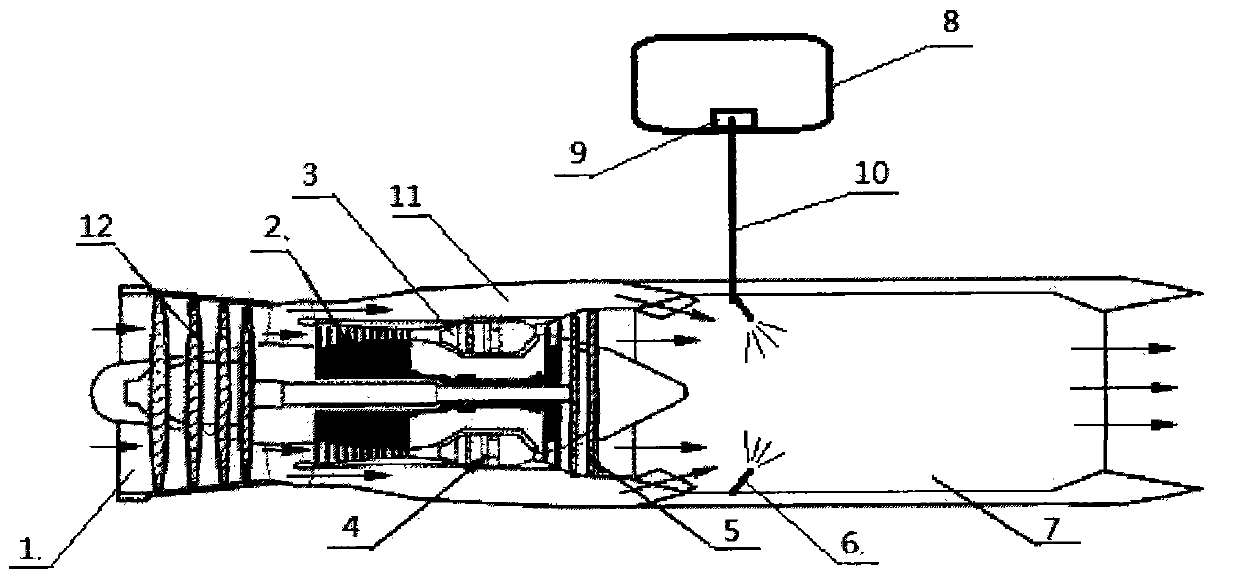

Liquid gas afterburner jet engine and method for realizing afterburning flying of jet plane

A technology of jet engine and liquid gas, applied in machines/engines, jet propulsion devices, etc., can solve the problems of less vaporized gas, waste of fuel, low temperature rise, etc., to reduce heat emissions, reduce costs, and reduce infrared characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 1

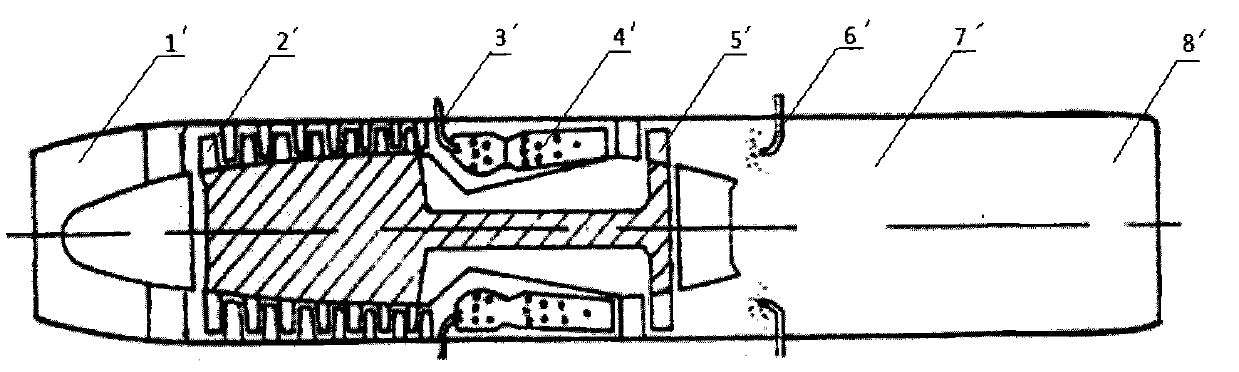

[0021] It goes without saying that although in figure 2 Not shown in , but, like the first embodiment of the present invention, the turbojet engine 100' of the second embodiment of the present invention can also be provided with a liquid gas storage tank, a liquid gas pump and a liquid gas pipeline, and with the same structure The connection between the liquid gas storage tank, the liquid gas pump and the liquid gas pipeline and its liquid gas nozzle is realized.

[0022] The liquid gas in the present invention can be liquid air, liquid nitrogen, liquid mixed gas or other liquid gases with lower boiling point, lower heat of vaporization, and lower critical temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com