Rocket nozzle and control method for combustion of the exhaust gas flow in rocket engine

A rocket engine, combustion gas technology, applied in rocket engine installation, engine manufacturing, engine components and other directions, can solve problems such as strong vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0032] Figure 7 A rocket motor 1 according to a first embodiment of the invention is shown. The rocket engine 1 includes a fuel cabin 2 , an oxidizer cabin 3 , a fuel turbo pump 4 , an oxidant turbo pump 5 and a rocket nozzle 8 . The fuel turbine pump 4 includes a pump 4a and a turbine 4b that rotates together with the pump 4a. The oxidizer turbo pump 5 includes a pump 5a and a turbine 5b rotating together with the pump 5a.

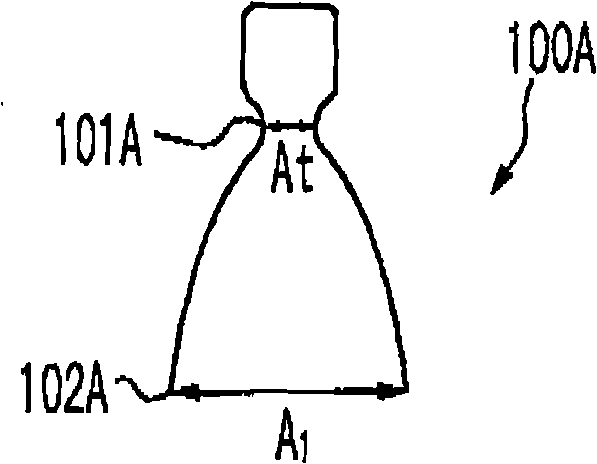

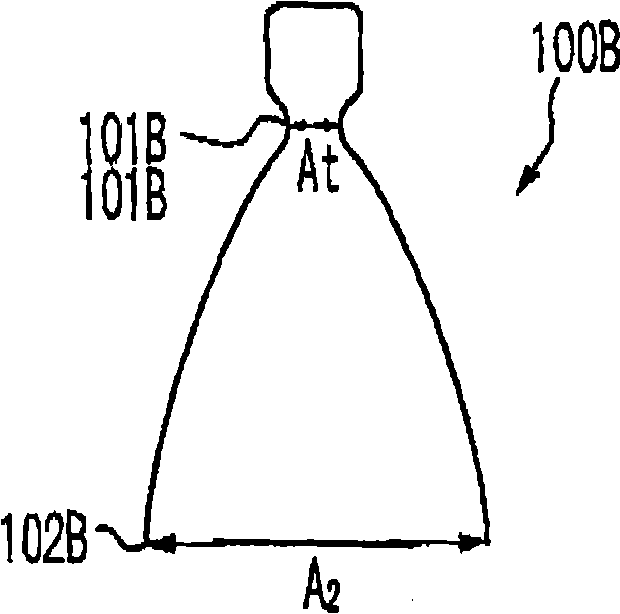

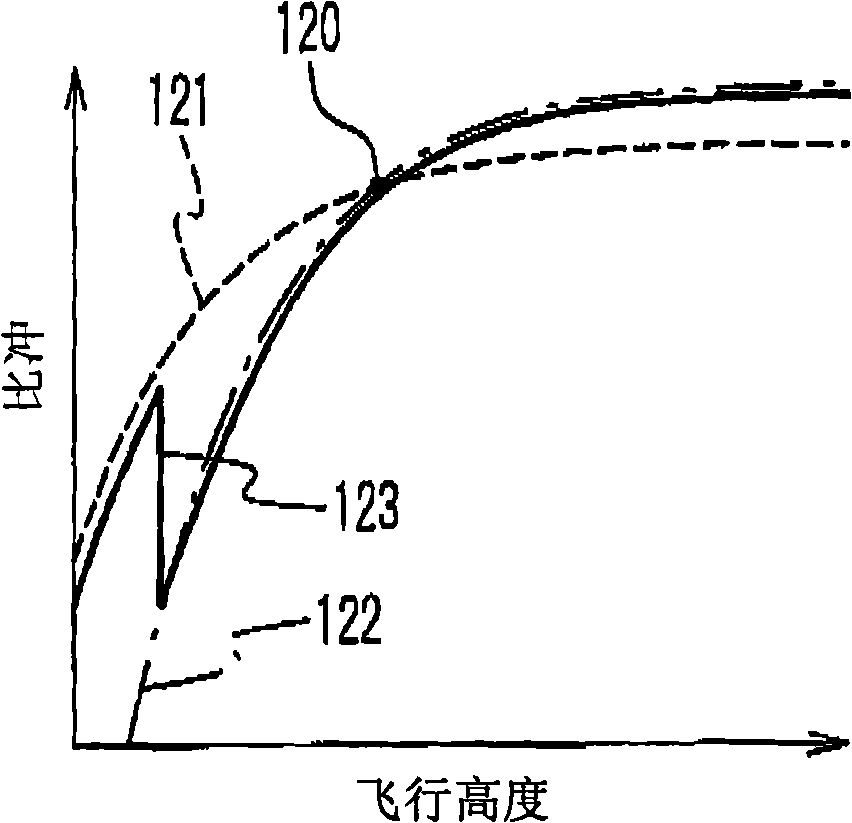

[0033] The rocket nozzle 8 includes an injector 6, a combustion chamber 7, a double bell nozzle 10, and a gas introduction portion 40A. The combustion chamber 7 is provided with a cooling path 7 a for cooling the wall surface of the combustion chamber 7 . The double bell nozzle 10 includes a first stage nozzle 20 as a portion from the throat 11 to an inflection point 12 and a second stage nozzle 30 as a portion from the inflection point 12 to a nozzle outlet 13 . The inflection point 12 is disposed between the first stage nozzle 20 and the second stag...

no. 2 example

[0044] The rocket engine 1 according to the second embodiment of the present invention is configured the same as the rocket engine 1 according to the first embodiment of the present invention except that the gas introduction portion 40A is replaced with the gas introduction portion 40B. refer to Figure 10 , in addition to the duct 41 , manifold 42 , introduction path 43 and inlet 45 described above, the gas introduction portion 40B includes an exhaust pipe 46 branched from the duct 41 and a valve 47 provided to the exhaust pipe 46 . The valve 47 is opened and closed according to the control signal 71 . When valve 47 is open, part of the turbine exhaust gas from oxidizer turbo pump 5 is introduced from inlet 45 into space 80 and the remaining part is expelled to atmosphere through exhaust pipe 46 . When valve 47 is closed, the entire turbine exhaust from oxidant turbopump 5 is directed from inlet 45 into space 80 .

[0045] The height H of the rocket containing the rocket mo...

no. 3 example

[0050] The rocket engine 1 according to the third embodiment of the present invention is configured the same as the rocket engine 1 according to the first embodiment of the present invention except that the gas introduction portion 40A is replaced with the gas introduction portion 40C. refer to Figure 11 , in addition to the pipe 41, manifold 42, introduction path 43, and inlet 45 described above, the gas introduction part 40C also includes a three-way valve 51 provided on the pipe 41 and a three-way valve provided at the side of the inflection point 12 of the manifold 42. Manifold 52 , whereby manifold 52 is adjacent to manifold 42 . The three-way valve 51 connects one of them to the oxidant turbopump 5 by switching between the manifold 42 and the manifold 52 according to the control signal 72 . The turbine exhaust gas from the oxidizer turbo pump 5 flows into the manifold 42 or the manifold 52 according to the switching state of the three-way valve 51 .

[0051] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com