Horizontal vortex compressor

A scroll compressor, horizontal technology, applied in the field of compressors, can solve the problems of easy blockage of the throttling structure, insufficient lubrication effect, compressor damage, etc., achieve the effects of small space, enhanced lubrication effect, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0074] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, so as to make the characteristics and advantages of the present invention more obvious.

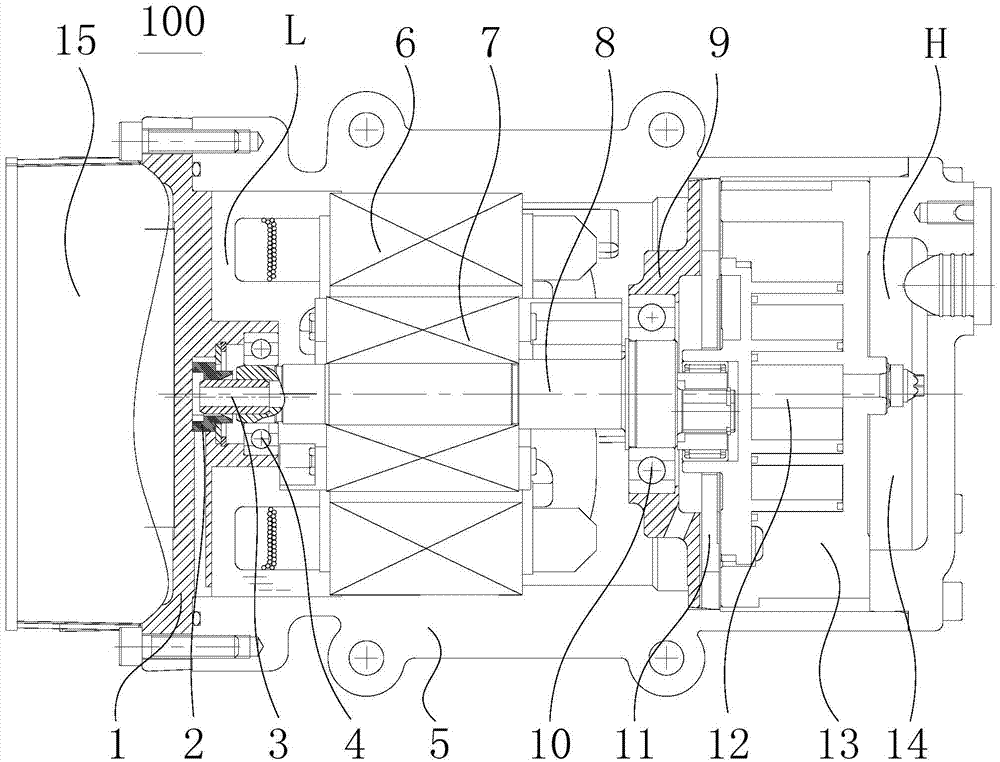

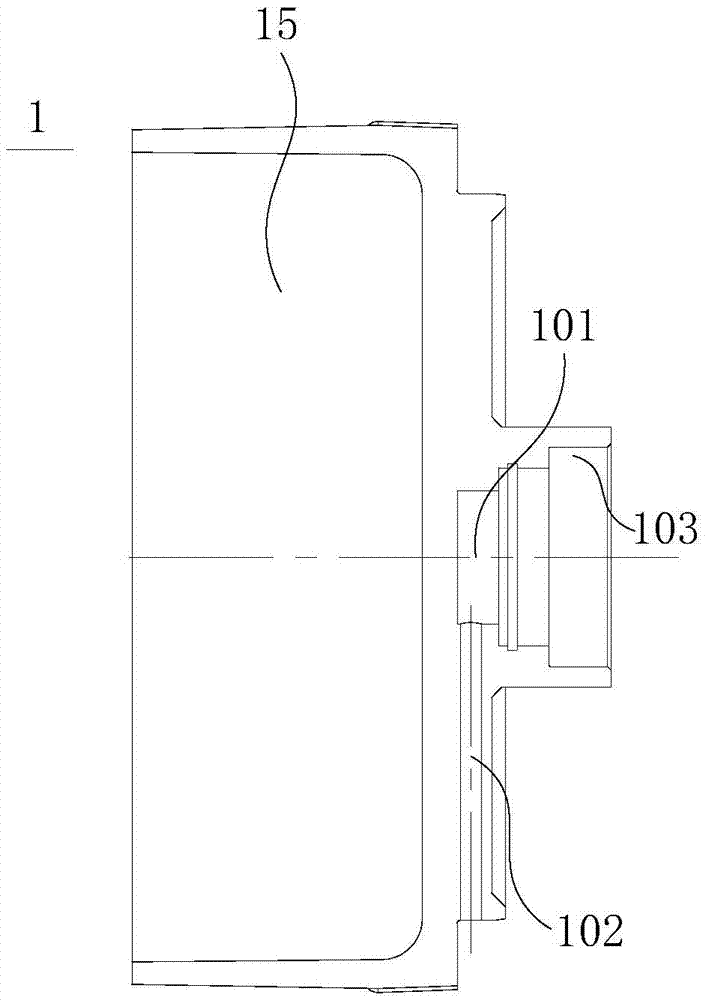

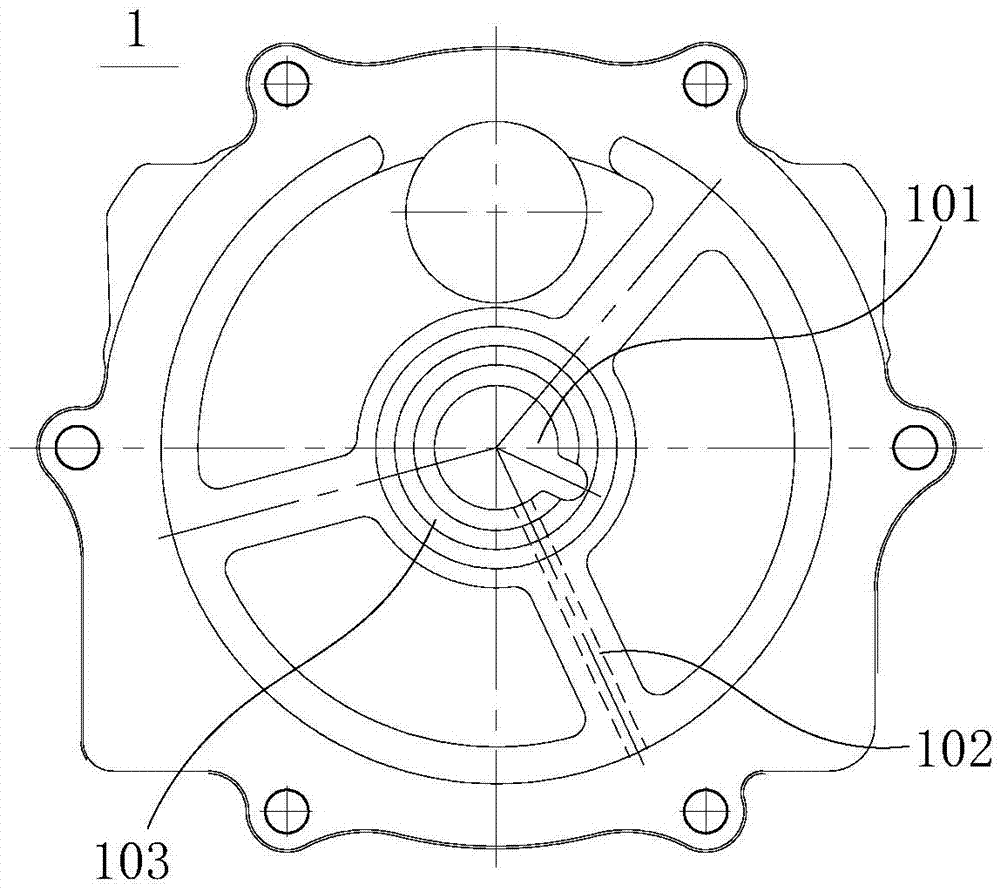

[0075] figure 1 It is a sectional view of the horizontal scroll compressor of the present invention. figure 2 It is a sectional view of the rear case in the present invention. image 3 It is the right side view of the rear shell in the present invention. Figure 4 It is a sectional view of the oil pump shaft in the present invention. Figure 5 for Figure 4 Left view in . Image 6 It is a sectional view of the eccentric crankshaft in the present invention. Such as Figures 1 to 6As shown, a horizontal scroll compressor 100 of the present invention includes: rear shell 1, oil pump rotor 2, oil pump shaft 3, auxiliary bearing 4, housing 5, stator 6, rotor 7 motor, eccentric crankshaft 8, main Bracket 9, main bearing 10, Oldh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com