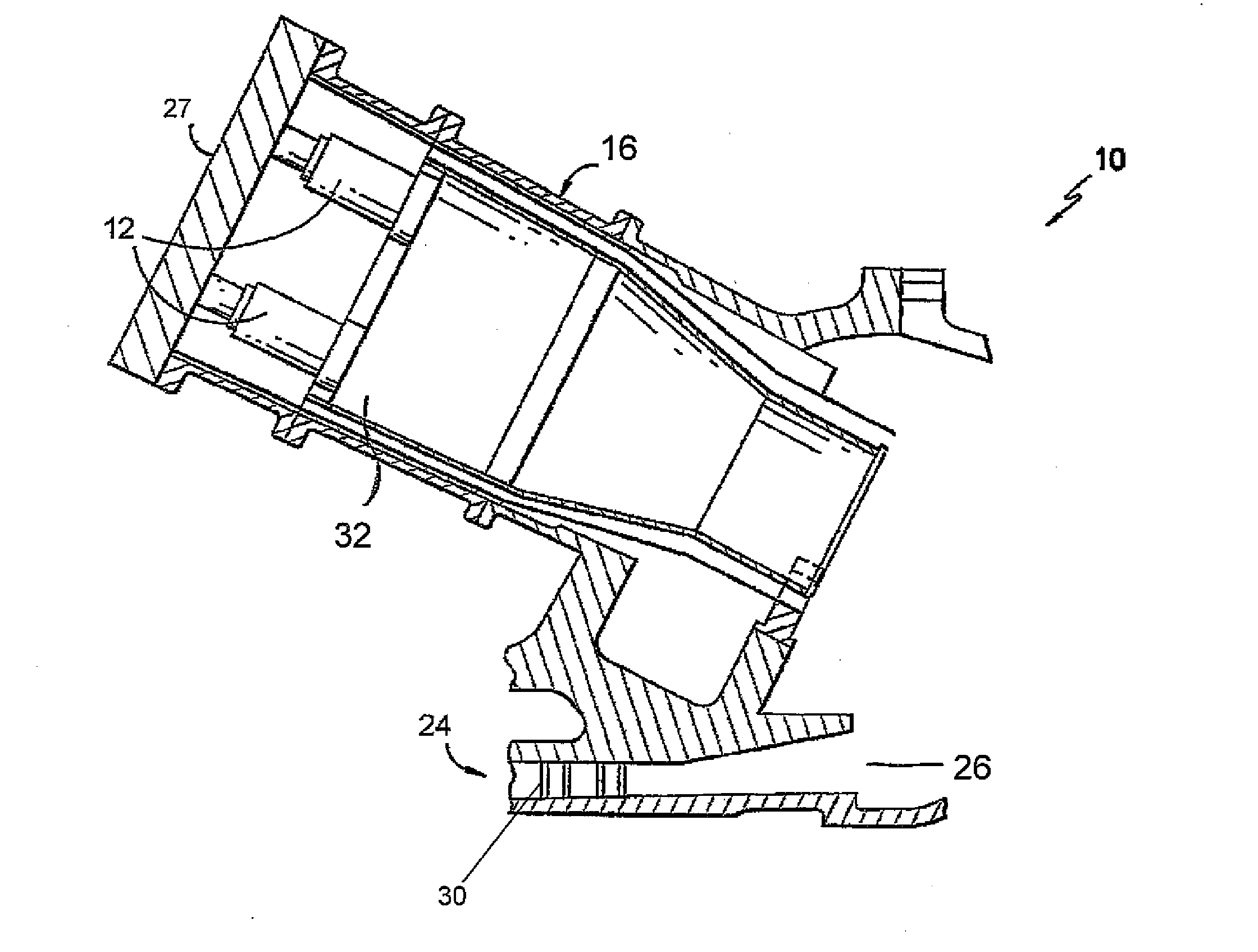

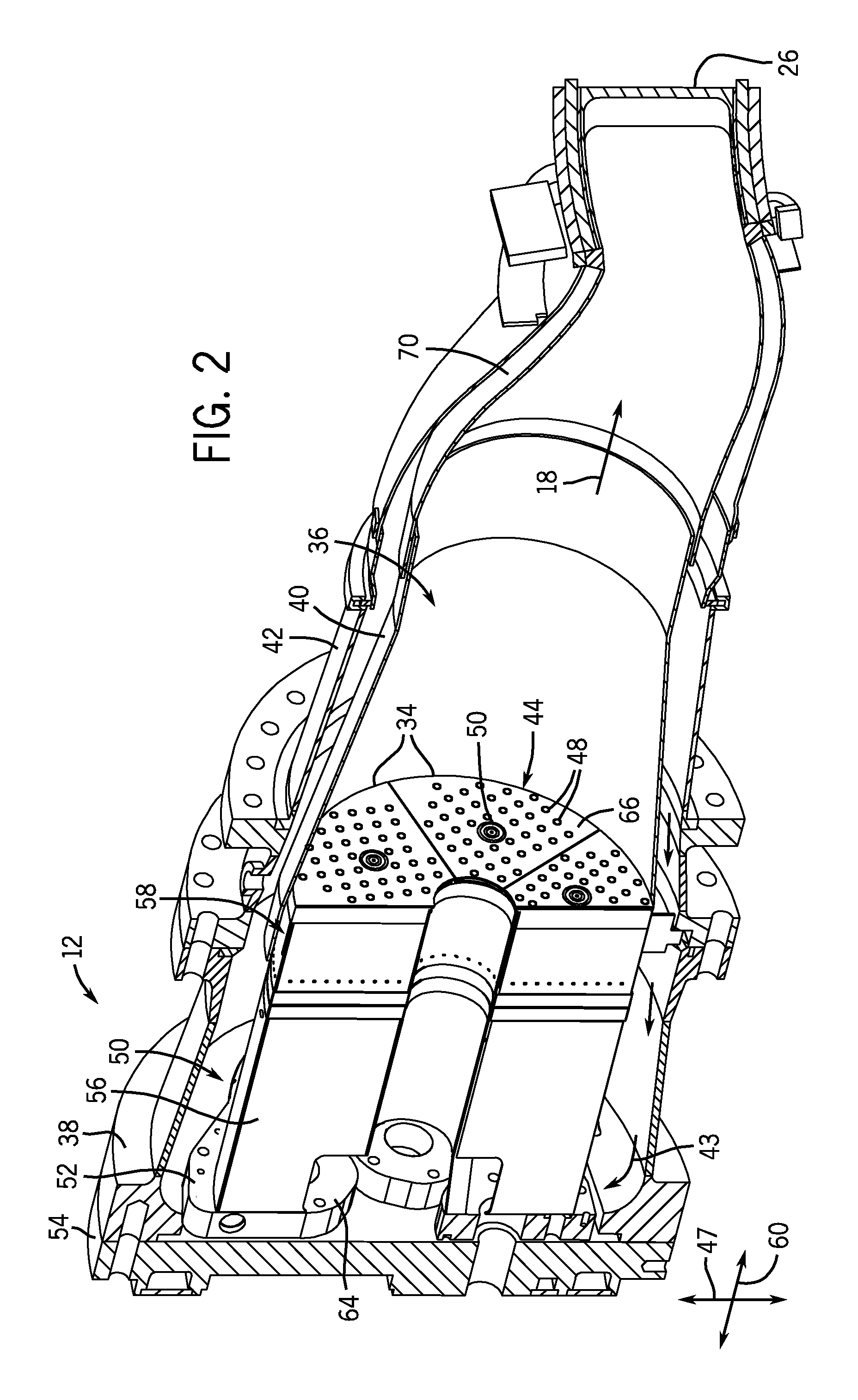

A combustor for a gas turbine engine has a head end portion that carries at least one fuel / air nozzle. Each fuel / air nozzle includes a premixed pilot nozzle having premix conduits that are configured with concentric axes that direct the fuel / air mixture axially from the premixed pilot nozzle. The premixed pilot nozzle can include an annular channel disposed radially outwardly from the premix and including air jets that direct air radially outwardly from the premix conduits.

Owner:GENERAL ELECTRIC CO

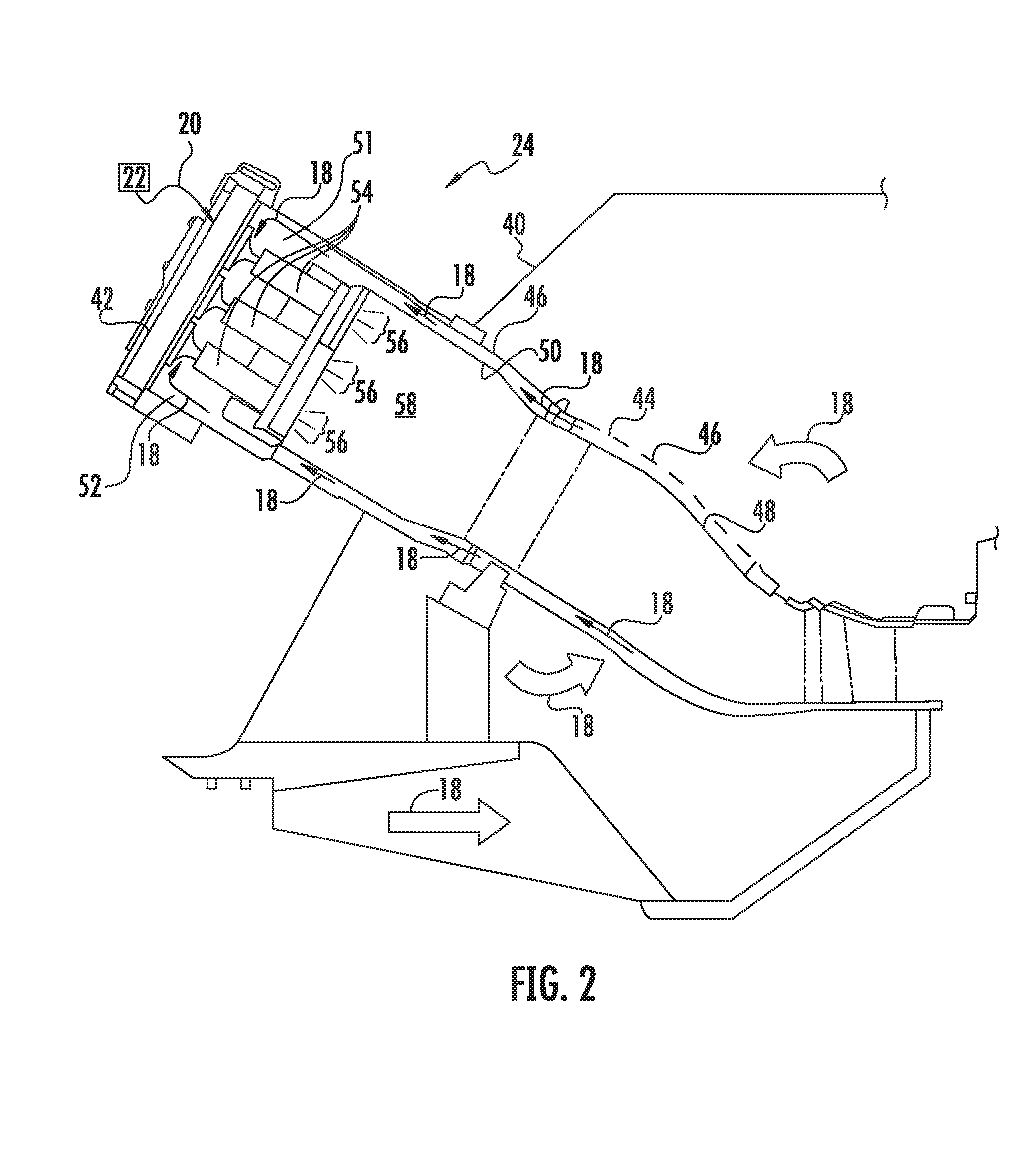

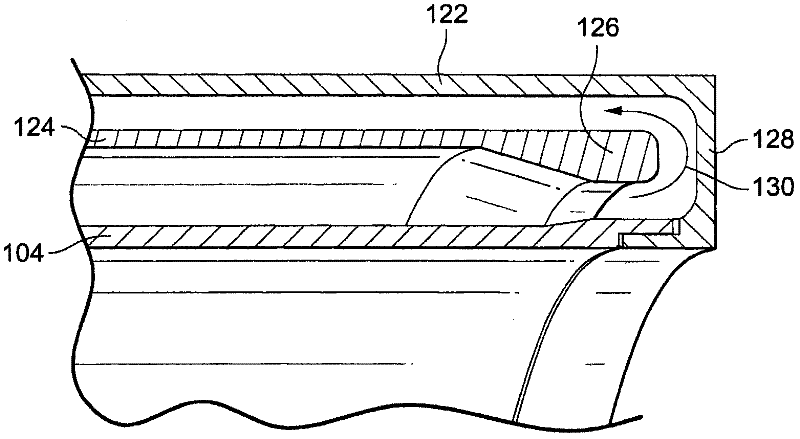

Cooling flowpath dirt deflector in fuel nozzle

A fuel nozzle assembly includes a chamfered leading edge of an annular wall section disposed between an outer pilot swirler and an inlet to an injector cooling flowpath surrounding the second pilot swirler. A radially inwardly facing conical chamfered surface of the chamfered leading edge deflects dirt from cooling flowpath.

Owner:GENERAL ELECTRIC CO

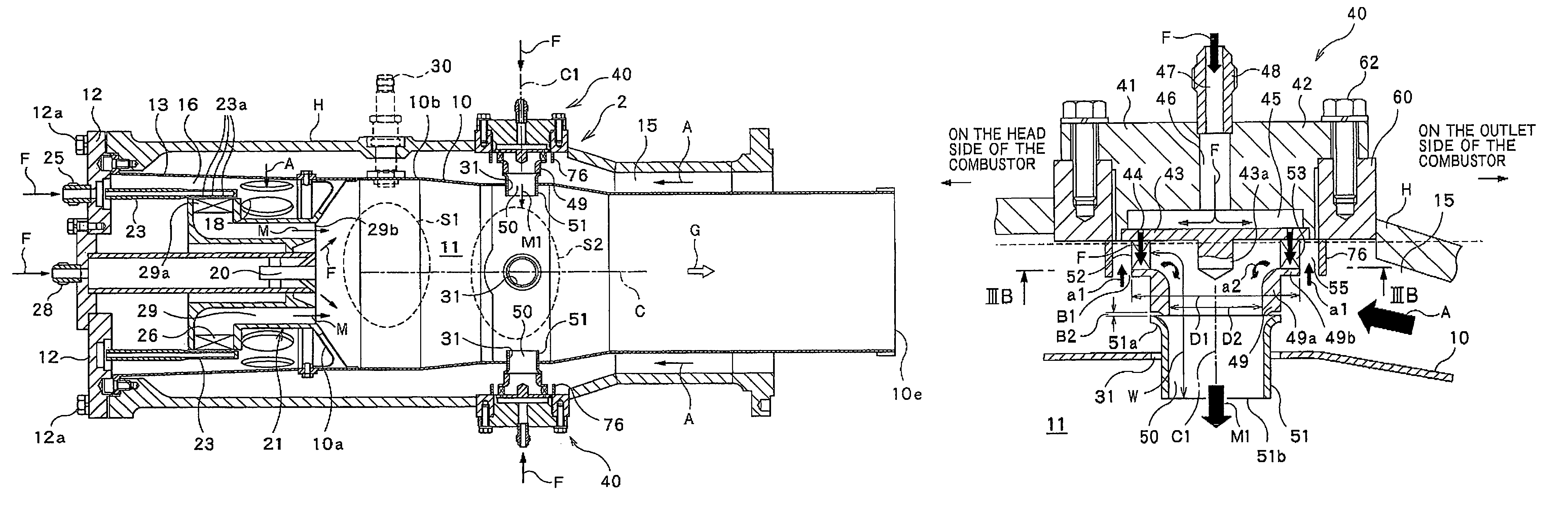

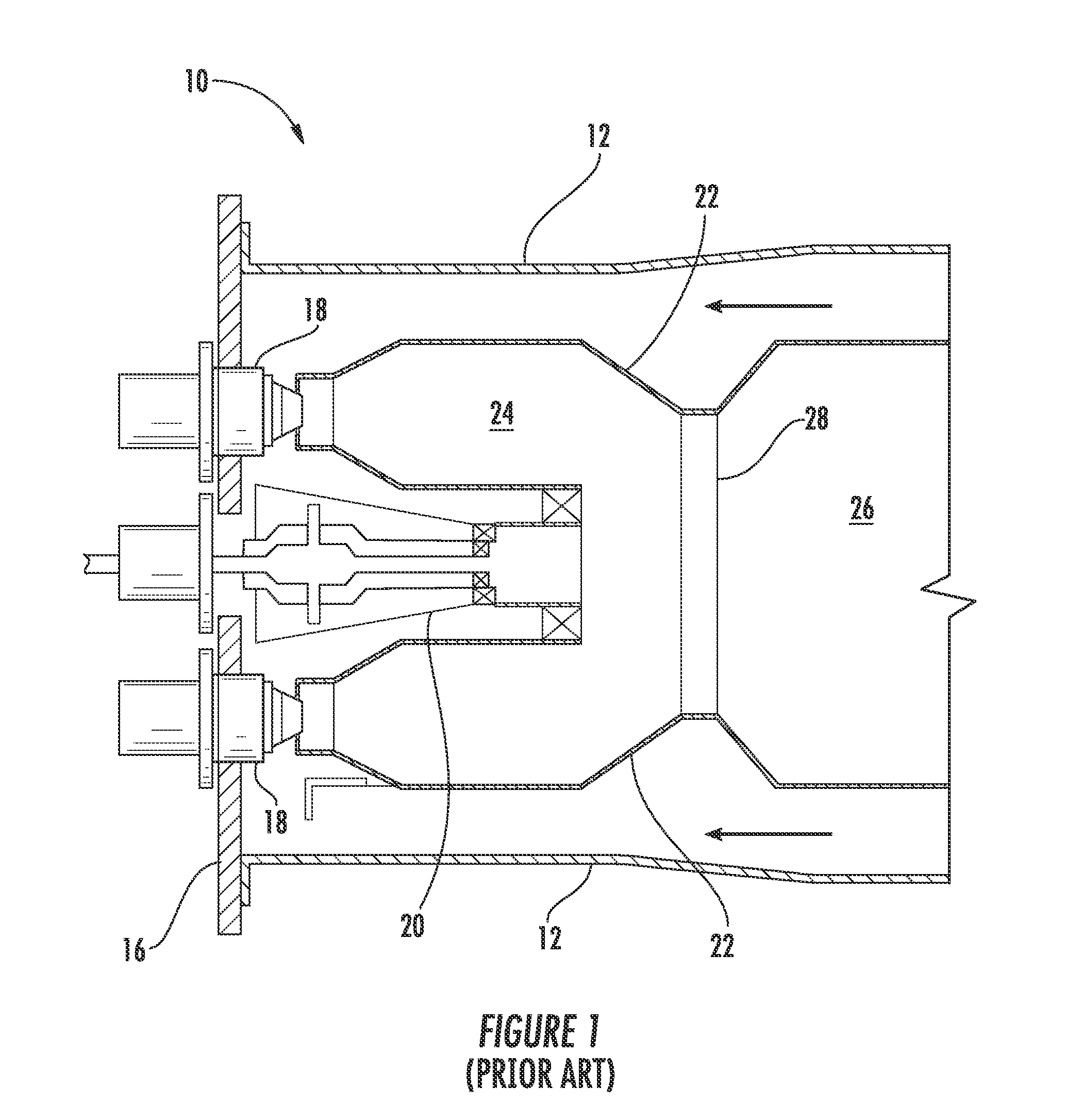

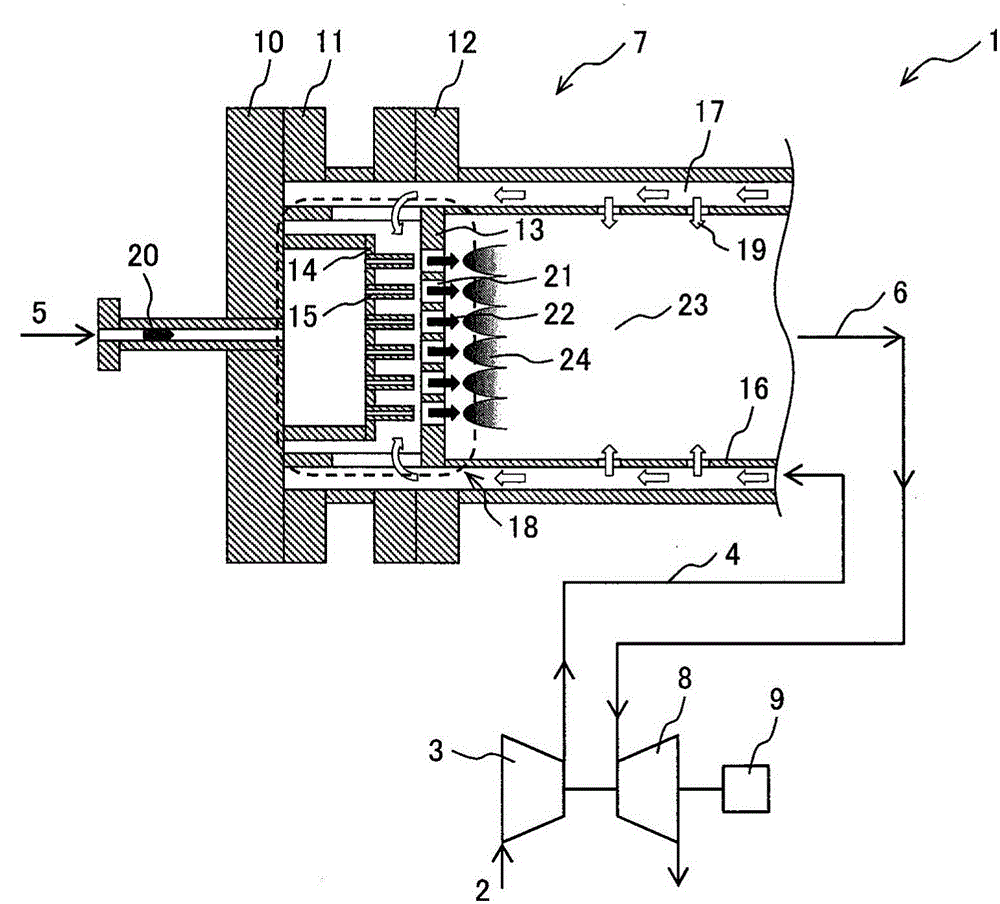

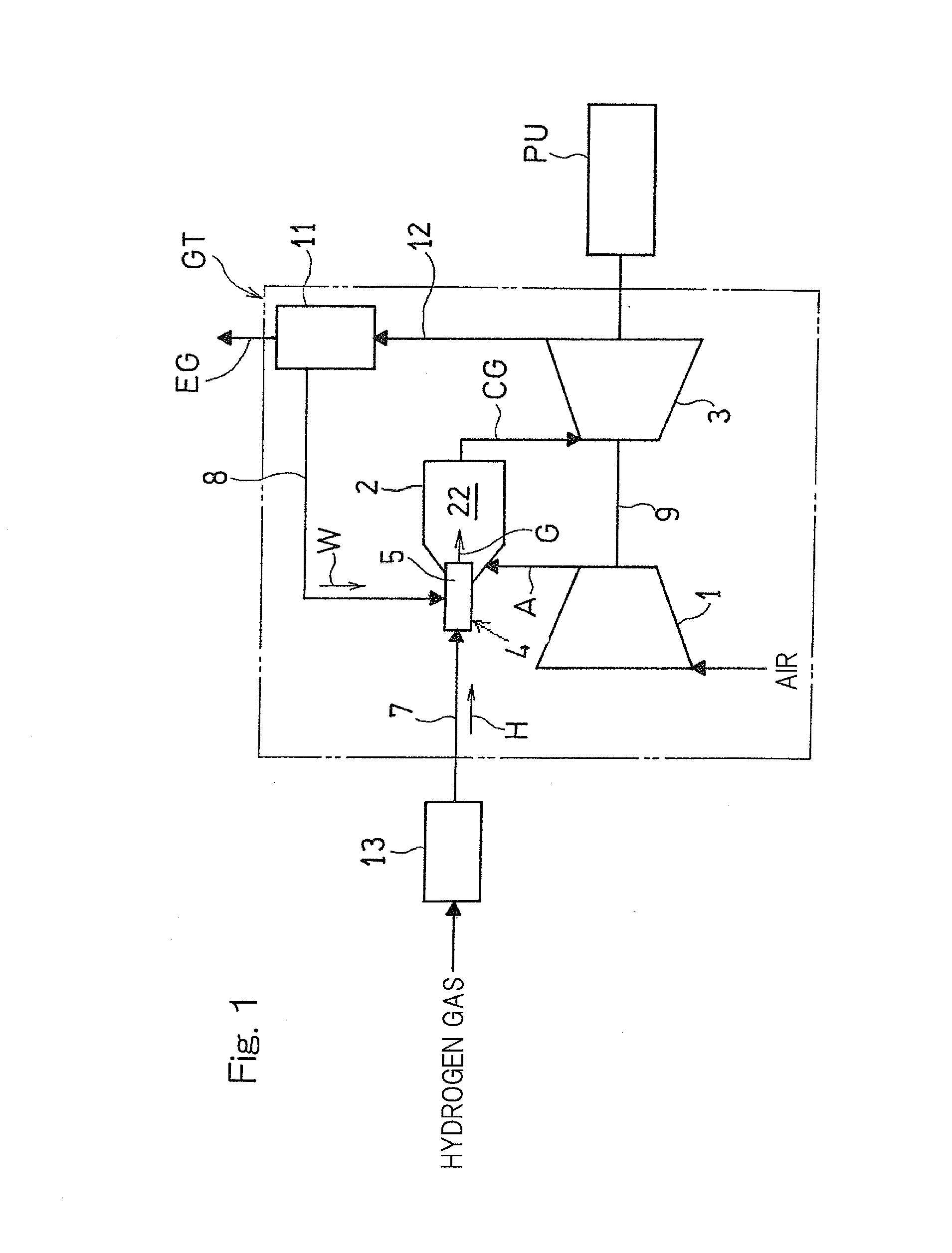

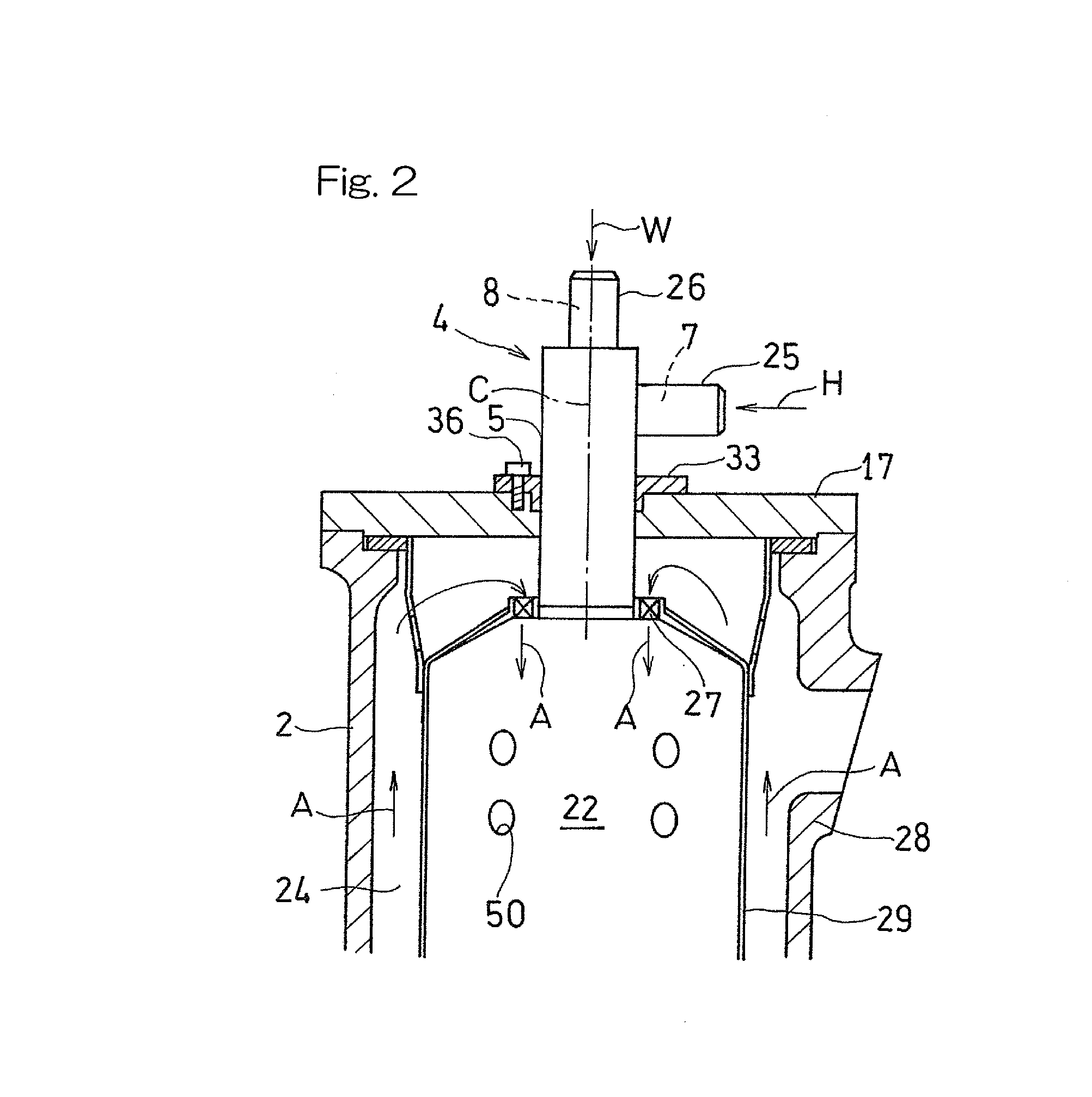

Gas turbine combustor including separate fuel injectors for plural zones

ActiveUS8656721B2Reduce the amount requiredCompact structureContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

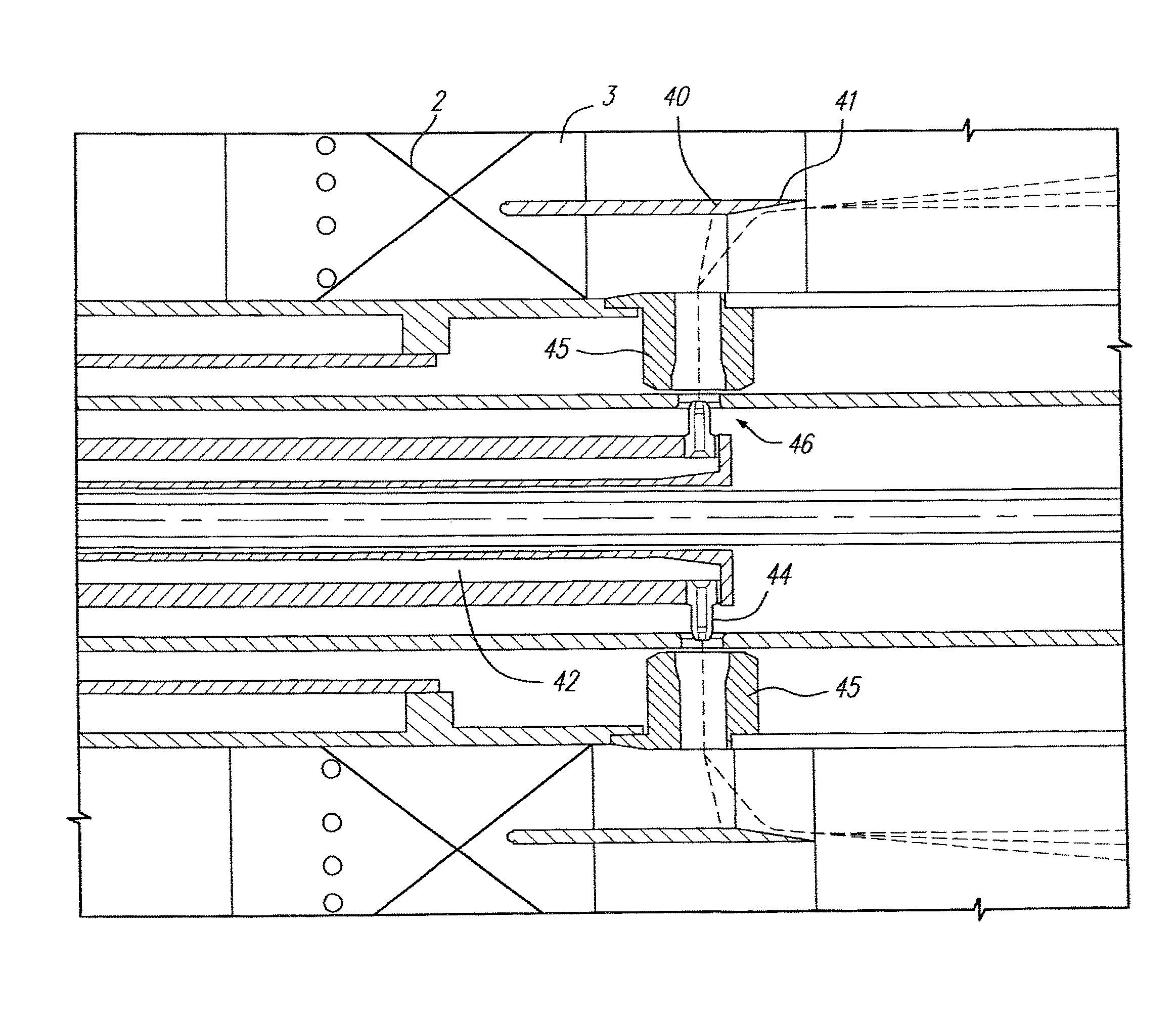

This invention provides a gas turbine combustor including: a main burner at a head portion of a combustor cylinder; and a pre-mixing type supplemental burner at a downstream portion of the combustor cylinder and extending through a circumferential wall thereof. The supplemental burner includes: an introducing passage configured to deflect a part of the compressed air radially inward, the compressed air flowing from an air passage between the circumferential wall of the combustor cylinder and a housing surrounding the circumferential wall toward the head portion of the combustor cylinder, and introduce the compressed air into the combustor cylinder; and a fuel nozzle configured to supply the fuel from fuel injection holes to the compressed air introduced into the introducing passage to produce a pre-mixed gas in the introducing passage.

Owner:KAWASAKI HEAVY IND LTD

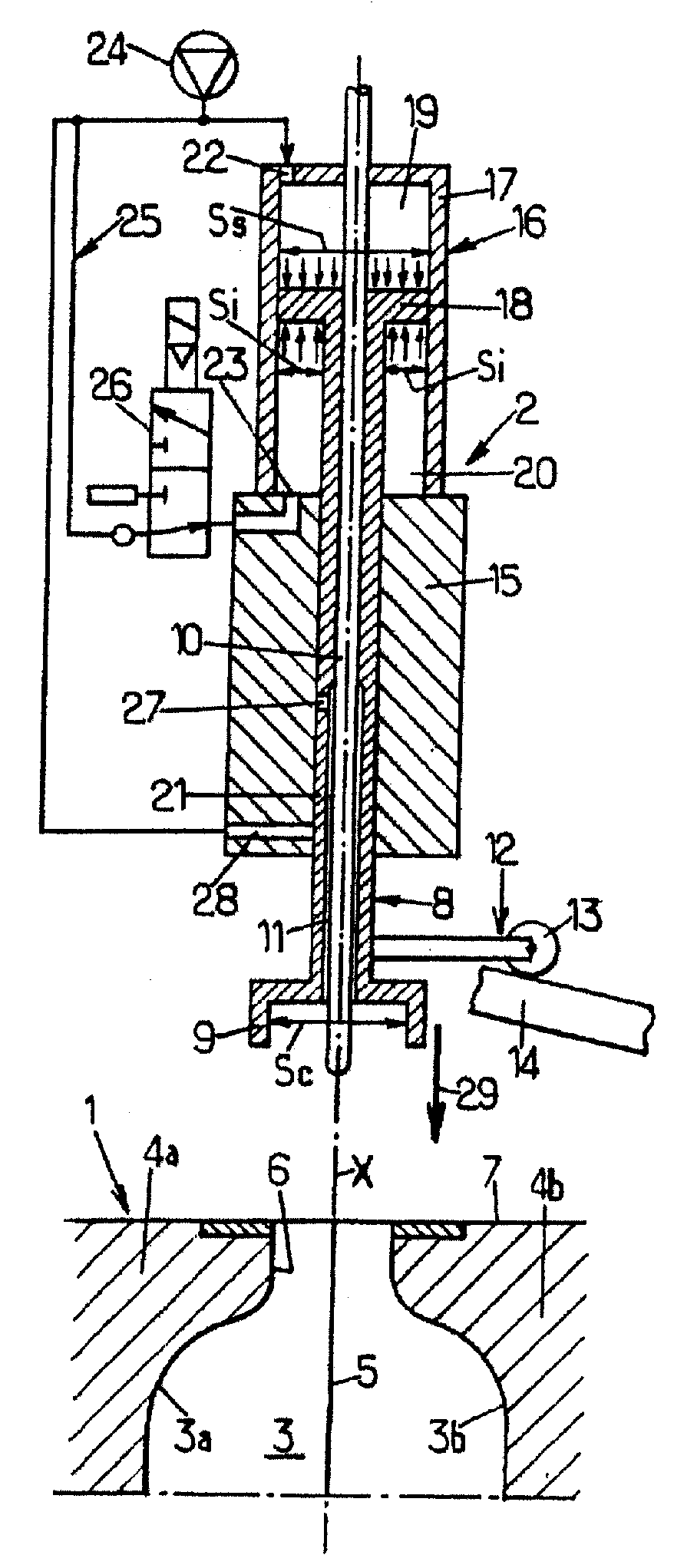

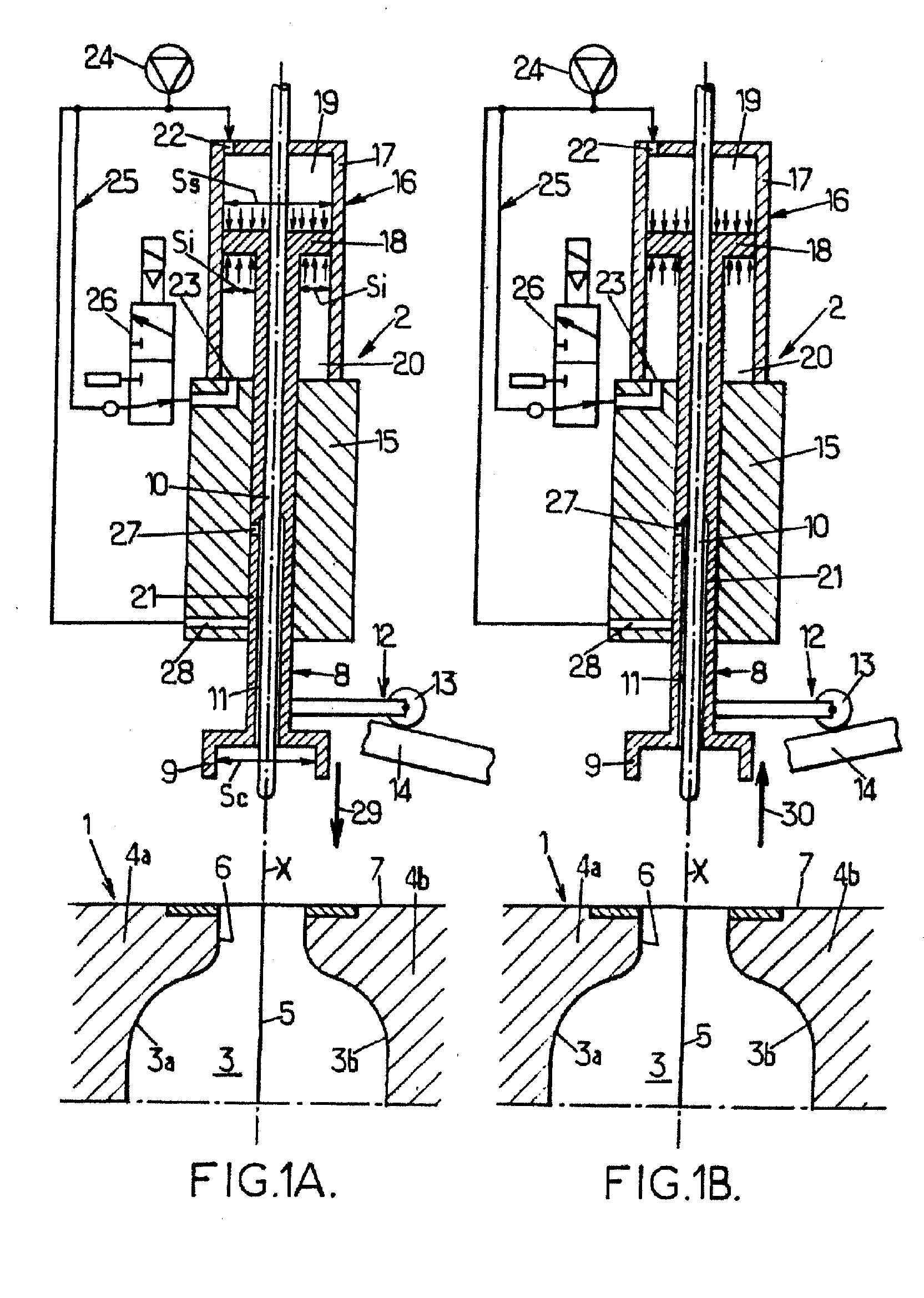

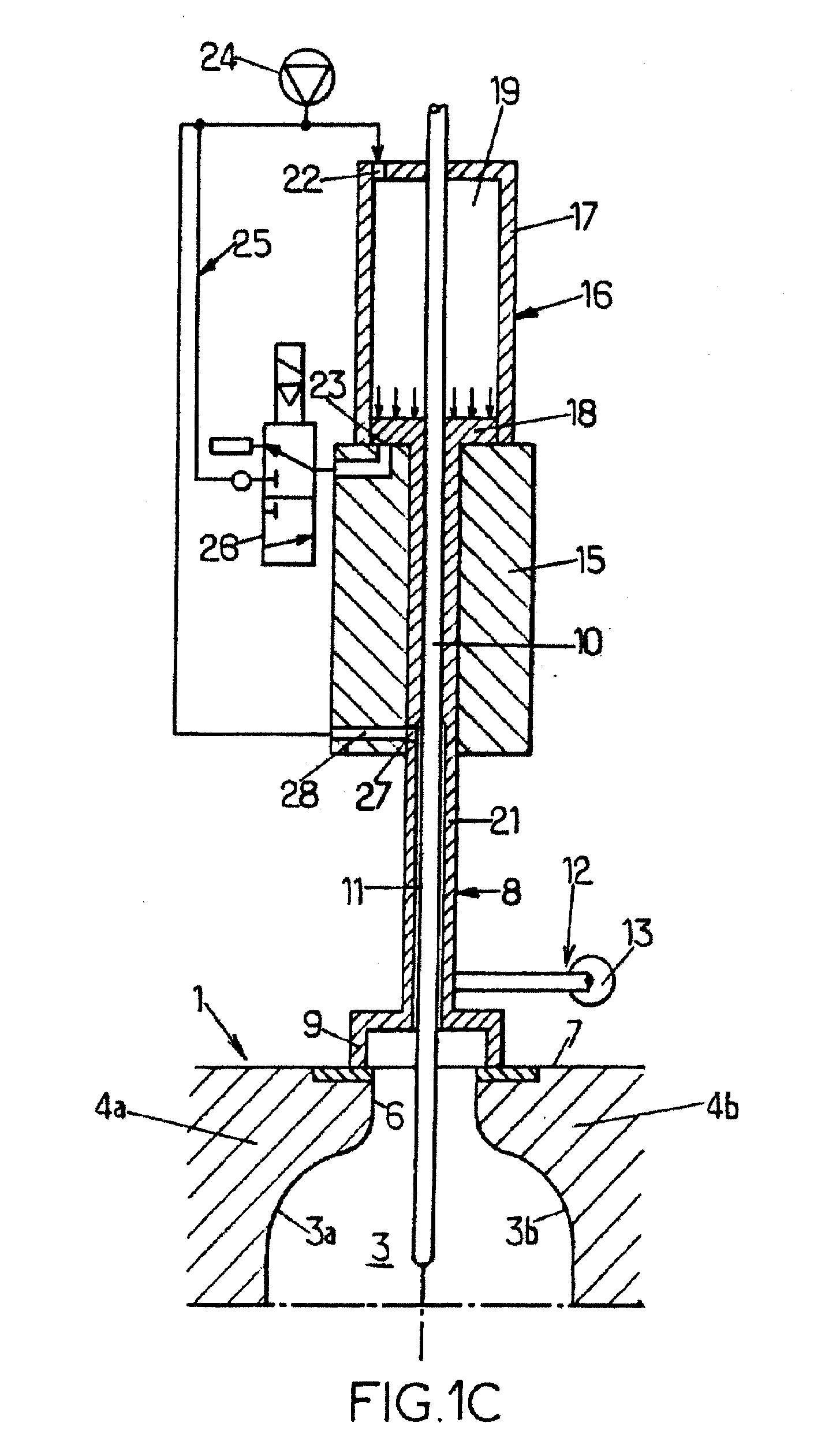

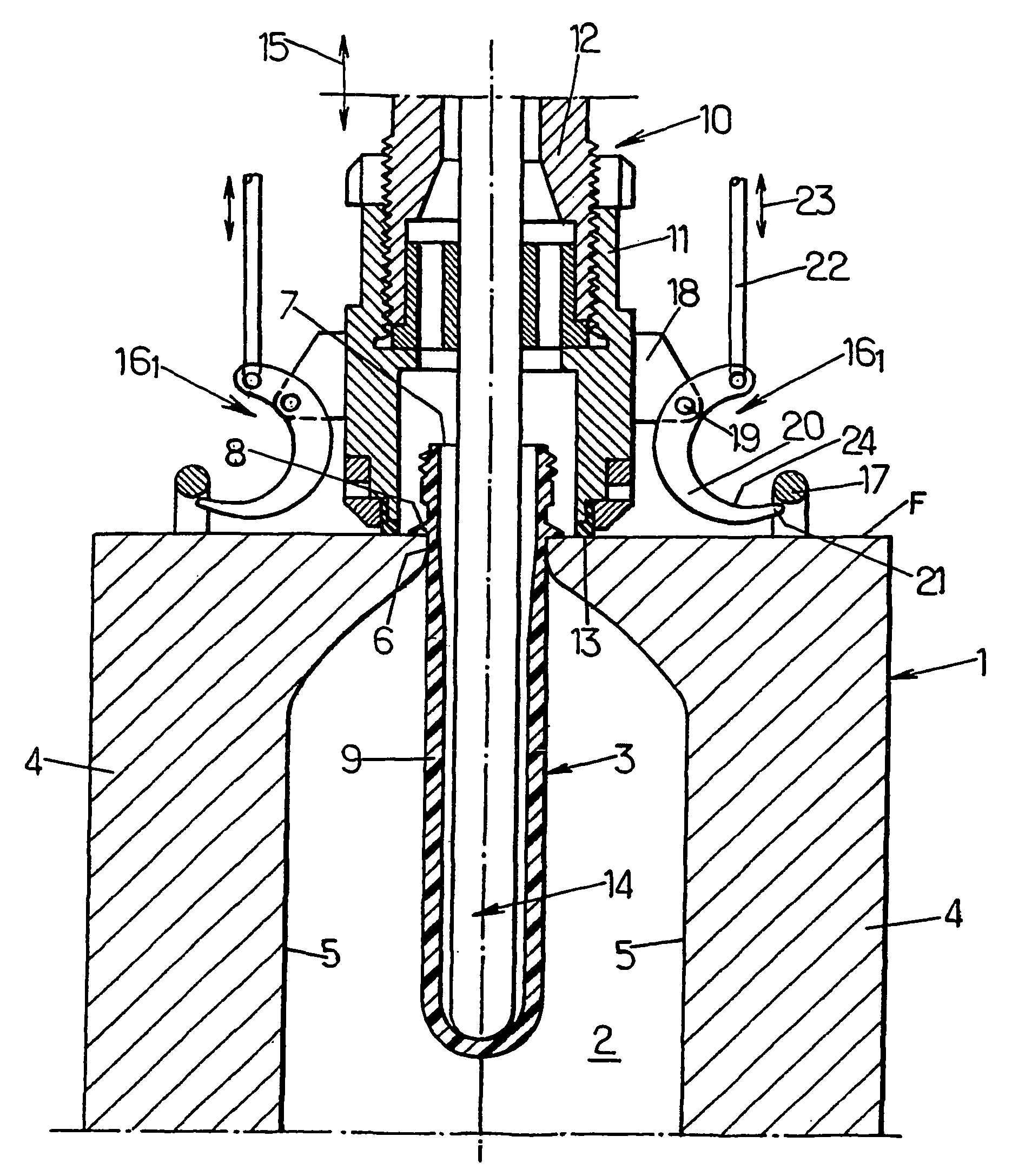

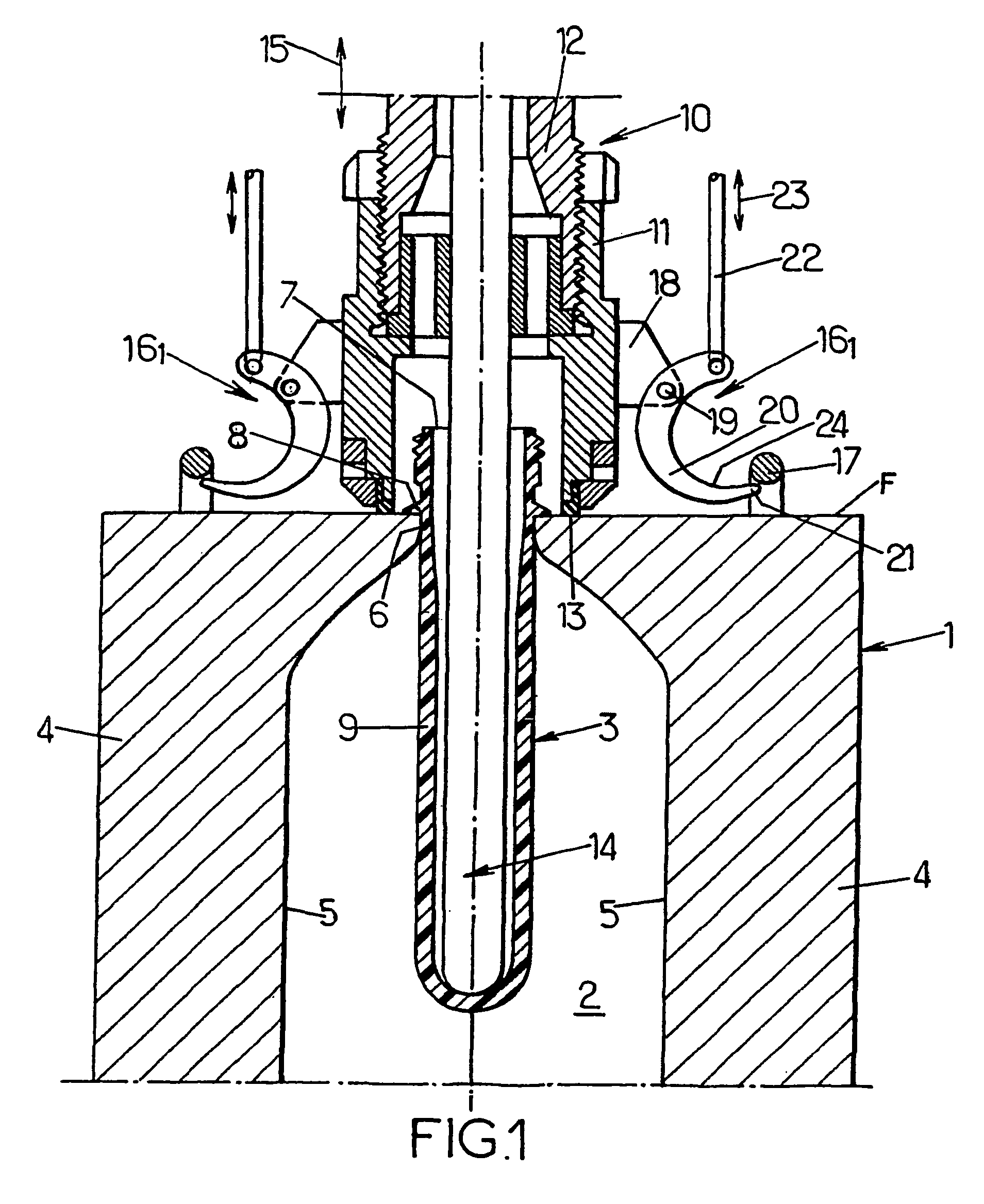

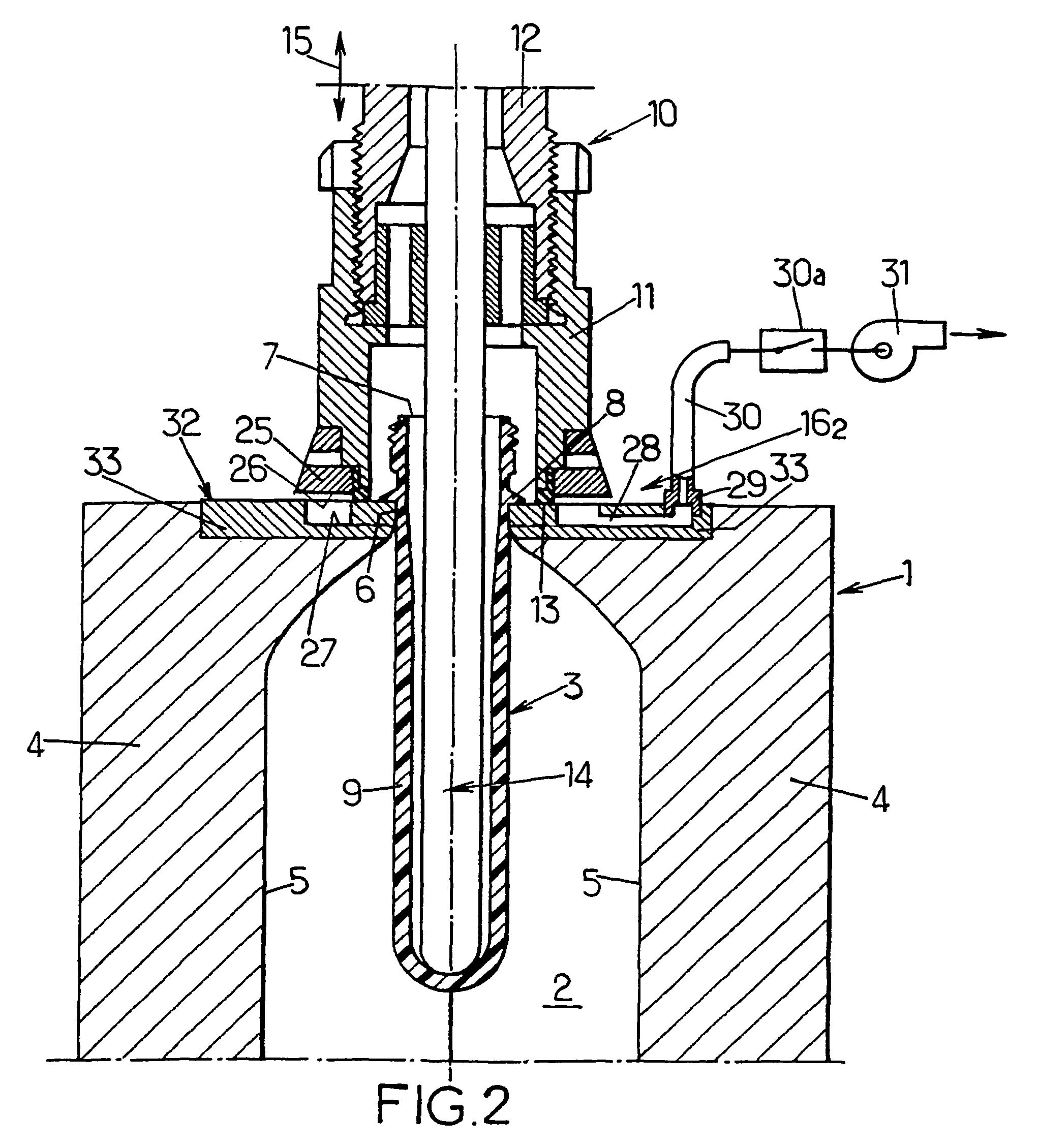

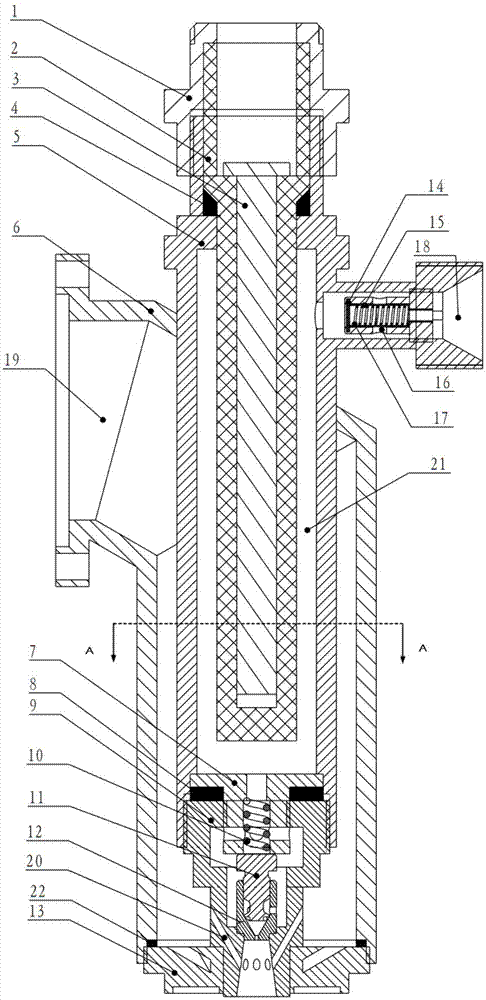

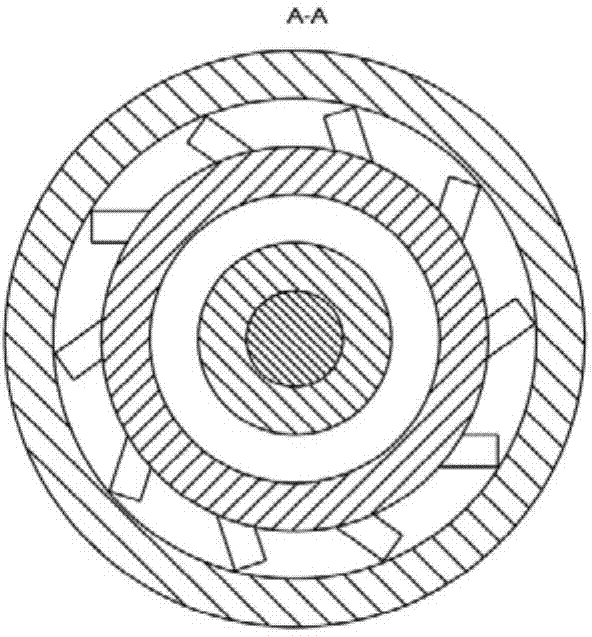

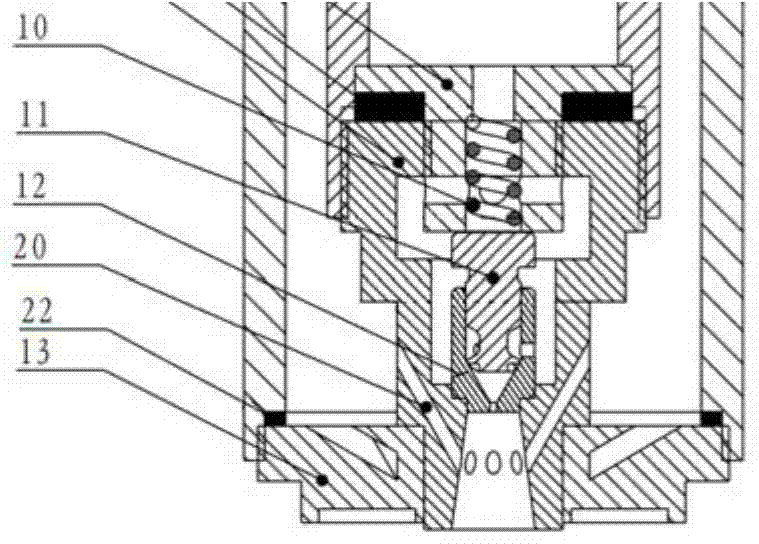

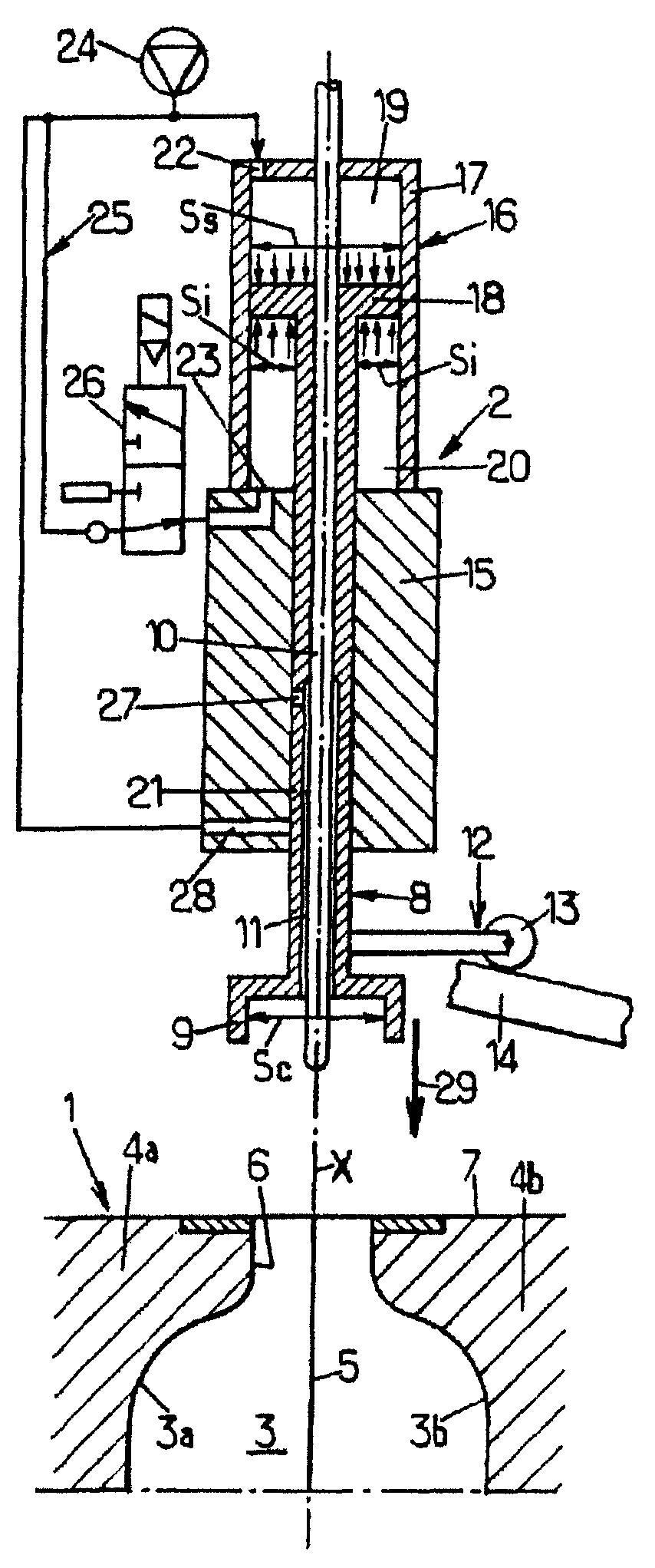

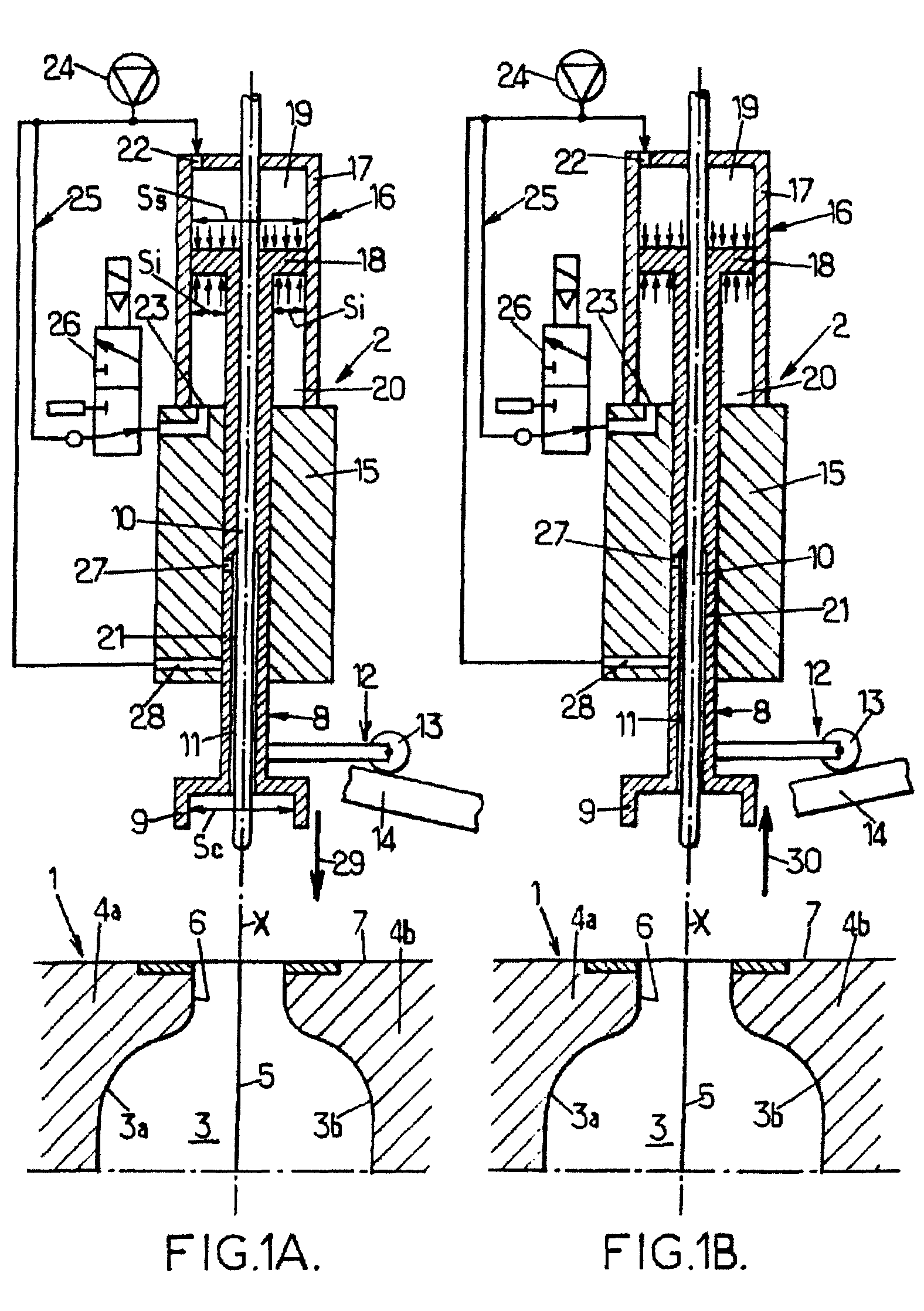

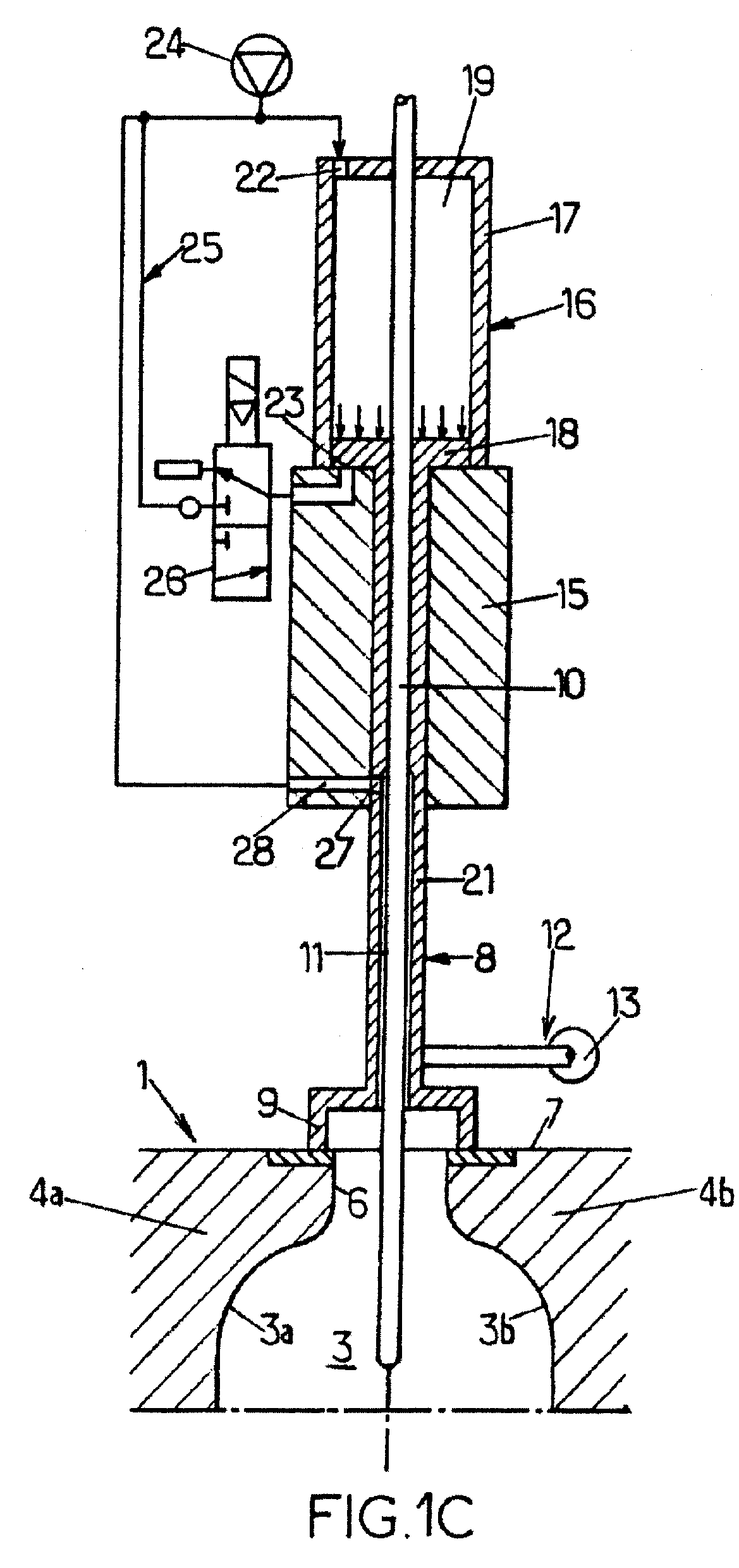

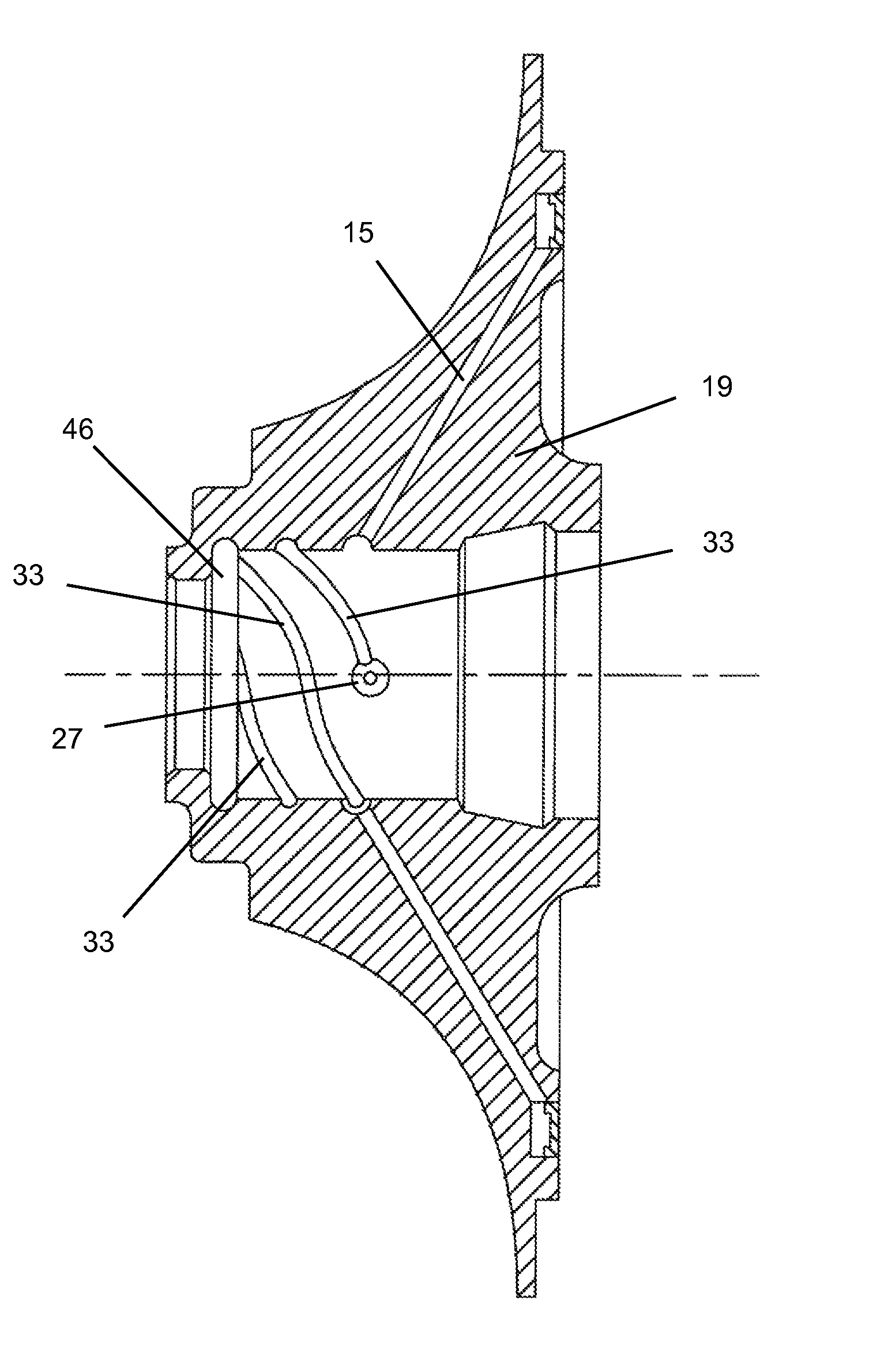

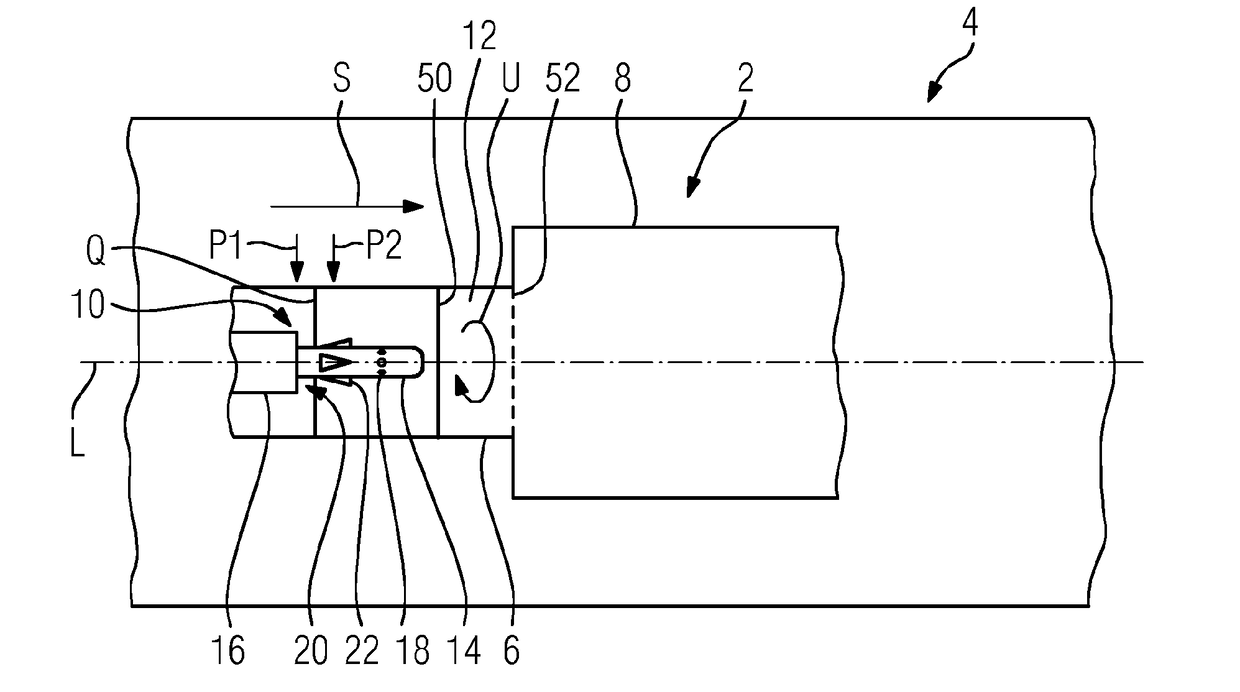

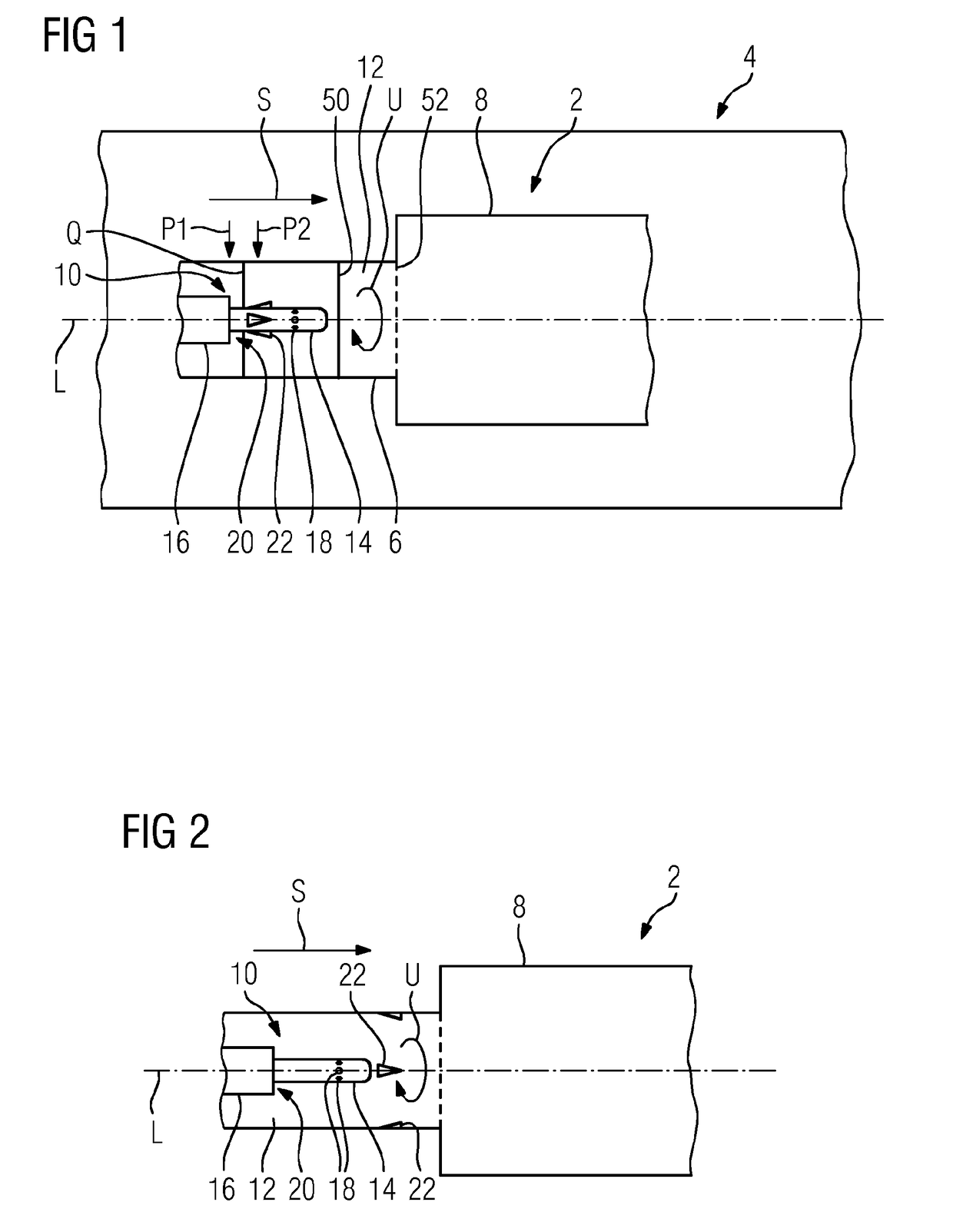

Device for moulding thermoplastic containers by blow-moulding or stretch blow-moulding

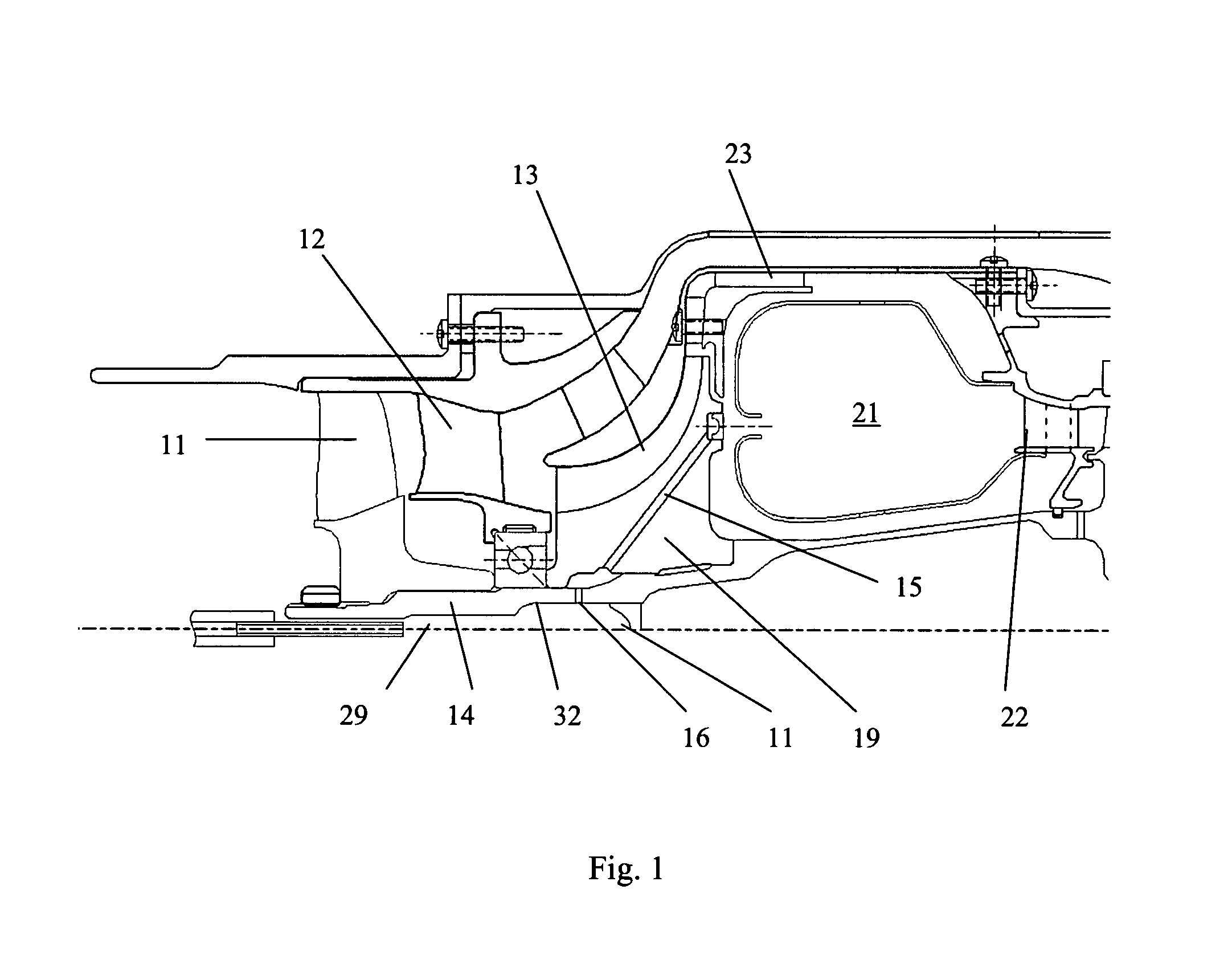

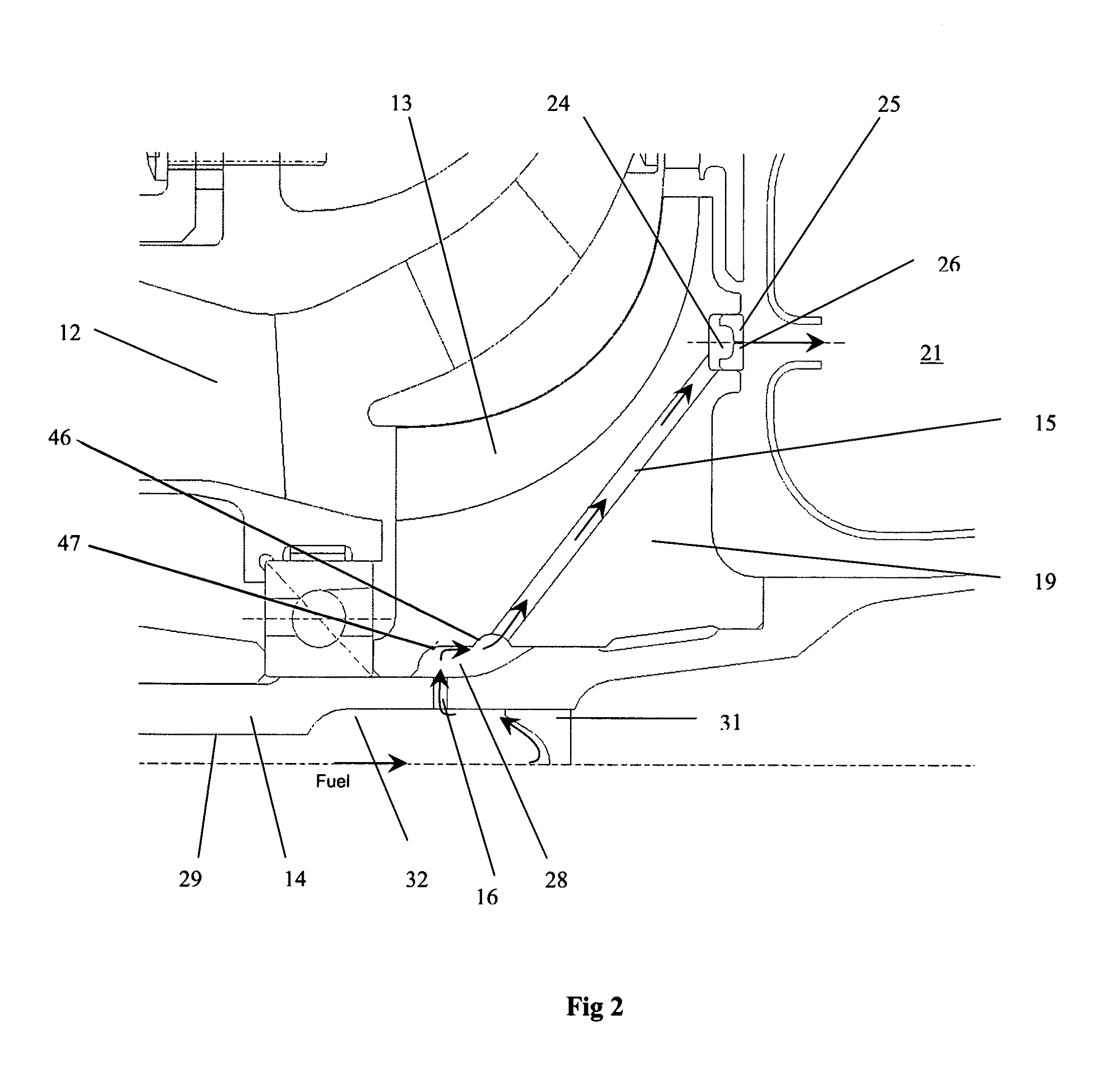

Device for moulding thermoplastic containers by blow-moulding hot preforms, comprising a mould (1) and blow-moulding means (2) comprising a bell nozzle (8) which is axially displaceable between a raised position and a blow-moulding position in abutment against the mould; the driving means comprising mechanical means (12) with a cam follower roller (13) / cam (14) and pneumatic means (16) with a piston (18) integral with the upper end of the nozzle and sliding in a fixed enclosure (17), defining therein an upper chamber (19) connected to a source (24) of control fluid and a lower chamber (20) connected to this source and to the upper chamber via a solenoid valve (26); the upper face of the piston has a surface area which is greater than that of its lower face and that of the bell (9) of the nozzle.

Owner:SIDEL PARTICIPATIONS SAS

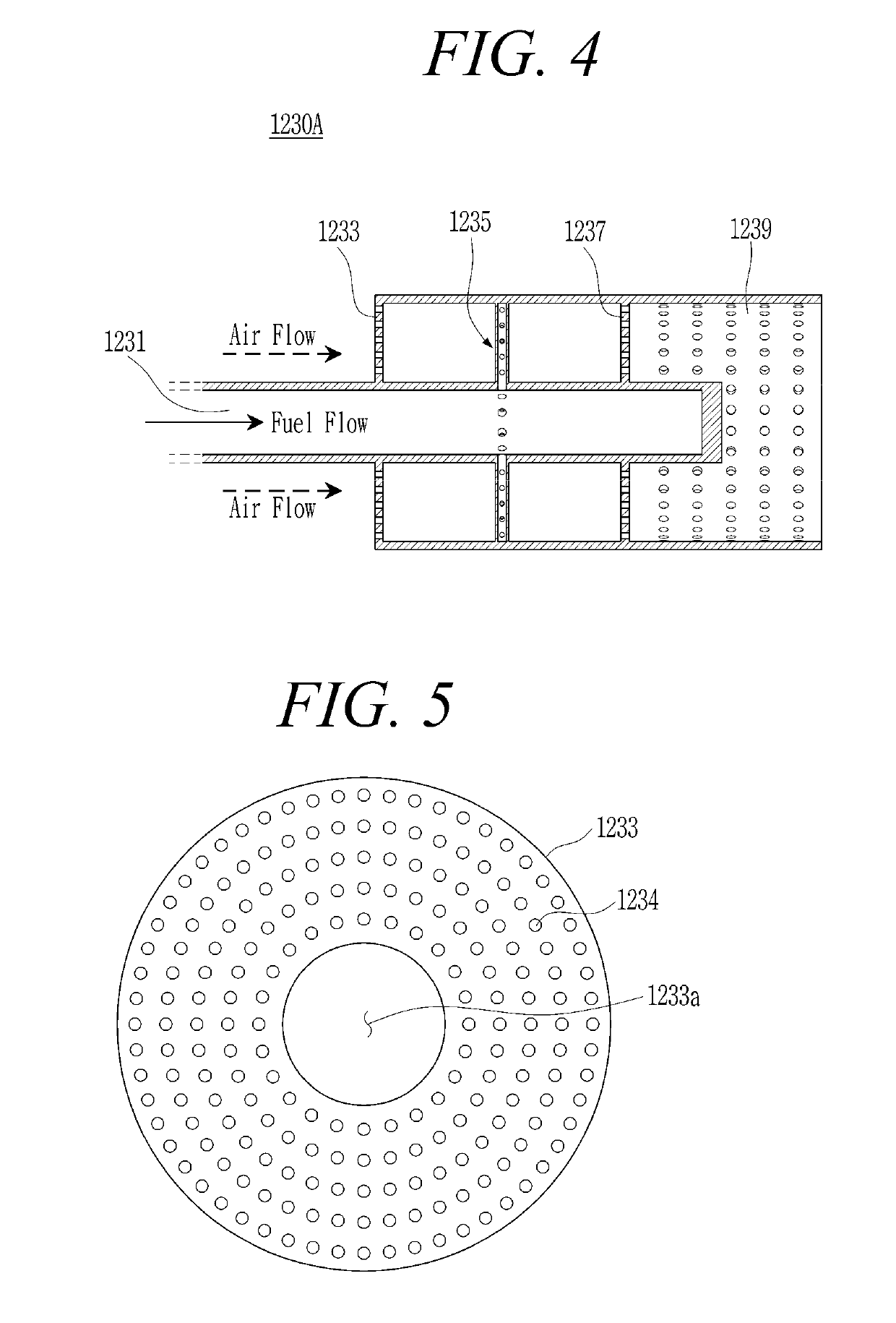

Fuel nozzles for injecting fuel in a gas turbine combustor

Fuel nozzles for gas turbines are provided that include liquid fuel cartridges. In one embodiment, a fuel nozzle includes a fuel plenum plate separating an air plenum from a fuel plenum. The fuel nozzle also includes a plurality of mixing tubes extending through the fuel plenum from the fuel plenum plate to a face plate. Each mixing tube includes an air inlet configured to receive air from the air plenum, a fuel inlet disposed in a tube wall within the fuel plenum to direct fuel from the fuel plenum into the mixing tube to produce a fuel-air mixture, and a fuel-air outlet configured to discharge the fuel-air mixture away from the face plate into a combustion region. The fuel nozzle further includes a liquid fuel cartridge extending through the air plenum and the fuel plenum to the face plate. The liquid fuel cartridge includes a liquid fuel passage.

Owner:GENERAL ELECTRIC CO

Fuel injector nozzles, with labyrinth grooves, for gas turbine engines

A fuel injector for a gas turbine engine of an aircraft, and more particularly a novel and unique heatshield structure for a fuel nozzle wherein a labyrinth seal is uniquely provided in the nozzle to isolate a portion of an insulating gap from an interface whereat fuel may enter the insulating gap, and the insulating gap is provided with a positive purge flow for forcing vapors out of the insulating gap.

Owner:PARKER INTANGIBLES LLC

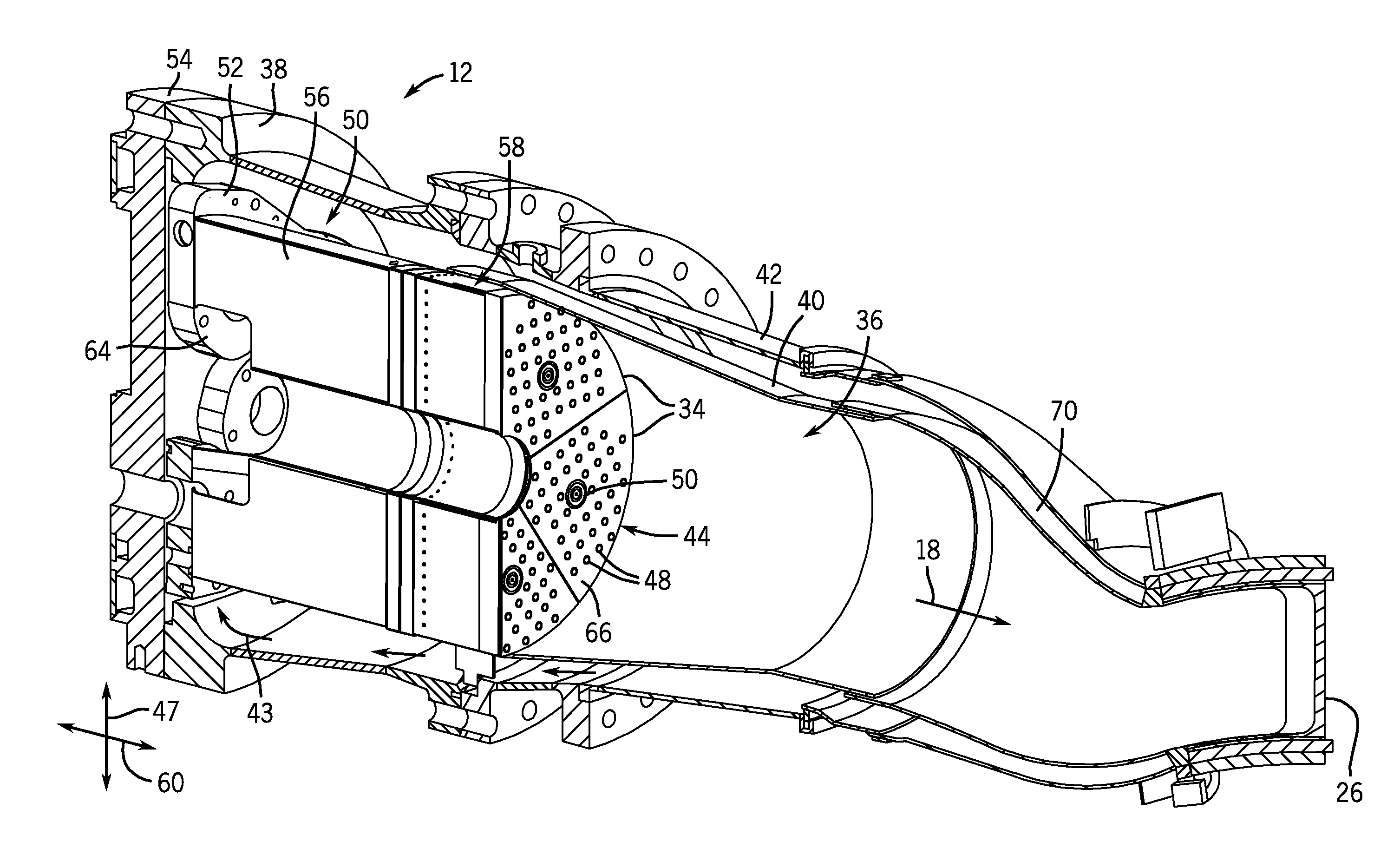

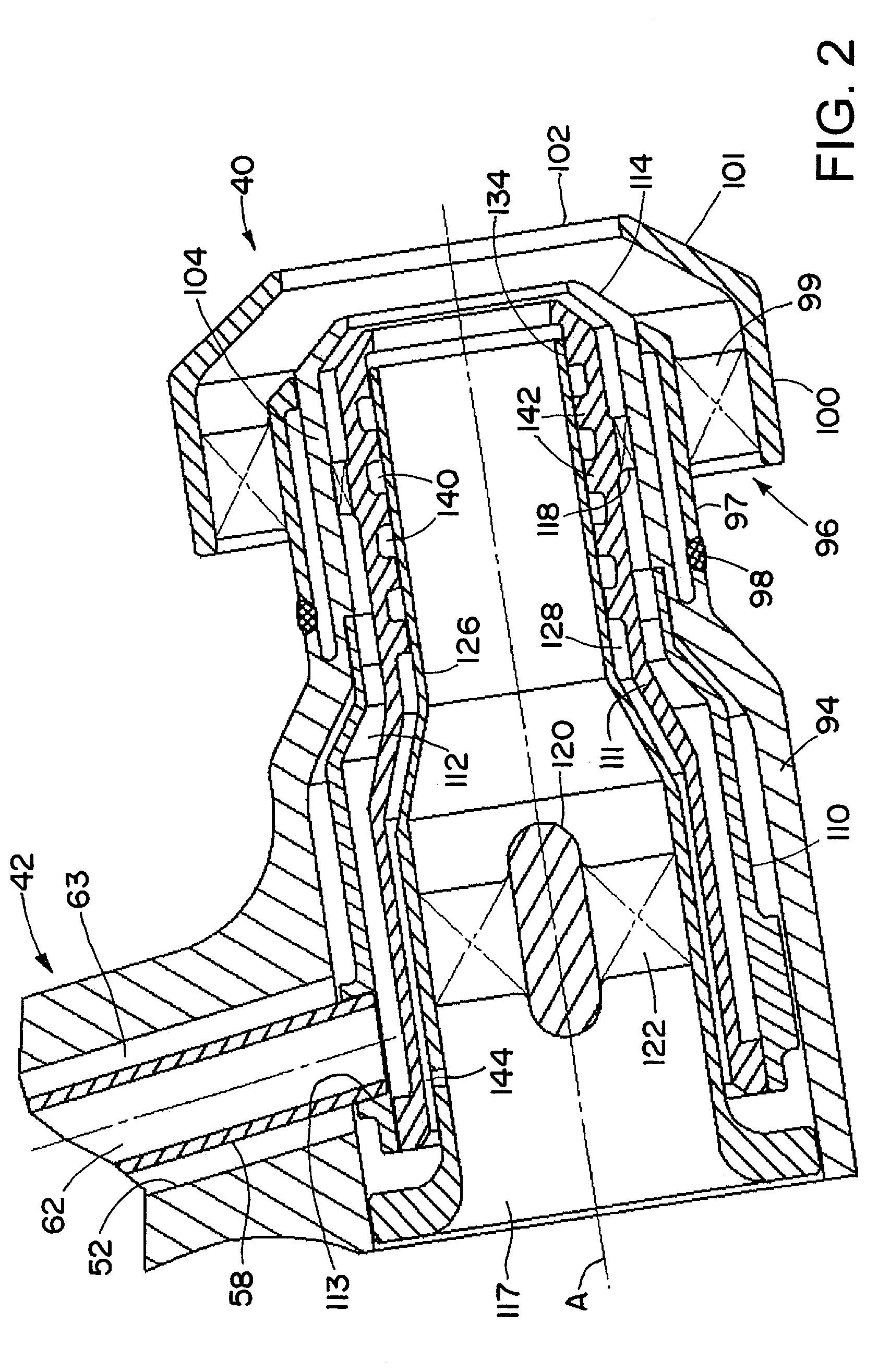

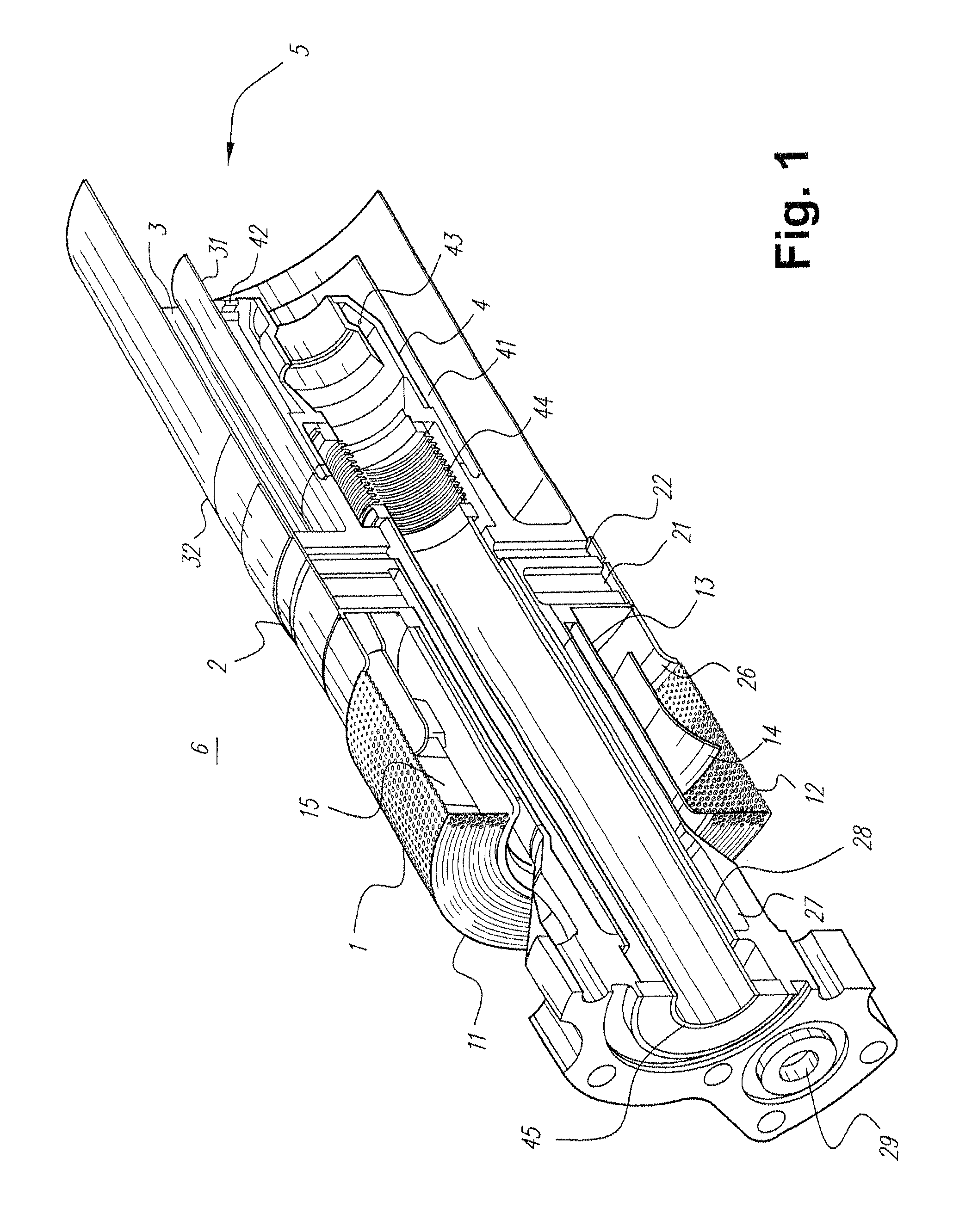

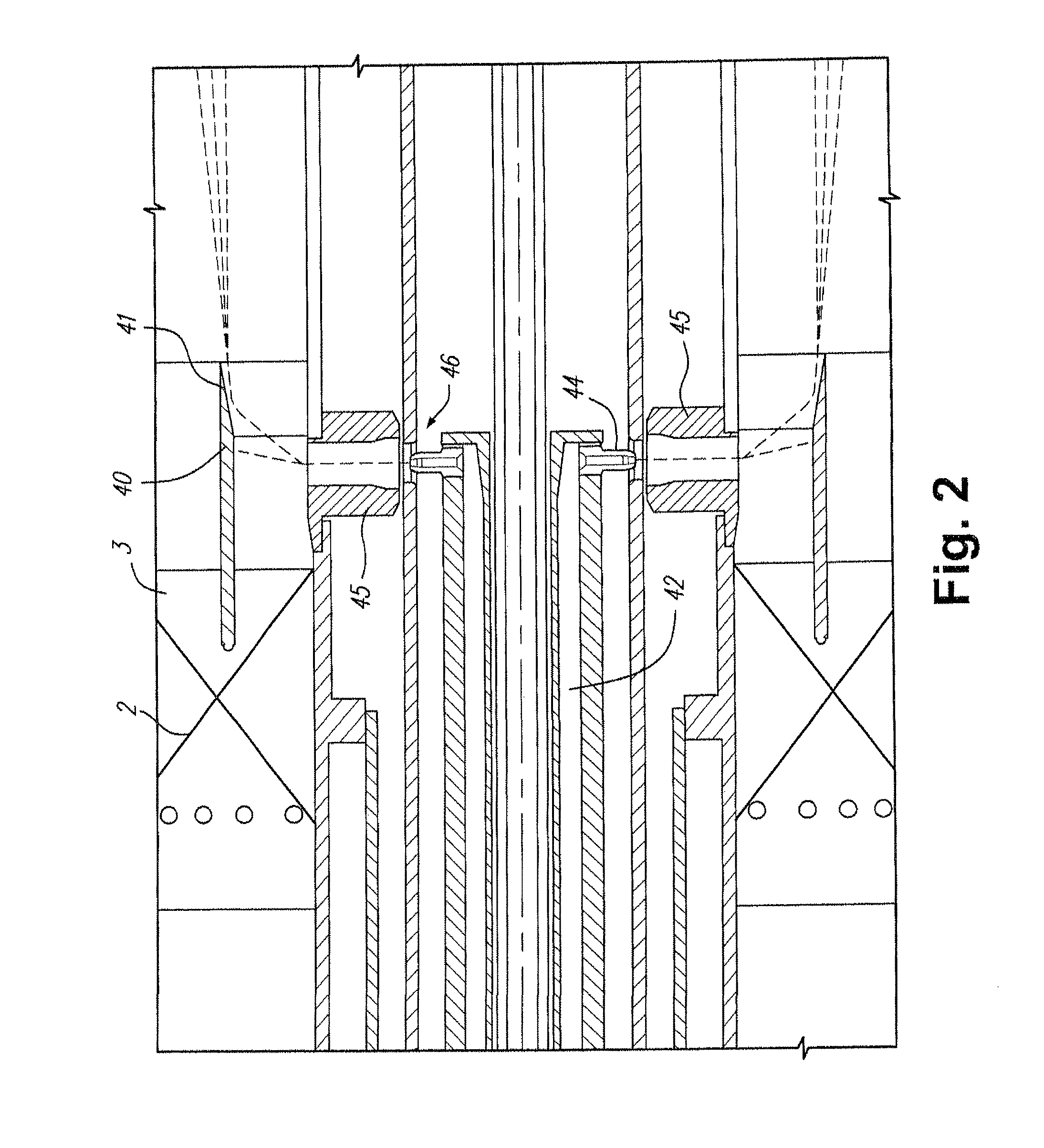

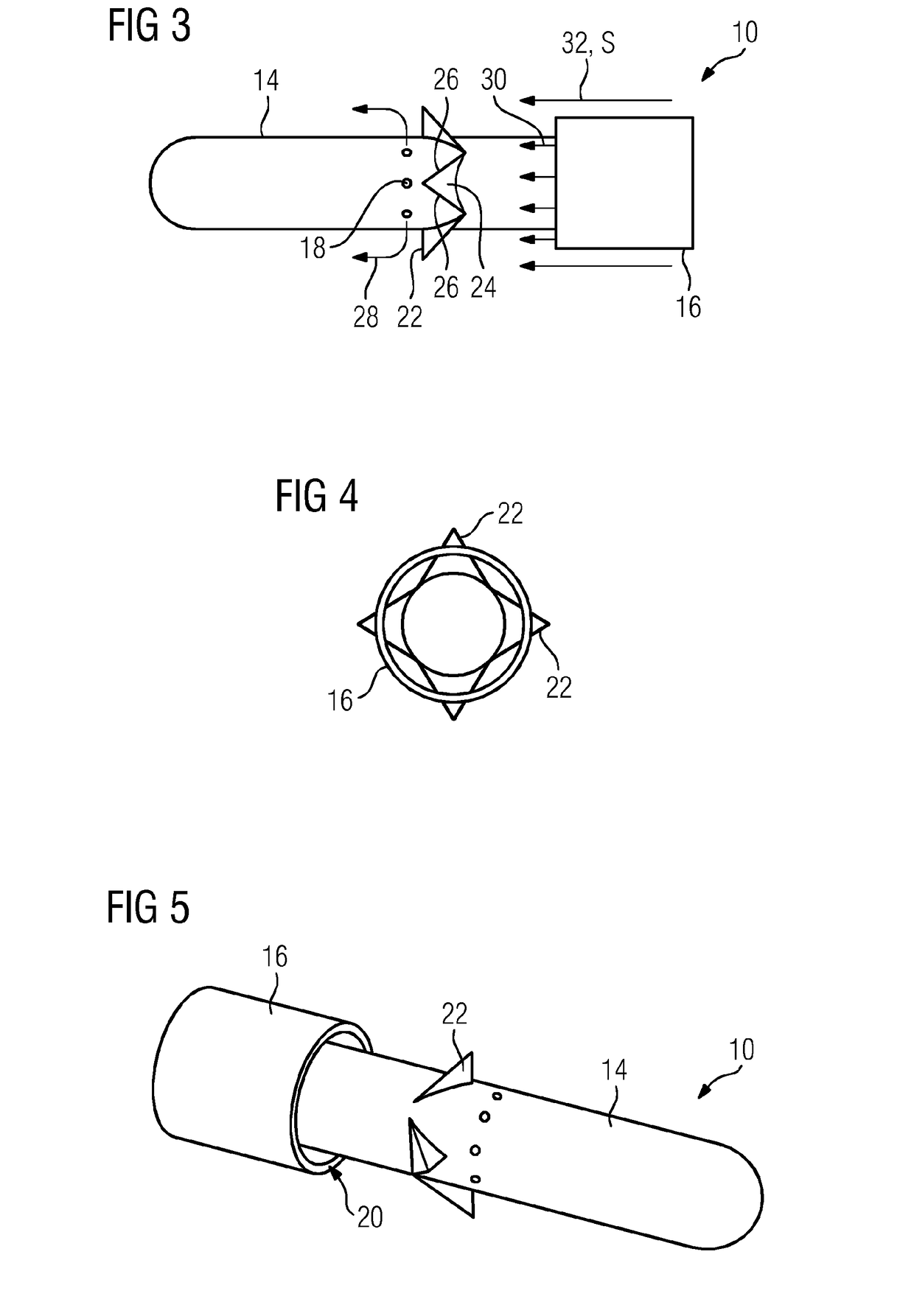

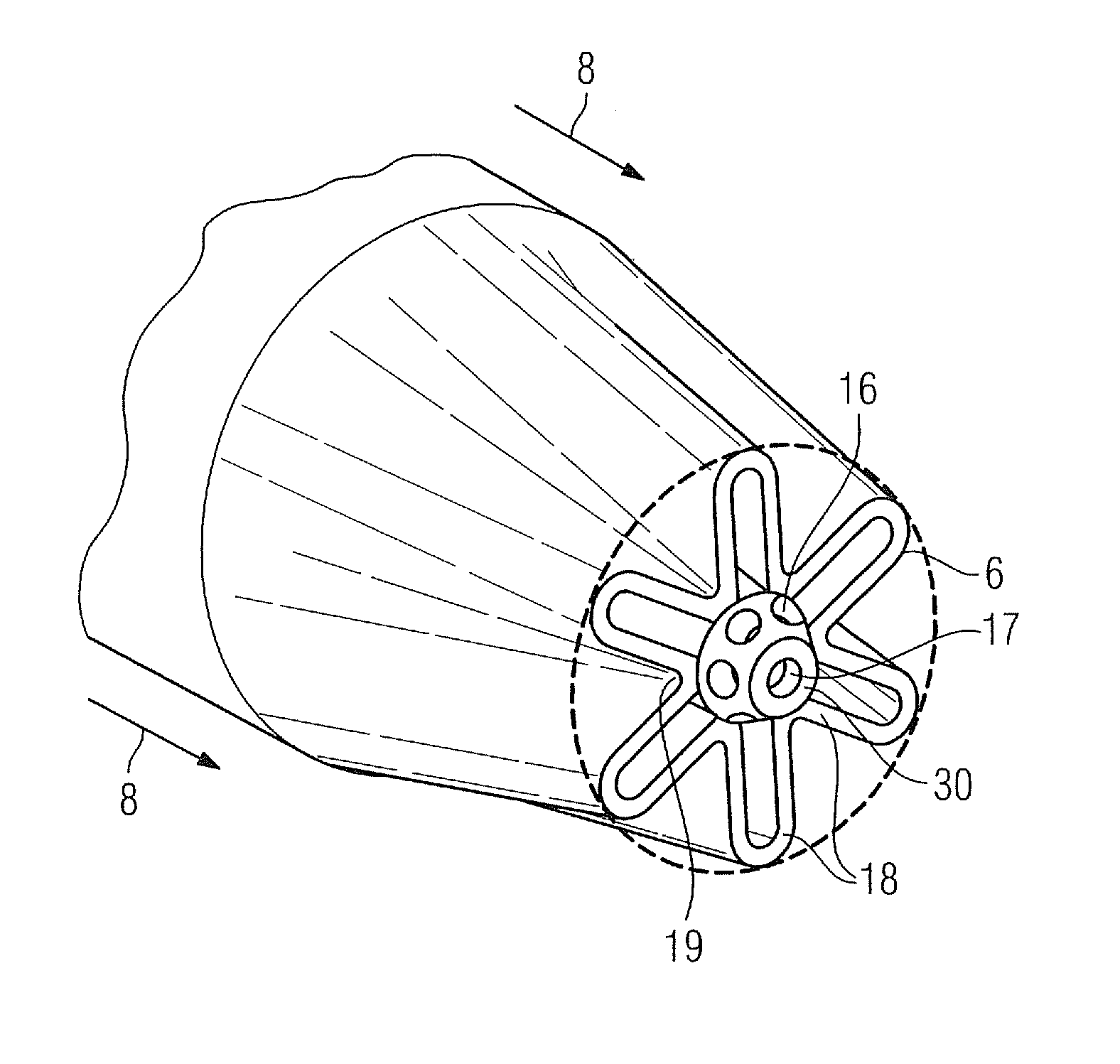

Bell-type nozzle blow-molding installation

InactiveUS7165956B2Light weightReduce weightAuxillary shaping apparatusDomestic articlesBlow moldingRepulsion force

A blow-molding installation for manufacturing receptacles from blanks of thermoplastic polymer, said installation comprising a bell-nozzle for blowing a fluid under pressure into a blank (3) disposed in a cavity (2) of a mold (1), the end of the nozzle being in the shape of a bell (11) which is suitable, during blow-molding, for being pressed into leaktight end-to-end abutment against a wall (F) of the mold while capping the neck (7) of the blank that emerges from said wall; said installation further comprises means (161) for securing the nozzle to the wall of the mold by mutual attraction, which means can be activated, after the nozzle has been brought into end-to-end contact with the wall (F) of the mold without flattening a sealing gasket (13), so as to attract the nozzle (10) and the wall (F) towards each other with an attraction force greater than the repulsion force due to the pressure of the blow-molding fluid.

Owner:SIDEL PARTICIPATIONS SAS

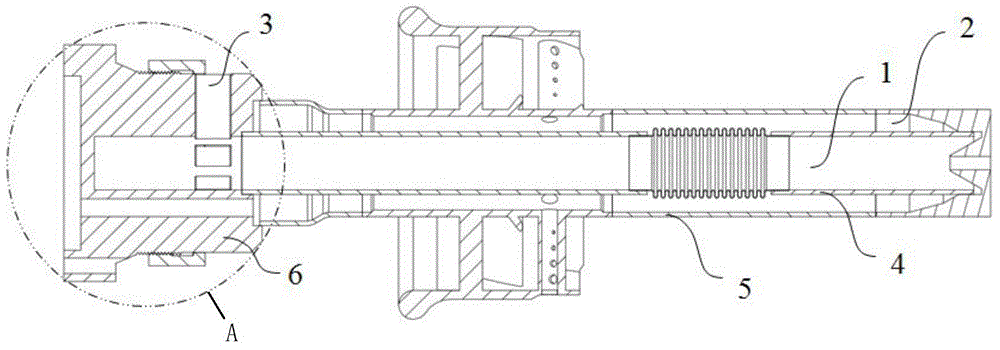

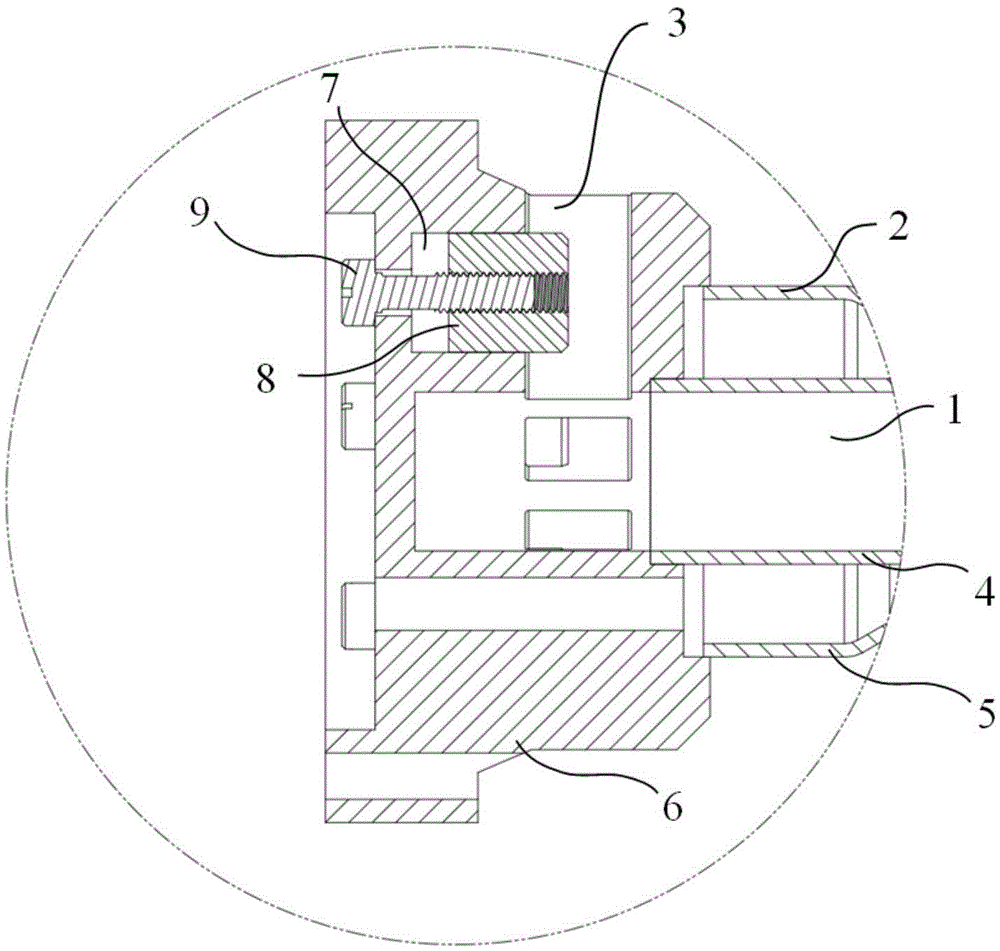

Dual-fuel nozzle for plasma and gas-assisted atomization burning

The invention provides a dual-fuel nozzle for plasma and gas-assisted atomization burning. The dual-fuel nozzle for plasma and gas-assisted atomization burning comprises a gas circuit assembly, a plasma discharging assembly, an oil filtering assembly and a gas-assisted swirl nozzle assembly. Liquid fuel passes through the oil filtering assembly and then enters an annular discharging gap of the plasma discharging assembly in the radial direction, the fuel is partially cracked through dielectric barrier discharging to form a plasma micelle which is mixed into the fuel, and instant bursting and inflammability of the plasma micelle at an outlet of the dual-fuel nozzle are utilized for strengthening atomization; one part of gaseous fuel enters the gas-assisted swirl nozzle assembly from an inlet through an annular gas cavity surrounding an external electrode so as to conduct impact assisted atomization on the liquid fuel, and the other part of the gaseous fuel flows out in a rotating mode through a gas flow guiding plate so as to achieve the shearing action on the liquid fuel, so that liquid drops are atomized deeply. According to the dual-fuel nozzle for plasma and gas-assisted atomization burning, deep fuel atomization and stable flow rotation can be well achieved, stability and completeness of burning are improved, and pollutant emission is reduced.

Owner:HARBIN ENG UNIV

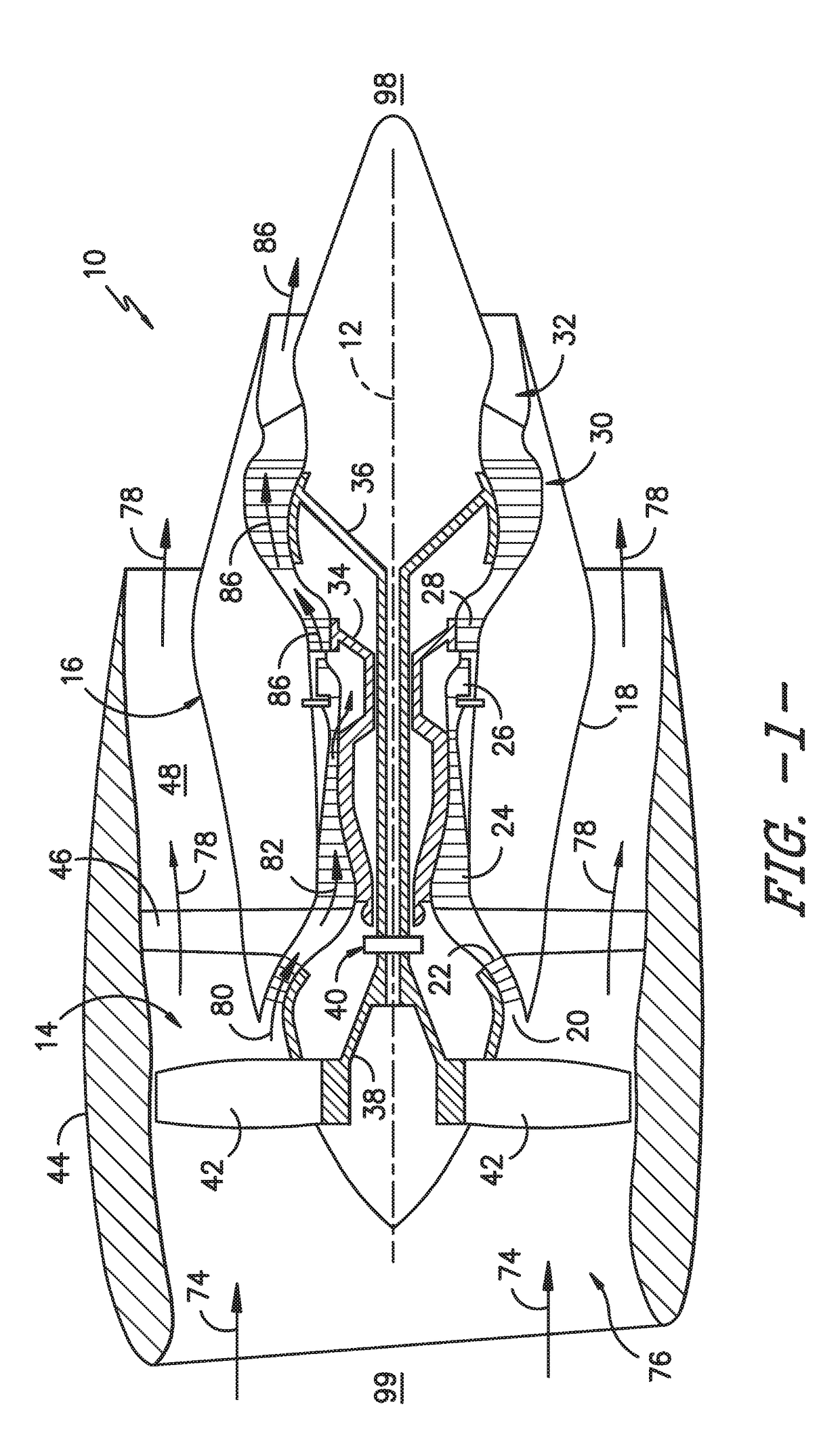

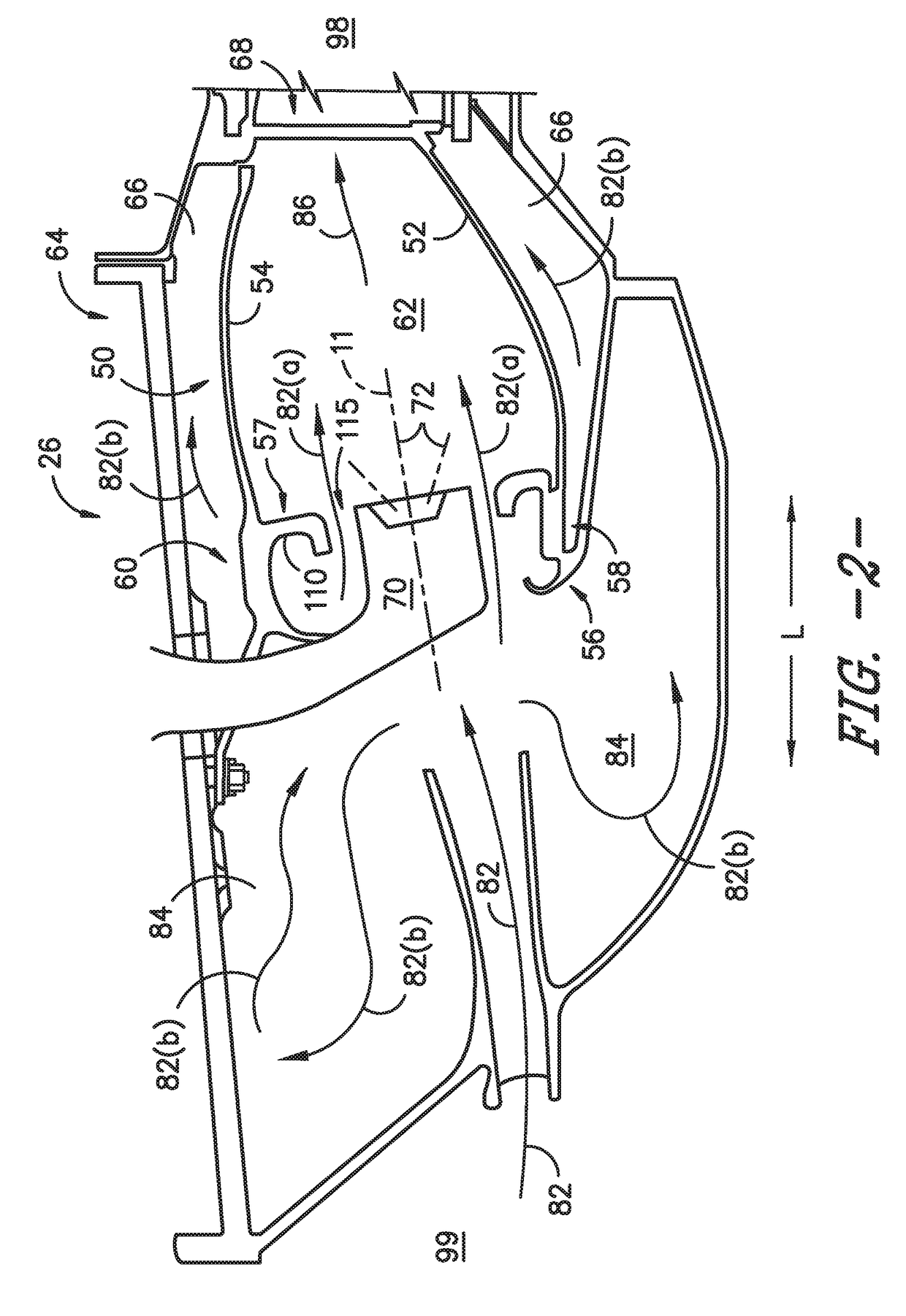

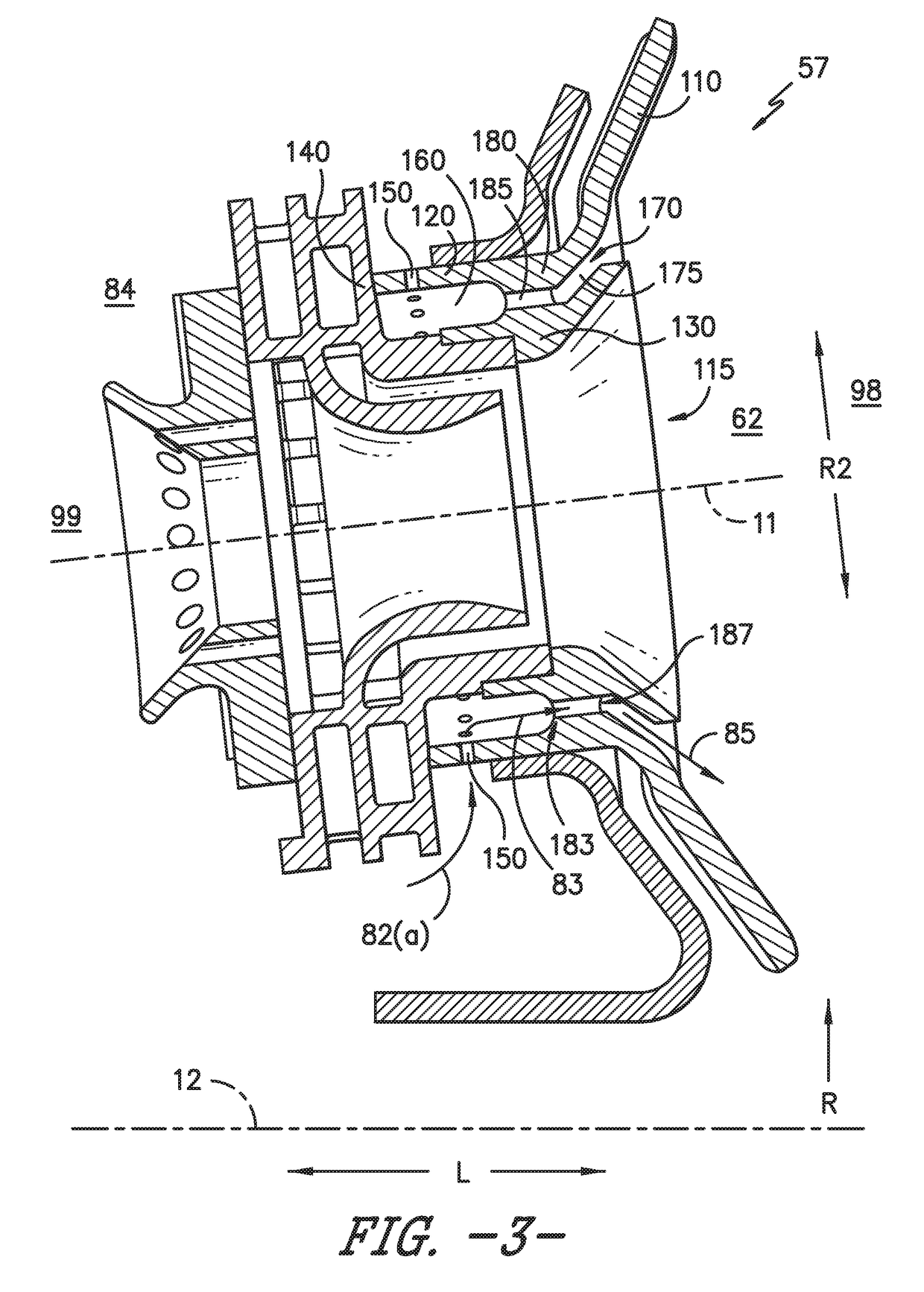

Turbine combustor with fuel nozzles having inner and outer fuel circuits

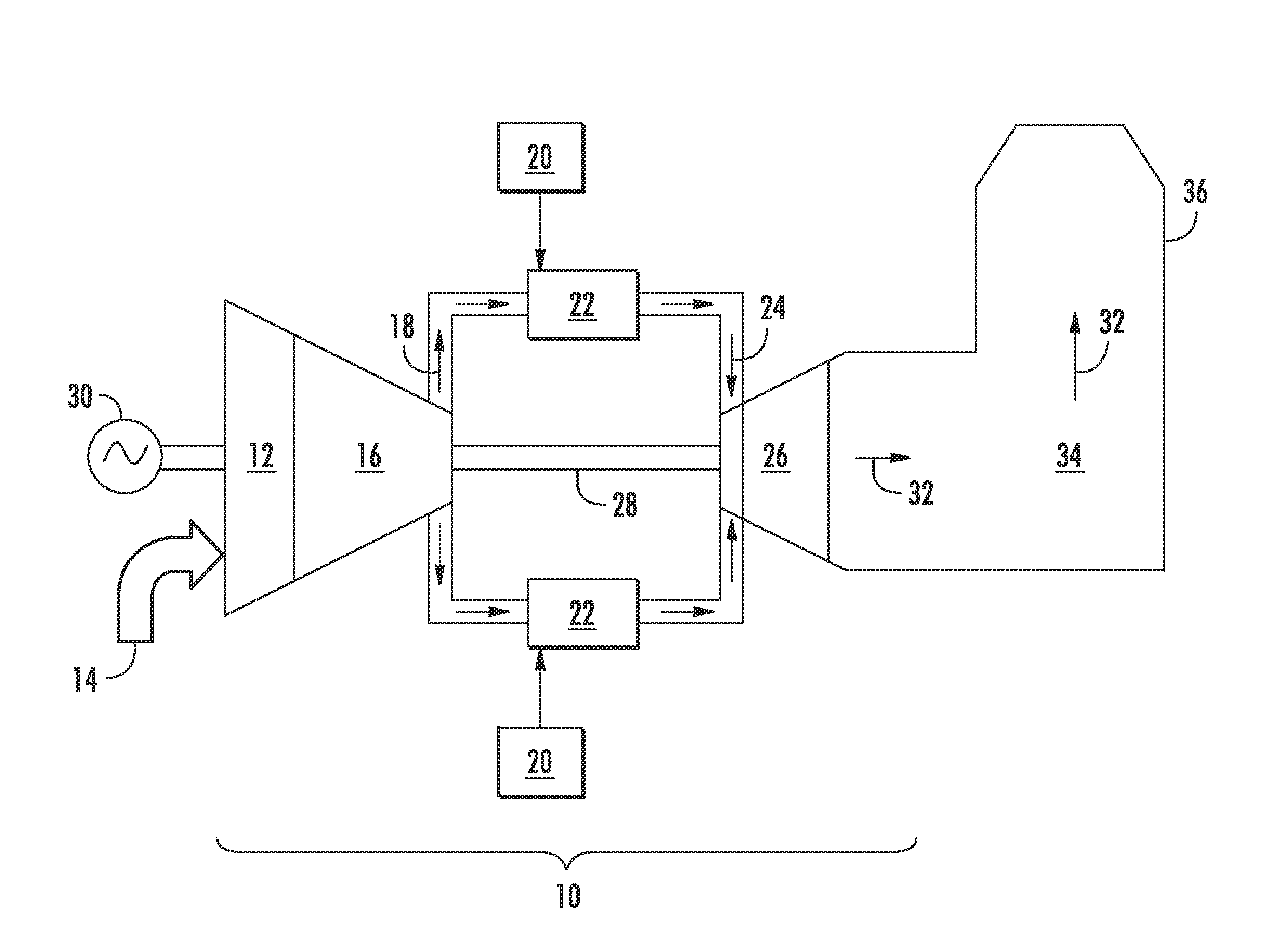

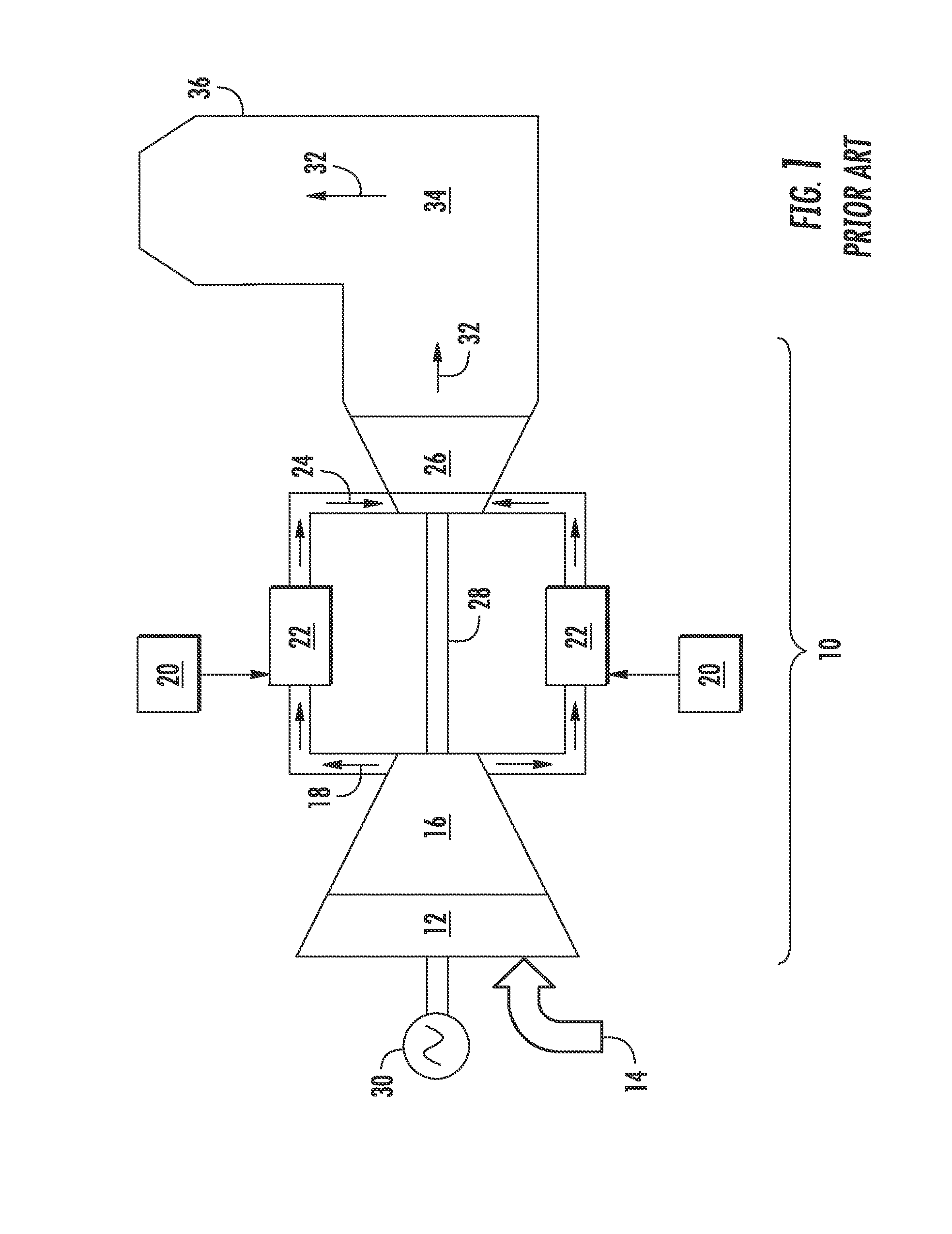

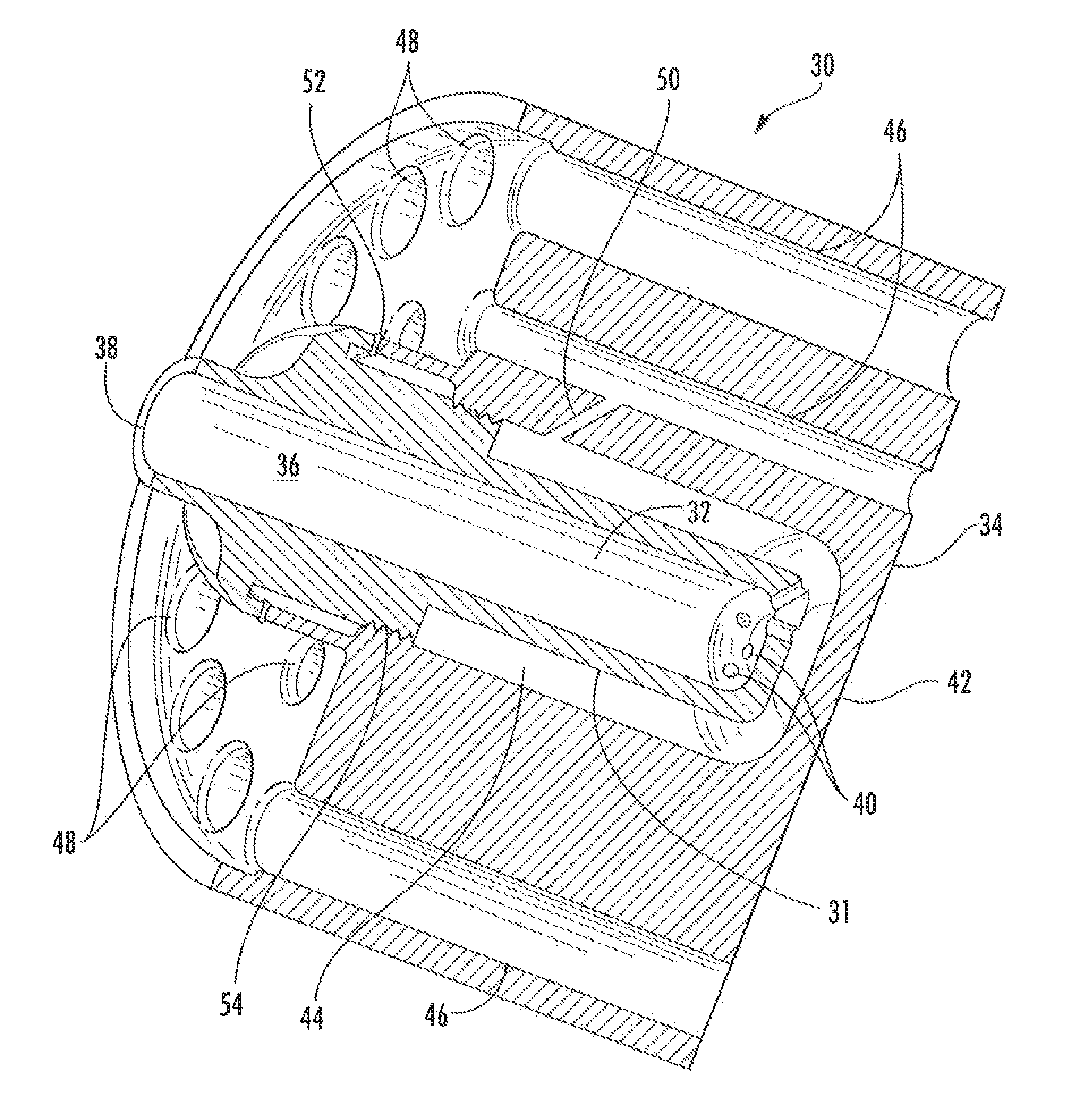

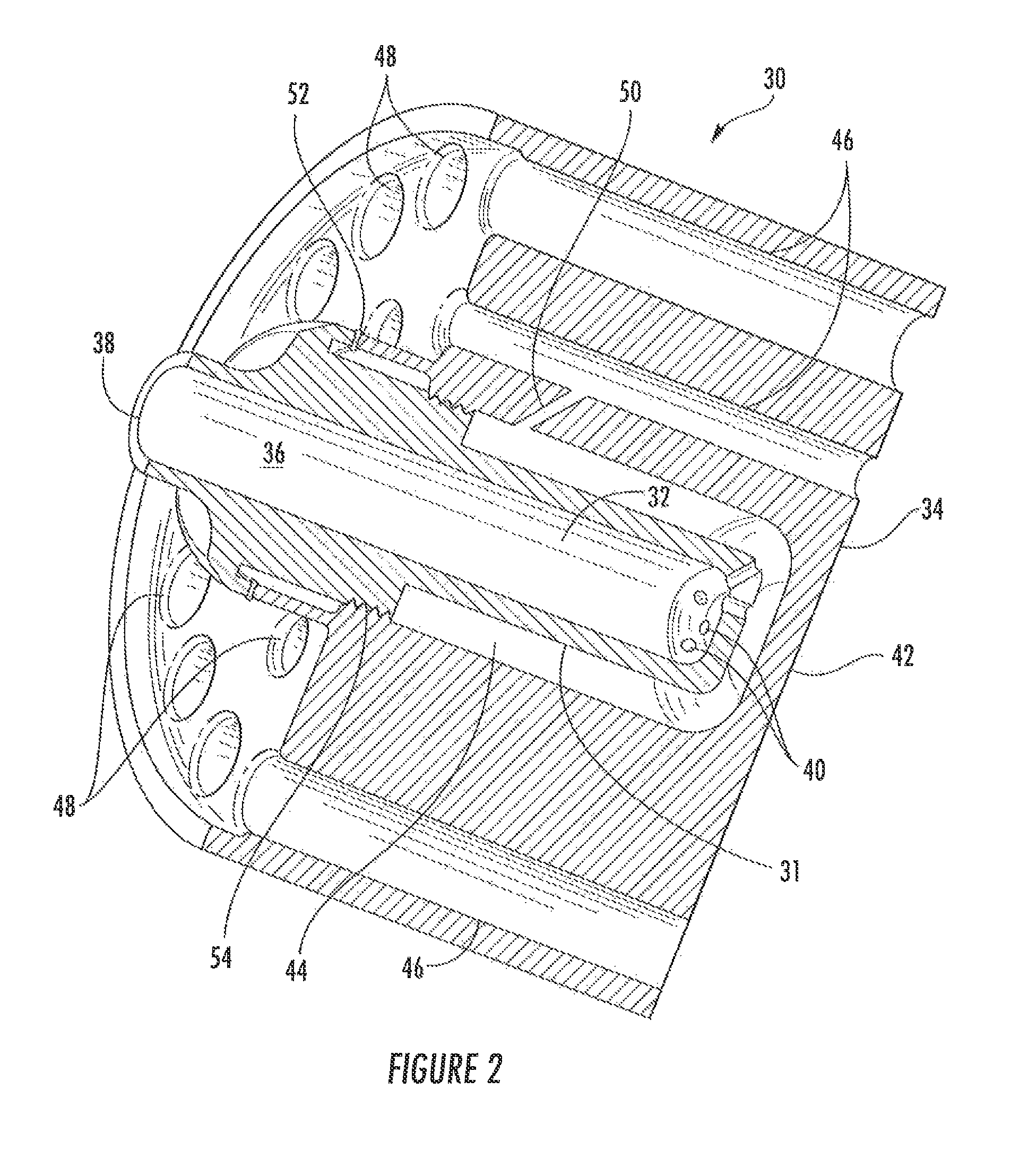

ActiveUS20120031102A1High combustion dynamicFuel supply regulationContinuous combustion chamberCombustorPhysical separation

A combustor cap assembly for a turbine engine includes a combustor cap and a plurality of fuel nozzles mounted on the combustor cap. One or more of the fuel nozzles would include two separate fuel circuits which are individually controllable. The combustor cap assembly would be controlled so that individual fuel circuits of the fuel nozzles are operated or deliberately shut off to provide for physical separation between the flow of fuel delivered by adjacent fuel nozzles and / or so that adjacent fuel nozzles operate at different pressure differentials. Operating a combustor cap assembly in this fashion helps to reduce or eliminate the generation of undesirable and potentially harmful noise.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

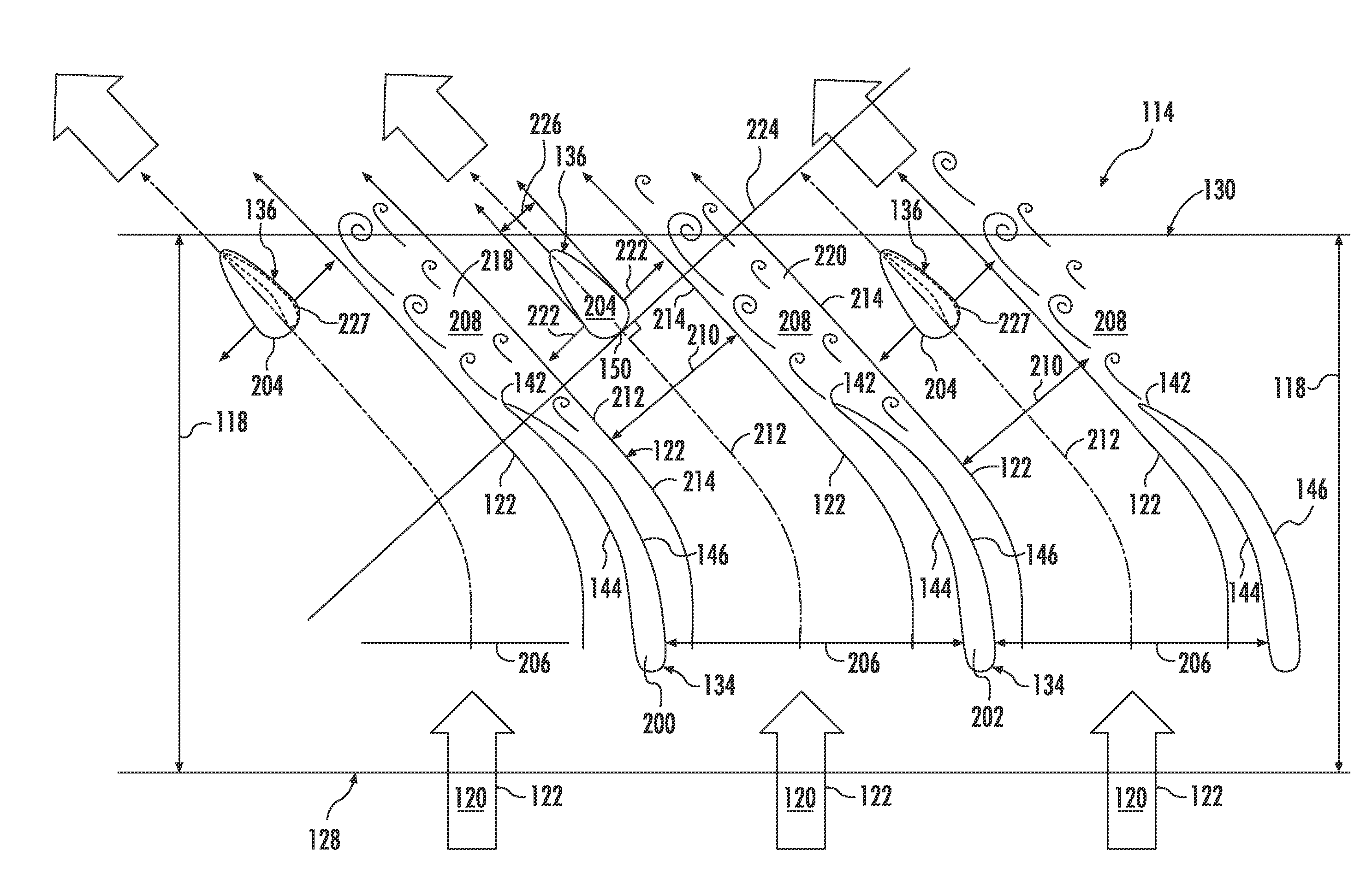

Hybrid prefilming airblast, prevaporizing, lean-premixing dual-fuel nozzle for gas turbine combustor

A dual fuel nozzle for a gas turbine combustor includes a hub defining a fuel inlet and a plurality of liquid fuel jets disposed at a downstream end of the hub. The fuel jets are oriented to eject liquid fuel radially outward from the hub. An annular air passage includes a swirler that imparts swirl to air flowing in the annular air passage, and a splitter ring is disposed in the annular air passage and surrounds the plurality of liquid fuel jets. The nozzle allows liquid fuels to be injected into a swirling annular airstream and then atomized, dispersed and vaporized inside a lean premixing dual fuel nozzle for a gas turbine combustor.

Owner:GENERAL ELECTRIC CO

Device for moulding thermoplastic containers by blow-moulding or stretch blow-moulding

Device for moulding thermoplastic containers by blow-moulding hot preforms, comprising a mould (1) and blow-moulding means (2) comprising a bell nozzle (8) which is axially displaceable between a raised position and a blow-moulding position in abutment against the mould; the driving means comprising mechanical means (12) with a cam follower roller (13) / cam (14) and pneumatic means (16) with a piston (18) integral with the upper end of the nozzle and sliding in a fixed enclosure (17), defining therein an upper chamber (19) connected to a source (24) of control fluid and a lower chamber (20) connected to this source and to the upper chamber via a solenoid valve (26); the upper face of the piston has a surface area which is greater than that of its lower face and that of the bell (9) of the nozzle.

Owner:SIDEL PARTICIPATIONS SAS

Fuel nozzle for a pre-mix combustor of a gas turbine engine

A fuel nozzle for use in a gas turbine includes a pre-mix flow passage for directing a flow segment of a flow of a working fluid through the fuel nozzle. A first swirler vane and a second swirler vane extend within the pre-mix flow passage. The first swirler vane provides a first wake region within the flow segment. The second swirler vane provides a second wake region within the flow segment. A fuel injection peg is disposed downstream from the first swirler vane and the second swirler vane. The fuel injection peg is positioned within the flow segment between the first wake region and the second wake region.

Owner:GENERAL ELECTRIC CO

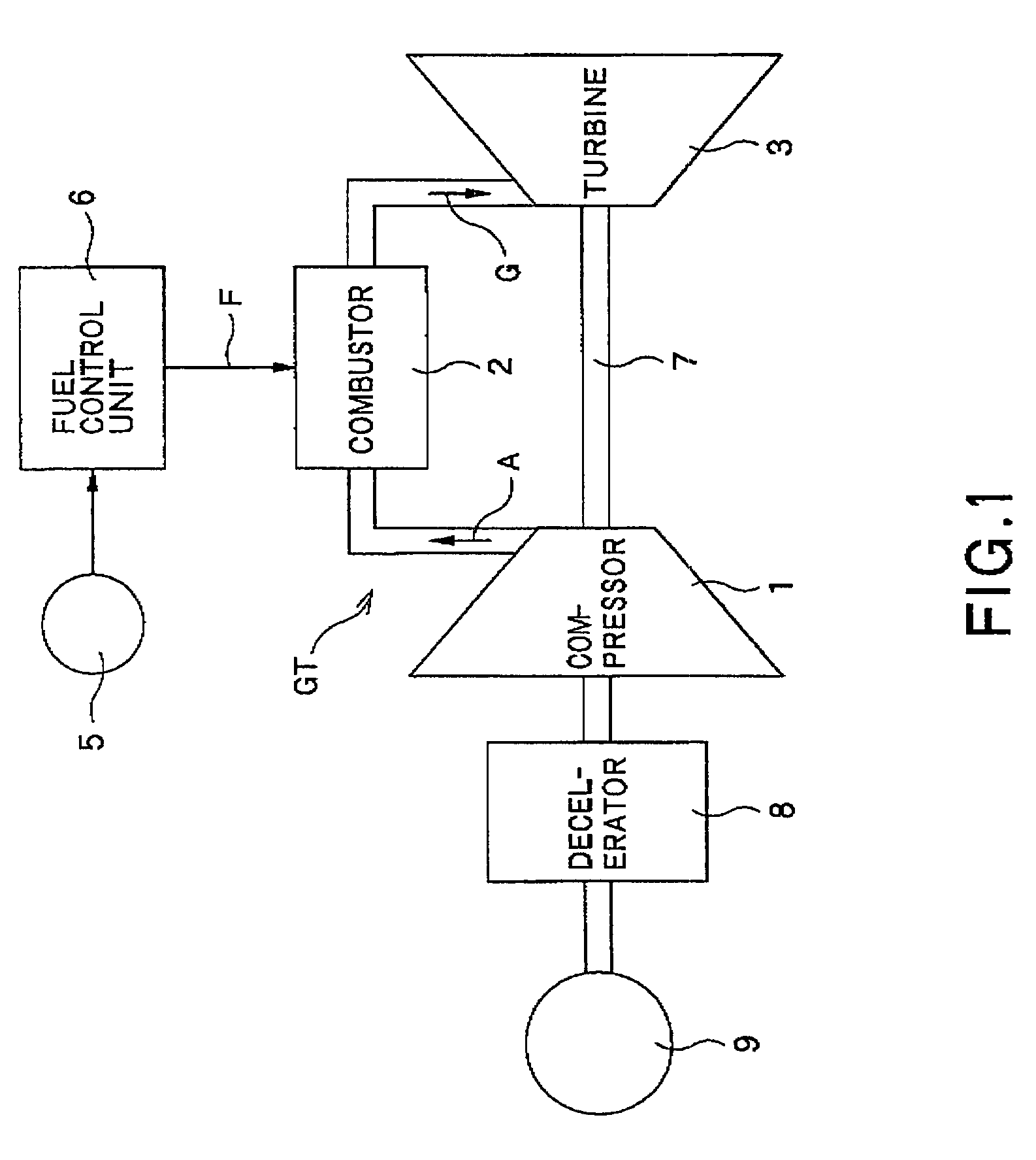

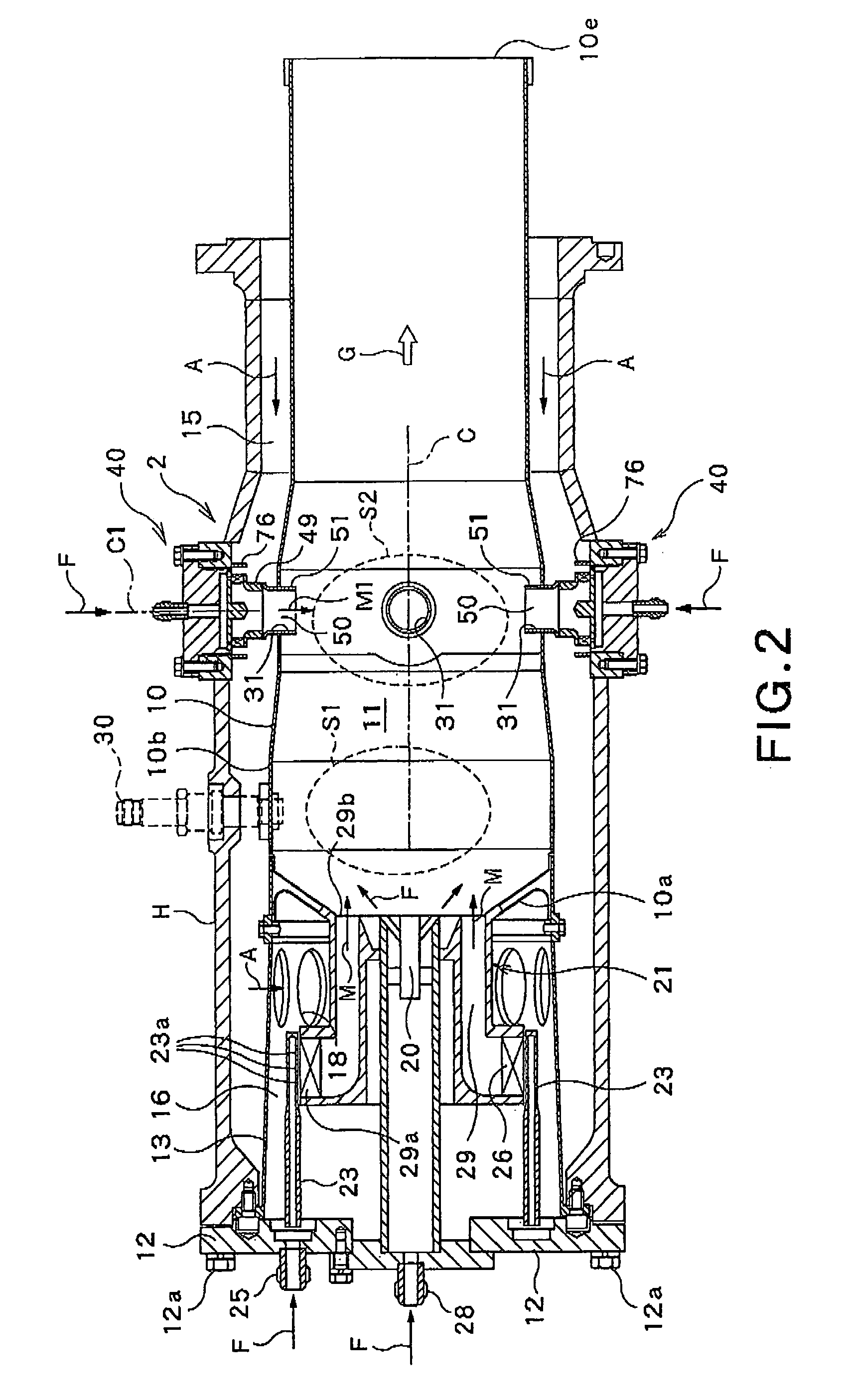

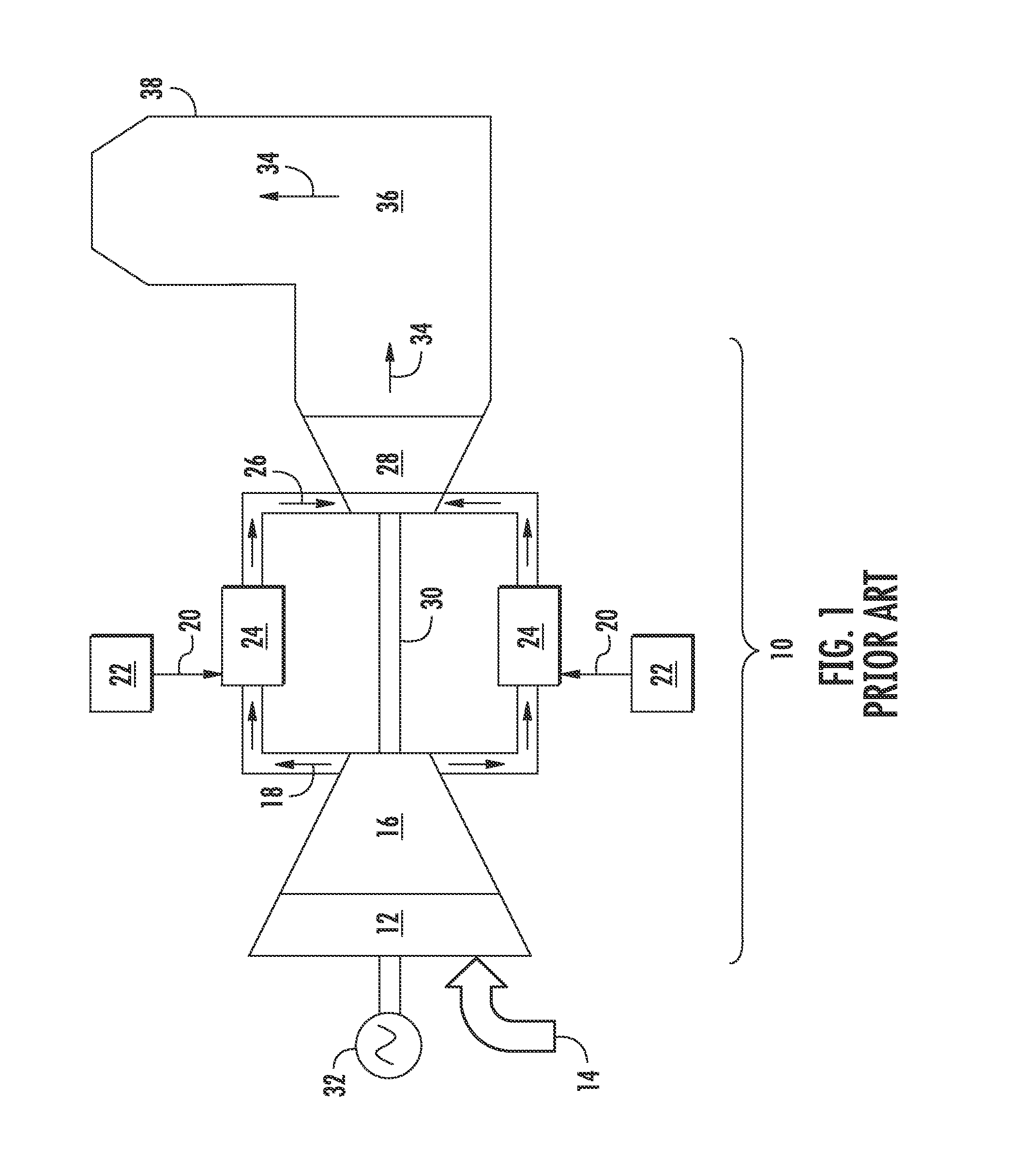

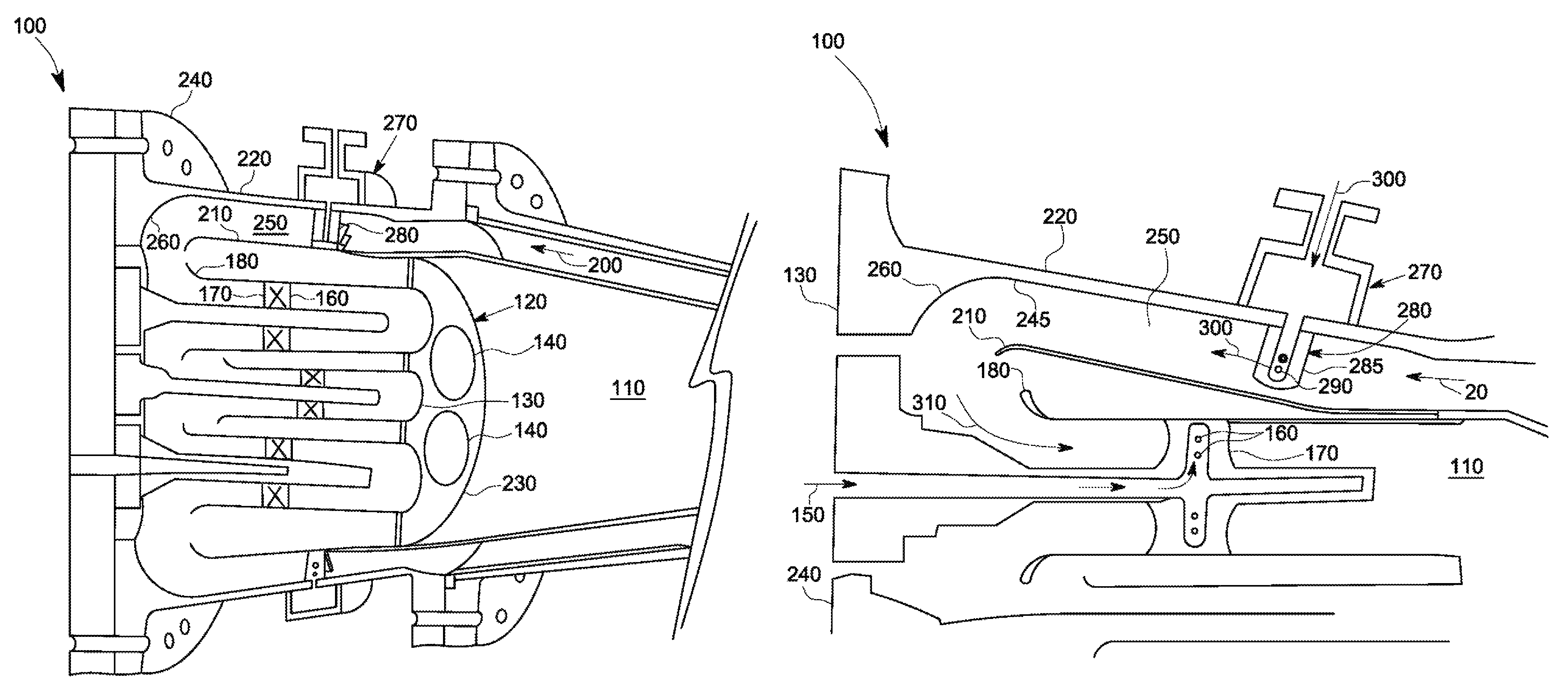

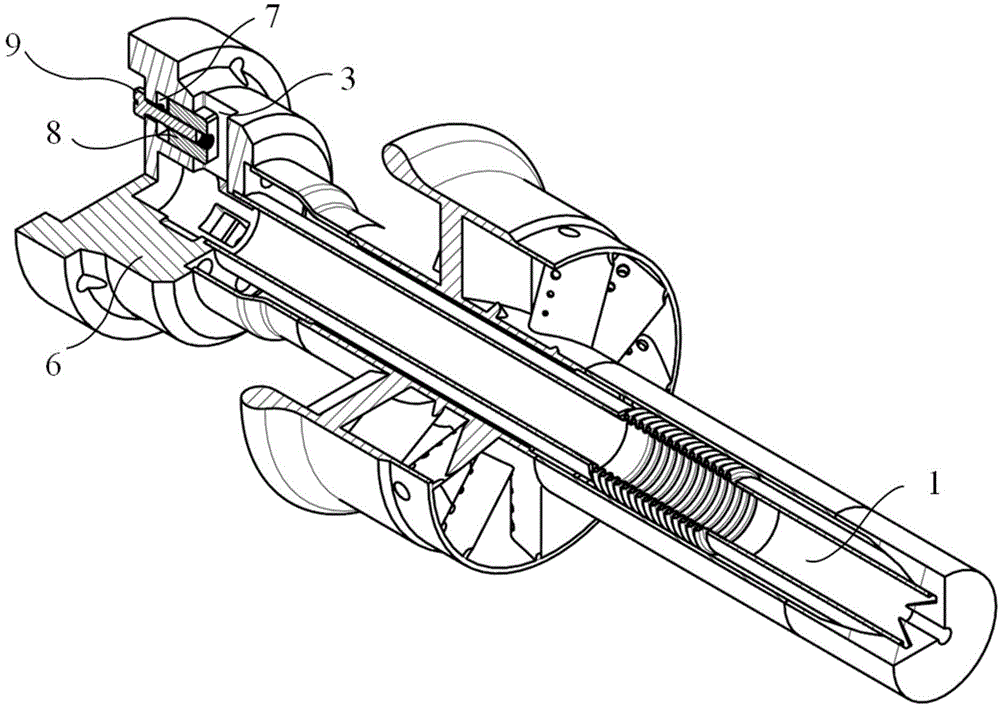

Integral gas turbine compressor and rotary fuel injector

InactiveUS7896620B1Rapid and effective fuel atomizationPromote combustionPropellersEngine manufactureCombustion chamberCombustor

An integral impeller and fuel pump for a small gas turbine engine, the impeller being a centrifugal impeller to supply compressed air to the combustor, the rotor disk of the centrifugal compressor having at least one radial fuel passage connecting a central bore of the rotor disk to a fuel nozzle located on the rear face of the rotor disk. A low pressure fuel supplied by a small pump delivers the fuel to the central bore where the fuel is collected within helical grooves and channeled into the radial fuel passages where the fuel is pressurized to a relatively high pressure due to the high rotational speed of the centrifugal compressor. Highly compressed fuel is injected into the combustor through fuel nozzles in an axial direction as the rotor disk rotates. Helical grooves in the central bore each connected to a radial fuel passage move the fuel to an opposite side of the central bore to counteract rotor imbalance. In another embodiment, a primary annular groove collects fuel and, at a low speed, passes all of the fuel to a first radial fuel passage into a first fuel nozzle such that only some of the fuel nozzles inject fuel into the combustor. At a higher speed, some of the fuel collected in the primary annular groove is spilled over into a secondary annular groove that passes the spilled-over fuel into a second radial passage and second fuel nozzle such that all of the fuel nozzles inject fuel into the combustor.

Owner:FLORIDA TURBINE TECH

Combustor with a lean pre-nozzle fuel injection system

ActiveUS8991187B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion chamberCombustor

The present application provides for a combustor for combusting a flow of fuel and a flow of air. The combustor may include a number of fuel nozzles, a lean pre-nozzle fuel injection system positioned upstream of the fuel nozzles, and a premixing annulus positioned between the fuel nozzles and the lean pre-nozzle fuel injection system to premix the flow of fuel and the flow of air.

Owner:GENERAL ELECTRIC CO

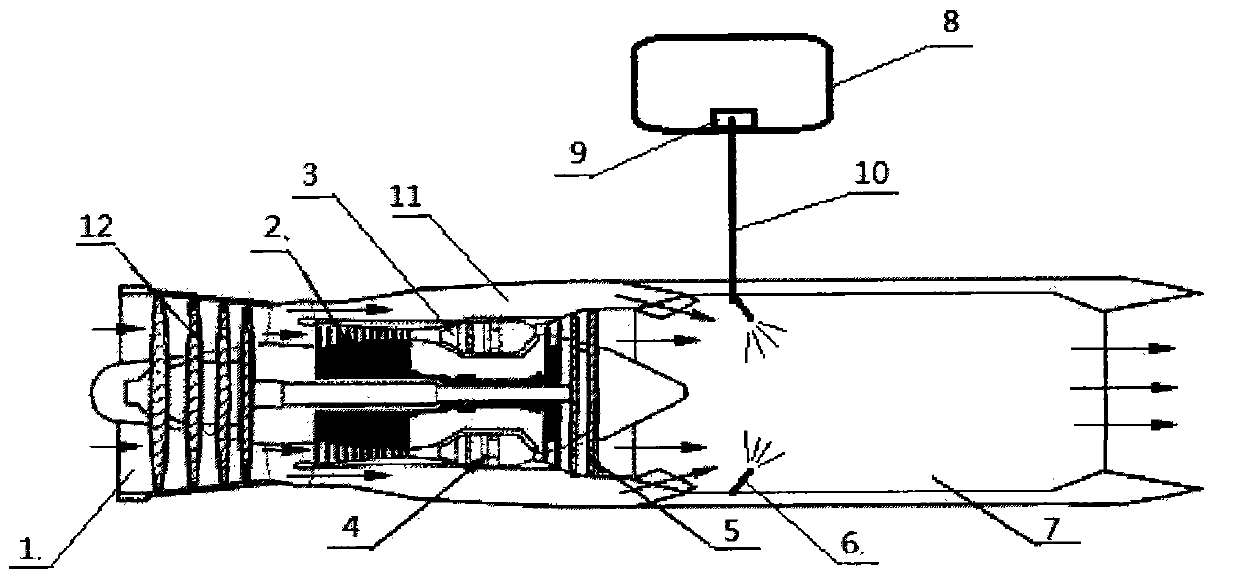

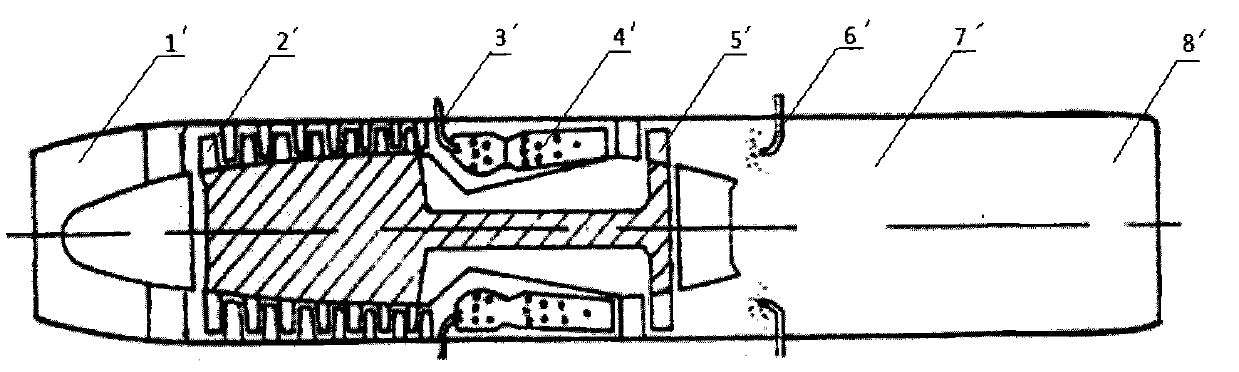

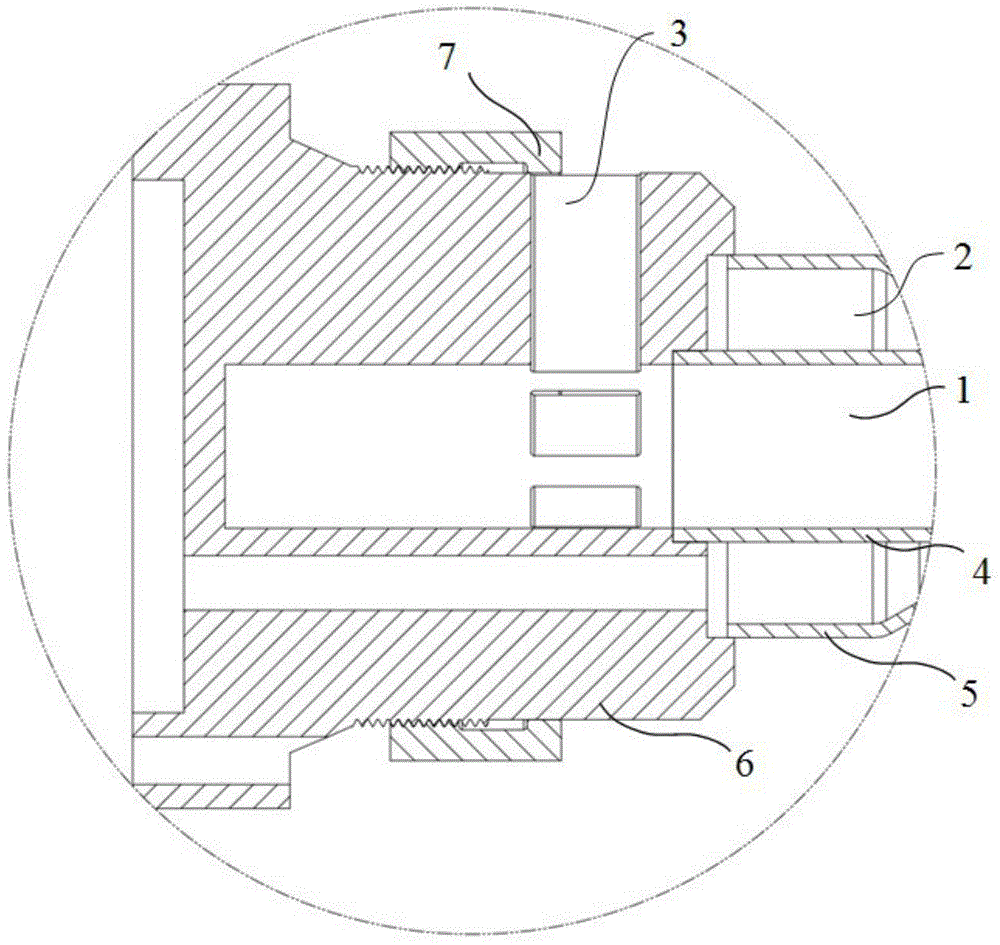

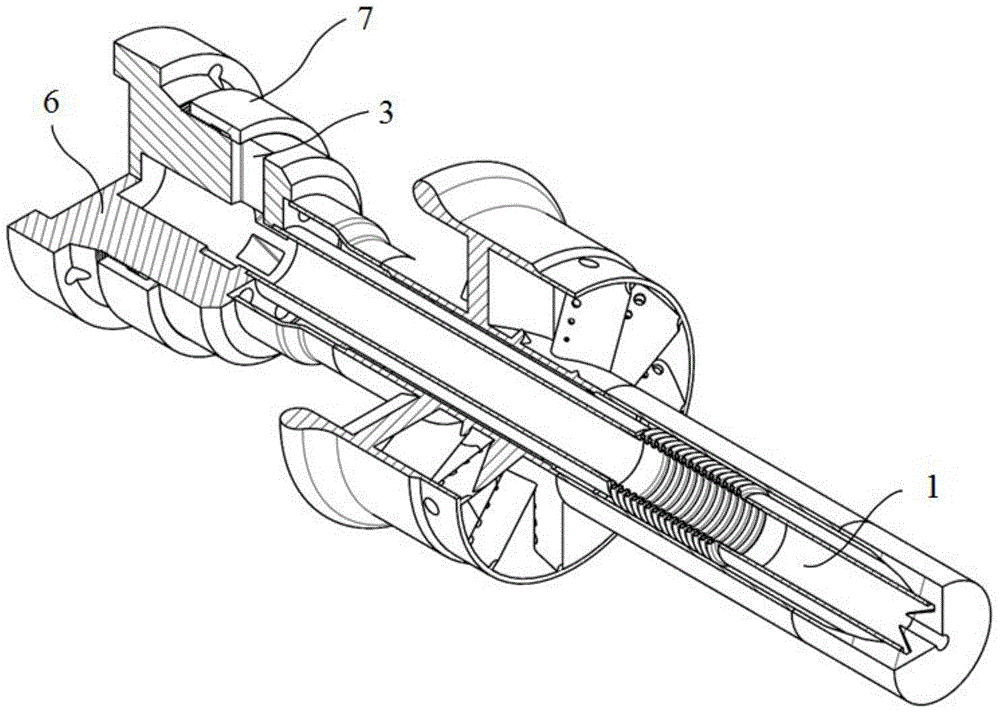

Rocket nozzle and control method for combustion of the exhaust gas flow in rocket engine

A rocket nozzle (8) includes a dual-bell nozzle (10) and a gas introducing section (40A, 40B, 40C, 40D) configured to introduce gas into space (80) surrounded by the dual-bell nozzle. Combustion gas flows in the space. The dual-bell nozzle includes a first stage nozzle (20) bell-shaped and surrounding an upstream portion (81) of the space, and a second stage nozzle (30) bell-shaped and surrounding a downstream portion (82) of the space. The dual-bell nozzle has an inflection point (12) between the first stage nozzle and the second stage nozzle. The gas introducing section includes a gas inlet (45, 63) provided to an inner wall surface of the first stage nozzle. The gas is introduced into the space from the gas inlet.

Owner:MITSUBISHI HEAVY IND LTD

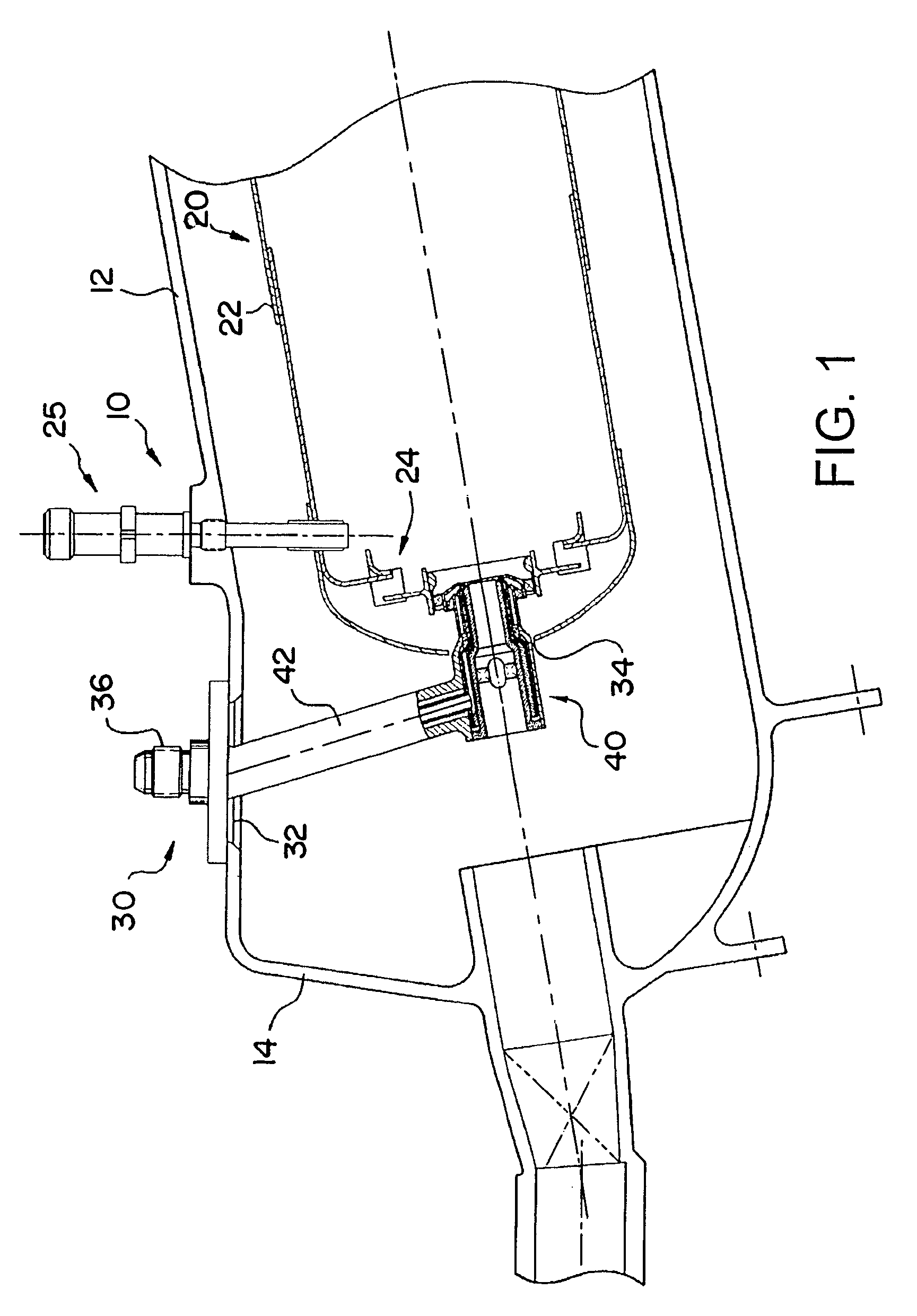

Combustor mixer purge cooling structure

The present disclosure is directed to a combustor assembly for a gas turbine engine. The combustor assembly includes a deflector wall, an annular axial wall, and an annular shroud. The deflector wall is extended at least partially along a radial direction and a circumferential direction relative to an axial centerline and adjacent to a combustion chamber. A fuel nozzle opening is defined through the deflector wall, and a nozzle centerline is extended through the fuel nozzle opening along a lengthwise direction. The annular axial wall is coupled to the deflector wall and extended through the fuel nozzle opening. The axial wall is defined around the nozzle centerline. The annular shroud is defined around the nozzle centerline and extended co-directional to the axial wall. The axial wall and the annular shroud are each coupled to a radial wall defined upstream of the deflector wall. The annular shroud, the axial wall, and the radial wall together define a cooling plenum therebetween. The axial wall defines a discrete inlet opening therethrough providing fluid communication from a diffuser cavity to the cooling plenum. The cooling plenum defines an exit opening providing fluid communication from the cooling plenum to the combustion chamber.

Owner:GENERAL ELECTRIC CO

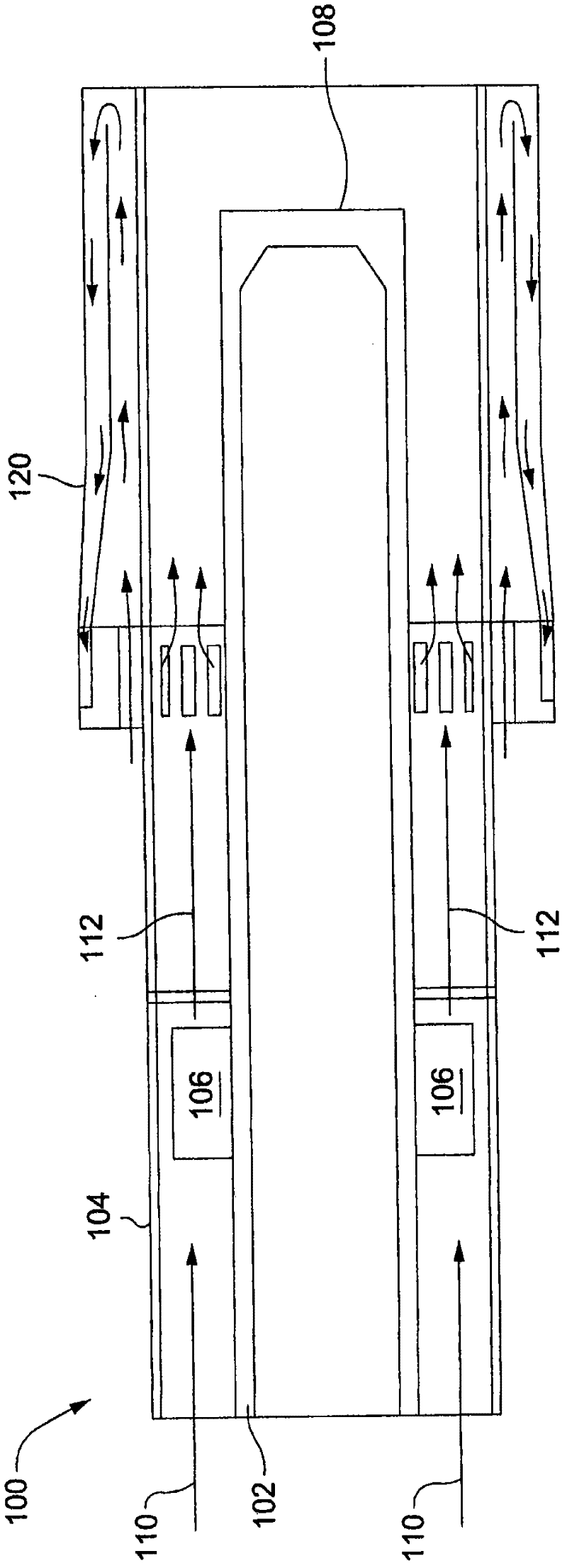

Burner, gas turbine having such a burner, and fuel nozzle

A burner having a plurality of pre-mixing chambers each having a fuel nozzle for two fuels, the fuel nozzle has a fuel lance extending in a flow direction, in which fuel lance first outlet openings for a first fuel are introduced. The fuel lance is surrounded by an outer pipe having at least one second outlet opening for a second fuel, the first outlet openings oriented radially and the second outlet opening oriented axially, a flow cross-section is formed between the fuel lance and the inside of the pre-mixing chamber and vortex generators are arranged on the fuel lance. At least one vortex generator is arranged upstream of the first outlet openings and downstream of the second outlet opening. The distance of the first outlet openings from an end of the pre-mixing chamber is at least three times as large as a cross-section of the pre-mixing chamber.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Fuel nozzle with central body cooling system

The invention relates to a fuel nozzle with a central body cooling system. Tje fuel nozzle for turbine engine includes a cooling shroud located at the downstream end of the fuel nozzle to help cool the downstream end of the fuel nozzle. The cooling shroud surrounds the exterior circumference of the downstream end of the fuel nozzle. A flow of air is admitted into the cooling shroud and the flow of air travels in the downstream direction through a first passageway which covers the exterior of the fuel nozzle. The cooling air flow then turns 180 DEG and travels in the upstream direction through a second passageway which is located concentrically outside the first passageway. The airflow then leaves the upstream end of the cooling shroud and enters the interior of the fuel nozzle.

Owner:GENERAL ELECTRIC CO

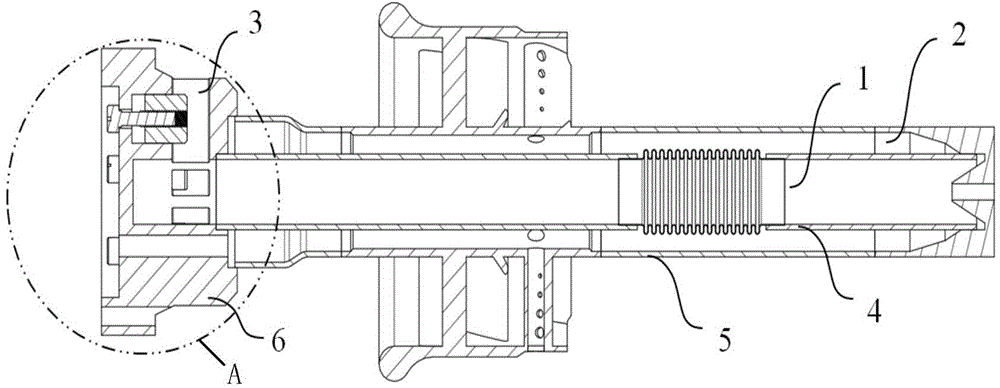

Mixed injector and small liquid rocket engine

The invention relates to the technical field of liquid rocket engines, and particularly relates to a mixed injector and a small liquid rocket engine. The mixed injector comprises a shell, a cover plate and a core, wherein an oxidant cavity and a fuel cavity are formed in the shell; the oxidant cavity is annular, and the oxidant cavity surrounds the fuel cavity; the cover plate covers the upper endsurface of the shell and is welded with the shell and is used for sealing the oxidant cavity; the core is arranged in the fuel cavity, and fuel in the fuel cavity can be rotational and centrifugal bythe core; and a panel is arranged on the lower end surface of the shell, a fuel nozzle and an oxidant nozzle are formed in positions, which correspond to the fuel cavity and the oxidant cavity, of the panel, the fuel which is rotational and centrifugal in the fuel cavity by the core is sprayed by the fuel nozzle, and oxidant in the oxidant cavity can be sprayed by the oxidant nozzle. According tothe mixed injector, the core structure of the fuel nozzle is additionally arranged, so that the centrifugal spraying of the fuel is realized, the mixed injector and a straight-flow oxygen nozzle forma mixed spraying mode, the atomization effect is good, and the combustion efficiency is high.

Owner:BEIHANG UNIV

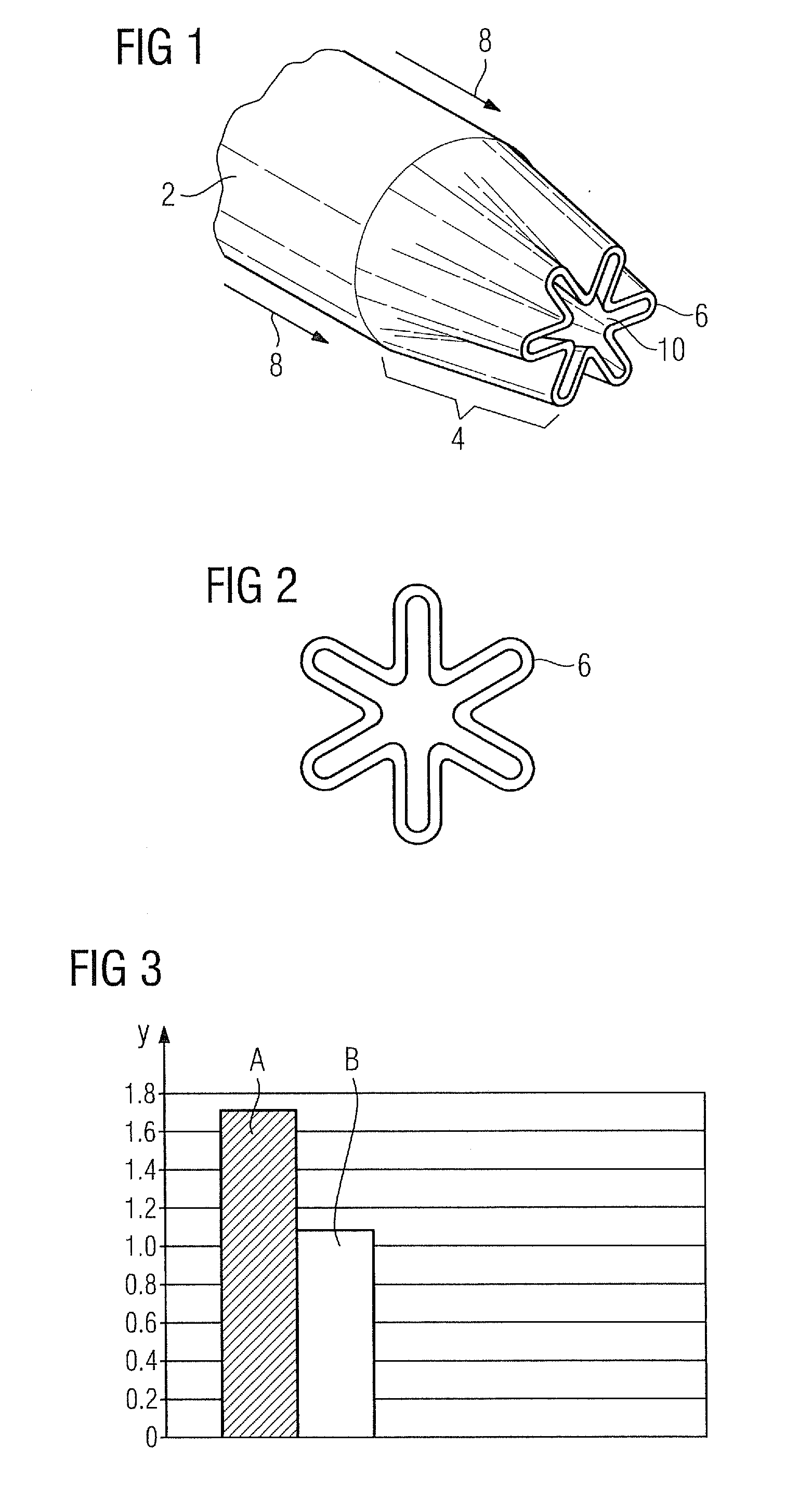

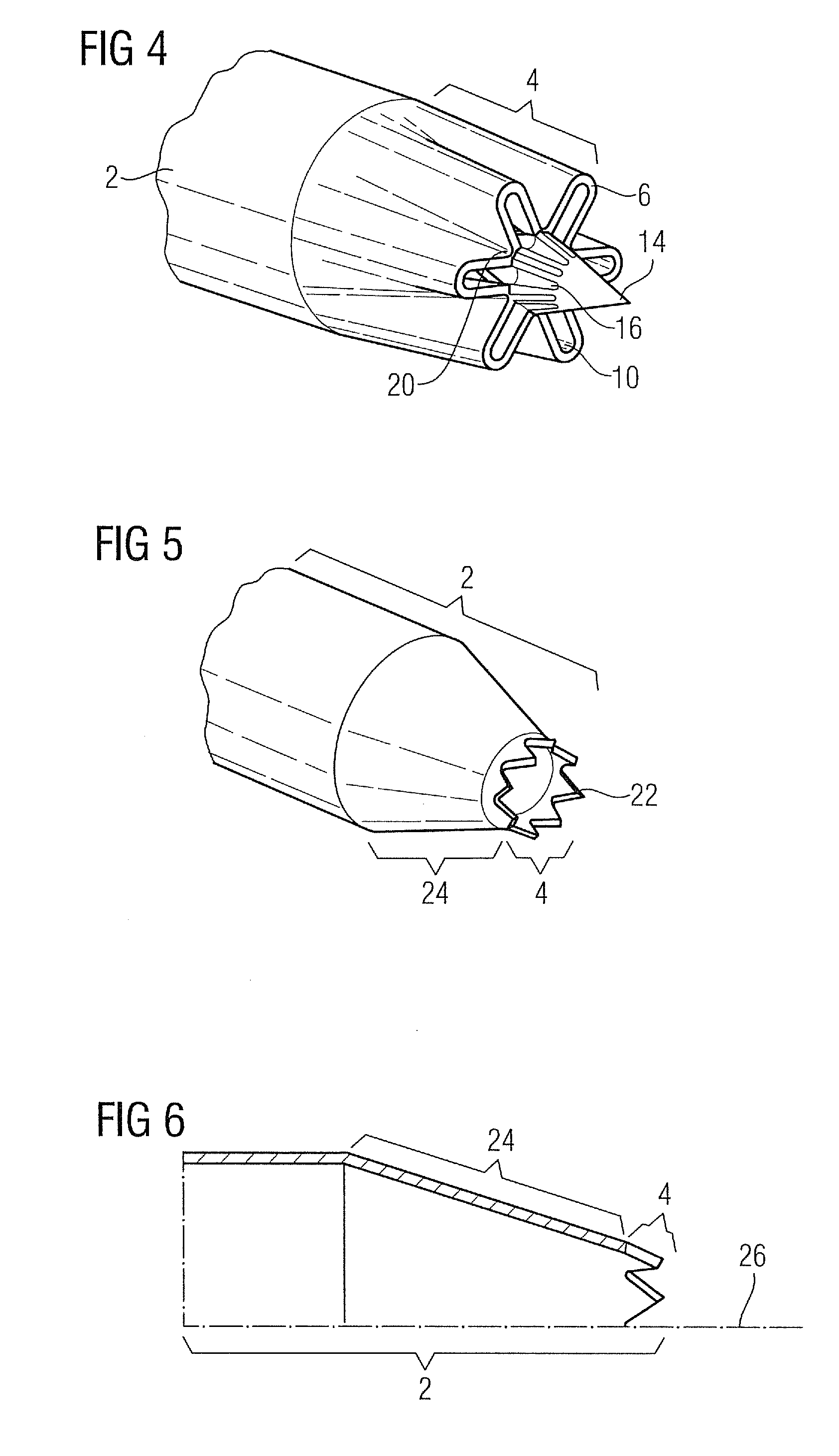

Fuel Nozzle

InactiveUS20110232289A1Facilitate flow velocityWell mixedContinuous combustion chamberGas turbine plantsBell nozzleAirflow

A fuel nozzle including a nozzle tube and a nozzle outlet opening is provided. The nozzle tube is connected to a fuel feed line for feeding a fuel to the nozzle tube, wherein the fuel is fed from the nozzle outlet opening to an annular air stream surrounding the fuel nozzle, wherein a first nozzle tube section that extends up to the nozzle outlet opening is designed in a floral pattern in such a way that the fuel may be fed substantially coaxially into the air stream.

Owner:SIEMENS AG

Liquid gas afterburner jet engine and method for realizing afterburning flying of jet plane

InactiveCN103742294ATake advantage ofFast absorptionJet propulsion plantsCombustion chamberJet engine

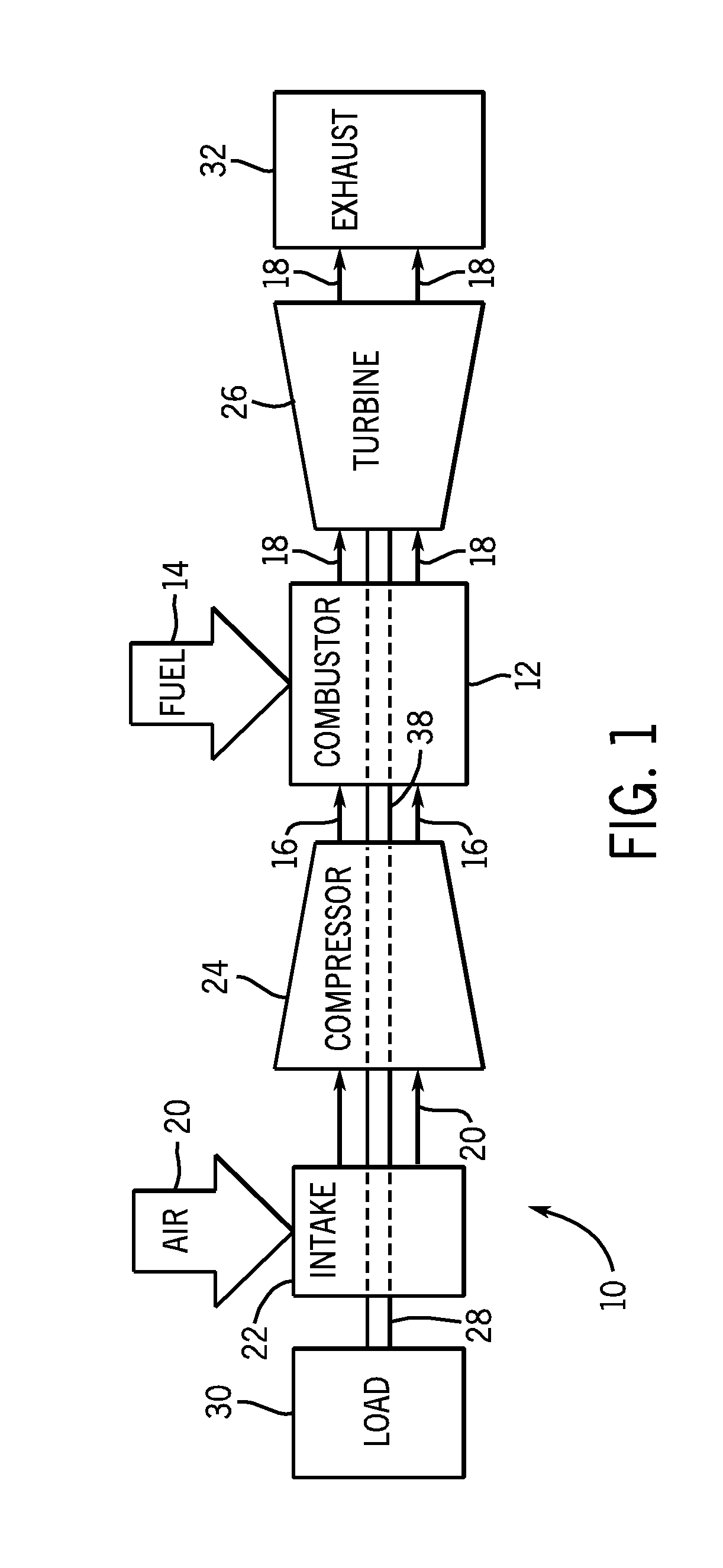

The invention provides a liquid gas afterburner jet engine and a method for realizing afterburning flying of a jet plane. The jet engine comprises an air incoming way, a gas compressor, burning chambers with fuel nozzles, a turbine, an afterburner, a tail nozzle and liquid gas nozzles extending into the afterburner. By the method, the jet engine can be ensured to fully utilize thermal expansion of liquid gas to do work during afterburning propelling, and thrust of the jet engine is increased more efficiently, so that burning efficiency of the jet engine is improved obviously, thrust is increased, power cost is lowered, environmental pollution is reduced, and probability of being attacked by an infrared weapon can be lowered.

Owner:苟仲武

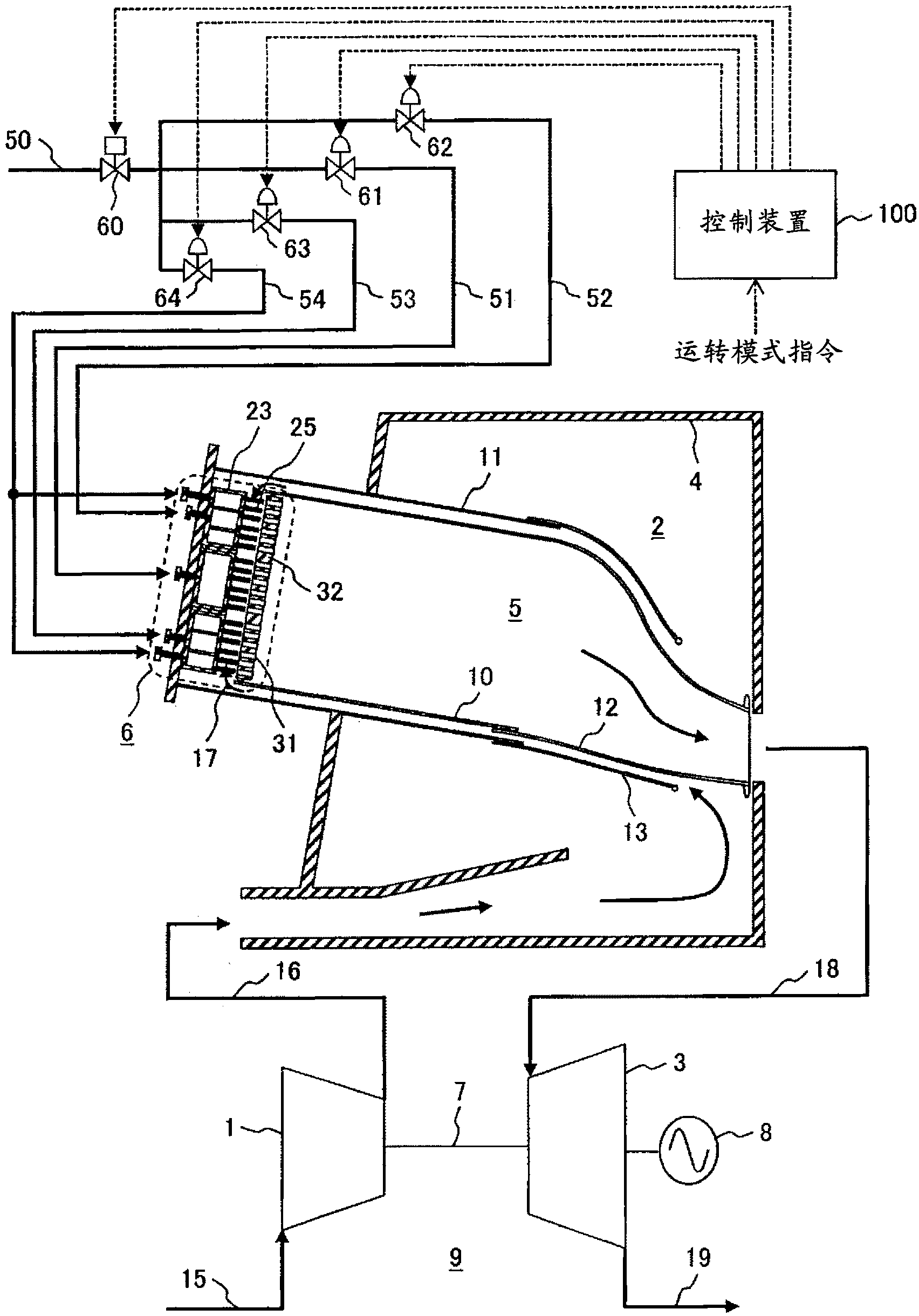

Gas turbine combustor and operating method thereof

ActiveCN103225822AAvoid temperature riseGuaranteed combustion stabilityBurnersFuel supply regulationCombustorCombustion chamber

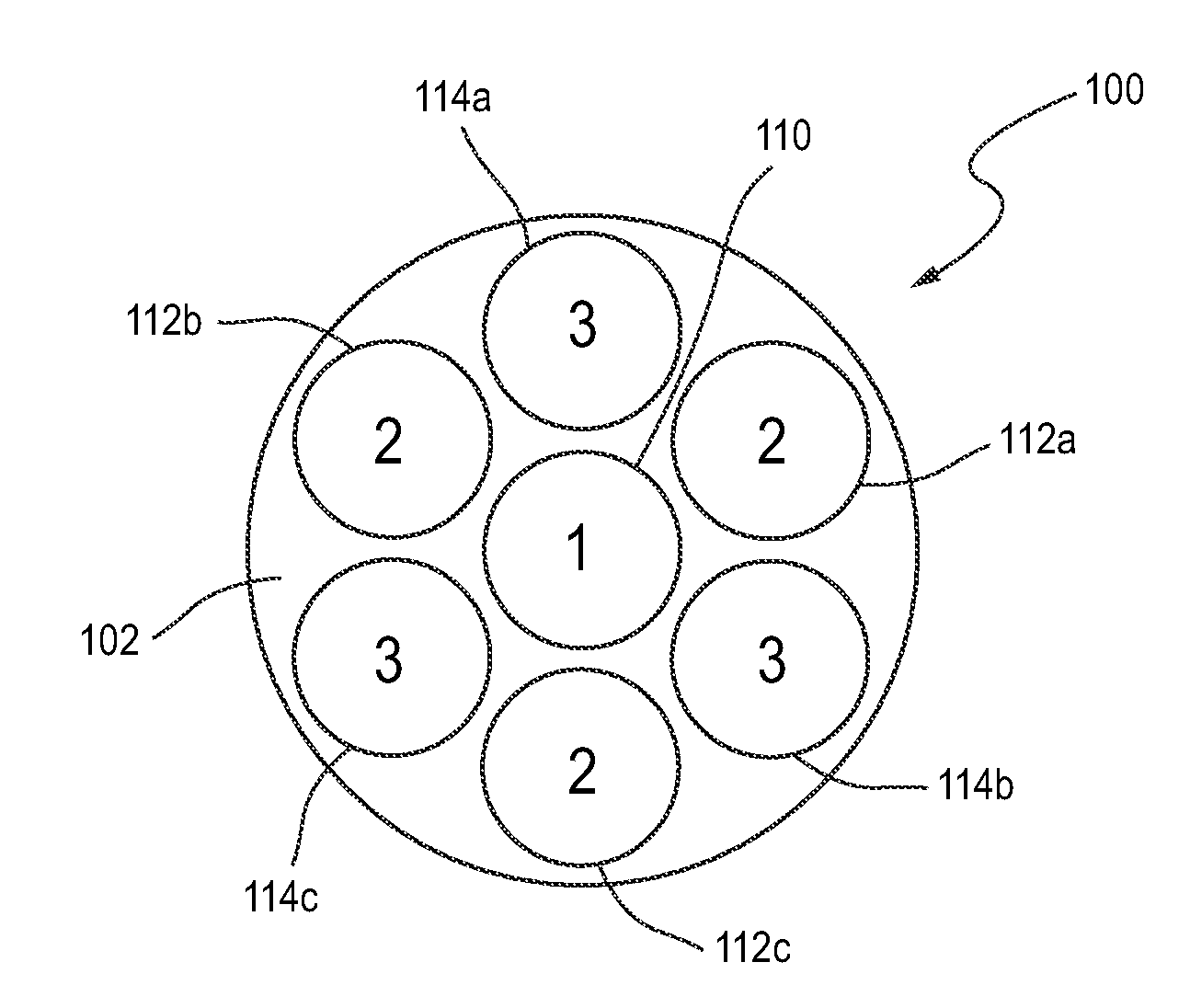

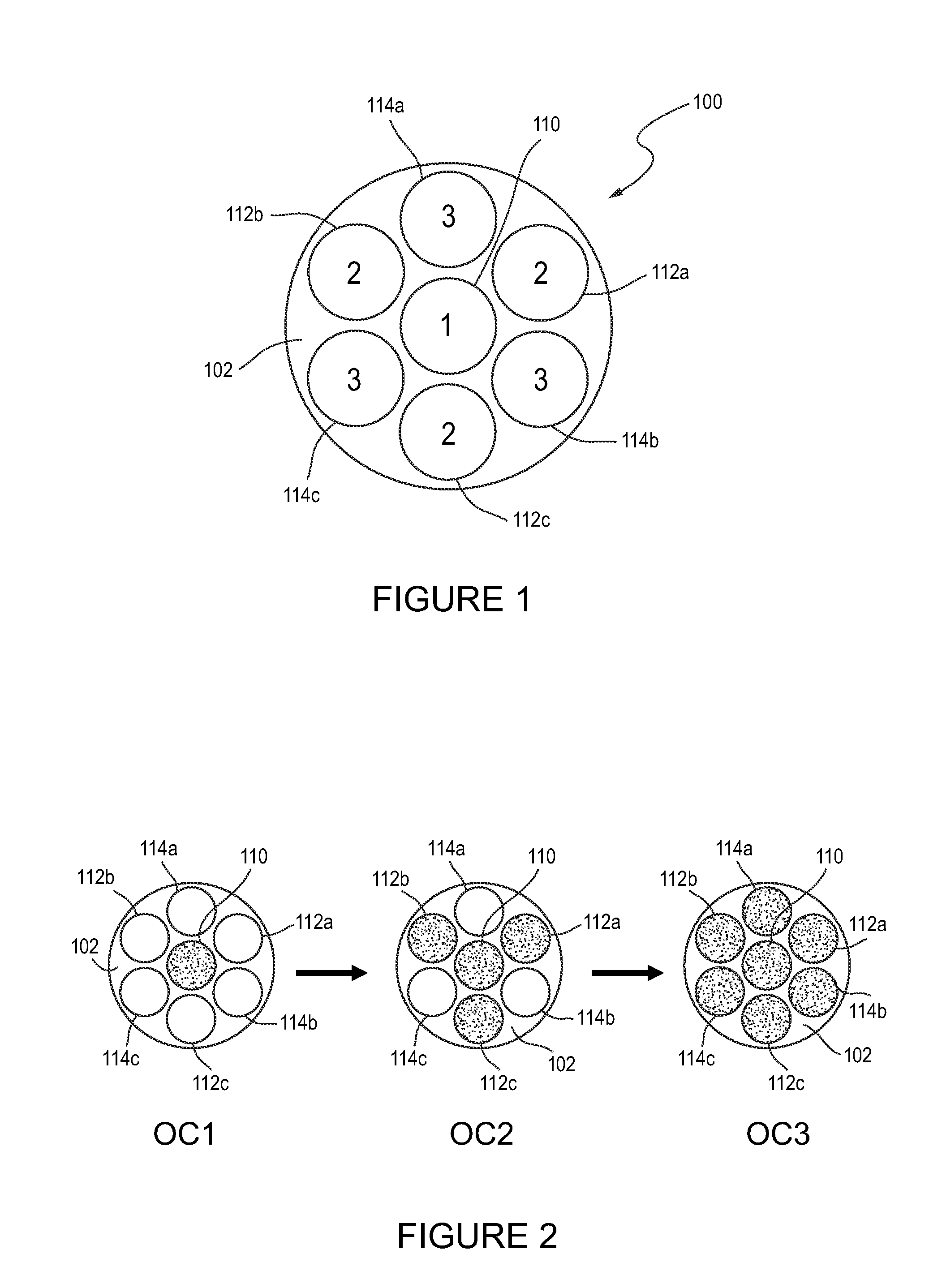

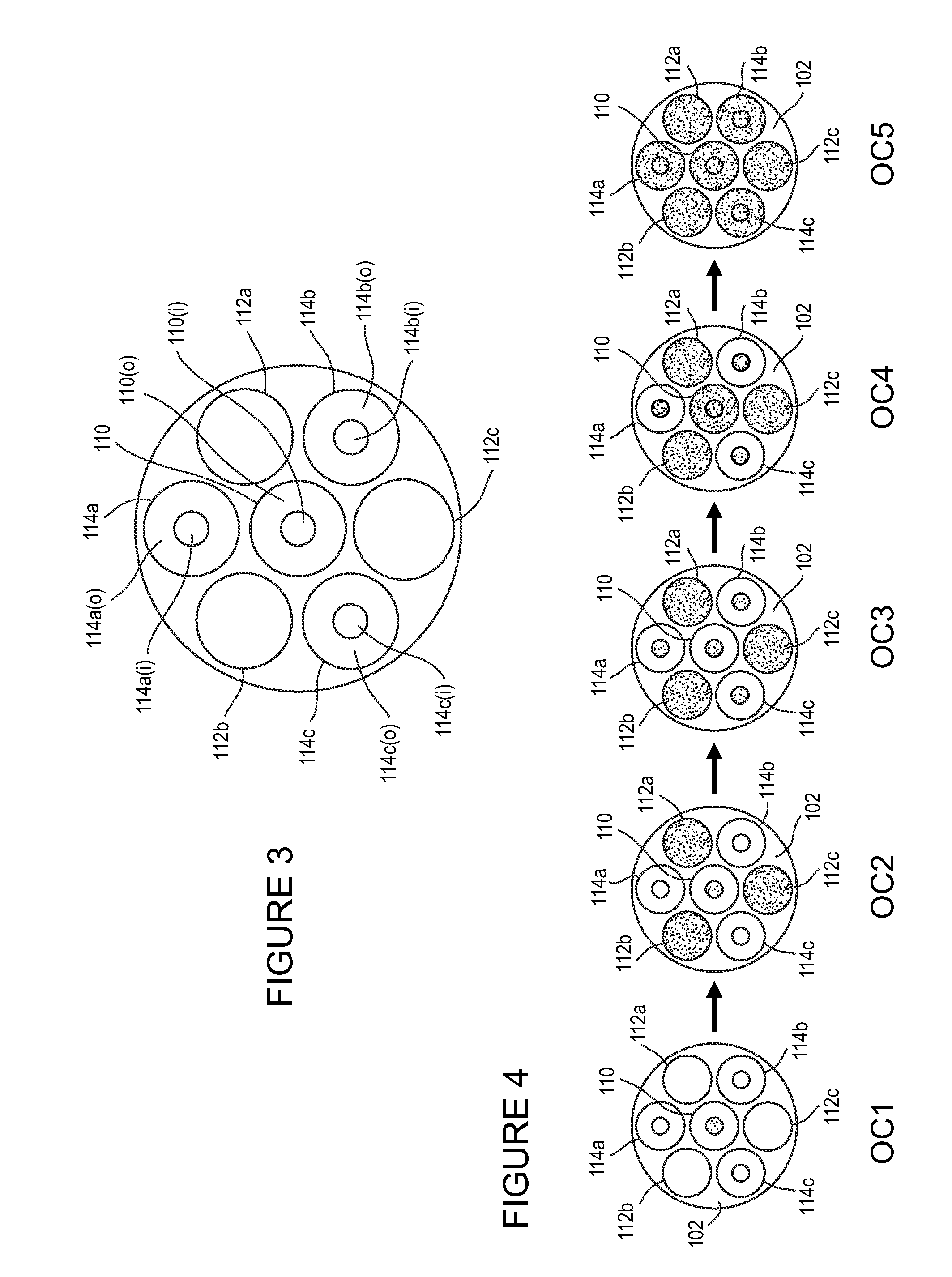

An object of the present invention is to provide a gas turbine combustor and an operating method of the gas turbine combustor to allow the gas turbine combustor to ensure combustion stability in the entire range of load conditions of the gas turbine and reduce the generation of unburned combustibles and an increase in liner metal temperature at the same time in partial load conditions of the gas turbine. The gas turbine combustor comprises: a chamber supplied with fuel and air; an air hole plate located in an upstream side of the chamber, forming a plurality of air holes for supplying the air; and a multi-burner having a plurality of burners provided with fuel nozzles. The multi-burner is made up of a center burner disposed in the center and a plurality of outer burners around the center burner, the outer burners are divided into inner fuel nozzles and outer fuel nozzles to separately supply fuel through fuel systems, and the fuel is supplied to the fuel nozzles in the center burner or to the fuel nozzles in the center burner and the inner fuel nozzles in the outer burners disposed around the center burner in a partial load condition in which the load is lower than that of when all the fuel systems are used to supply fuel.

Owner:MITSUBISHI POWER LTD

Apparatus and method for a fuel nozzle

A fuel nozzle includes a fuel plenum, an outer body surrounding the fuel plenum, and bore holes that extend longitudinally through the outer body. The fuel nozzle also includes means for fixedly attaching the fuel plenum to the outer body and passages that provide fluid communication between the fuel plenum and the bore holes. A method for manufacturing a fuel nozzle includes drilling bore holes longitudinally through an outer body and drilling passages in the outer body to the bore holes. The method further includes inserting a fuel plenum into the outer body, wherein the passages provide a fluid communication between the bore holes and the fuel plenum, and attaching the fuel plenum to the outer body.

Owner:GENERAL ELECTRIC CO

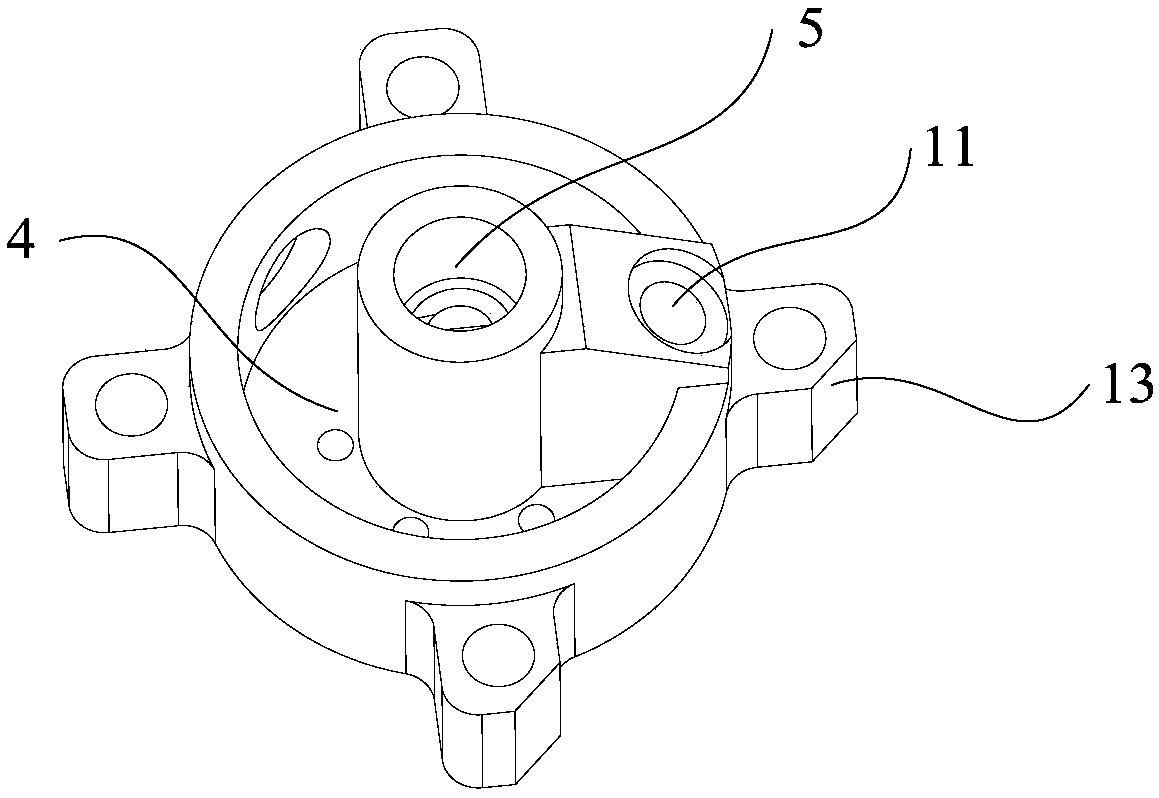

Air inlet structure for fuel nozzle of gas turbine

ActiveCN104456624ARealize stepless speed changeImprove reliabilityContinuous combustion chamberInlet channelMixing effect

The invention relates to the technical field of gas turbines, and provides an air inlet structure for a fuel nozzle of a gas turbine. The fuel nozzle comprises a center air channel and a fuel cavity which are communicated with each other, and the center air channel is used for connecting the air into the fuel cavity. A nozzle hanging flange is arranged at one end of the center air channel, and the nozzle hanging flange is provided with air inlet channels used for connecting the air into the center air channel. The nozzle hanging flange is movably sleeved with an adjusting sleeve, and the adjusting sleeve is used for limiting the sizes of openings of the air inlet channels through axial movement. By axially adjusting the adjusting sleeve, the flow of the air entering the center air channel can be adjusted, hence, it is guaranteed that fuel and air have a good pre-mixing effect, tempering can be prevented from happening to a nozzle outlet, and the reliability of the nozzle is improved; in addition, stepless speed change of the gas turbine can be achieved through the adjusting sleeve.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

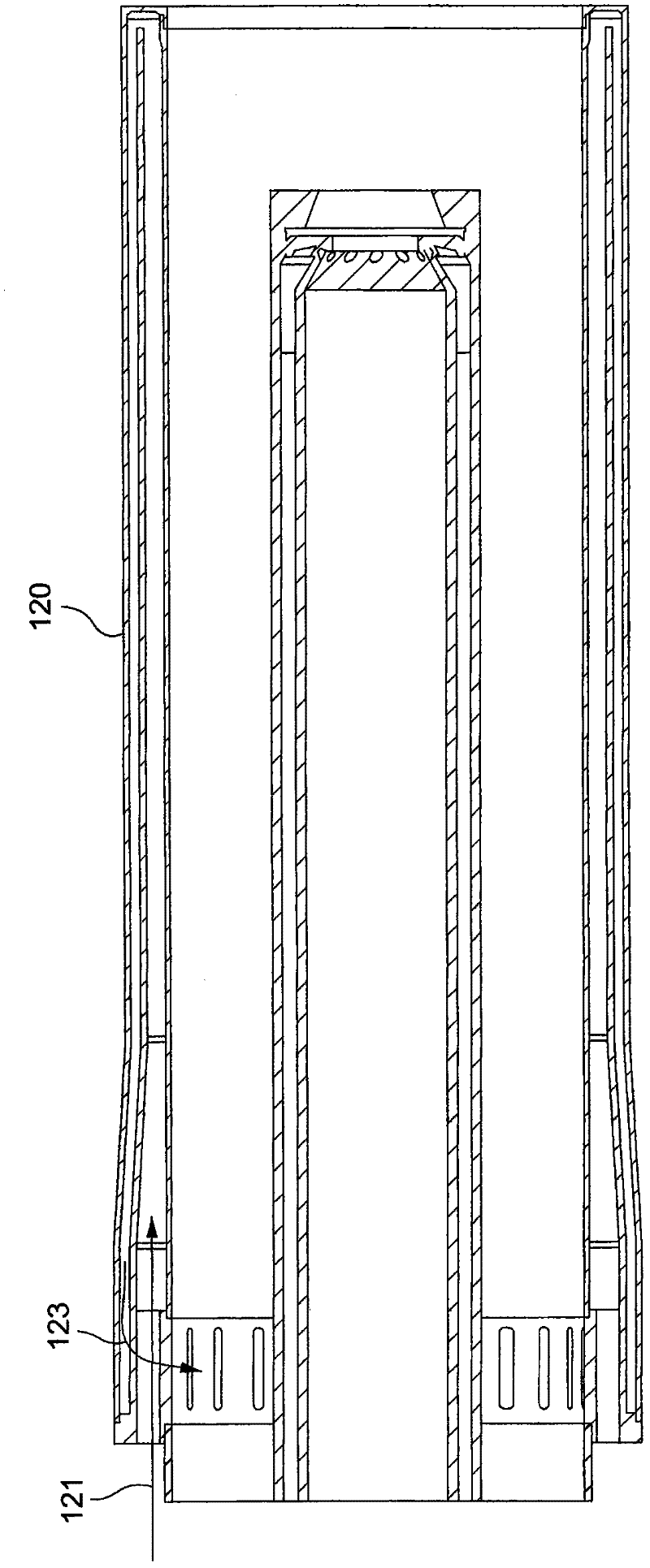

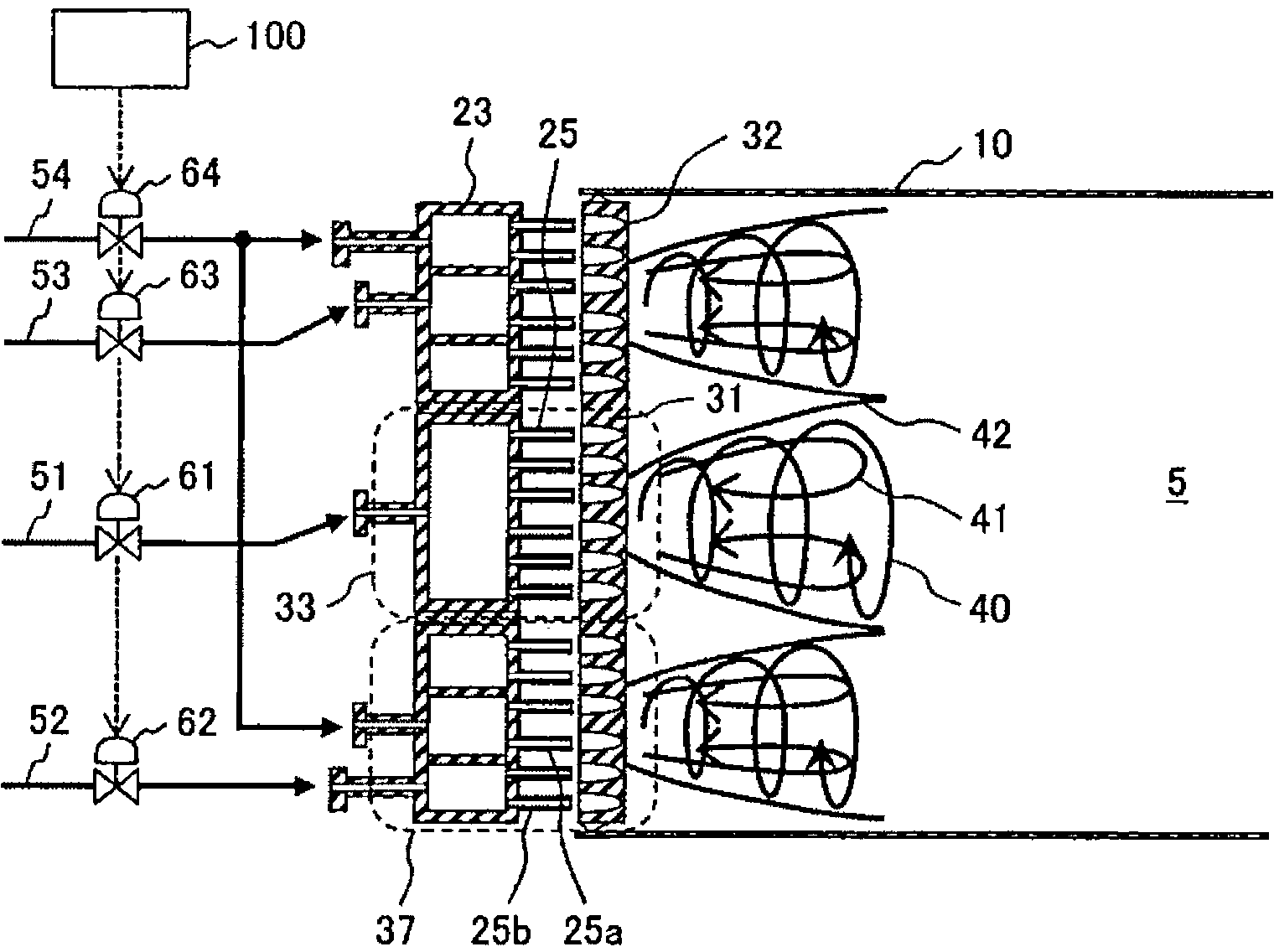

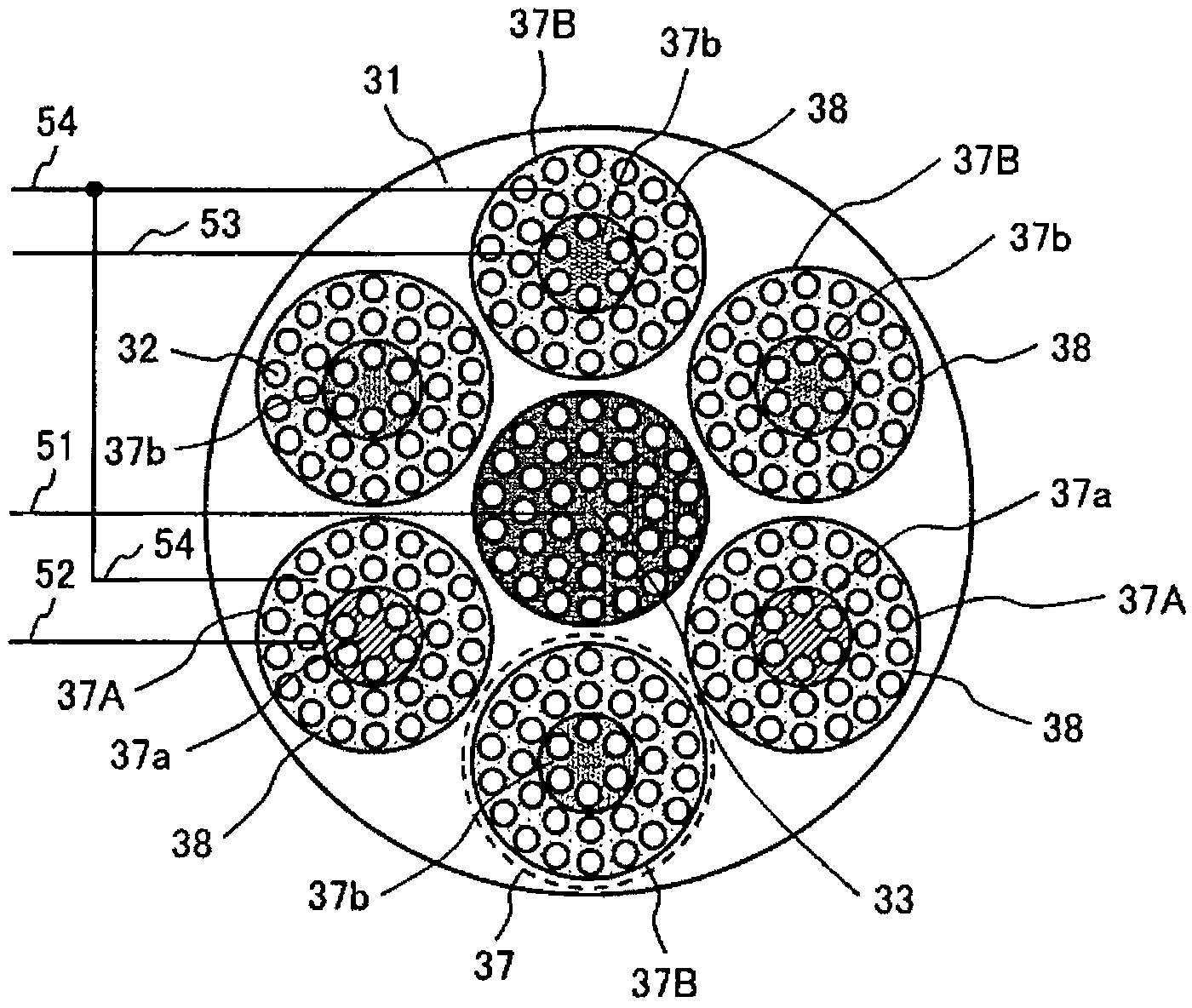

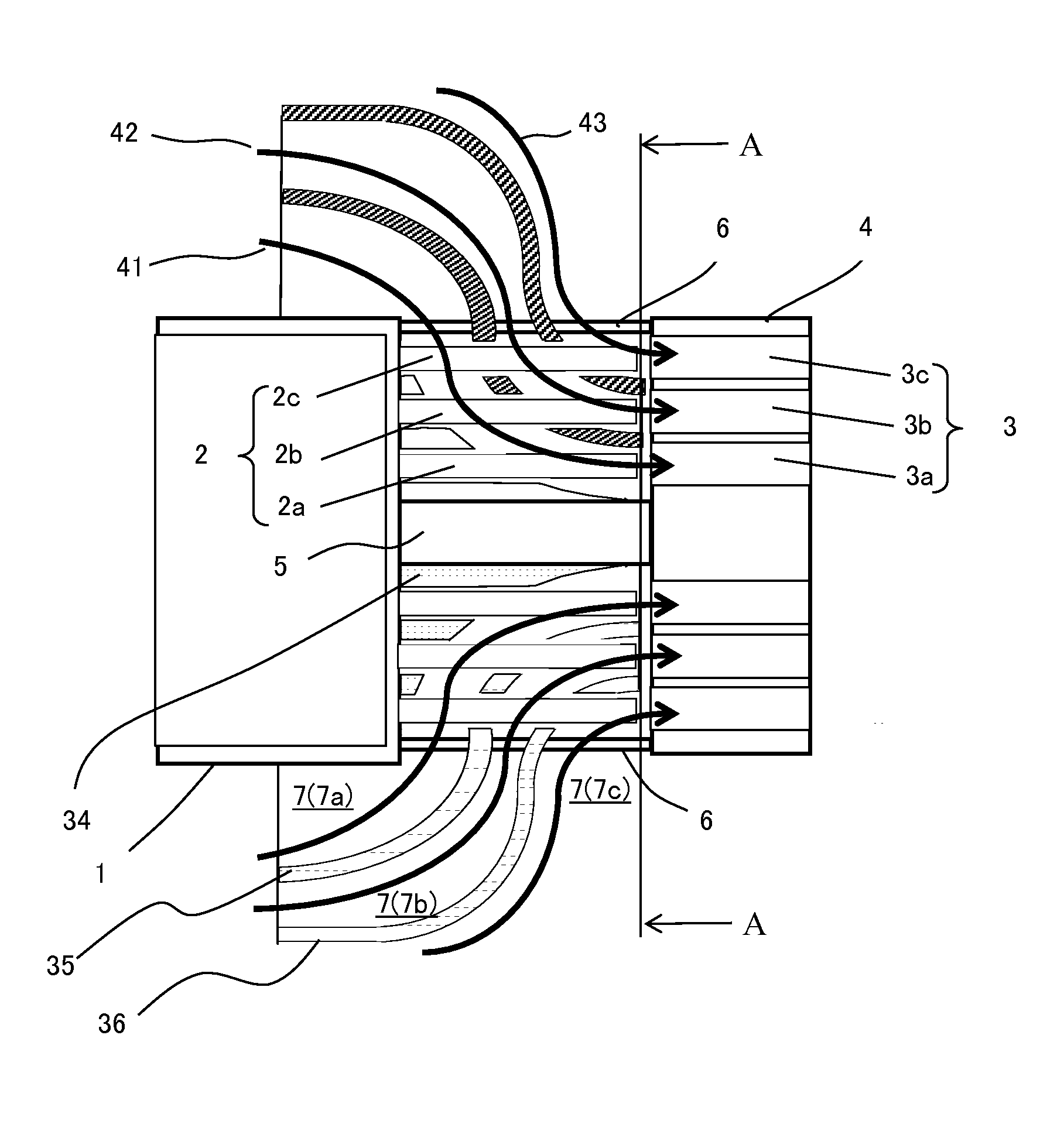

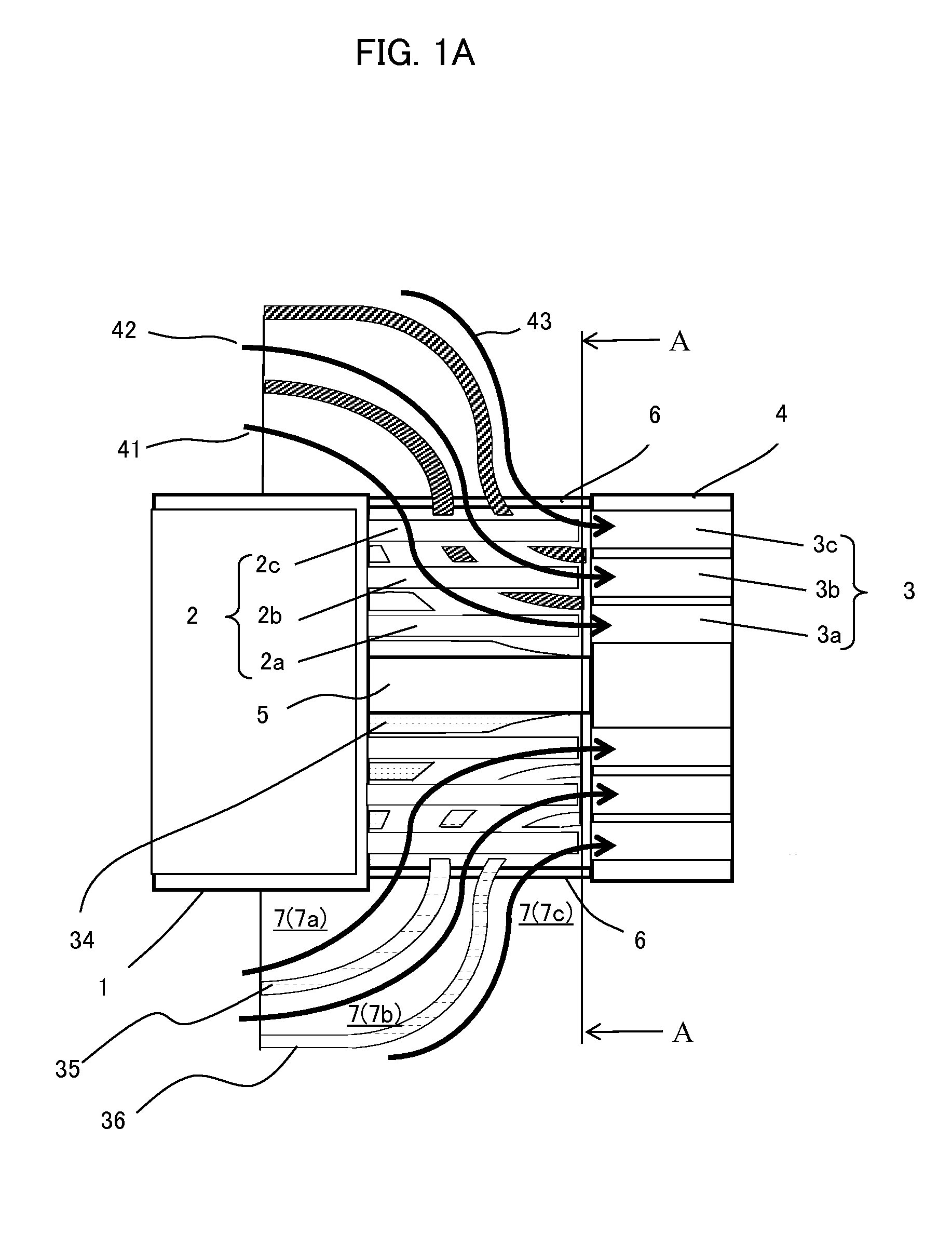

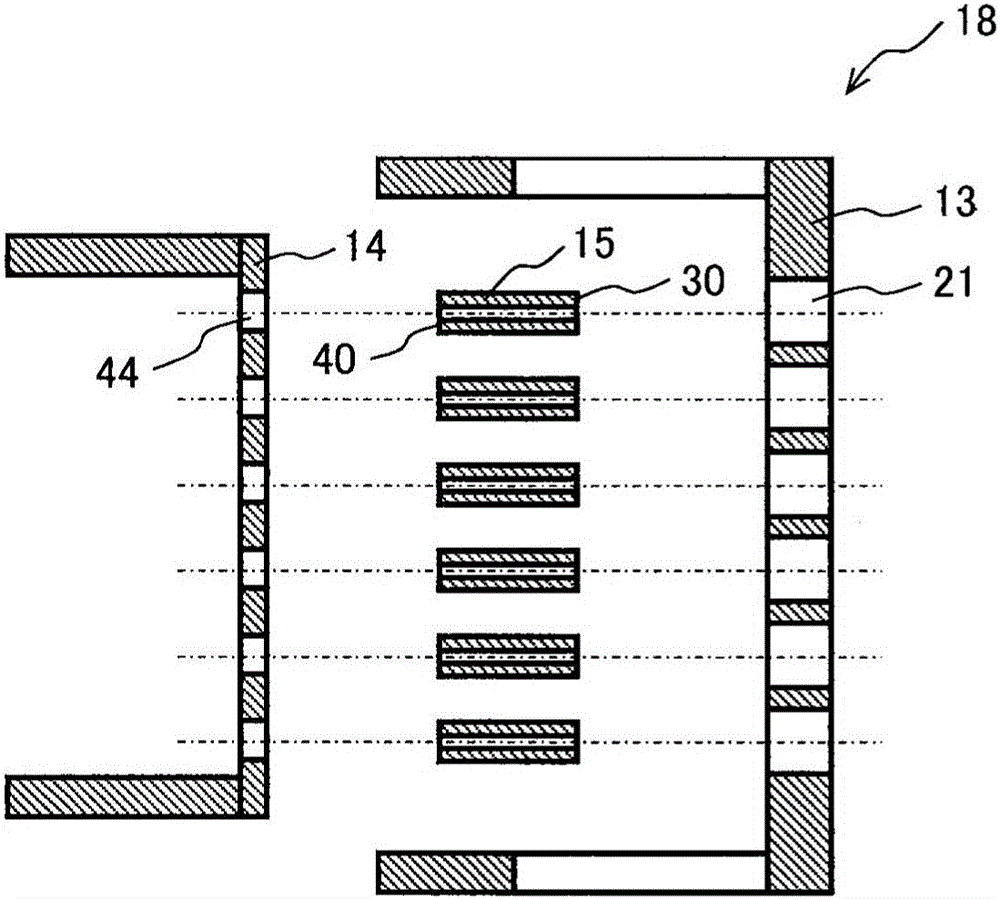

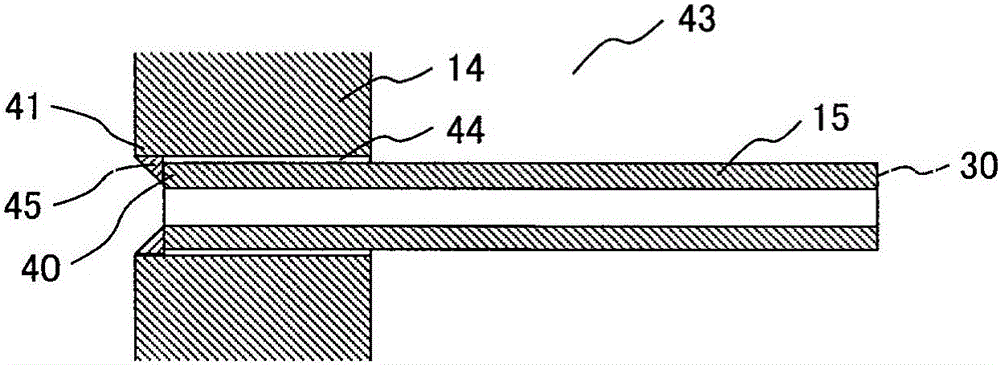

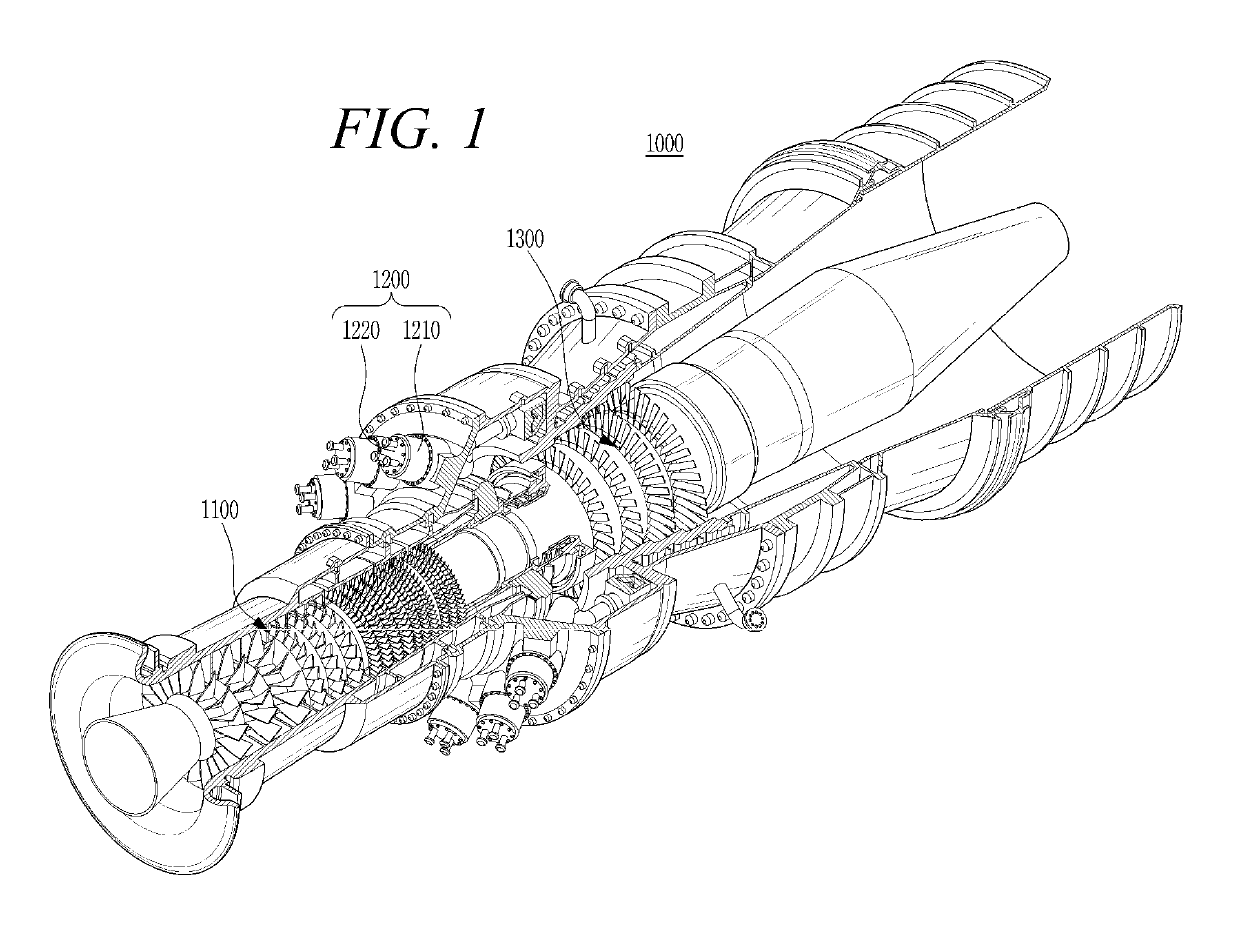

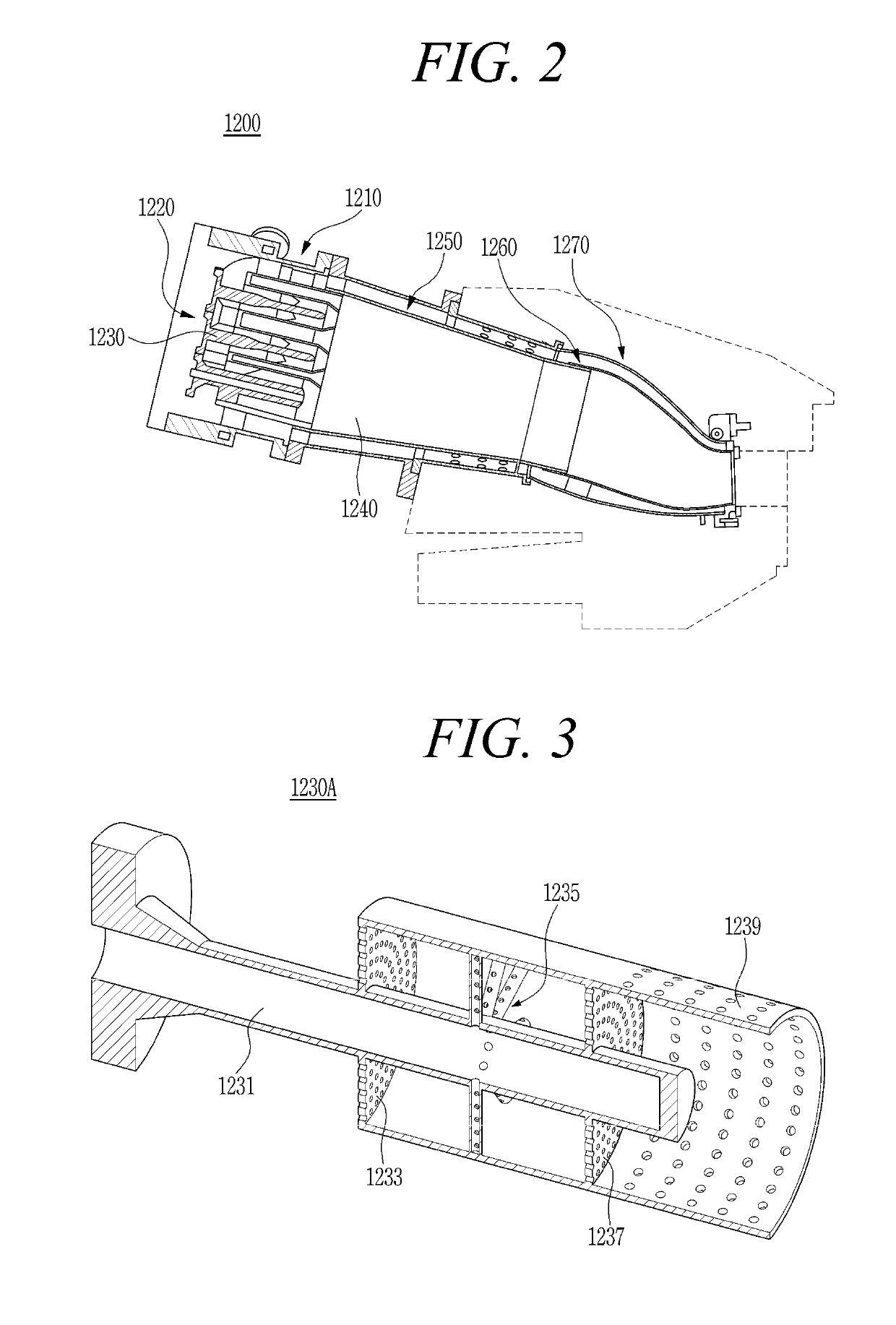

Gas Turbine Combustor

ActiveUS20150135717A1Simple processAvoid differencesContinuous combustion chamberGas turbine plantsCombustion chamberCombustor

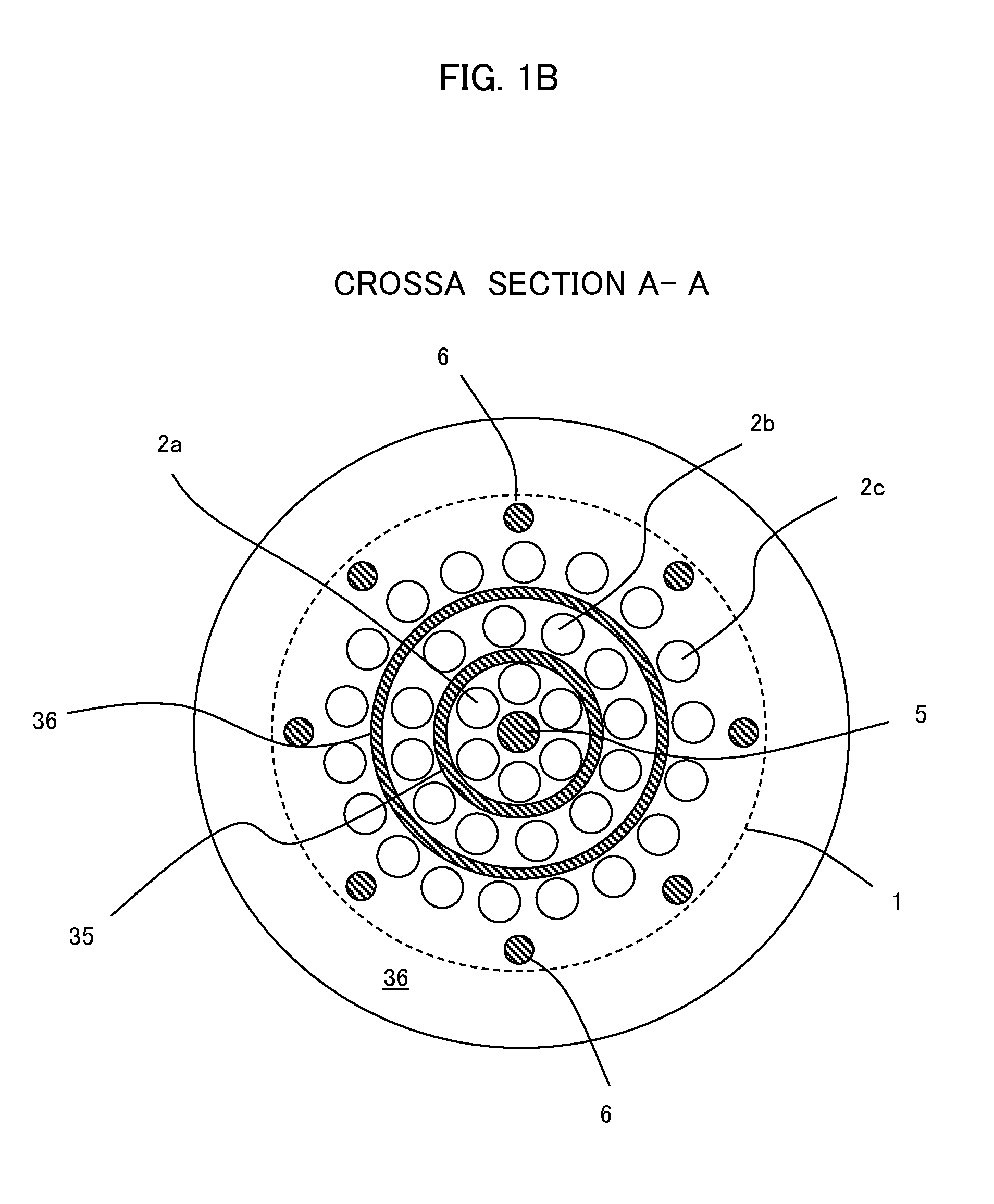

A gas turbine combustor including a cluster-type burner is adapted to stabilize a combustion state by supplying a desired flow rate of combustion air to inner circumferential and outer circumferential fuel nozzle regions. A burner section of the combustor includes a plurality of fuel nozzles 2 and a premixing plate 4 in which are formed a plurality of premixing passages 3 each positioned at a downstream side of the corresponding one of the fuel nozzles 2, injected fuel from the plurality of fuel nozzles 2 being mixed with air in the premixing passage 3 before being supplied to a combustion chamber and burnt therein. The burner section also includes guide vanes 34, 35, 36 that rectify a flow of air and guide this air flow from an upstream side of the fuel nozzles 2 to fuel injecting ports of the fuel nozzles 2; wherein the guide vanes guide a desired amount of air to the fuel injecting ports of the fuel nozzles and stabilize combustion.

Owner:MITSUBISHI POWER LTD

Gas turbine combustor

ActiveCN105318355AEasy to joinHigh precisionContinuous combustion chamberCombustorStructural stability

The invention provides a gas turbine combustor which can easily perform welding of fuel nozzles and a fuel nozzle plate and realize improvement of precision of welding of the fuel nozzles and the fuel nozzle plate even if the space around the fuel nozzles is narrow, thereby improving structural stability. The gas turbine combustor comprises a burner (18) including: a plurality of fuel nozzles (15) to supply a fuel (5); a fuel nozzle plate (14) to supports end portions of the fuel nozzles structurally and being configured to distribute the fuel flowing from an upstream side to the fuel nozzles; and a swirler (13) including a plurality of air holes (21) to supply combustion air, wherein the fuel nozzle plate is provided with a fuel nozzle receiving hole to receive the fuel nozzle, and the fuel nozzle plate and the fuel nozzle inserted in the fuel nozzle receiving hole are connected to each other from an upstream side of the fuel nozzle plate by welding.

Owner:MITSUBISHI POWER LTD

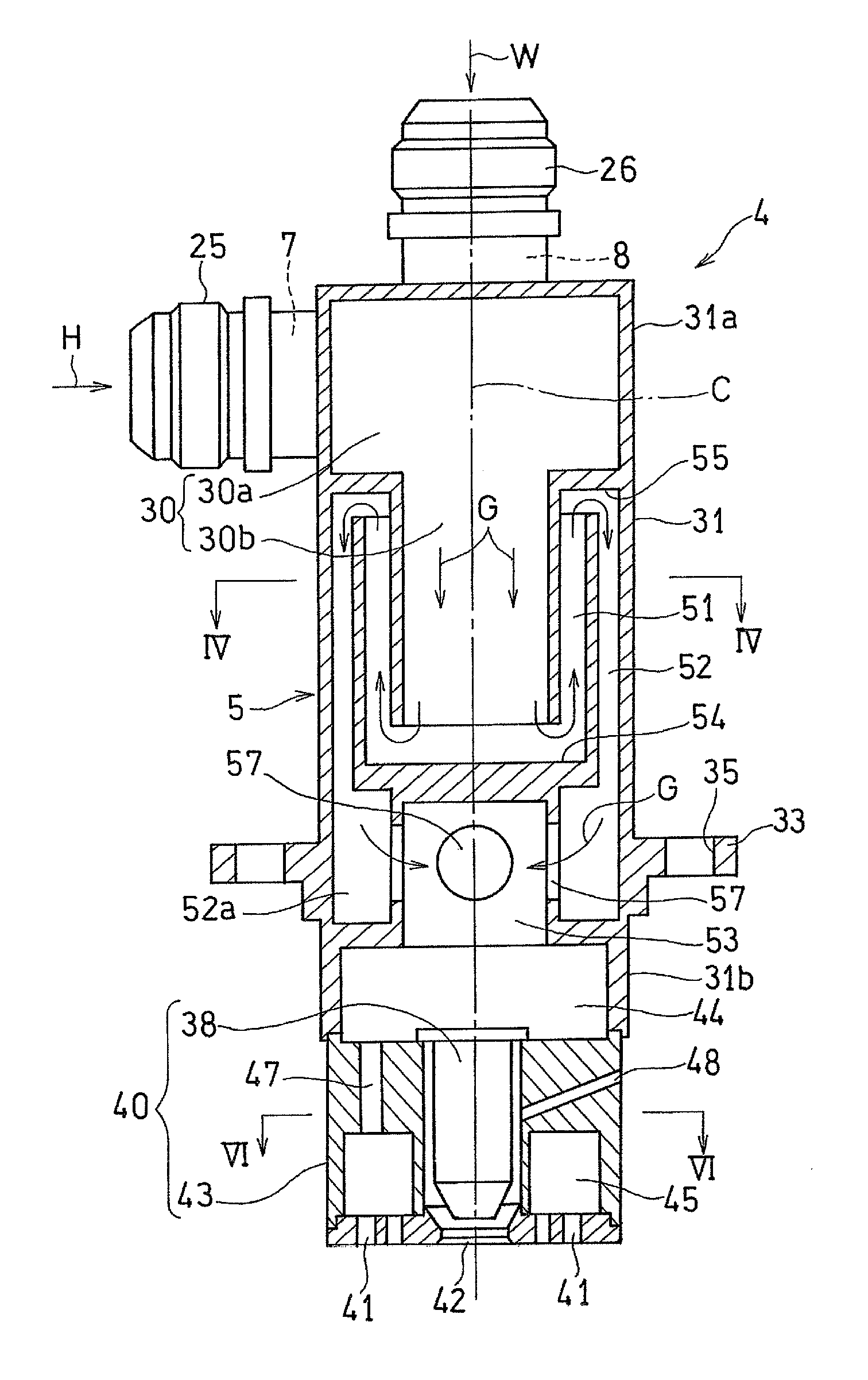

Fuel injection device for gas turbine

ActiveUS20160169160A1Simple structureReduce the production of nitrogen oxidesContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberWater vapor

A fuel injection device, for a gas turbine, which enhances uniform distribution in concentration of fuel gas and water vapor in a combustion chamber with simple structure and at low cost to effectively reduce NOx, is provided. The fuel injection device with a fuel nozzle to mix fuel gas and water vapor and inject the fuel gas and water vapor into a combustion chamber, includes: a nozzle housing having a mixing chamber thereinside; a first introduction passage to introduce the fuel gas into the mixing chamber from outside of the nozzle housing; and a second introduction passage to introduce the water vapor into the mixing chamber from an outside of the nozzle housing; and a plurality of reverse passages communicating with a downstream end of the mixing chamber and configured to allow for a plurality of reverses of flow of mixed gas from the mixing chamber.

Owner:KAWASAKI HEAVY IND LTD

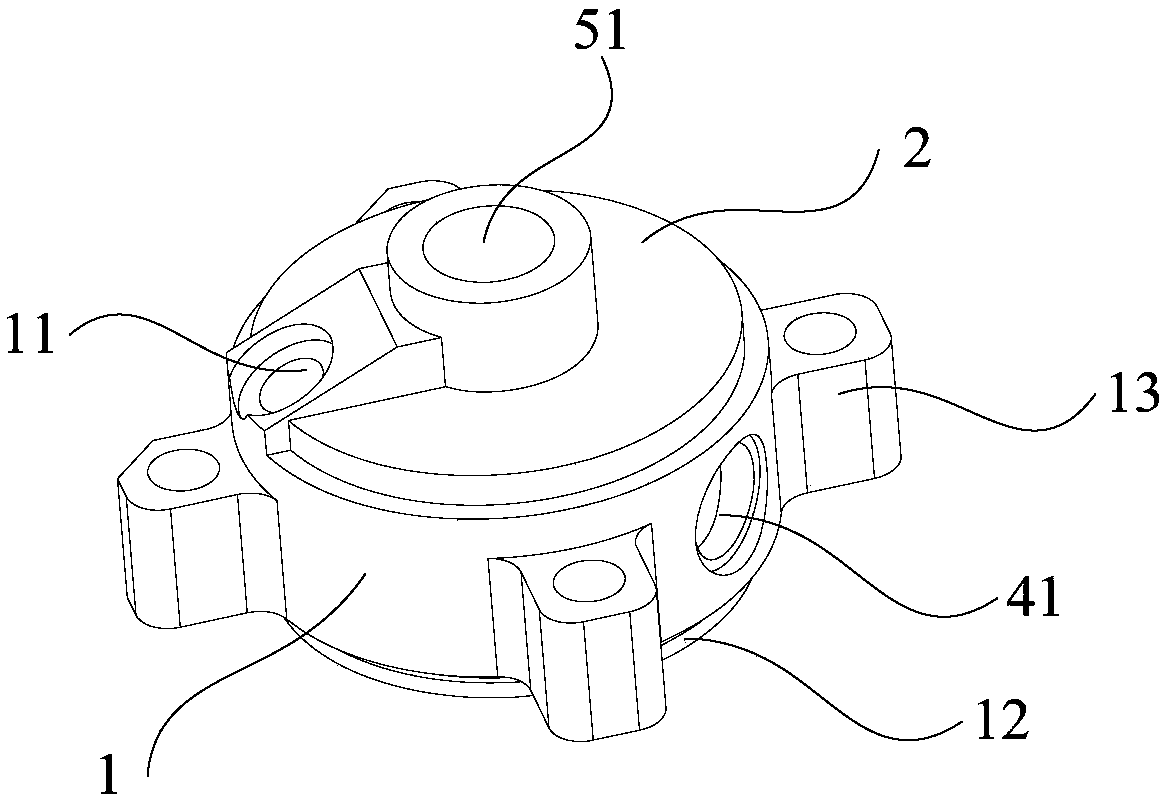

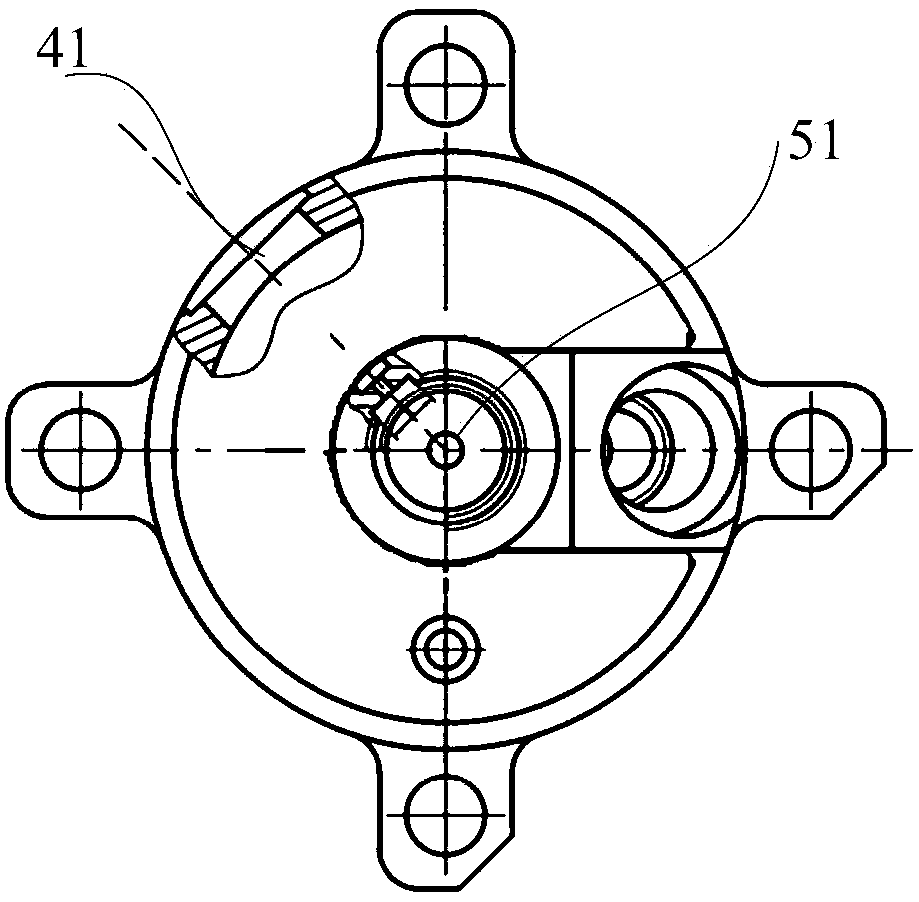

Air inlet structure for fuel nozzle of gas turbine

ActiveCN104456625ARealize stepless speed changeImprove reliabilityContinuous combustion chamberInlet channelCombustion chamber

The invention relates to the technical field of gas turbines, and provides an air inlet structure for a fuel nozzle of a gas turbine. The air inlet structure comprises a center air channel and a fuel cavity which are communicated with each other, and the center air channel is used for connecting the air into the fuel cavity. A nozzle hanging flange is arranged at one end of the center air channel, the nozzle hanging flange is provided with a plurality of air inlet channels used for connecting the air into the center air channel, and the air inlet channels are evenly distributed in the circumferential direction of the nozzle hanging flange. Each air inlet channel is provided with an adjusting mechanism, and each adjusting mechanism is used for limiting the size of the minimum flow area of the corresponding air inlet channel. Each adjusting rod can be adjusted independently, the speed distribution of the air on the head portion of a combustion chamber is effectively improved, the mixing effect of fuel and the air is improved, hence, tempering can be effectively prevented from happening at a nozzle outlet, and the reliability of the nozzle is improved. The air flow can be steplessly adjusted, stepless speed change of the air turbine can also be achieved, and the fuel can be fully burnt ultimately.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

Fuel supply device for gas turbines and fuel nozzle and gas turbine having the same

ActiveUS20190285278A1Stable combustionReduce nitrogen oxidesContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberNitrogen oxide

The present disclosure relates to a fuel supply device for gas turbines, and a fuel nozzle and gas turbine having the same. The fuel supply device of present disclosure is mounted to the fuel nozzle for a uniform flow of air introduced thereinto and for allowing uniform mixing with fuel. The present disclosure allows a uniform fuel-air mixture to be supplied to a combustion chamber. According to the present disclosure, it is possible to uniformly supply a fuel-air mixture to a combustion chamber by arranging a plurality of perforated plates in a fuel supply device for gas turbines, to suppress generation of nitrogen oxides, and to prevent flame from stagnating or flowing backward.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com