Fuel injection pump driving device of diesel engine

A driving device and fuel injection pump technology, which is applied to fuel injection devices, fuel injection pumps, components of pumping devices for elastic fluids, etc., and can solve the problem of constant overall structure of the fuel drive mechanism, uneven fuel supply, and abnormal wear To achieve the effect of increasing the effective oil distribution area, increasing the oil storage capacity and increasing the oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0025] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

[0026] In the description of the embodiments of the present invention, unless otherwise specified, "plurality" means two or more.

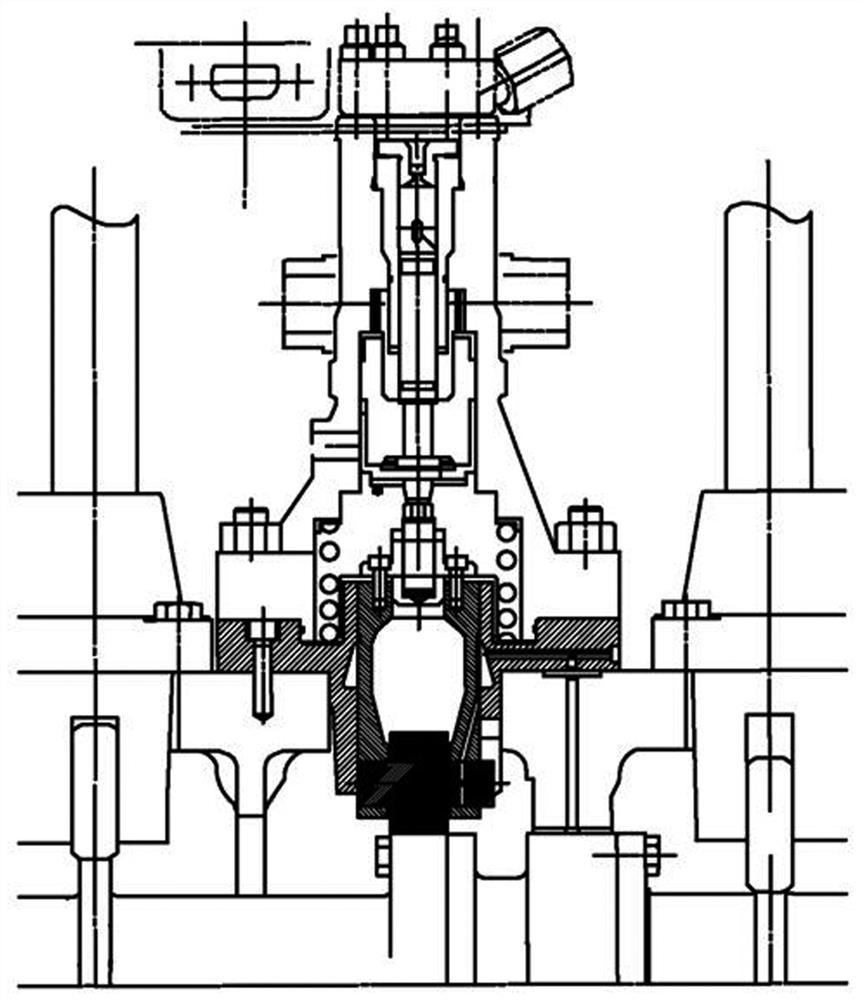

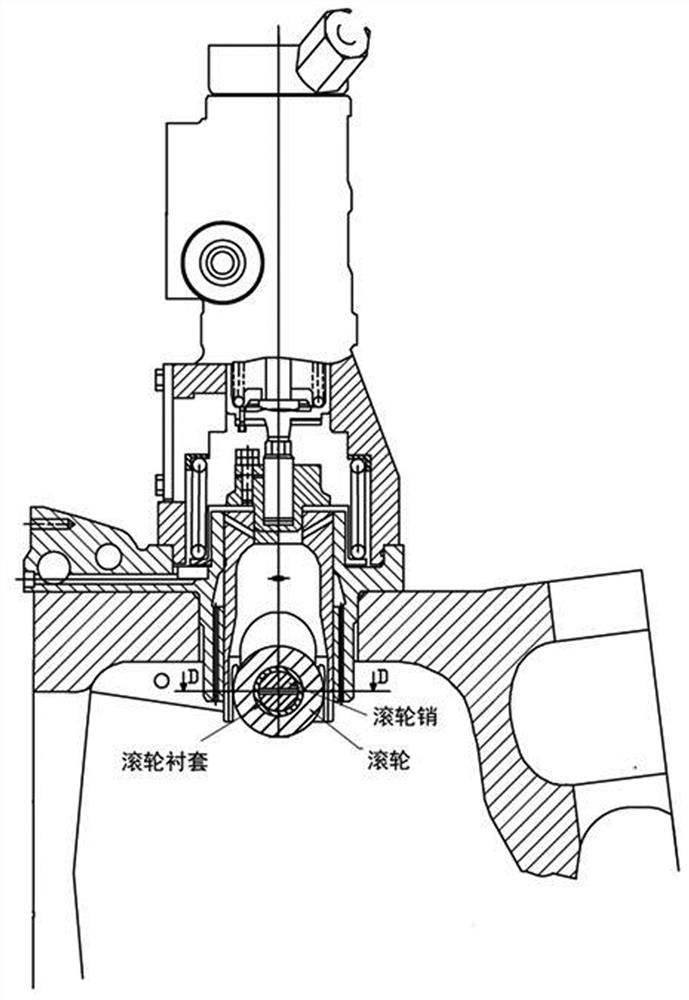

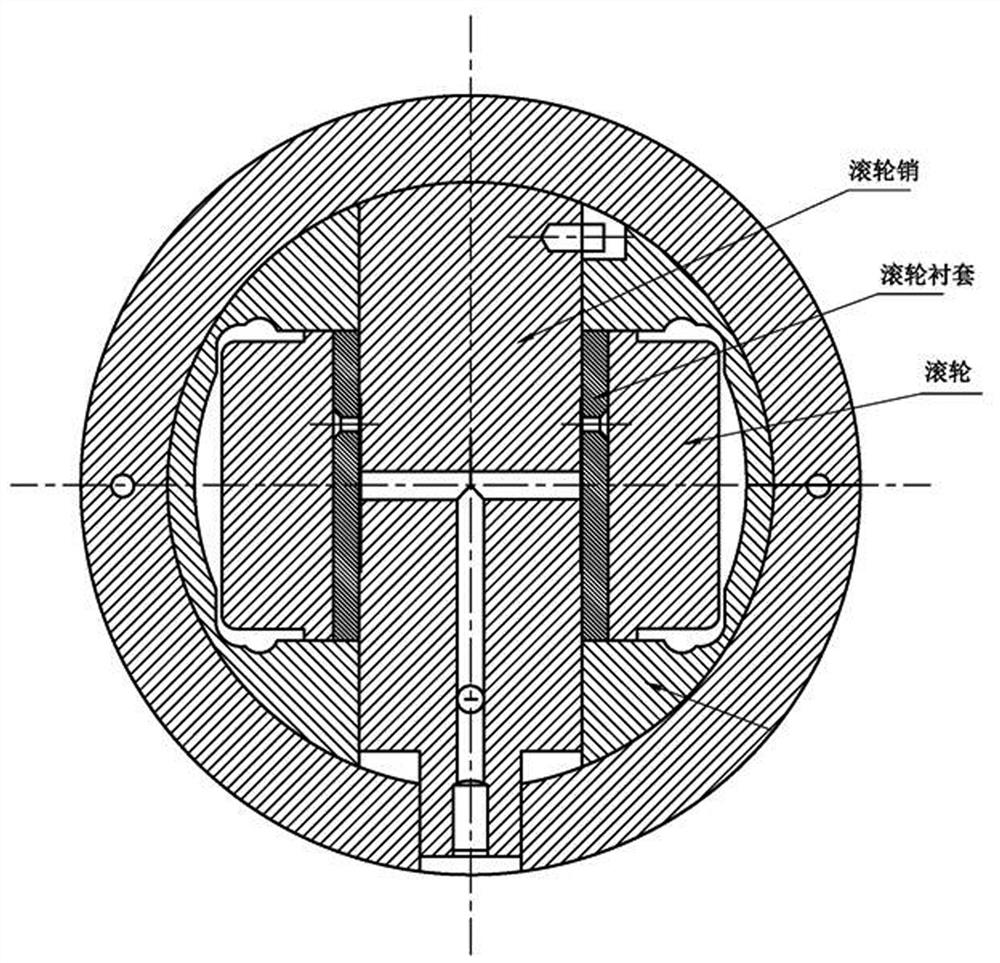

[0027] Such as figure 1 , figure 2 , image 3 As shown, in the prior art, the tappet reciprocates up and down in the guide sleeve, the roller pin and the roller pin hole of the tappet are an interference fit, a roller bushing is installed between the roller pin and the roller, and the roller bushing and the roller pin The outer diameter and the inner hole of the roller are clearance fit. The existing technology does not use forced lubrication on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com