Fuel nozzle with central body cooling system

A technology for fuel nozzles and cooling holes, which is applied in the direction of burner cooling, burner, combustion chamber, etc., and can solve the problem of damaging fuel nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

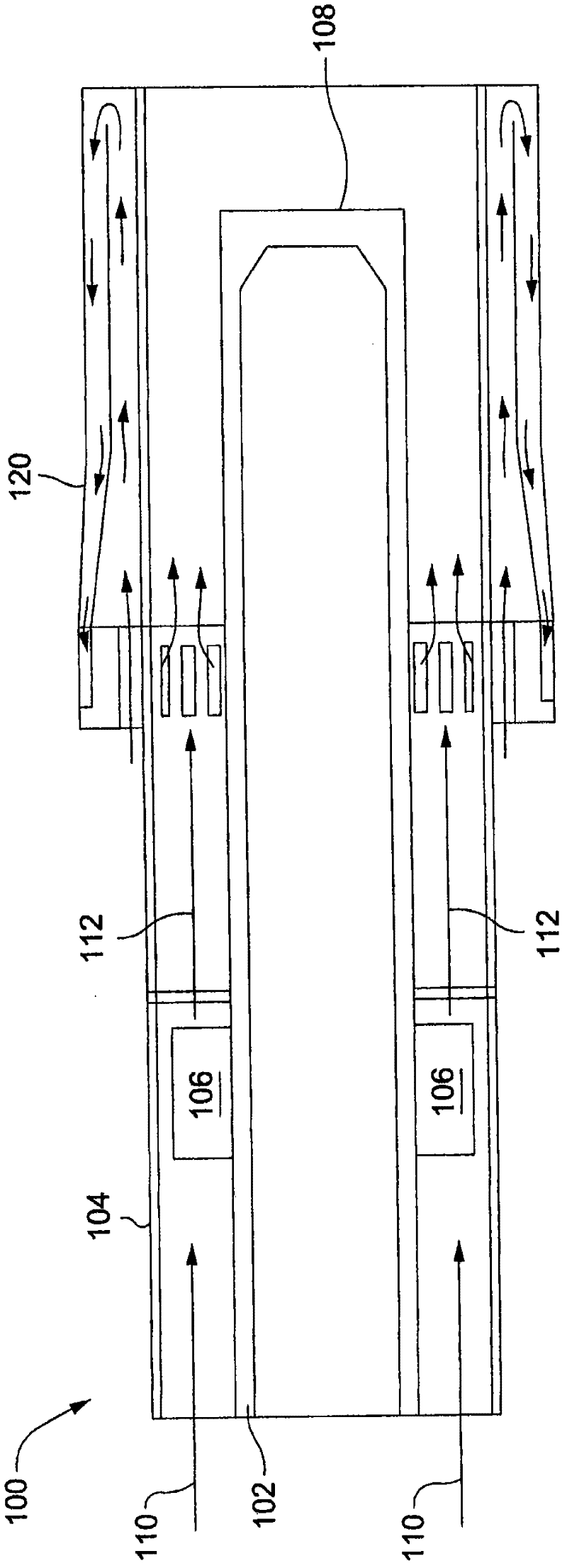

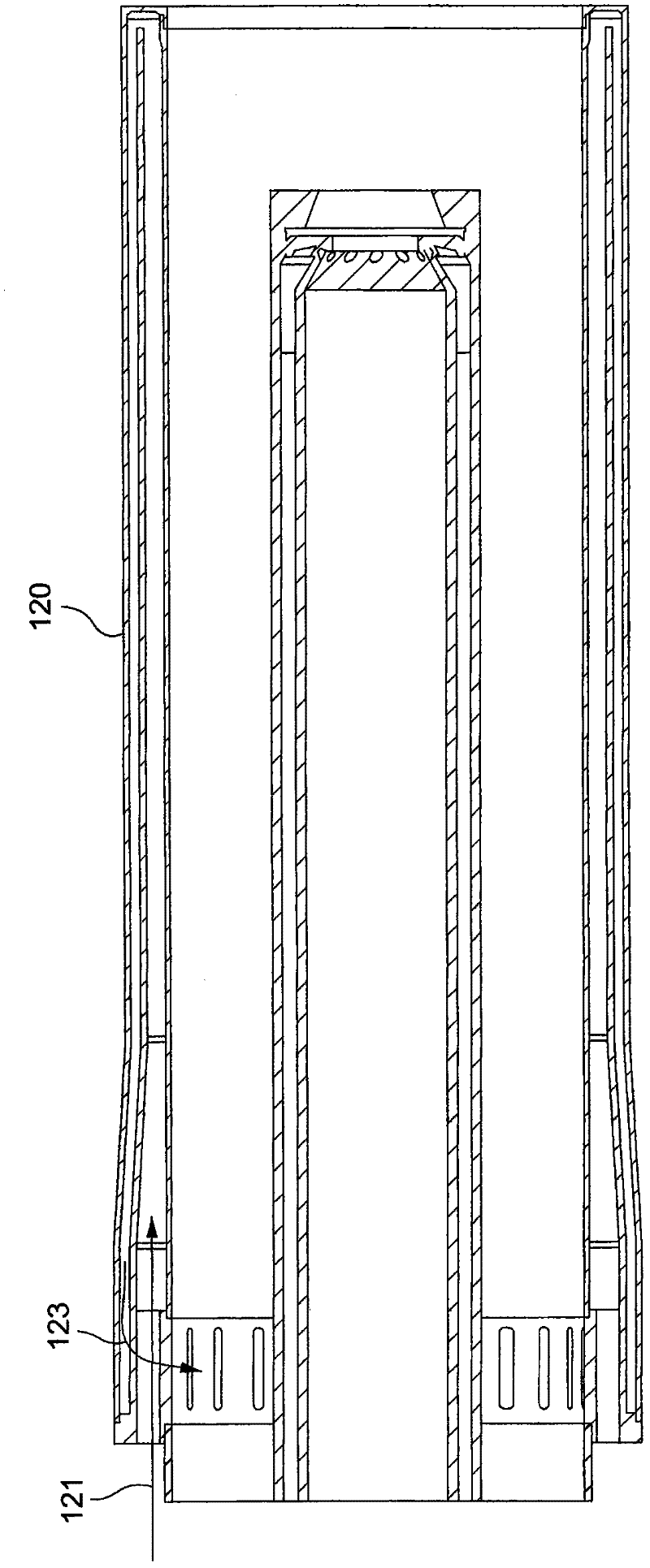

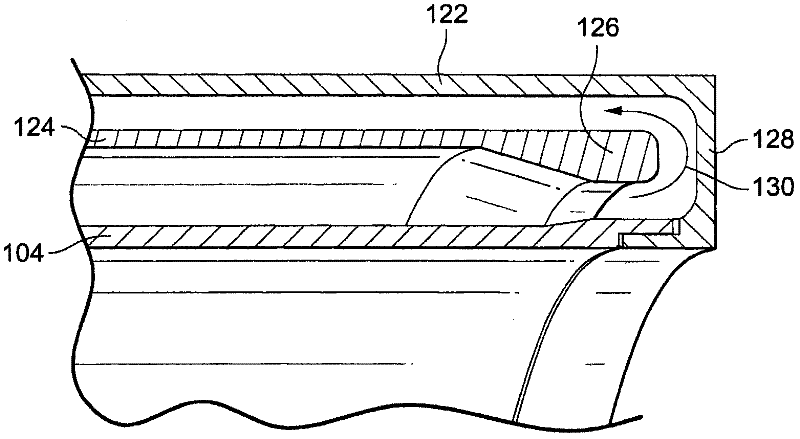

[0033] figure 1 A fuel nozzle for a turbine engine including a cooling shroud is shown. As shown, the fuel nozzle includes a generally cylindrical central nozzle area 102 located within the housing 104. The air flow indicated by arrow 110 enters the upstream end of the fuel nozzle. The air entering the fuel nozzle passes through the annular space between the outer wall of the central nozzle area 102 and the inner wall of the housing 104. The air flow passes through fuel guide vanes 106 that deliver fuel into the air flow. The fuel guide vane 106 may also be angled with respect to the longitudinal axis of the nozzle, which causes the air and fuel mixture to swirl within the fuel nozzle, and the swirl can help to mix the fuel and air.

[0034] Once the fuel is delivered to the air, the fuel-air mixture indicated by arrow 112 continues to flow in the downstream direction through the annular space between the outer side of the central nozzle area 102 and the inner wall of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com