Gas turbine combustor and operating method thereof

A gas turbine and burner technology, which is applied in combustion methods, gas turbine devices, burners, etc., can solve problems such as reducing the discharge of unburned parts, and achieve the effect of ensuring combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

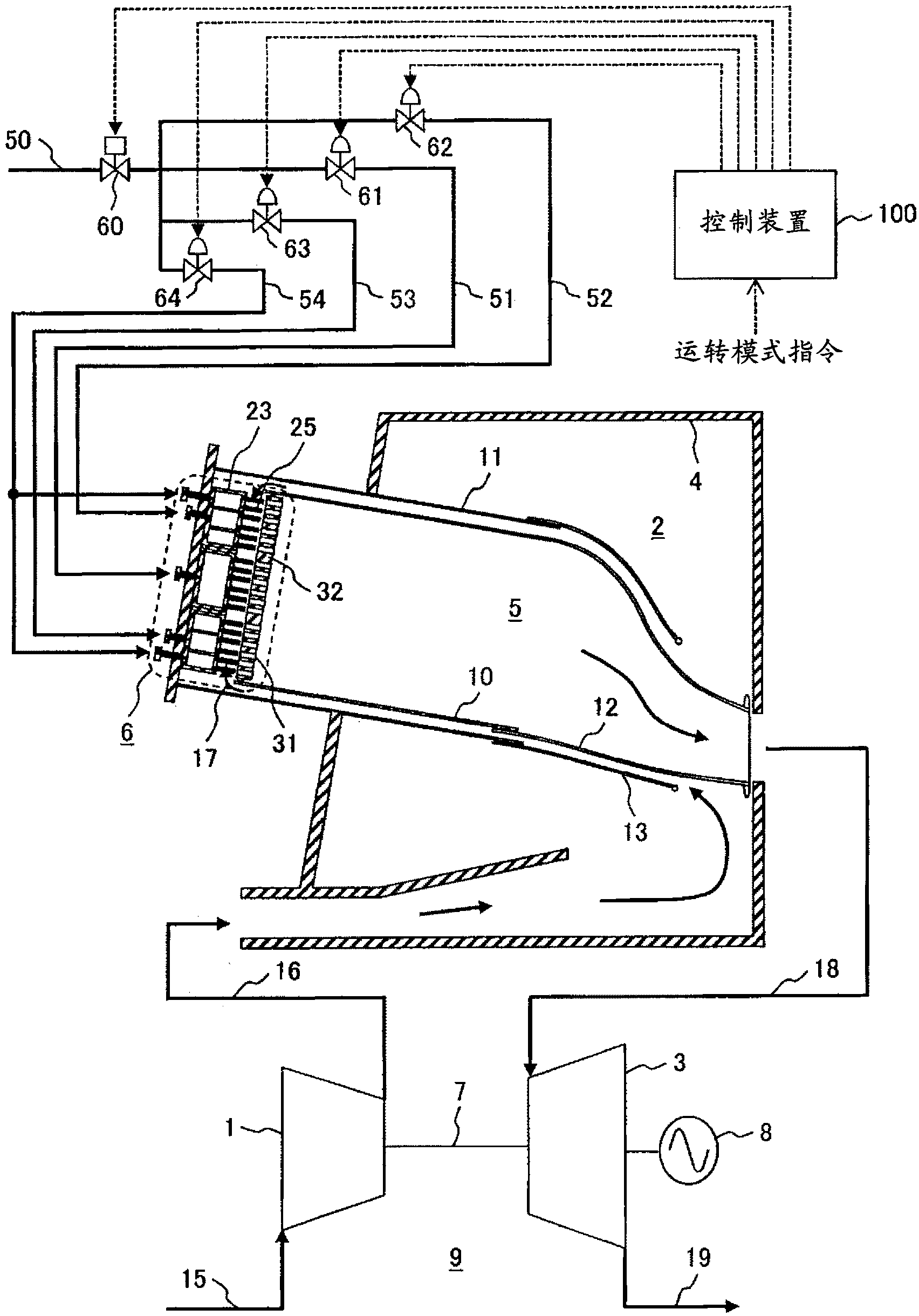

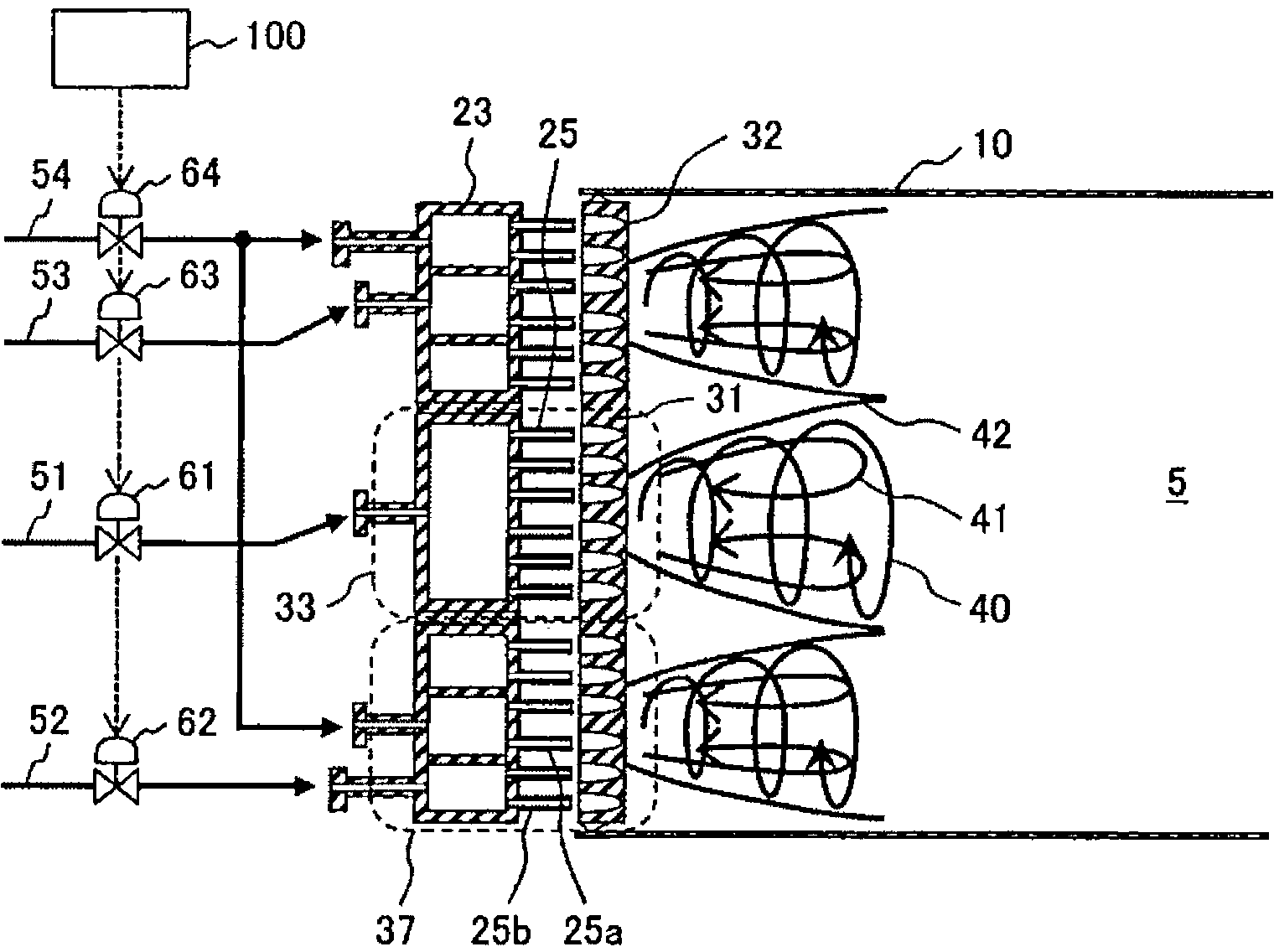

[0031] use Figure 1 to Figure 3 A gas turbine combustor and a gas turbine combustor operating method according to a first embodiment of the present invention will be described.

[0032] figure 1 It is a systematic diagram showing the overall configuration of a gas turbine facility for power generation.

[0033] exist figure 1 In the gas turbine facility 9 shown, the gas turbine for power generation is composed of: a compressor 1 that pressurizes intake air 15 to generate high-pressure air 16; A gas turbine combustor 2 generating high-temperature combustion gas 18; a steam turbine 3 driven by the high-temperature combustion gas 18 generated by the gas turbine combustor 2; a generator 8 driven to rotate by the steam turbine 3 to generate electric power; the compressor 1, steam turbine 3 And the shaft 7 to which the generator 8 is connected as one.

[0034] Furthermore, the gas turbine combustor 2 is accommodated inside the casing 4 . In addition, the gas turbine combustor ...

Embodiment 2)

[0095] use Figure 7 as well as Figure 8 A gas turbine combustor 2 according to a second embodiment of the present invention will be described.

[0096] The gas turbine combustor 2 of the present embodiment and Figure 1 to Figure 5 The gas turbine combustors 2 of the first embodiment shown are the same in basic structure and effect, so the description of the common parts will be omitted, and the different parts will be described below.

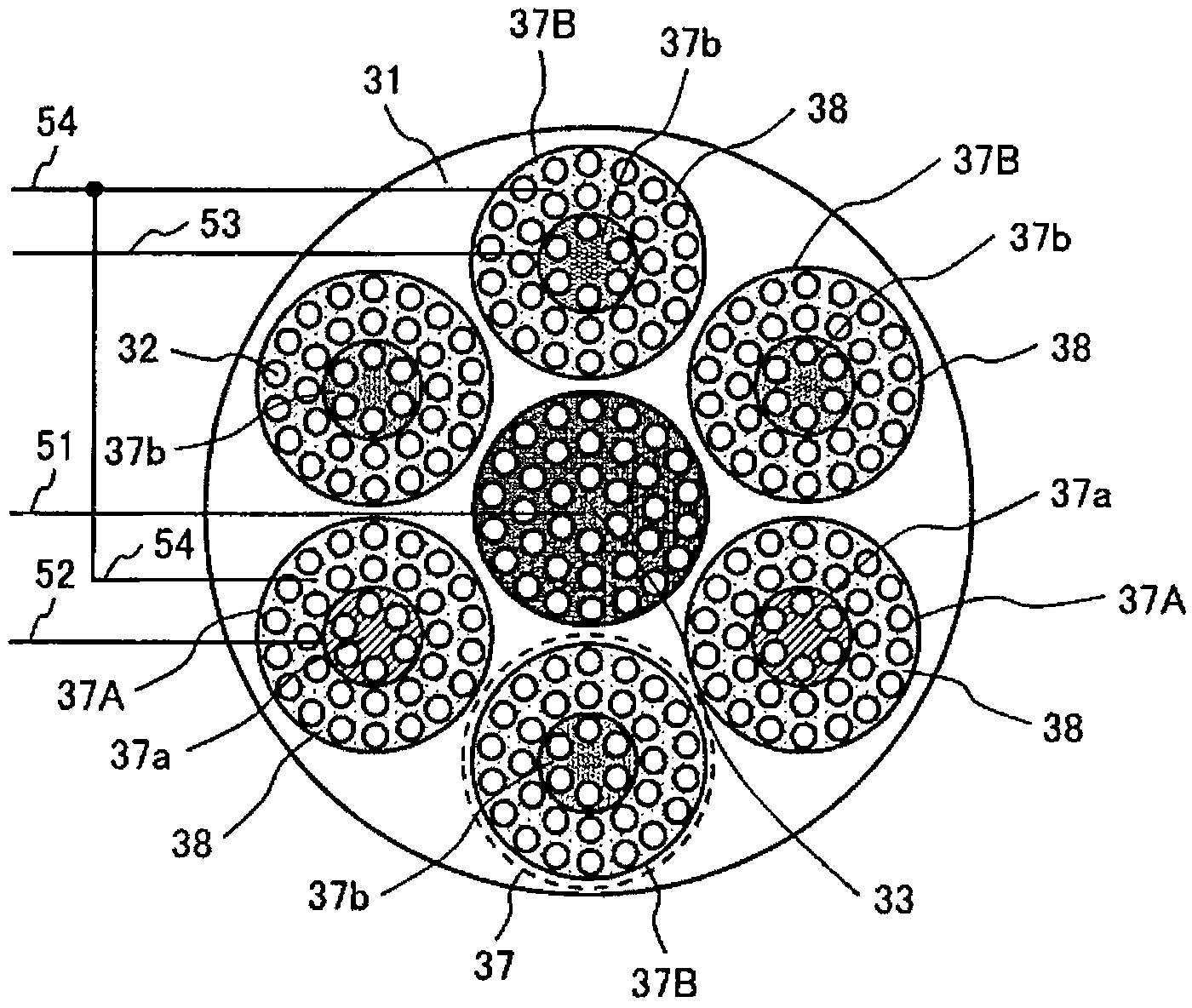

[0097] Figure 7 The gas turbine combustor 2 of the present embodiment shown is a front view of the burner viewed from the combustion chamber, and for each burner, a region supplied with fuel by the same fuel system is shown separately.

[0098] exist Figure 7 In the gas turbine combustor 2 shown in this embodiment, as Figure 7 As shown, six outer burners 37 are provided in the peripheral area of the air orifice plate 31, including: on both sides of the central burner 33 located in the center of the air orifice plate 31, which are o...

Embodiment 3)

[0109] use Figure 9 as well as Figure 10 A gas turbine combustor 2 according to a third embodiment of the present invention will be described.

[0110] The gas turbine combustor 2 of the present embodiment and Figure 1 to Figure 5 The gas turbine combustors 2 of the first embodiment shown are the same in basic structure and effect, so the description of the common parts will be omitted, and the different parts will be described below.

[0111] Figure 9 The gas turbine combustor 2 of the present embodiment shown is a front view of the burner viewed from the combustion chamber, and for each burner, a region supplied with fuel by the same fuel system is shown separately.

[0112] exist Figure 9 In the gas turbine combustor 2 shown in this embodiment, as Figure 9 As shown, six outer burners 37 are arranged in the peripheral area of the air orifice plate 31 and are configured to include: positions on both sides of the obliquely lower side (the side of the cross-fire tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com