Lubricating device for sewing machine

A technology for oil supply devices and sewing machines, which is applied to sewing machine components, sewing equipment, lubricating/cooling devices, etc. It can solve the problems that the oil volume cannot be adjusted well, and the diameter of the pipe cannot be adjusted correctly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

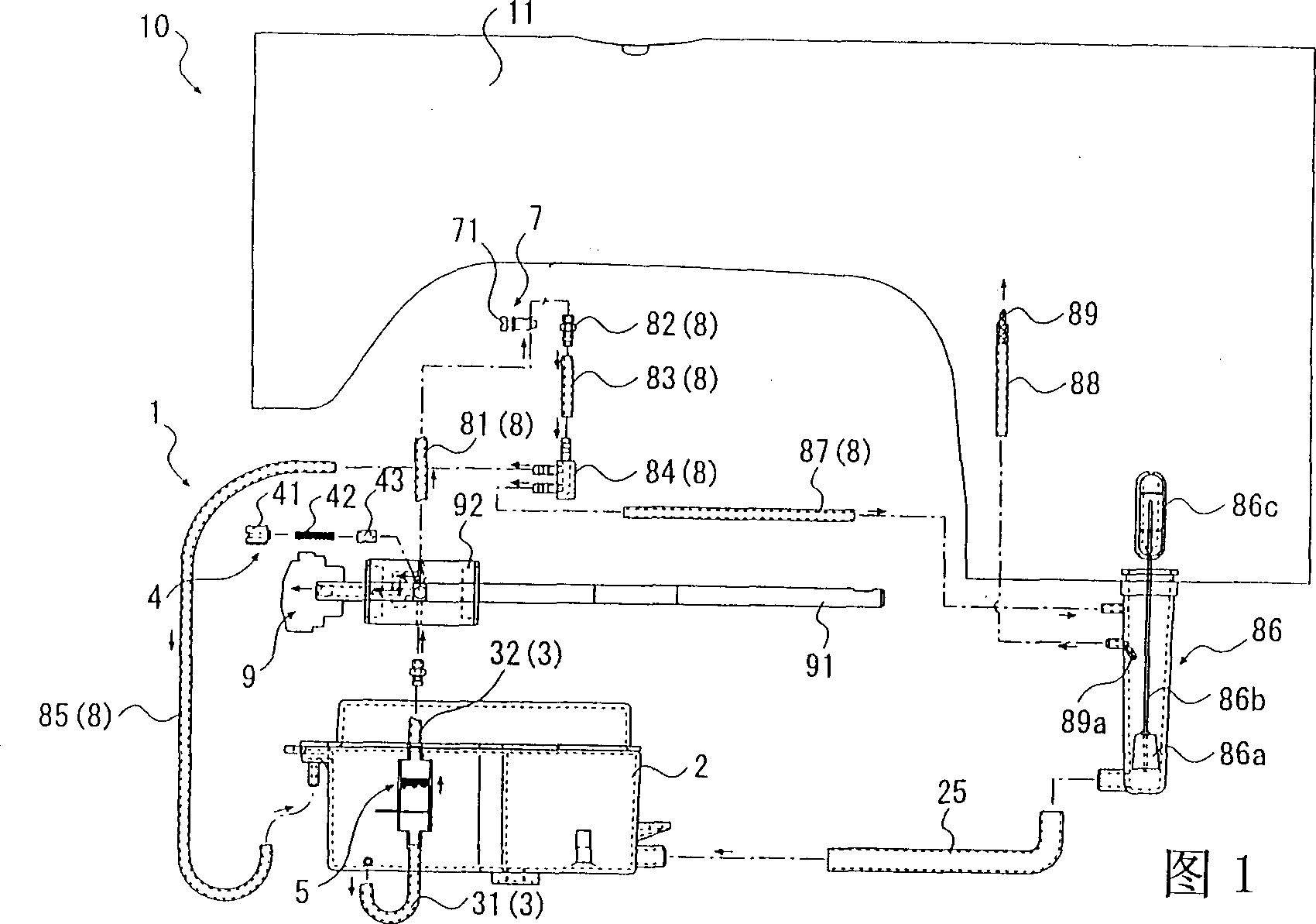

[0025] Below, refer to Figure 1 to image 3 Embodiments of the sewing machine oil supply device according to the present invention will be described. In addition, the sewing machine oil supply device according to the present invention is installed on an industrial sewing machine.

[0026] The sewing machine oil supply device 1 related to the present invention shown in Fig. 1 is composed of an oil tank 2 positioned in the sewing machine base, an oil supply pipe (oil supply pipeline) 3, a plunger type oil pump (oil pump) 4, a filter 5, an oil It is composed of quantity regulating part 7 and oil return pipeline 8.

[0027] The lubricating oil is stored in the oil tank 2 and connected with the plunger type oil pump 4 through the oil supply pipe 3 . A filter 5 is attached to the oil supply pipe 3 in order to filter the lubricating oil flowing through the oil supply pipe 3 .

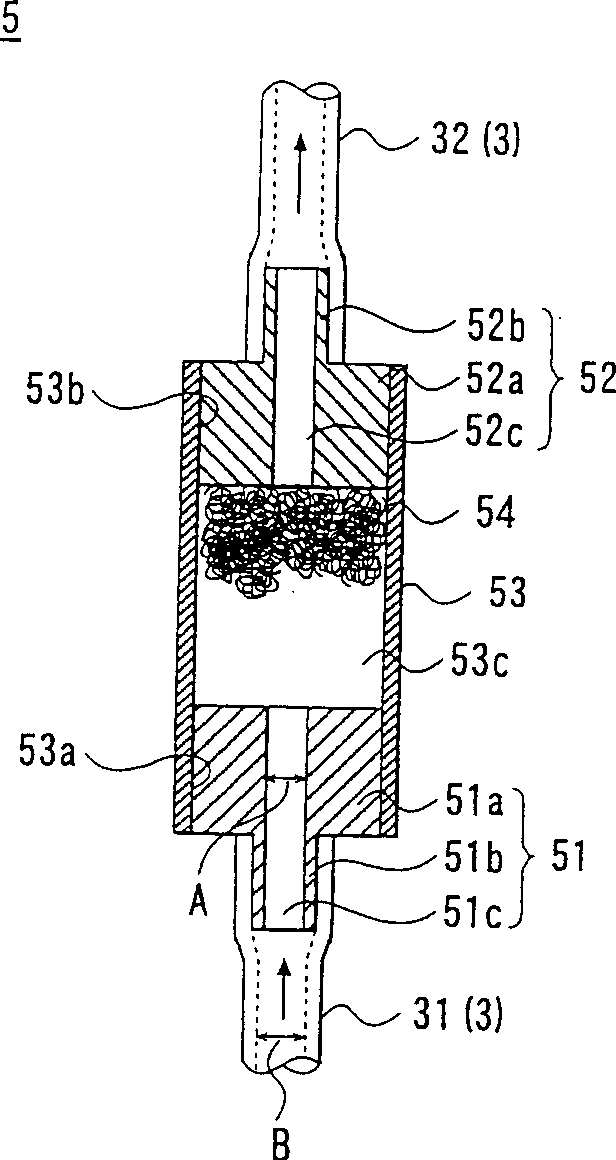

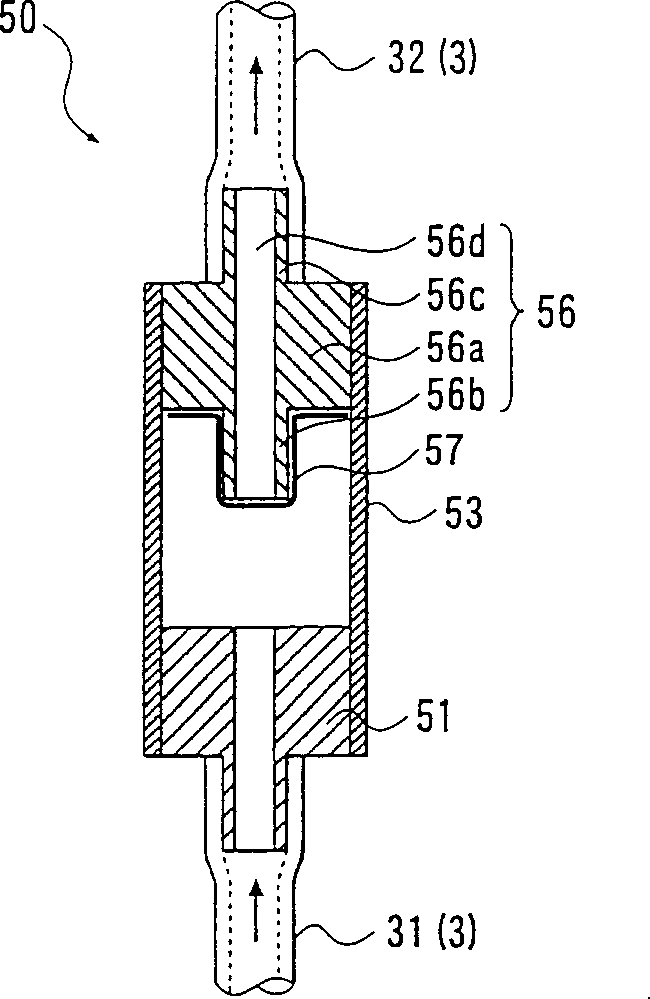

[0028] Such as figure 2 As shown, on the filter 5 , detachable first and second joint members 51 and 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com