Gas turbine combustor

A technology of gas turbines and burners, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve problems such as shortened distances, narrow space for fuel nozzles, and inability to ensure sufficient space, and achieve the effects of improved accuracy and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

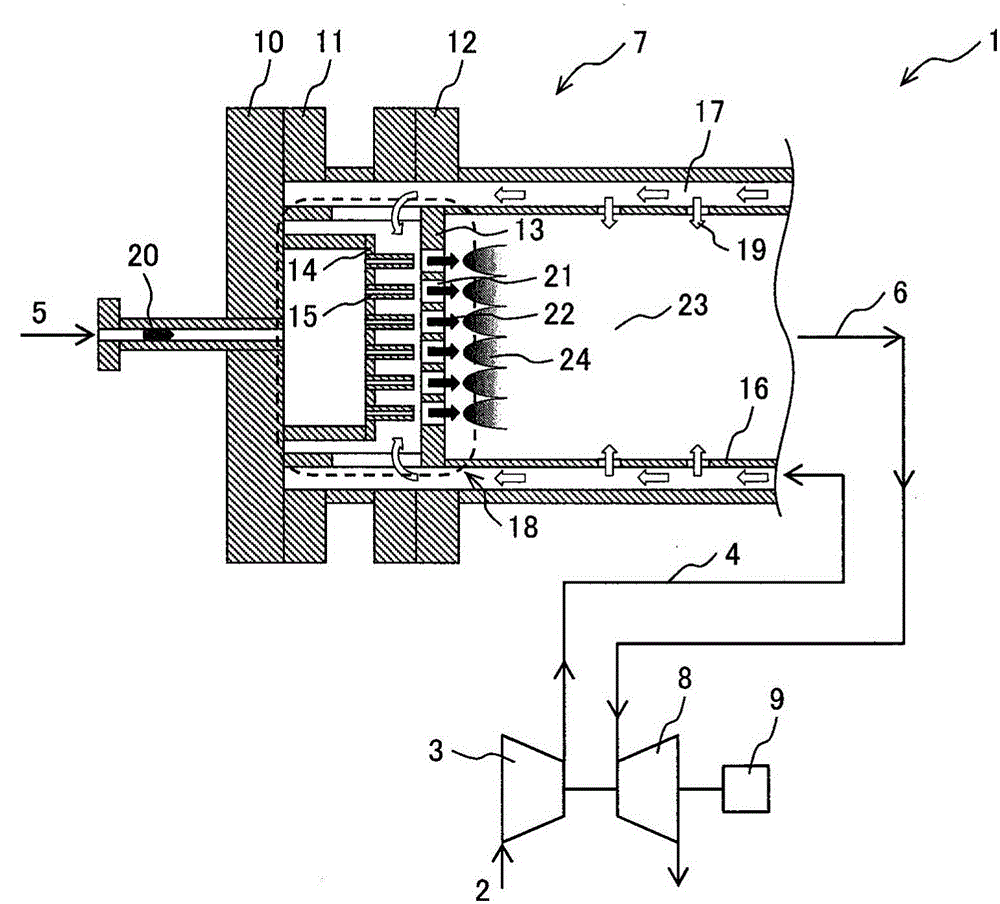

[0032] use figure 1 The structure of a gas turbine facility to which the gas turbine combustor according to Embodiment 1 of the present invention is applied will be described.

[0033] in application figure 1 In the gas turbine equipment 1 of the gas turbine combustor shown in Embodiment 1, the gas turbine equipment 1 includes: a compressor 3 that introduces air 2 from the atmosphere and compresses it; a gas turbine combustor 7 that compresses the air 2 compressed in the compressor 3 The compressed air 4 and the fuel 5 are combusted to generate high-temperature and high-pressure combustion gas 6; the turbine 8, which is driven by the combustion gas 6 generated by the gas turbine combustor 7, obtains the energy of the combustion gas 6 as rotational power; and the generator 9, It uses the rotational power of the turbine 8 to generate electricity.

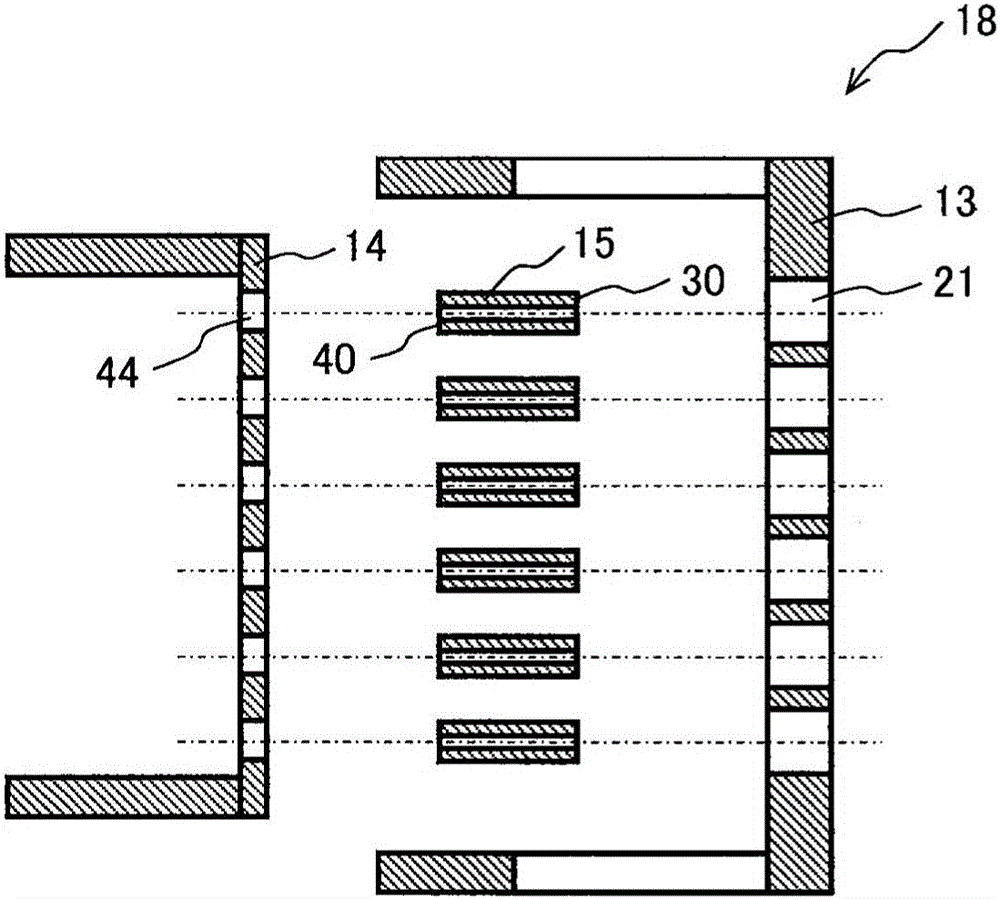

[0034] The gas turbine combustor 7 includes an end cover 10 provided at the end of the gas turbine combustor 7 , a cylindrical fro...

Embodiment 2

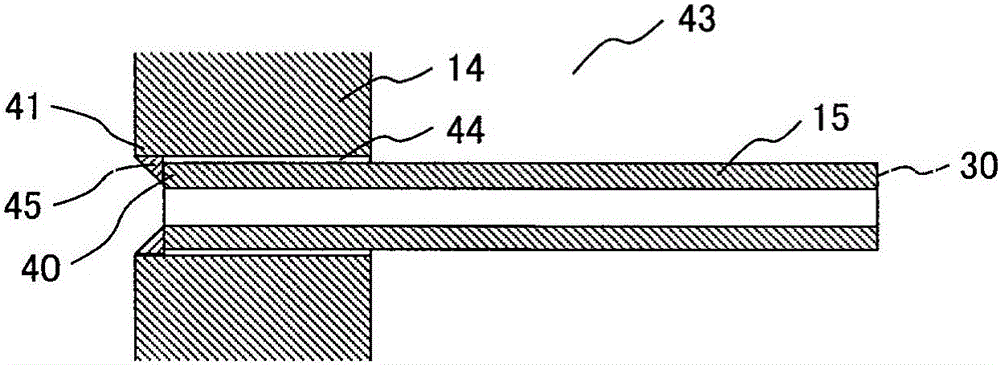

[0060] Next, use Figure 5 The partial enlarged view of the gas turbine combustor 7 according to the second embodiment of the present invention will describe the method of joining the fuel nozzle 15 constituting the burner 18 and the fuel nozzle plate 14 .

[0061] Figure 5 The partial enlarged view of the figure shows the details of the structure of the burner 18 provided on the gas turbine combustor 7 of Embodiment 2, which is different from the composition of the gas turbine combustor 7 of the embodiment 1 of the present invention described above. The basic structure of the joining method of the fuel nozzle 15 and the fuel nozzle plate 14 is similar, so the description of the same structure will be omitted, and the different parts will be described below.

[0062] Figure 5 The partial enlarged view of FIG. 2 shows that in the burner 18 of the gas turbine combustor 7 of the embodiment 2, the fuel nozzle 15 is engaged with the upstream side end 41 of the fuel nozzle plate...

Embodiment 3

[0070] Next, use Figure 6 The partial enlarged view of the gas turbine combustor 7 according to the third embodiment of the present invention will describe the method of joining the fuel nozzle 15 constituting the burner 18 and the fuel nozzle plate 14 .

[0071] Figure 6 The partial enlarged view of the figure shows the details of the structure of the burner 18 in the gas turbine combustor of Embodiment 3, which is different from the fuel that constitutes the burner 18 of the gas turbine combustor 7 of the embodiment 1 of the present invention shown earlier. The basic structure of the joining method of the upstream end 40 of the nozzle 15 and the upstream end 41 of the fuel nozzle plate 14 is similar, so the description of the same structure will be omitted, and the different parts will be described below.

[0072] Figure 6 Details of the structure of the burner 18 in the gas turbine combustor 7 of the third embodiment are shown.

[0073] exist Figure 6 In the burner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com