Oil pump

An oil pump and oil cavity technology, applied in the field of oil pumps, can solve the problems that the filter can not completely filter the oil debris, affect the operation of the oil pump, and the oil flow is not smooth, so as to improve the pump oil efficiency and oil supply, improve the Long service life, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

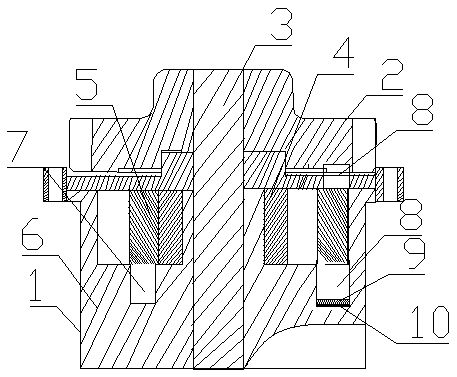

[0020] Reference attached figure 1 The embodiment of a kind of engine oil pump of the present invention is described further:

[0021] An oil pump, comprising a pump body 1, a pump cover 2, a pump shaft 3, an inner rotor 4, and an outer rotor 5, the pump cover 2 is arranged on the pump body 1, the pump cover 2 and the pump body 1 to form an oil chamber 6, the pump shaft 3 extends through the pump cover 2 to the inside of the oil chamber 6, the pump shaft 3 is sleeved with the inner rotor 4, the inner rotor 4 is arranged inside the outer rotor 5, the inner rotor 4 and the outer rotor 5 are both arranged inside the oil chamber 6, and the bottom of the left end of the outer rotor 5 is provided with an oil outlet chamber 7, so The lower end and the upper end of the right end of the outer rotor 5 are provided with an oil inlet chamber 8, which adopts a double-sided oil inlet structure, which improves the oil pumping efficiency and oil supply of the oil pump, and the uniformity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com