Air inlet structure for fuel nozzle of gas turbine

A technology for gas turbines and fuel nozzles, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems that affect the safety and reliability of gas turbines, head burnt, nozzles prone to tempering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

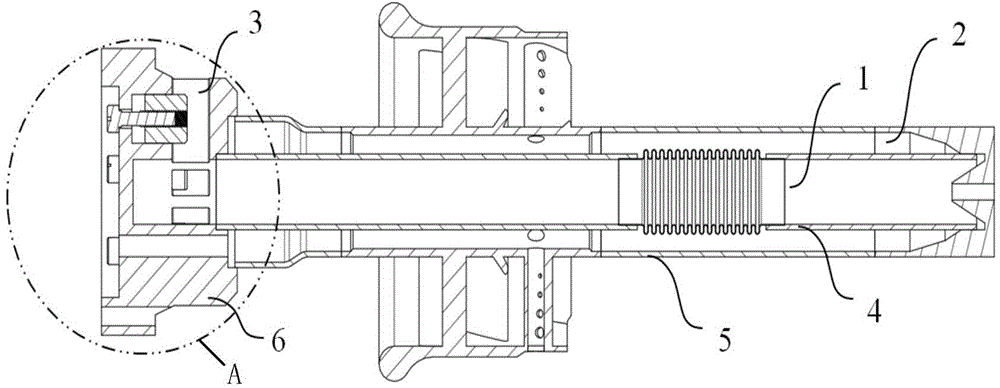

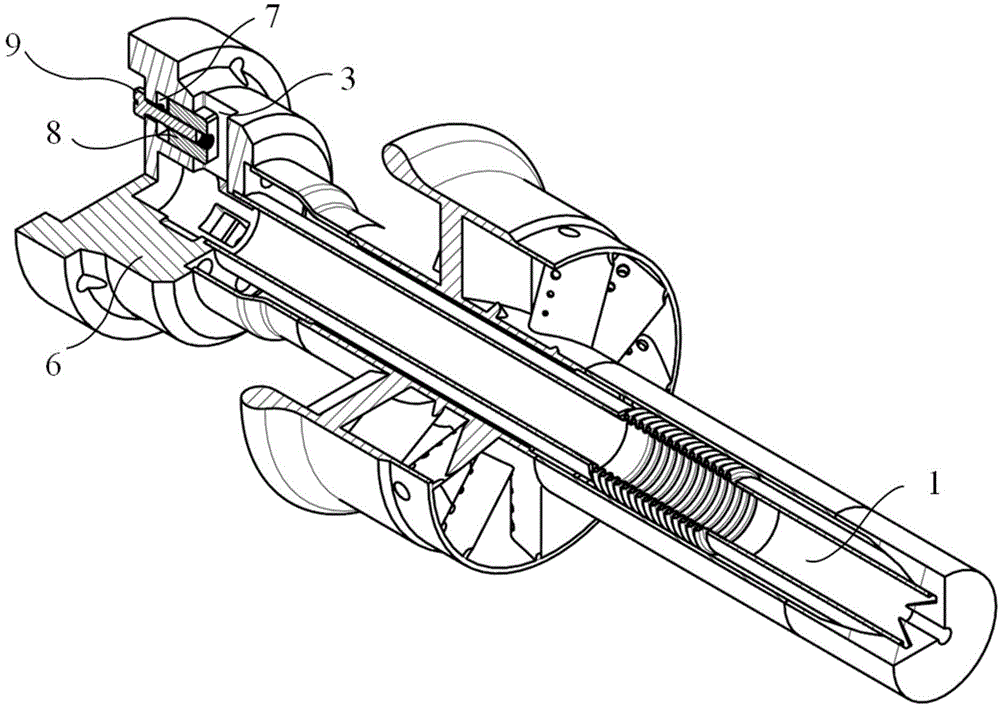

[0029] combine Figure 1 to Figure 3 As shown, the gas turbine fuel nozzle intake structure provided by Embodiment 1 of the present invention includes an inner pipe 4 and an outer pipe 5, the inner pipe 4 is inserted into the outer pipe 5 and relatively fixedly connected, and the inner pipe 4 is defined as a center The air passage 1, the fuel chamber 2 is defined between the inner pipe 4 and the outer pipe 5, and the central air passage 1 and the fuel chamber 2 communicate with each other. The fuel is easier to achieve full combustion, which can effectively prevent backfire at the nozzle outlet and improve the reliability of the nozzle.

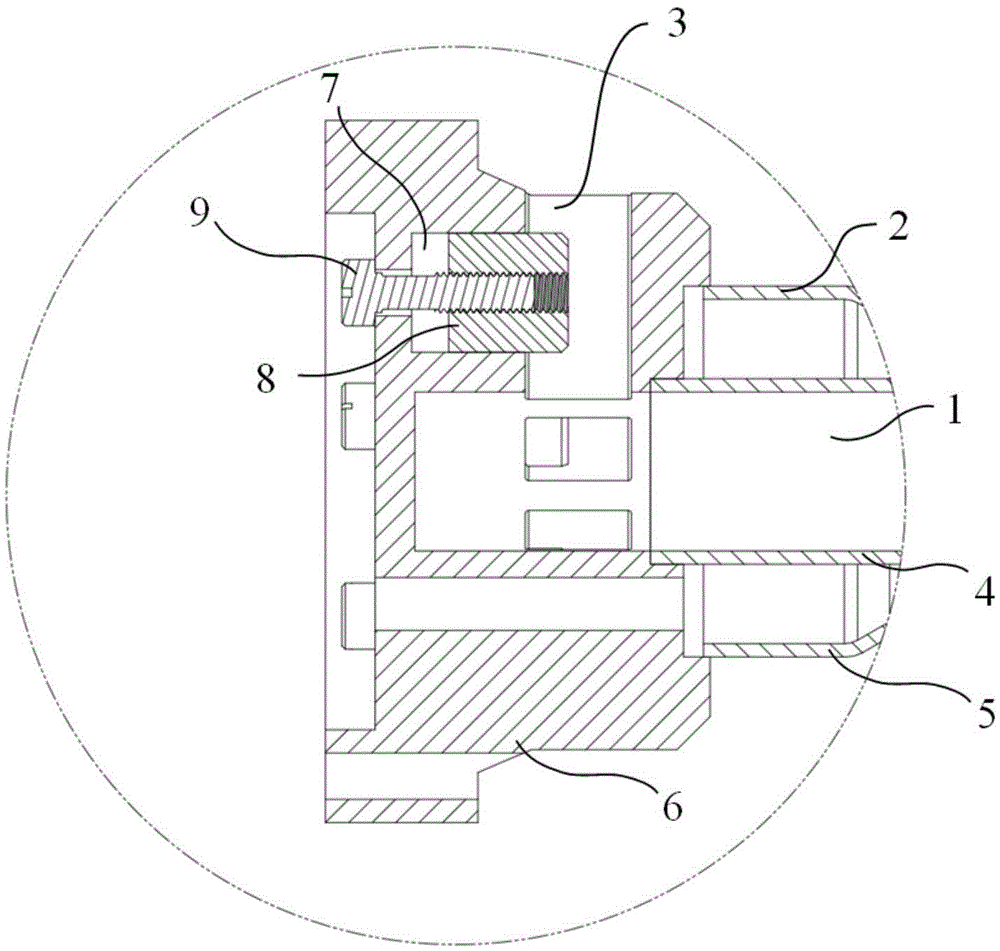

[0030] One end of the central air passage 1 is provided with a nozzle suspension flange 6, which is used to fix the inner pipe 4. The nozzle suspension flange 6 of this embodiment is provided with a The air inlet channel 3 that feeds the air, the air inlet channel 3 is preferably a plurality of evenly distributed in the circumferential direc...

Embodiment 2

[0038] The intake structure of a gas turbine fuel nozzle provided in Embodiment 2 is basically the same as the structure of Embodiment 1, and the similarities will not be described again. The difference lies in:

[0039] combine Figure 4 and Figure 5As shown, one end of the adjustment rod 9 is threadedly connected with the shaft hole, the other end of the adjustment rod 9 is against one side of the flow limiting block 8, and the other side of the flow limiting block 8 and the side wall of the air inlet channel 3 are provided. There is an elastic part, and the elastic part can be a spring. The adjusting rod 9 pushes the current limiting block 8 forward through the cooperation with the shaft hole, and the current limiting block 8 is returned by the elastic force of the elastic part; if other elastic parts are adopted, the elastic part The width should be smaller than the width of the air inlet channel 3, so as not to have an excessive impact on the intake air; compared with E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com