Engine body delayed oil supply lubricating system

A technology for lubricating systems and bodies, applied in closed-circuit lubricating systems, lubricating engines, controlling lubricant pressure, etc., can solve problems such as inability to lubricate connecting rod journals, insufficient oil supply to bearing pads, and large oil cut-off angles, etc., to achieve Simple structure, low cost, and the effect of reducing pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

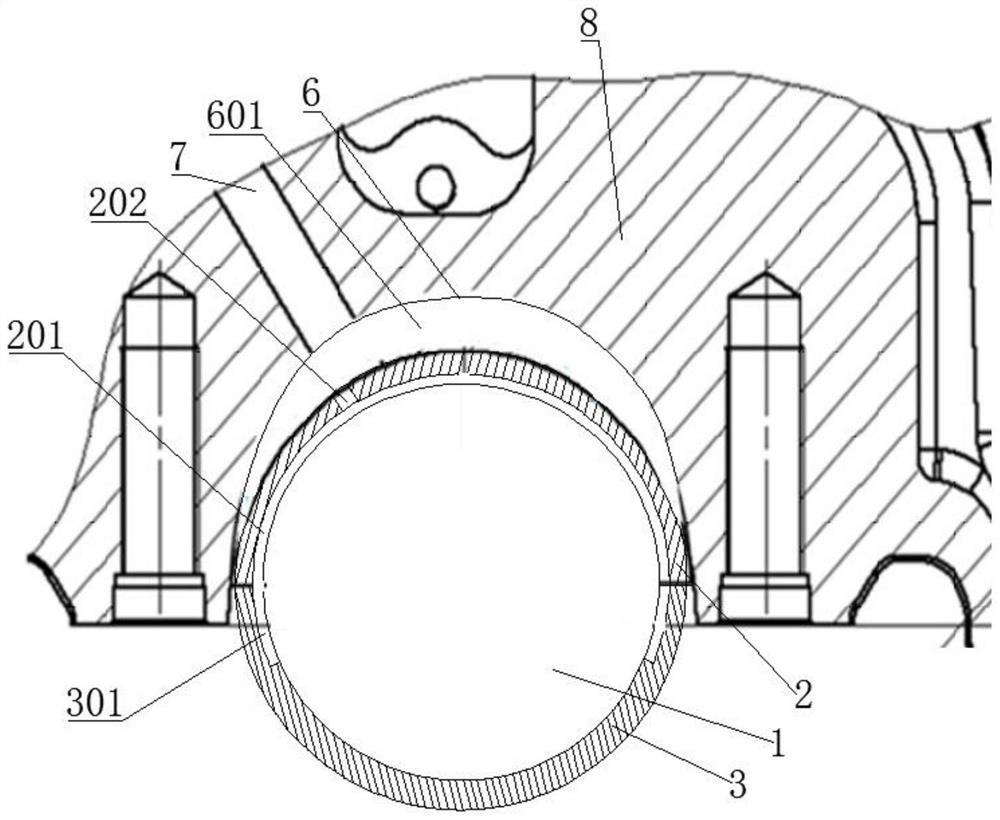

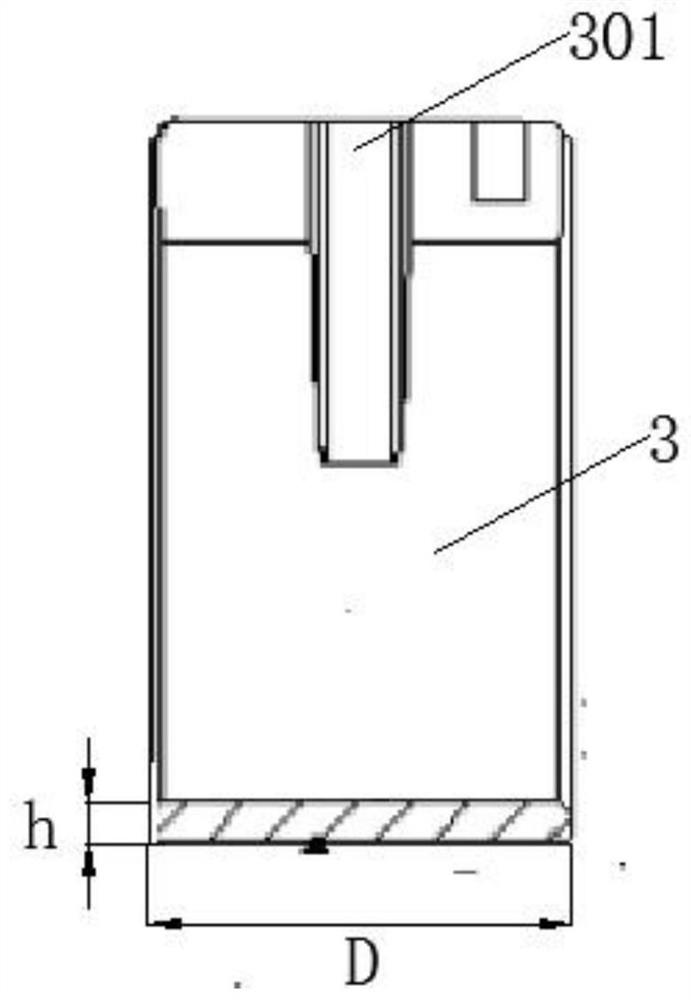

[0032] A body delay oil supply lubrication system, comprising a main journal 1, an upper bearing bush 2, a lower bearing bush 3, a journal oil passage 4 and a body 8, the upper bearing bush 2 is press-fitted on the upper part of the lower bearing bush 3, and the The body 8 is provided with a bearing seat 6 for installing the upper bearing bush 2, the journal oil passage 4 communicates with the main journal 1 and the connecting rod journal 5, an organic oil storage tank 601 is provided on the bearing seat, and the oil storage tank 601 of the body The oil groove 601 communicates with the main oil passage 7 on the machine body, and the upper oil storage tank 201 is arranged circumferentially on the inner peripheral surface of the upper bearing bush 2 . A lower oil storage tank 301 is arranged downward on the parting surface, and the lower oil storage tank 301 communicates with the end of the upper oil storage tank 201. The arc angle of the lower oil storage tank 301 is 25-35°. The...

Embodiment 2

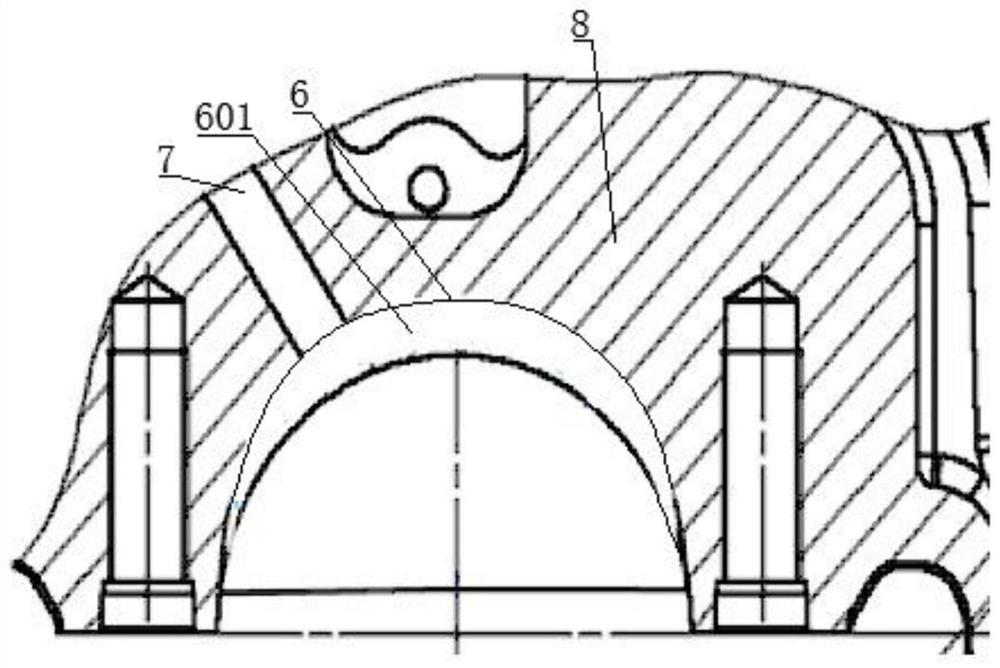

[0036] Such as Figure 1~6 As shown, a delayed oil supply lubricating system for the machine body includes a main journal 1, an upper bearing shell 2, a lower bearing shell 3, a journal oil passage 4 and a machine body 8, and the upper bearing shell 2 is press-fitted on the upper part of the lower bearing shell 3 , the body 8 is provided with a bearing seat 6 for installing the upper bearing bush 2, and the journal oil passage 4 communicates with the main journal 1 and the connecting rod journal 5;

[0037] Such as figure 2 As shown, the bearing seat is provided with an organic oil storage tank 601, which communicates with the main oil passage 7 on the machine body, and an upper oil storage tank 201 is provided on the inner peripheral surface of the upper bearing bush 2 in the circumferential direction. On the inner circumference of the lower bearing bush 3, a lower oil storage tank 301 is arranged downward from the parting surface of the upper bearing bush 2. The lower oil st...

Embodiment 3

[0044] The difference between this embodiment and the above-mentioned embodiment 2 is: as image 3 The arc angle α where the lower oil storage tank 301 is located is 35°, which increases the oil supply continuation angle to the greatest extent, and the angle between the axis of the journal oil passage 4 and the vertical direction is viewed from the crankshaft axial direction β is 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com