Self-lubricating sliding bearing for high-speed large-power motor

A sliding bearing, high-power technology, applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve problems such as unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

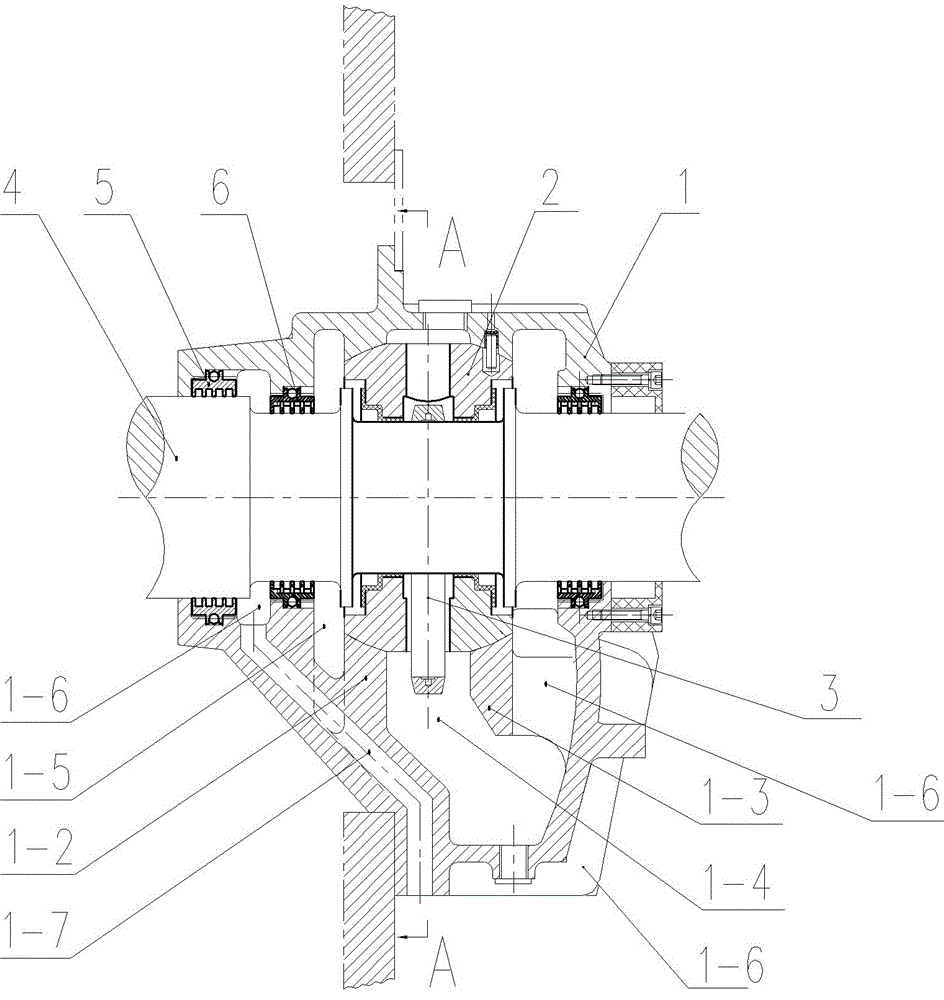

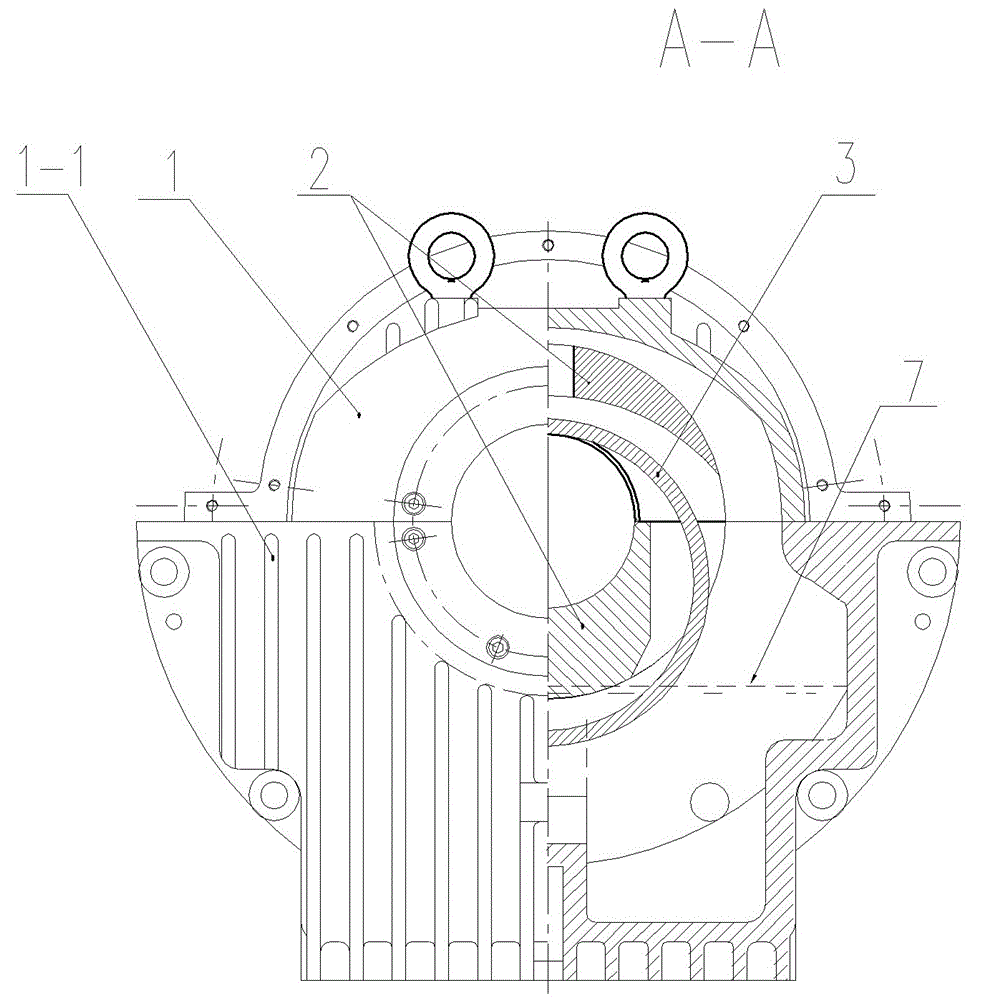

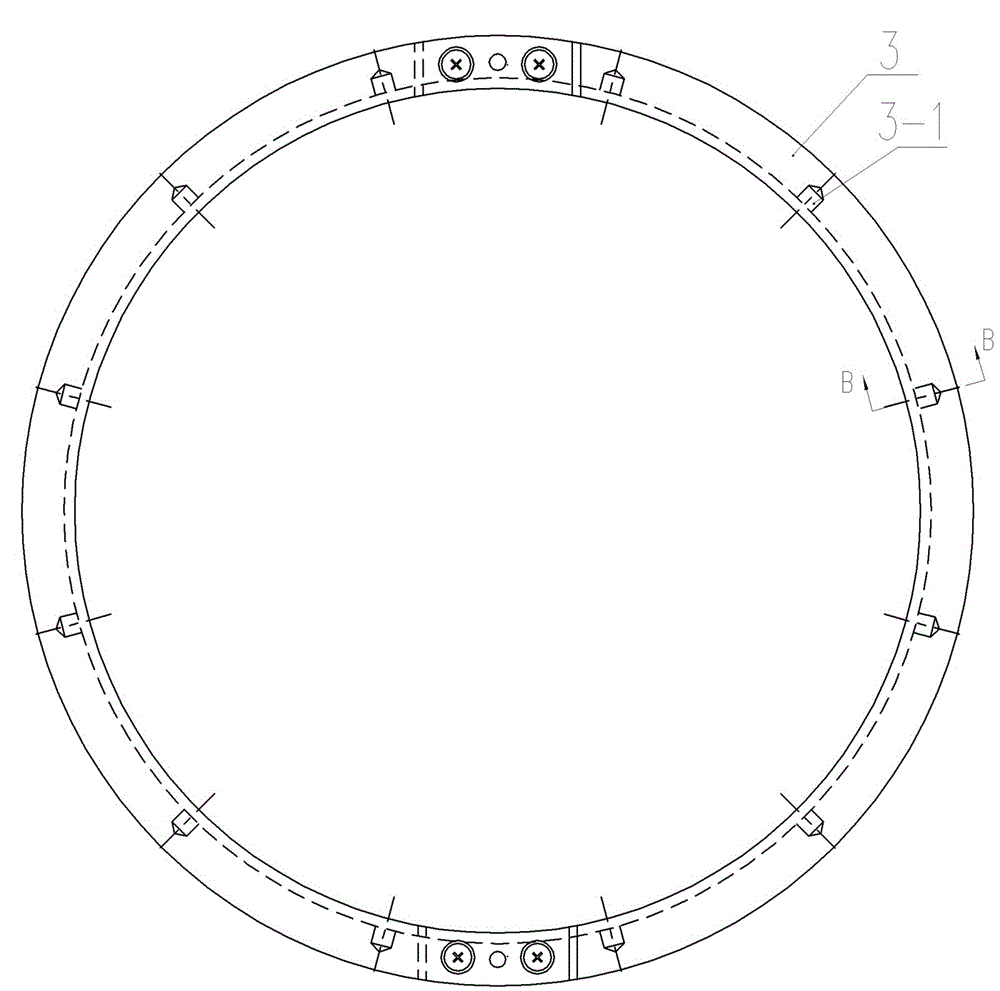

[0014] see figure 1 with figure 2 , The structure of the sliding bearing of the present invention includes a bearing housing 1, a bearing bush 2, an oil ring 3, a motor shaft 4, and floating sealing rings 5 and 6. Among them, the bearing housing 1 is the upper and lower parts of the shell, and the lower part of the shell adopts a high-strength aviation aluminum alloy to integrally cast a D-shaped large oil chamber structure, and the outer side is vertically cast with cooling fins 1-1. The D-shaped structure increases the heat dissipation area on the outside of the bearing box 1, and at the same time, the cooling fins 1-1 can enhance the heat dissipation capacity on the outside of the bearing box. The D-shaped structure bearing box 1 can enhance the convection and radiation heat dissipation capabilities of the bearing box, and reduce the temperature of the lubricating oil in the bearing box. The inside of the bearing housing 1 is cast with an inner support 1-2 for supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com