Lubricant composition for sewing machines

A technology of lubricant composition and sewing machine, which is applied in the field of lubricant composition and sewing machine device, and can solve the problems such as inability to exert the additive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

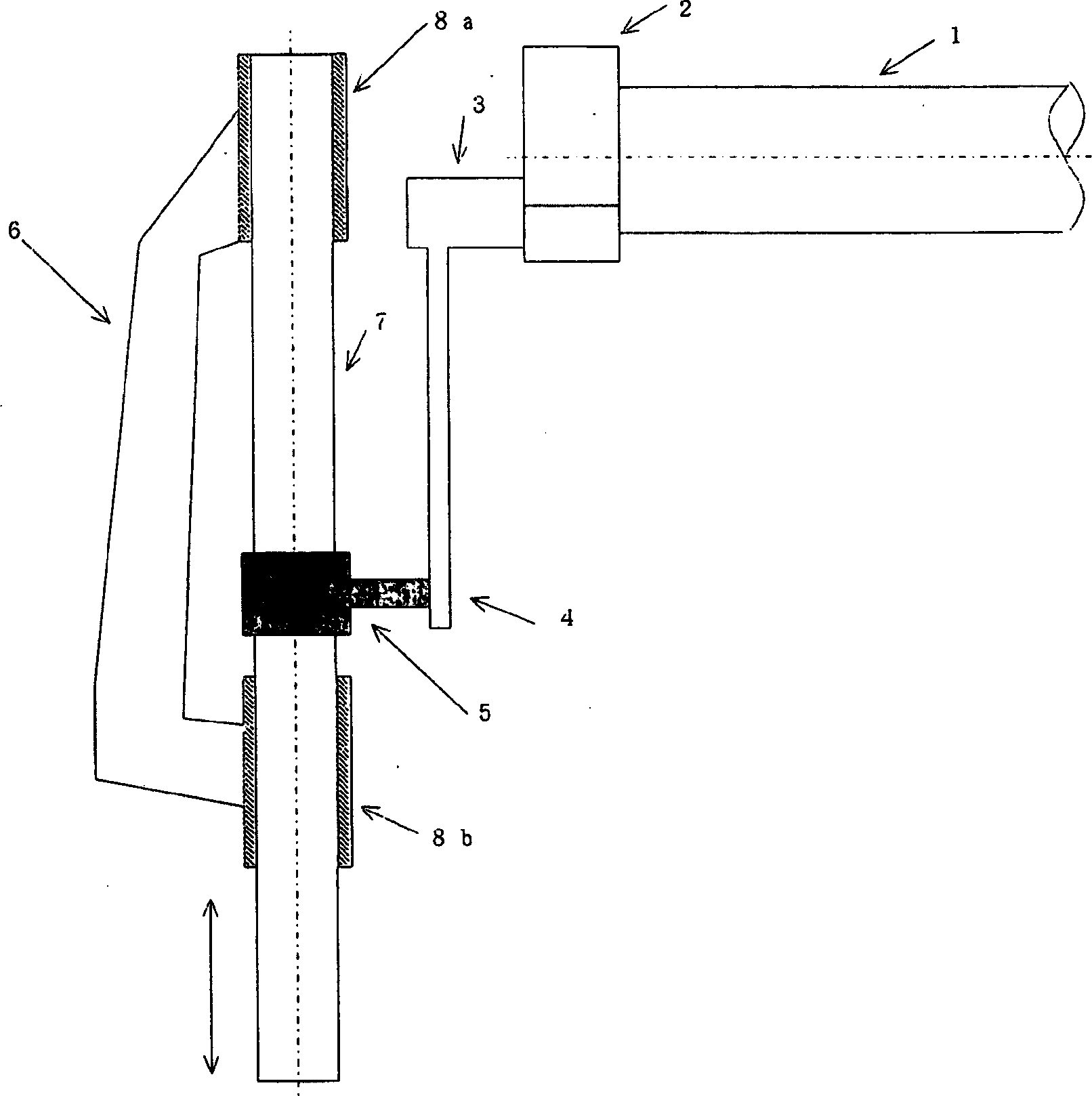

Image

Examples

Embodiment

[0037] Next, the present invention will be described by way of examples and comparative examples. ,

[0038] Using the base oils shown in Table 1, the lubricating oil compositions for sewing machines shown in Tables 2 to 5 were obtained. For the lubricant compositions for sewing machines of Examples 1 to 14 and the compositions of Comparative Examples 1 to 11, a sewing machine durability tester (spindle rotation speed: 4000 rpm, surface pressure: 0.4 N / mm, Test time: until sintering stops), carry out endurance test. The amount of lubricant injected into the bearing is about 1 cc. The rule at the end of the test is that the formed circuit controls the current value of the motor that rotates the spindle. When an overcurrent exceeding the specified current value occurs, the motor is turned off. Lubricant is only injected initially. Table 6 shows the results of the sewing machine durability test.

[0039] In the examples and comparative examples shown in Tables 2 to 5, the same...

Embodiment 6

[0067] Both the base oils of Example 6 and Comparative Example 1 are polyalphaolefins. However, comparing the base oil PO2 of Example 7 with a single-component base oil composition and the PO3 initially obtained as a mixture at the time of manufacture, it can be clearly seen that the single-component PO2 is clearly efficient. When lubricating oil having a molecular weight distribution is used as the base oil, it is considered that low molecular weight components are introduced into the lubricating surface and high molecular weight components are excluded, resulting in insufficient oil (oil shortage) in the sliding part. Therefore, the once-excluded high-molecular-weight component does not provide permanent lubrication to the sliding part, and cannot produce an effect beyond expectation.

[0068] Example 14 and Comparative Example 11 were used to compare oil-soluble additives and non-oil-soluble additives, and it was found that the durability time was long when the oil-soluble ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com