Dynamic-pressure bearing stable in oil supply

A dynamic pressure bearing, a stable technology, applied in the field of dynamic pressure bearings, can solve the problems of easy oil being thrown out of the oil chamber, bearing vibration, insufficient oil volume in the oil chamber, etc., and achieve the effect of stable oil volume and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

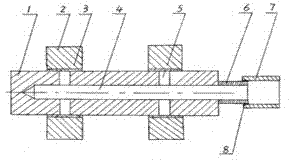

[0010] Such as figure 1 As shown, a dynamic pressure bearing includes a rotating shaft 1 and a shaft sleeve 2. There is a wedge-shaped oil chamber 3 between the rotating shaft 1 and the shaft sleeve 2. It is characterized in that there is a central oil hole 4 in the center of the rotating shaft 1. There is a vertical oil hole 5 perpendicular to the shaft centerline at the position corresponding to the rotary shaft 1 and the wedge-shaped oil chamber 3. The vertical oil hole 5 communicates with the central oil hole 4. A rotary oil pipe 6 is installed at the position of the central oil hole 4 at one end of the rotary shaft. Oil pipe 6 is contained in the fixed oil pipe 7, and sealing ring 8 is housed in the middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com