Oil supply device for curving needle holder of sartorius

An oil supply device, sewing machine technology, applied in the direction of sewing machine components, sewing equipment, lubricating/cooling devices, etc., can solve the problems of dirty processing cloth, trouble, poor lubrication of sliding surfaces, etc., and achieve the effect of suppressing wear and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

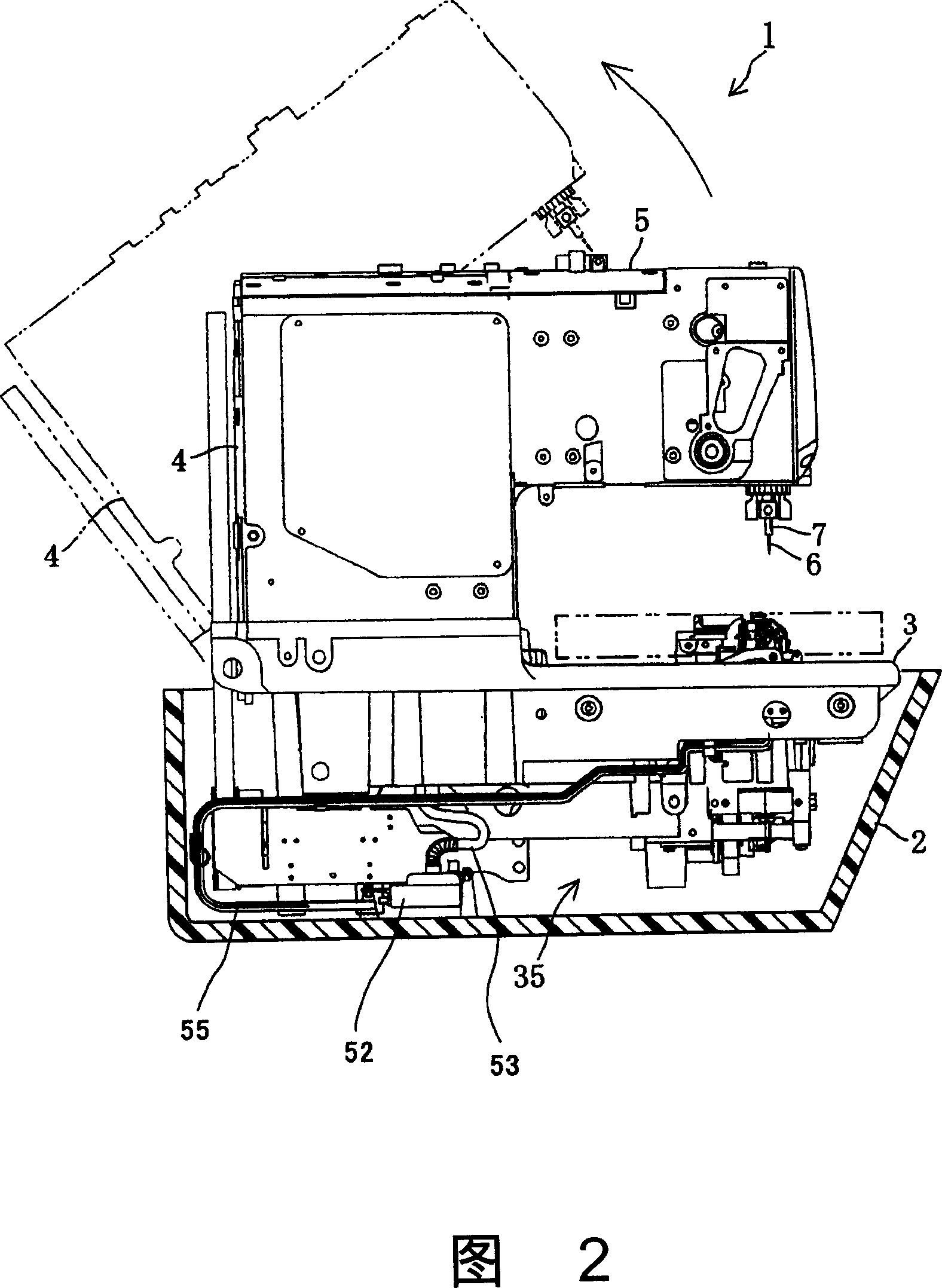

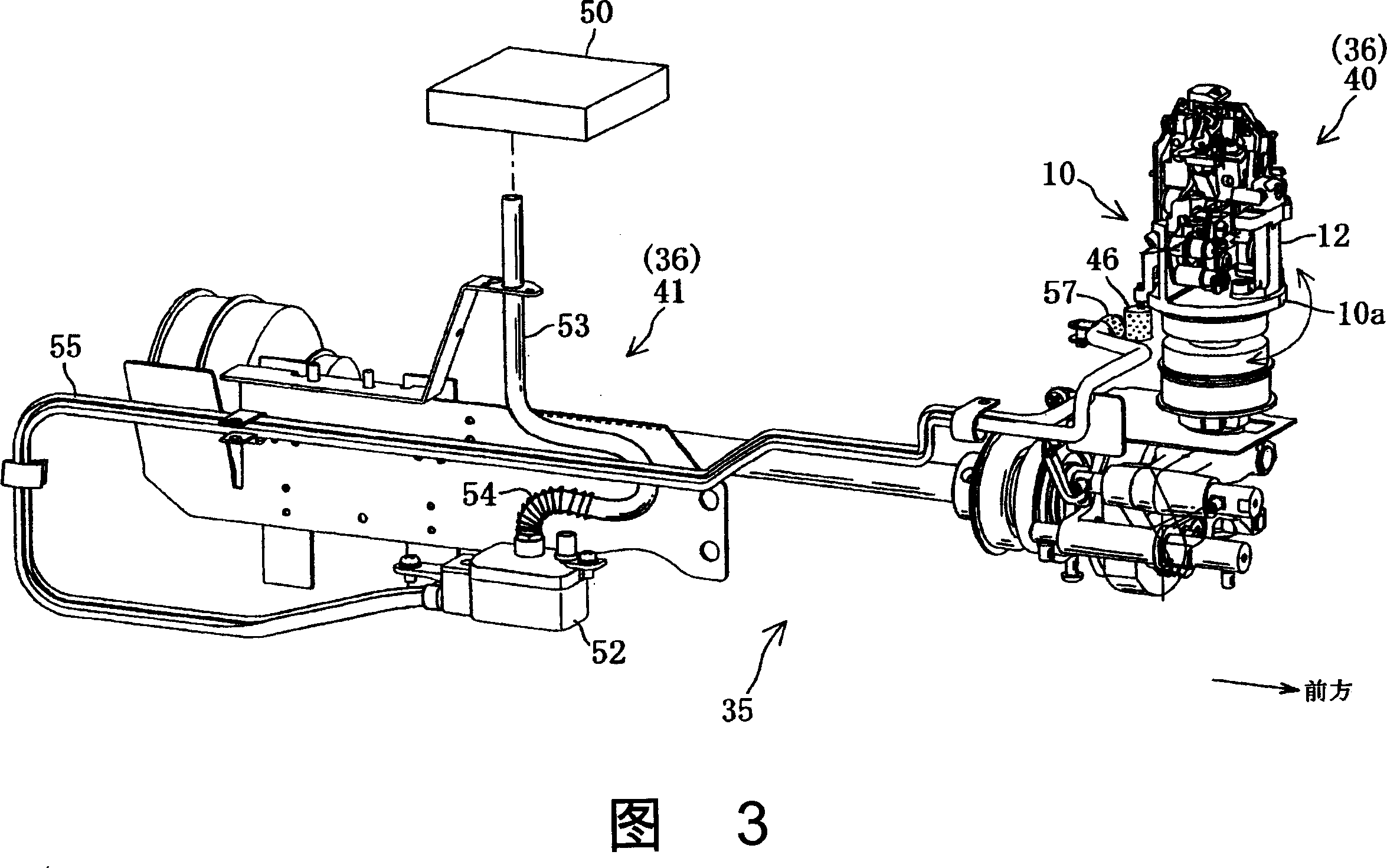

[0029] The oil supply device for supplying oil to the looper seat of the present invention can pass through the second oil line in the supply pipe connected to the lubricating oil tank provided in the bed base of the buttonhole sewing machine and the first oil line in contact with the second oil line. thread, supply lubricating oil to the sliding surface of the cam plate for operating the spreader of the looper base.

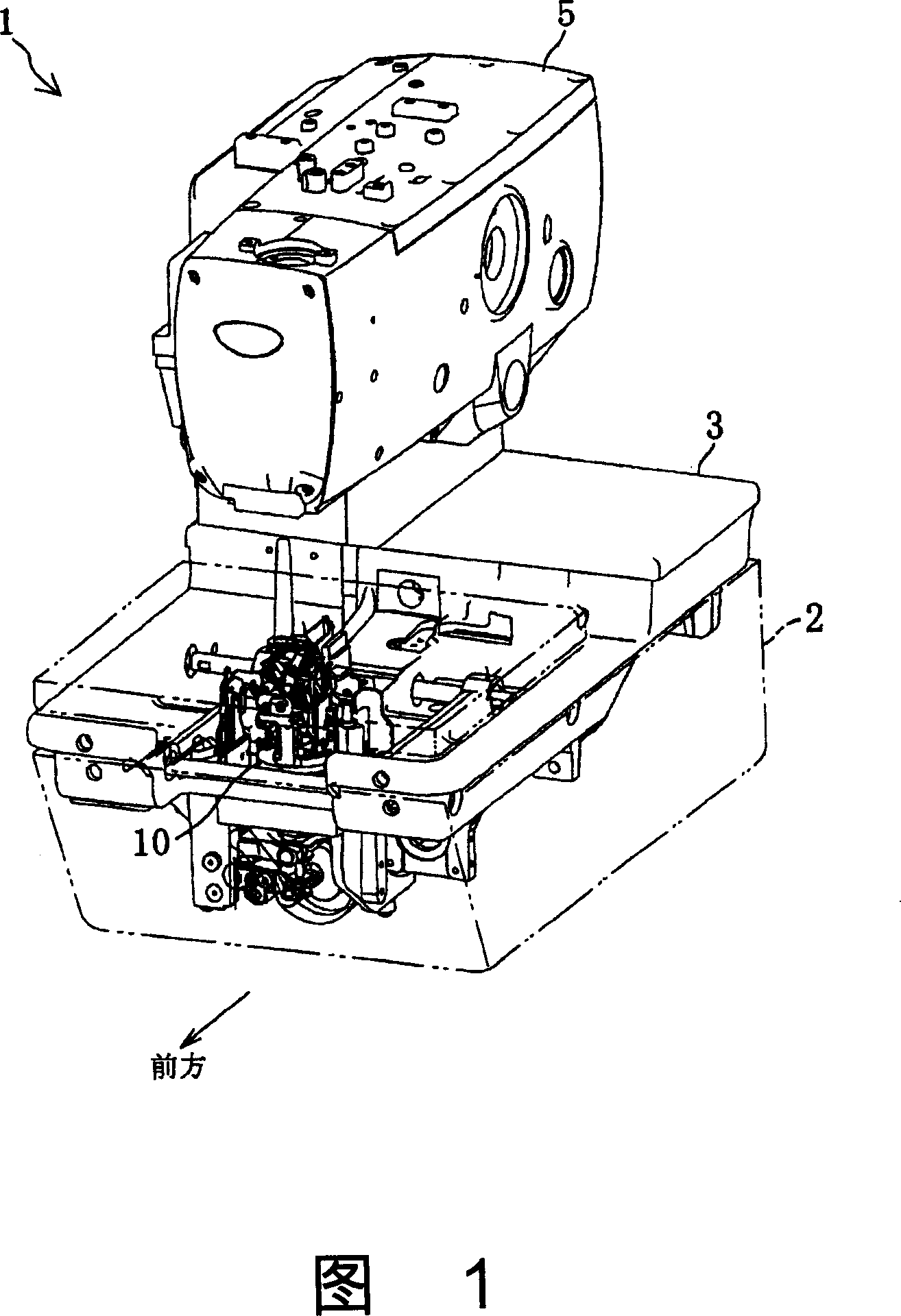

[0030] As shown in Fig. 1 and Fig. 2, the buttonhole sewing machine 1 has: a rectangular box-shaped floor base 2 with an open upper part, a bottom plate part 3 mounted on the open part of the bottom plate seat 2 in an embedded form, and a bottom plate part 3 standing on the bottom plate part 3. The post 4 at the rear and the casing 5 extending forward from the upper part of the post 4, and the buttonhole sewing machine 1 is mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com